Rail butt joint clamping base

A technology of butt joints and rails, applied in the direction of rails, movable rails, roads, etc., can solve problems such as safety accidents and hinder the passage of the claw, and achieve the effects of preventing derailment accidents, increasing strength, and preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

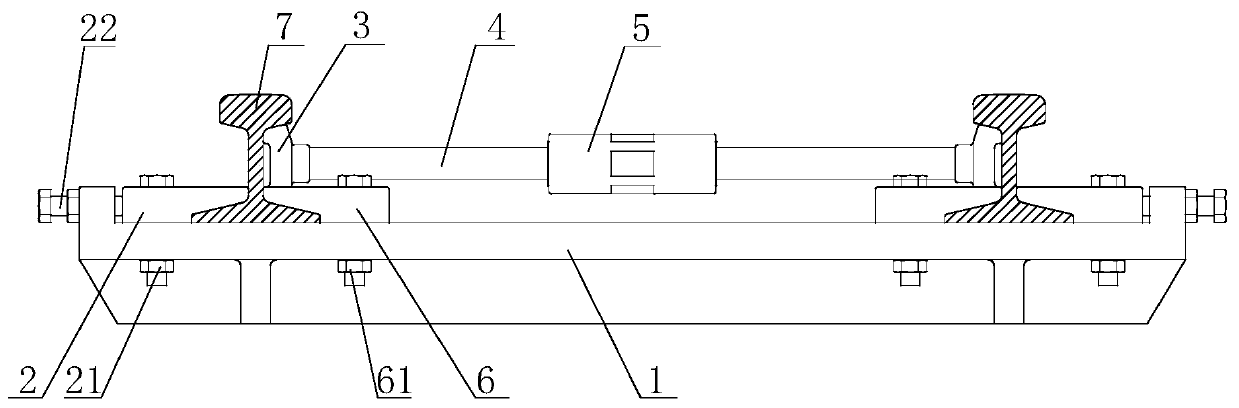

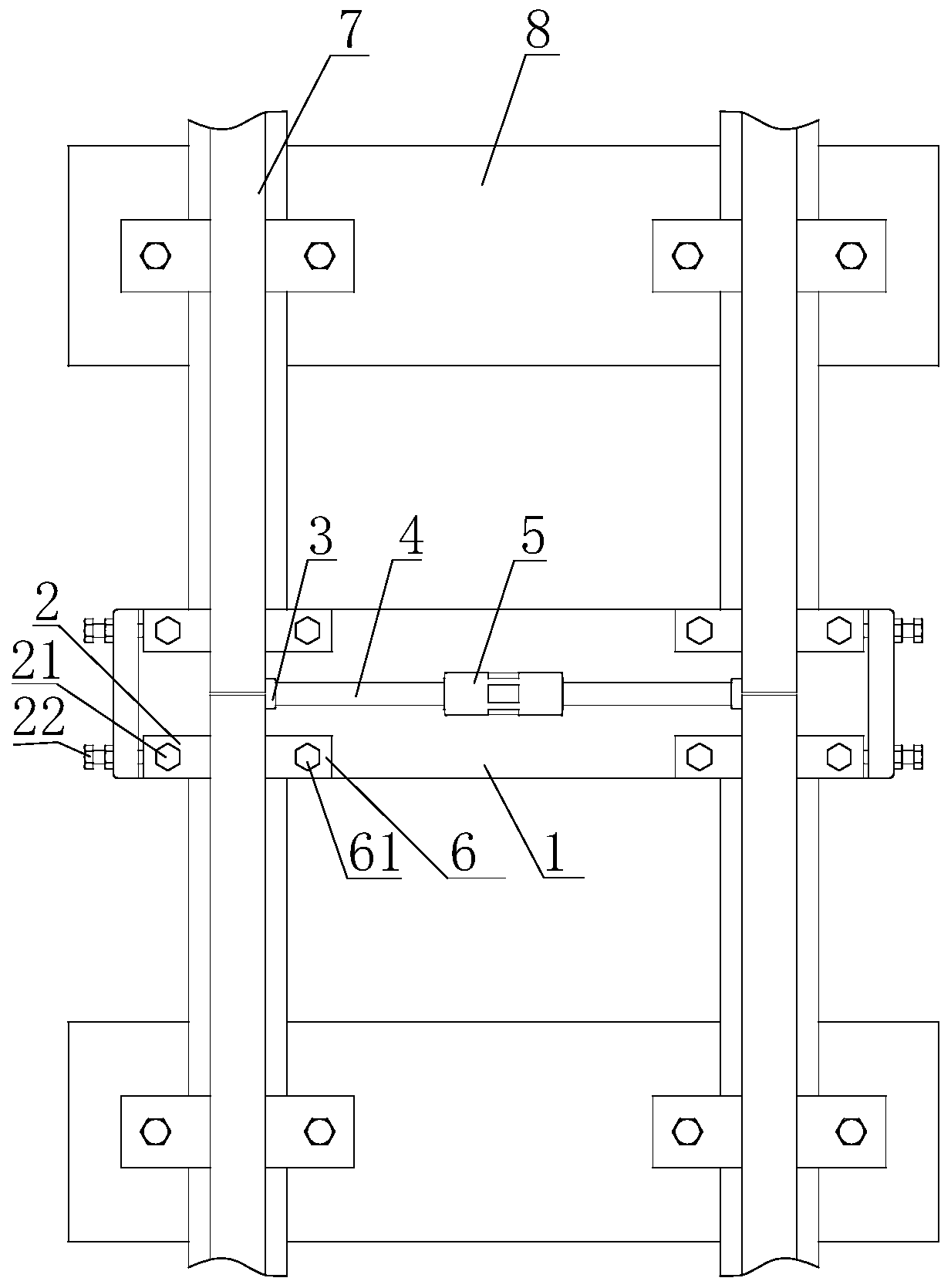

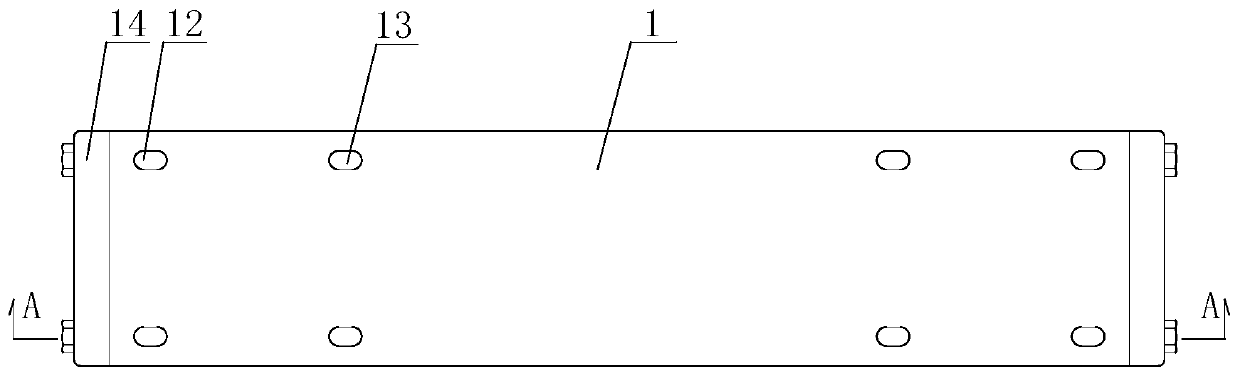

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a rail butt joint card seat includes a track card seat 1, a pair of track outer pressure blocks 2, and a pair of inner rail waist top blocks 3; Block waist-shaped bolt holes 12, outer pressure block bolt holes 23 are opened on the outer pressure block 2 of the track, and the outer pressure block fasteners 21 pass through the outer pressure block bolt holes 23 and the outer pressure block waist bolt holes 12 to fasten the track Outer briquetting block 2; Ejector rod 4 is arranged on inner rail waist top block 3, and the ejector rod 4 of a pair of track inner side top block 3 is connected by left and right wire nuts 5.

[0022] There are flanges 14 on both sides of the rail holder 1, and screw holes 15 are formed on the flanges 14, and in the screw holes 15, there are outer pressing blocks to tighten bolts 22.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com