Producer of light hollow partition plate with four-sides tongue

A technology for production equipment and partition wall panels, which is applied in the field of production equipment for four-side tongue-and-groove lightweight hollow partition panels, which can solve the problems of poor wall firmness, low operating efficiency, and high product cost, so as to prevent deformation and dislocation and improve operating efficiency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

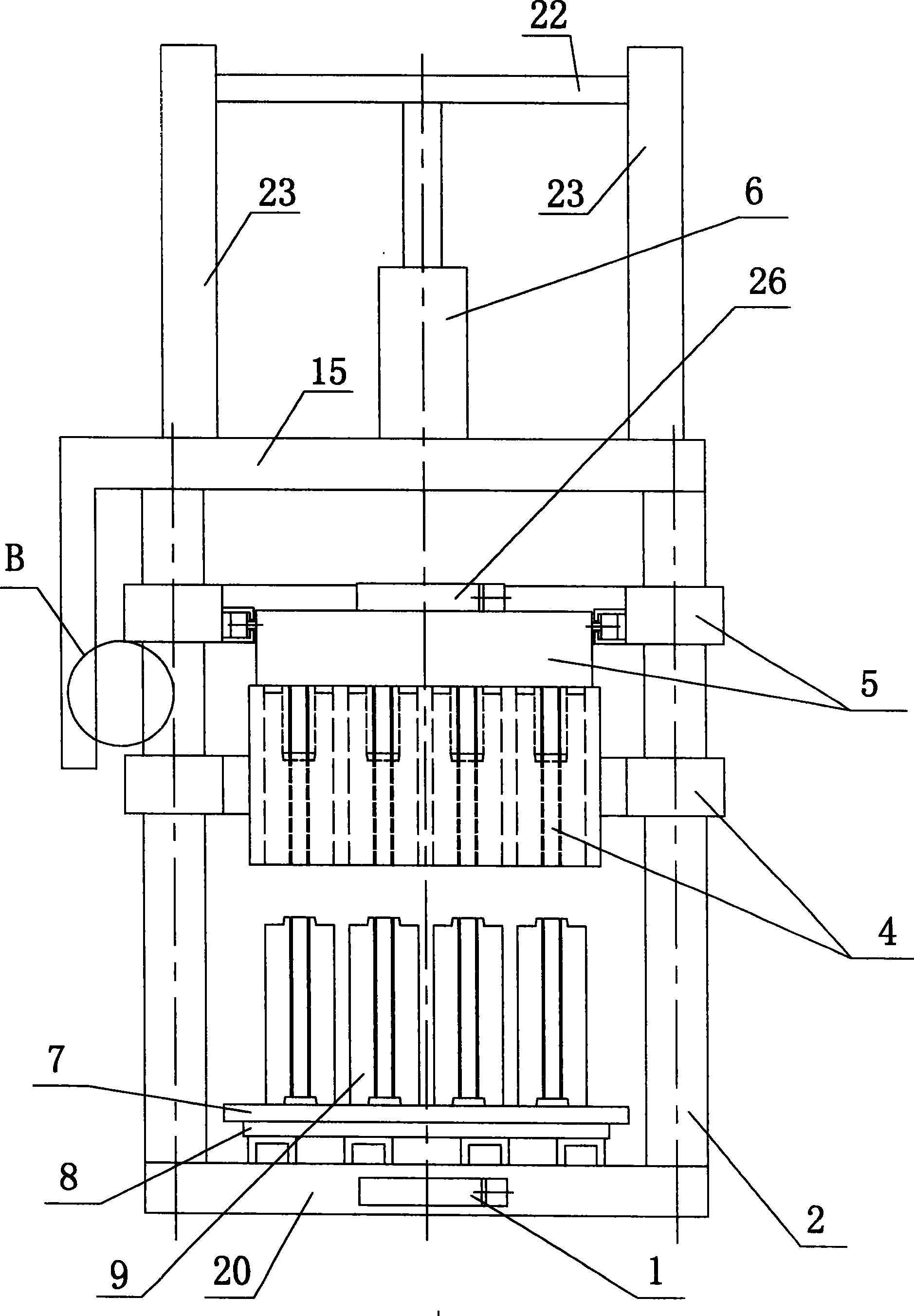

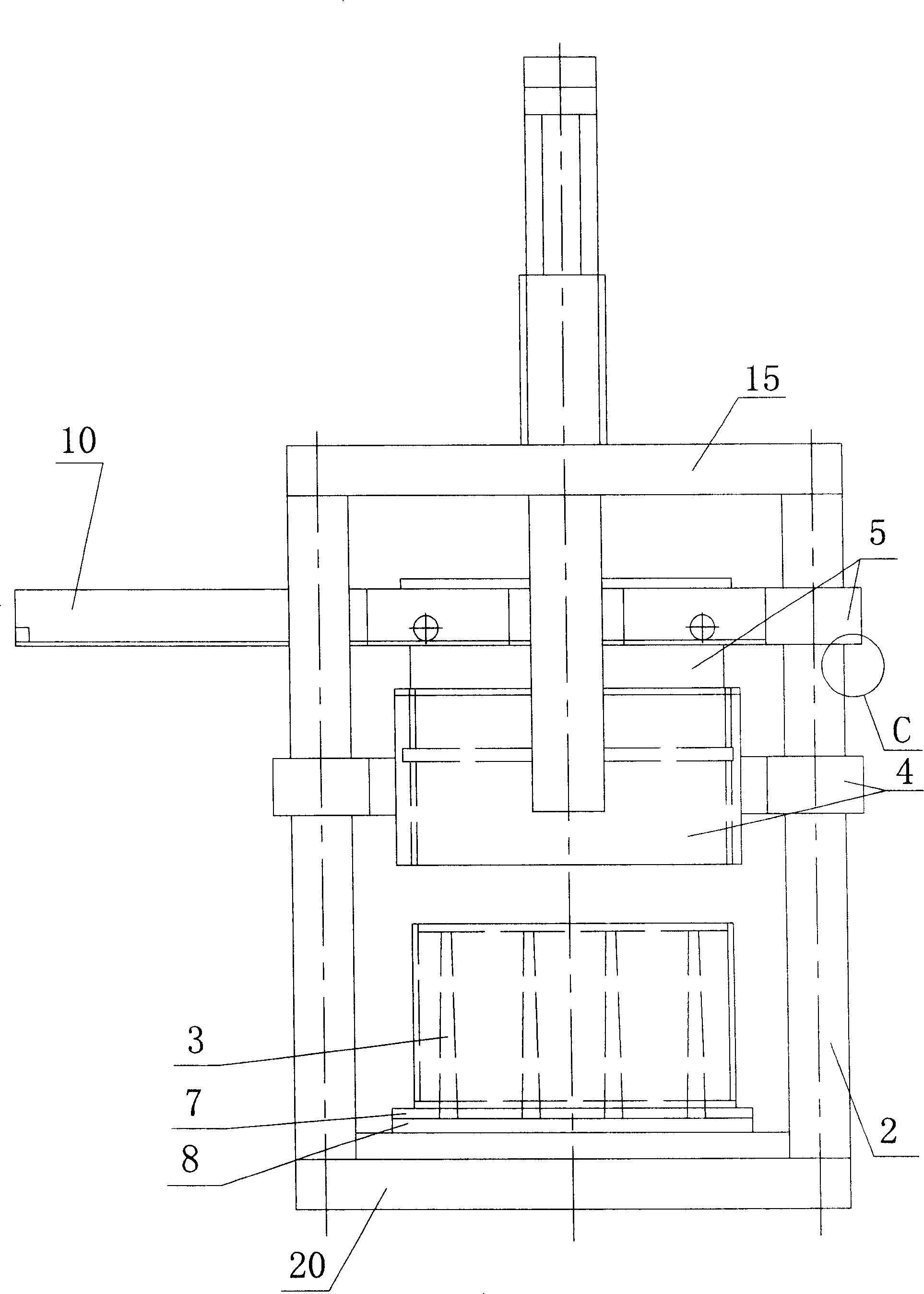

[0017] As shown in the figure: 20 is a machine base, and the base 20 is provided with a stem bottom plate 8, which is connected with the stem bottom plate 8 and arranged with stems 3, and this structure is provided with four rows of stems 3 arranged in parallel. Medium-sized box 4 is covered on the outside of stem 3 and is seated on the stem bottom plate 8, and the inside of medium-sized box 4 is provided with dividing plate and forms four cavities, and every row of stems 3 is all positioned at the center line of the cavity. On the inboard limit of medium-sized case 4, be provided with tongue and groove, above-mentioned is prior art part, no longer auspicious state.

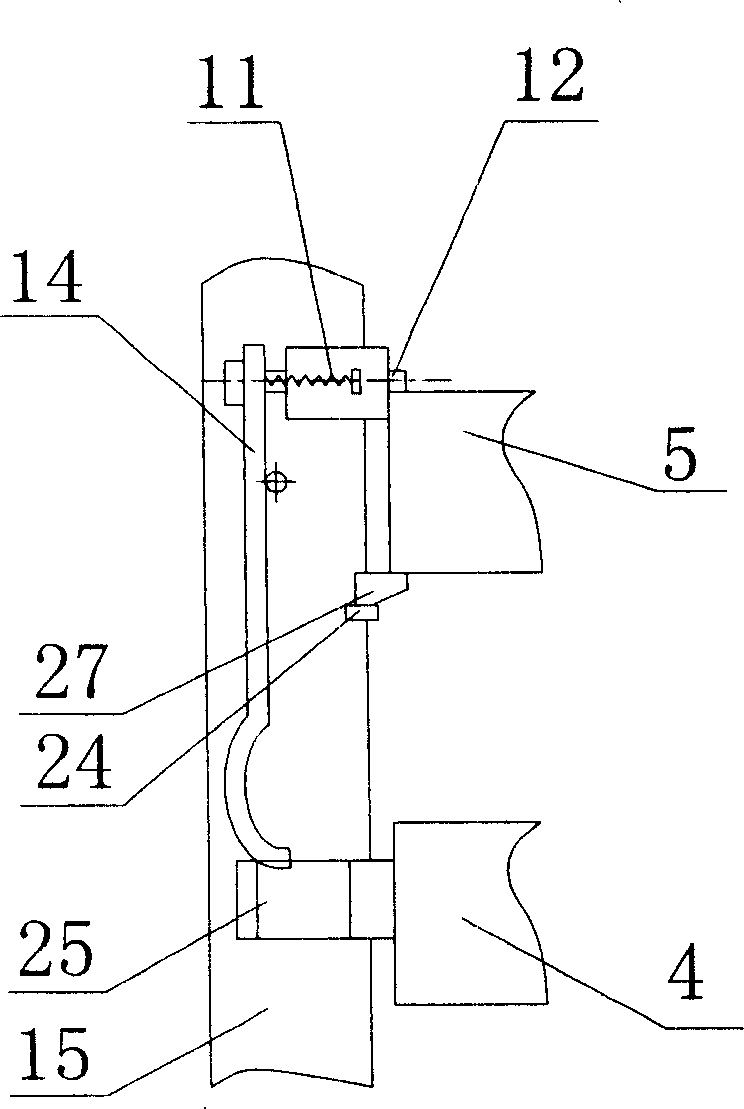

[0018] A template 7 is provided on the stem bottom plate 8, and a hole matched with the stem 3 is provided on the template 7 to fit on the stem 3, and the template 7 is made of plastic material. A corresponding coping box 5 is provided above the stem column 3, and a tongue and groove is provided on the lifting te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com