Assembly welding tool of installation bases and connecting method of lifting mechanism and balance arm

A lifting mechanism and mounting seat technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of heavy lifting mechanism 1 and balance arm 2, increased welding numbering process, and common workpieces Poor performance and other problems, to achieve the effect of improving processing accuracy, reducing potential safety hazards, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the following describes specific implementations of the present invention.

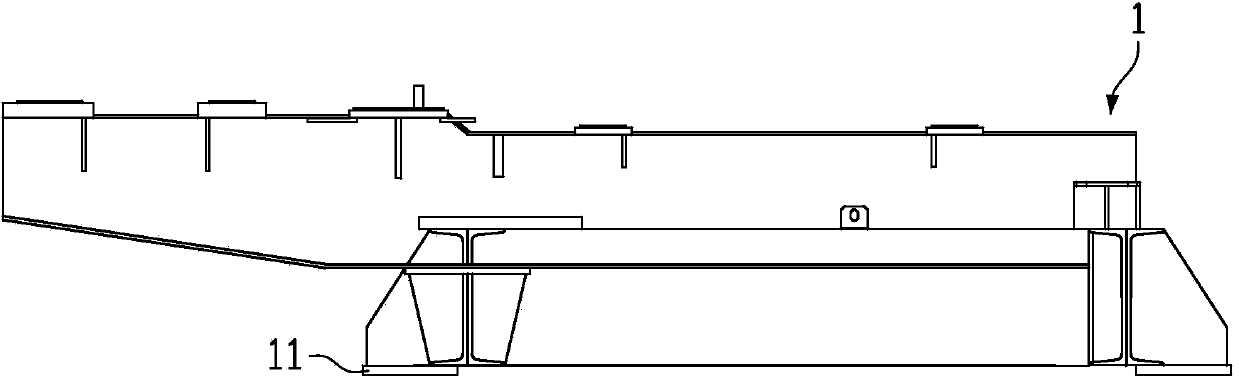

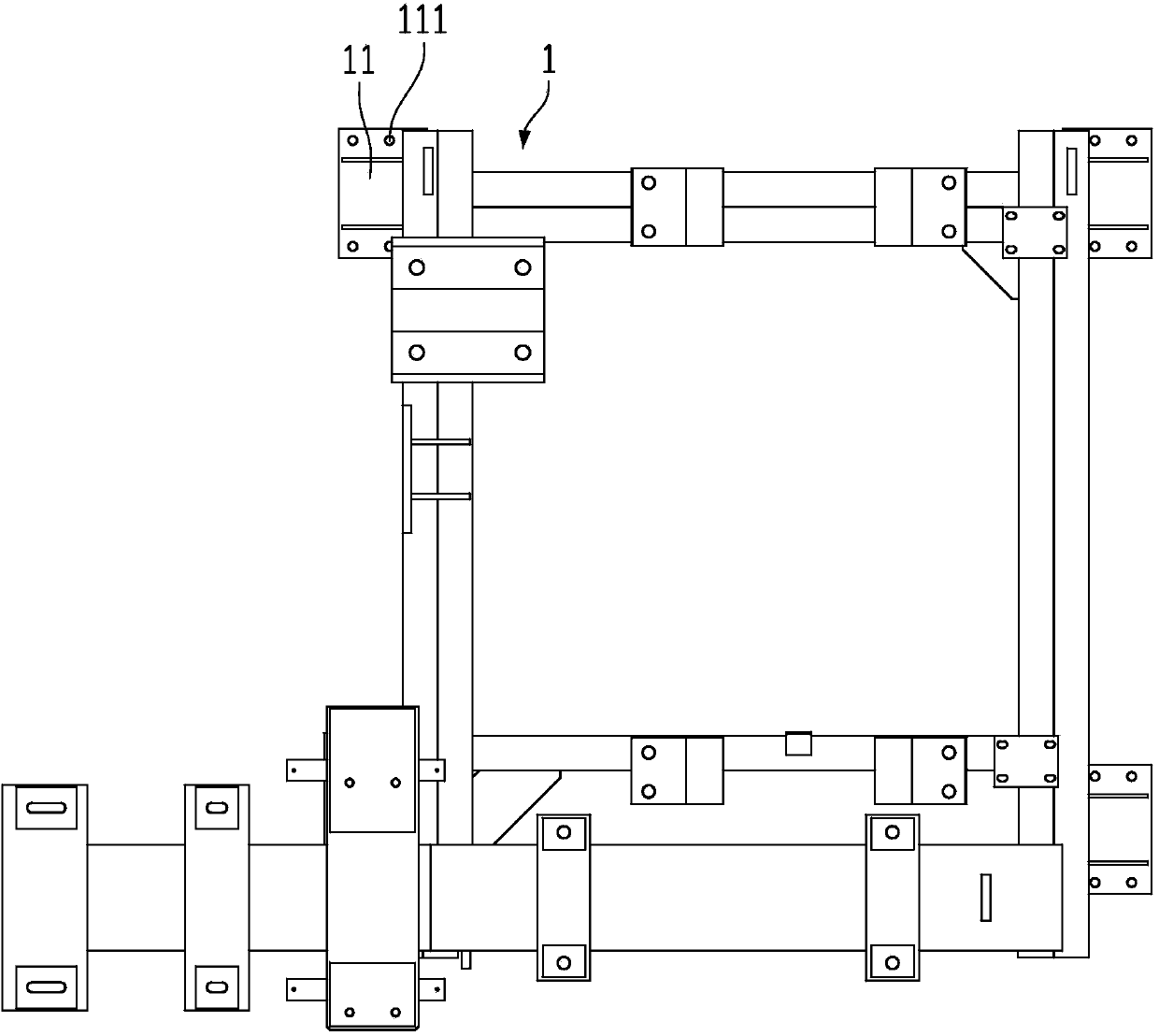

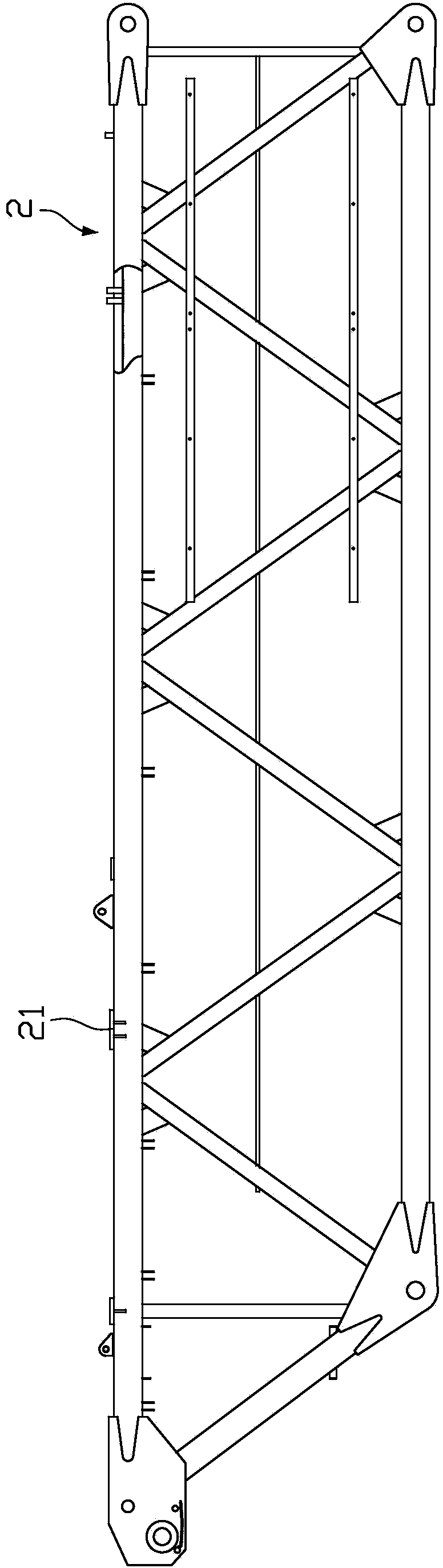

[0042] Please refer to Figure 7 , Figure 8 with Figure 9, is a structural schematic diagram of the welding tooling of the mounting seat of the embodiment of the present invention, the welding tooling 10 includes a frame 101 and a plurality of welding plates 102 arranged on the frame 101, and each welding plate 102 is provided with at least A positioning hole 1021 . The fitting and welding tool 10 is used for fitting and welding a plurality of installation seats to the balance arm of the tower crane, so that the plurality of installation seats for matching and welding can correspond to the plurality of connection seats arranged on the hoisting mechanism of the tower crane respectively. Installed together, the positions of the plurality of welding plates 102 respectively correspond to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com