New-concept railway safety dead end

A technology of railway safety and new concept, applied in the field of the end line, can solve the problems of long occupied track length, poor vehicle adaptability, complex structure, etc., and achieve the effect of short length, strong adaptability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

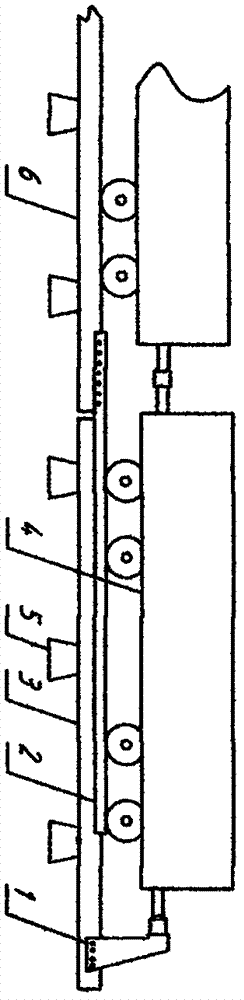

[0012] The structure of the first embodiment is as attached figure 2 As shown, the arresting pile 1 is connected to the moving rail 3, one end of the rail bridge 2 is connected to the static rail 6, and the other end and the moving rail 3 are in contact with each other, and can slide relative to each other and are attached to each other in parallel.

[0013] The working principle is that when the vehicle 4 collides with the arresting pile 1, the arresting pile 1 will drive the moving rail 3 to move together with the vehicle 4. The upper part of the moving rail 3 carries the gravity of the vehicle 4, and the lower part is the sleeper 5, so when the moving rail 3 When sliding on the sleeper 5, there will be a great frictional resistance, and this resistance will in turn be transmitted to the vehicle 4 through the blocking pile 1, causing the vehicle 4 to decelerate and stop quickly, avoiding the occurrence of derailment accidents. The main function of the rail bridge 2 is to ac...

Embodiment 2

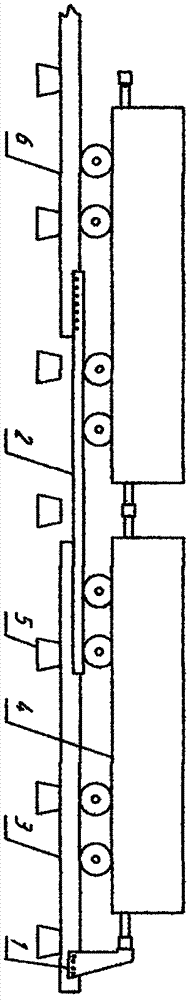

[0014] The structure of the second embodiment is as attached image 3 As shown, the arresting pile 1 is connected to the moving rail 3, one end of the rail bridge 2 is connected to the moving rail 3, and the other end and the static rail 6 not only contact each other, but also slide relative to each other, and abut against each other in parallel.

[0015] The working principle is the same as that of the first embodiment.

Embodiment 3

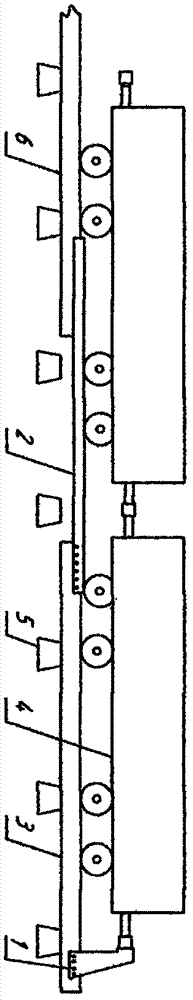

[0016] The structure of the third embodiment is as attached Figure 4 As shown, the arresting pile 1 is connected to the moving rail 3, and the rail bridge 2 is fixedly installed on the sleeper 5, and abuts against the moving rail 3 and the static rail 6 in parallel with each other, respectively.

[0017] The working principle is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com