Full-automatic bottom sealing type closed power filling system and process

A closed, fully automatic technology, used in electrode manufacturing, filling tube/bag electrodes, lead-acid battery electrodes, etc., can solve the problems of flying lead powder, human body hazards, and loud noise, and achieve convenient maintenance and reduction. The effect of low noise and guaranteed longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

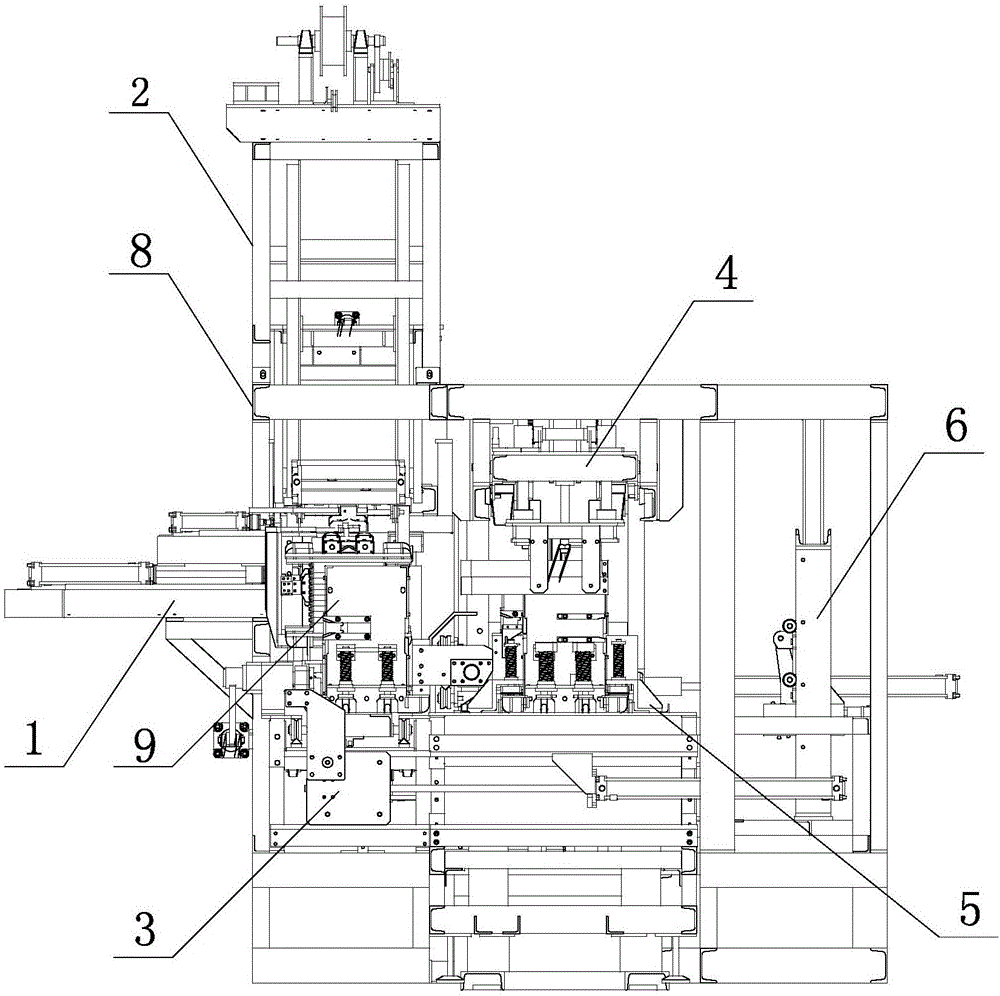

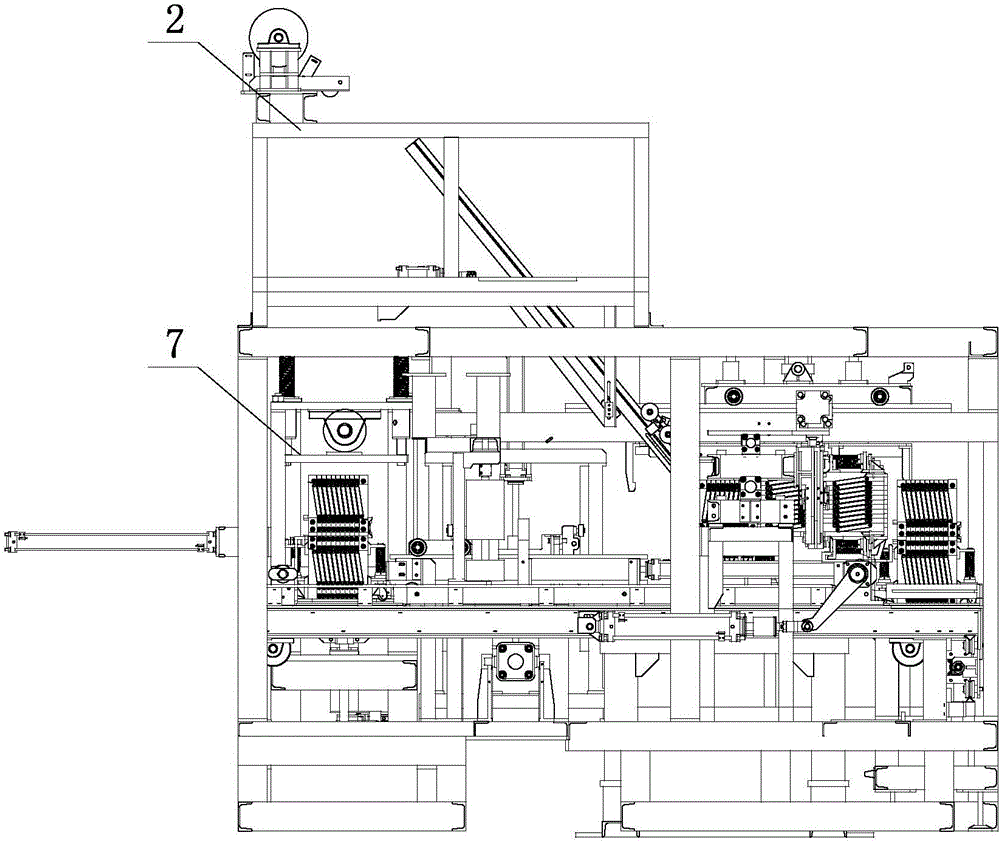

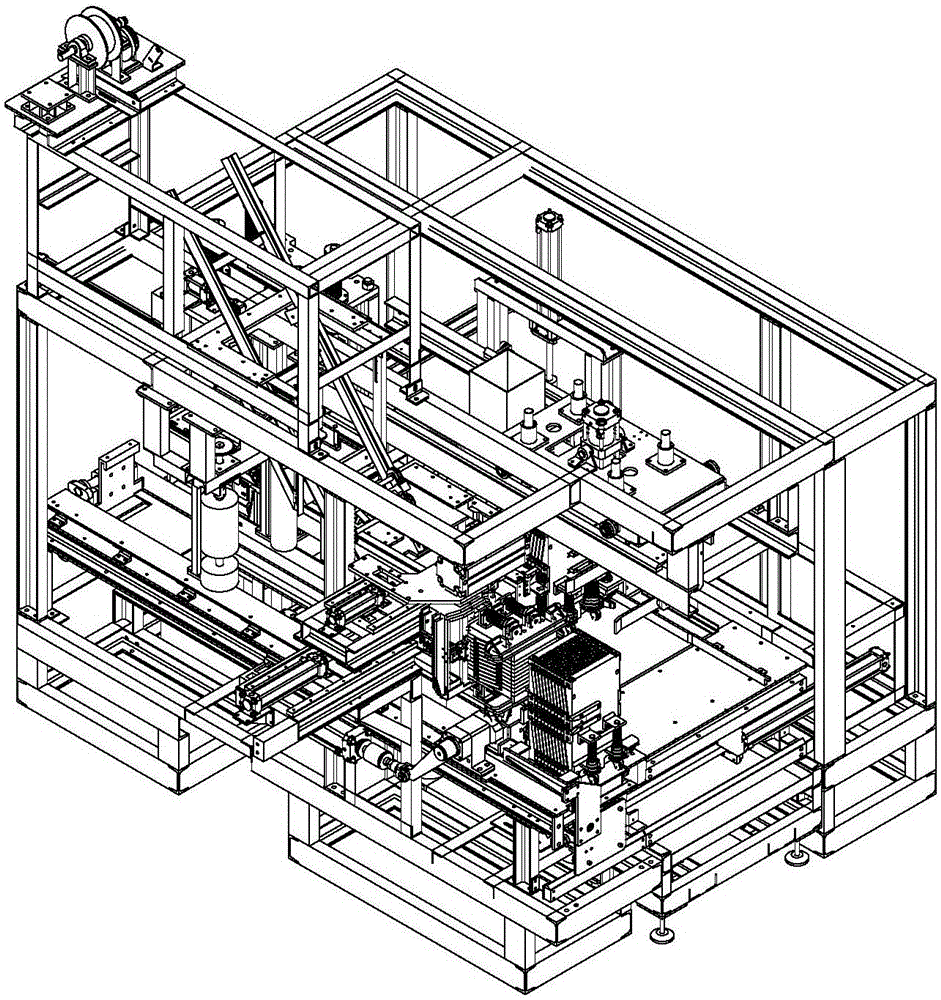

[0045] Such as Figure 1-Figure 3 As shown, the fully automatic bottom-covered closed powder filling system is characterized in that it includes a complete machine frame 8, and the complete machine frame 8 is provided with a tooling locking device 1, a tooling opening device 2, a mobile stand device 3, and a tooling transfer device 4. Vibration platform device 5, flipping powder brushing device 6 and automatic bottom sealing device 7;

[0046] The tooling locking device 1 comprises a mounting bracket 1-1, the mounting bracket 1-1 is provided with a lower mounting frame 1-2, the lower mounting frame 1-2 is provided with a glideway and a first push cylinder 1-3, and the glideway is mounted on the There is an upper mounting frame 1-4, the piston rod of the first push cylinder 1-3 is connected to the upper mounting frame 1-4, and one end of the upper mounting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com