Track butt joint connector fixing clamp

A technology of butt joints and fixed cards, which is applied in the direction of track, movable track, railway fixing device, etc., can solve the problems of hindering the passage of claws, safety accidents, etc., and achieve the effect of increasing strength and preventing derailment accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

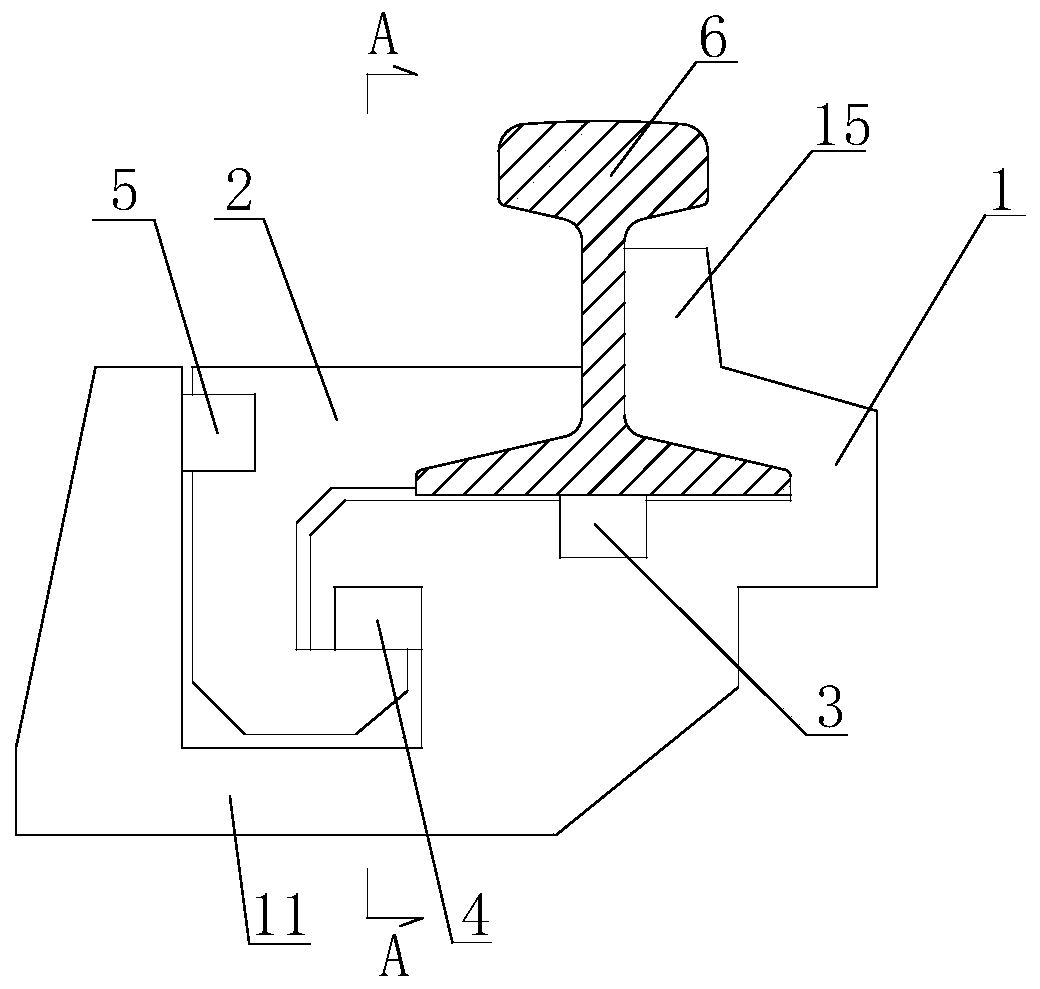

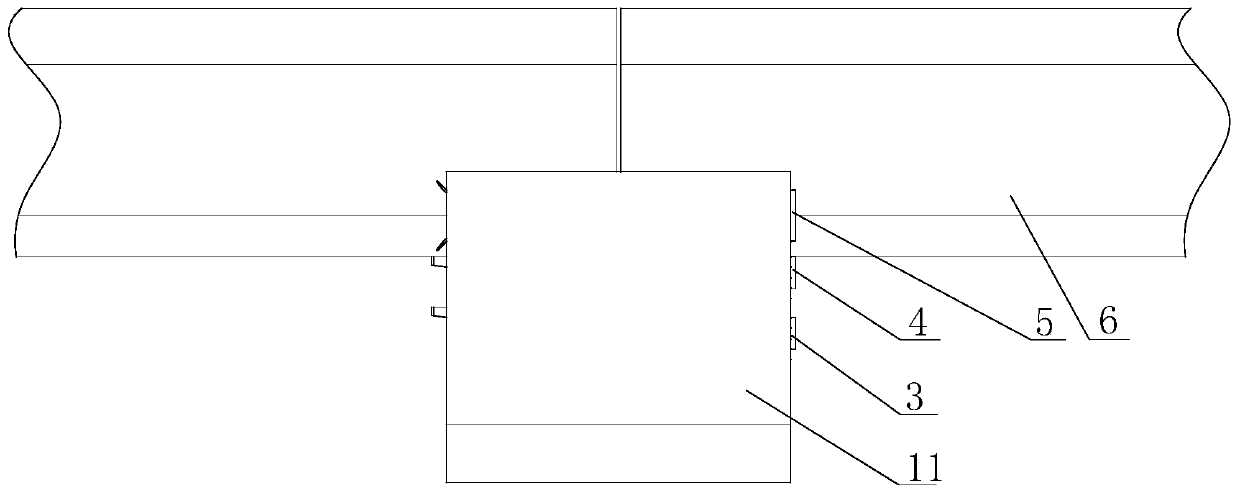

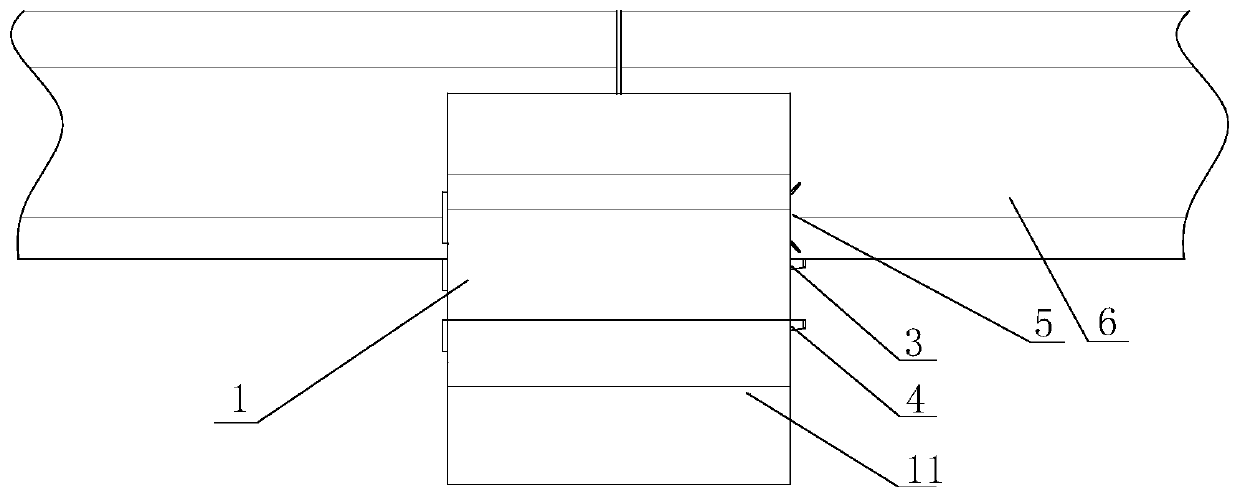

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a track butt joint fixing card includes a fixing card, and the fixing card includes a track inner card 1, and a fixed pressure plate slot 11 is provided outwardly at the bottom of the track inner card 1. There is a through groove 12 adapted to the rail bottom on one side of the track 6 on the inner side, the rail bottom on one side of the track 6 is covered in the through groove 12, the fixed pressure plate 2 is embedded in the fixed pressure hook slot 11 from one end of the fixed card, and is inserted from the outer side of the track 6. Fixed on the rail bottom of track 6.

[0023] On the track inner card 1 opposite to the track bottom of the track 6, there is a track fastening wedge groove 13, and a track fastening wedge 3 is inserted in the track fastening wedge groove 13.

[0024] There is a track inboard clamping wedge gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com