Method for producing boron-amine compound and its special apparatus

A technology of compound, boron amine, which is applied in the field of preparation of boron amine compounds, can solve problems such as complex production process, unfavorable environmental protection, energy loss, etc., and achieve the effect of increasing reaction yield, overcoming the biggest disadvantage, and reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

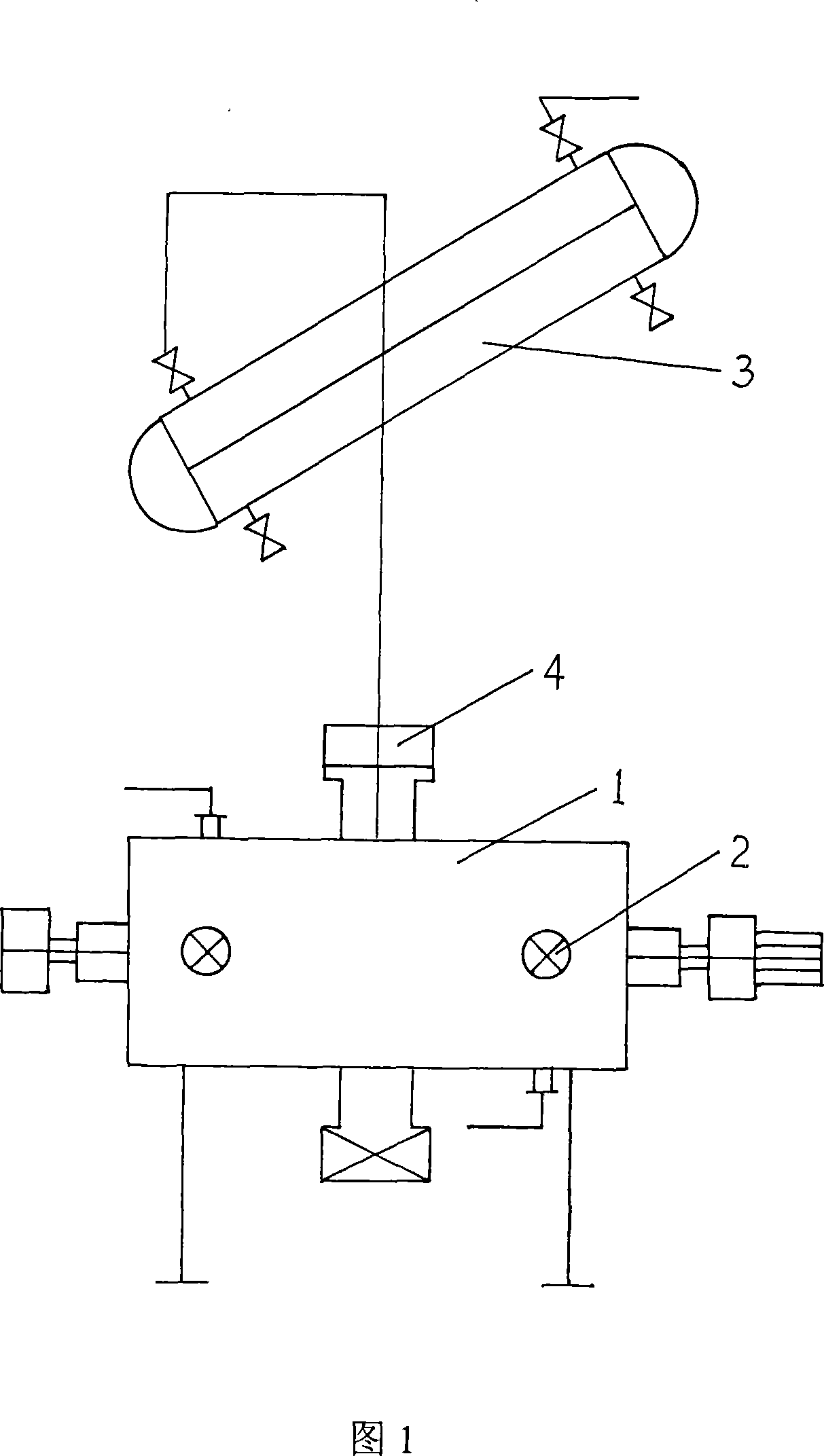

[0016] As shown in Figure 1, a 200-liter rake dryer is converted into a special equipment for the reaction of boron amine compounds, that is, two air inlets 2 are opened on the body 1, and a return device 3 and a gas outlet on the body are added. 4 connected.

[0017] Using the above-mentioned special equipment, put 38.5kg of dimethylamine and 80kg of sulfolane at -20°C, feed 25kg of boron trichloride under stirring, adjust the ventilation rate, and control the reaction temperature -20°C-80°C. After aeration, keep stirring for half an hour. Heat the system to 90°C to ensure that the system is clear and transparent, and distill off the solvent and the product bis(dimethylamino)boron chloride under a vacuum of -0.095Mpa. The separation yield reached 85.3%, and the reaction kettle residue was released in the form of solvent.

Embodiment 2

[0019] Using the same reaction device as in Example 1, 38.5kg of dimethylamine and 60kg of toluene were put into the mixture at -20°C, and 25kg of boron trichloride was introduced under stirring, the ventilation rate was adjusted, and the reaction temperature was controlled to be less than 80°C. After aeration, keep stirring for half an hour. Heat the system to 90°C, and distill off the solvent toluene and the product bis(dimethylamino)boron chloride under a vacuum of -0.095Mpa. The separation yield reached 70%, and the residue was released in solid form, mostly the hydrochloride of dimethylamine.

Embodiment 3

[0021] Using the same reaction device as Example 1, 38.5kg of dimethylamine was dropped in at -20°C, and 16.68kg of boron trichloride was introduced under stirring, the ventilation rate was adjusted, and the reaction temperature was controlled to be less than 80°C. After aeration, keep stirring for half an hour. Heat the system to 90°C, and distill the product tris(dimethylamino)boron under vacuum -0.098Mpa, and the separation yield reaches 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com