Assembly type spring mattress

An assembly type, mattress technology, applied in the field of mattresses, can solve the problems of waste of resources, frameless roll packing pads, single structure selectivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

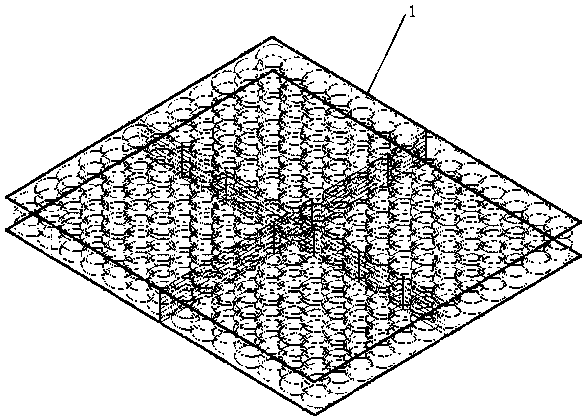

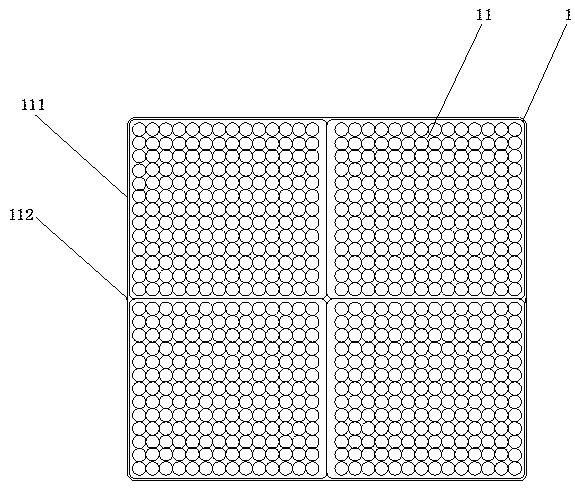

[0041] like Figures 1 to 8 As shown, the assembled spring mattress of the present invention includes a spring bag assembly 1 , a spring bag cover 2 , a cushion cover 3 , a surface cover 4 and hardware accessories 5 .

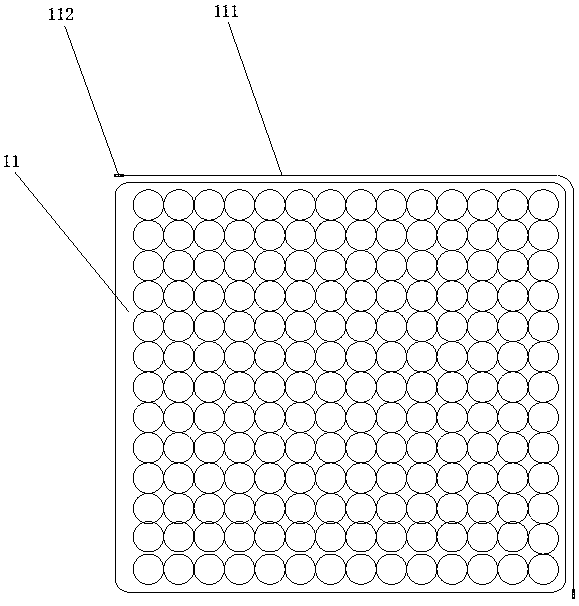

[0042] The spring pack assembly 1 is assembled from two or more single-body spring packs 11 with the same structure (in this embodiment, the spring pack assembly 1 is assembled with four single-body spring packs with the same structure), each Each single spring package 11 has a rectangular structure and is assembled from a plurality of loose springs; one group of right-angled surfaces of each single spring package 11 is located inside the spring package assembly 1 and is evenly sewed on the right-angled sides of the upper and lower sides. Be shaped on spring bag zipper, another group of right-angled surfaces of each monomer spring bag 11 is positioned at the outside of spring bag assembly 1 and all is equipped with a side rib 111 on the right-angled sides of up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com