Design method of a railway flexible guard rail device

A design method and technology for rail protection, applied in the field of rail transit, can solve the problems of difficult installation and limited installation space of rail protection devices, and achieve the effects of convenient installation, reduced maintenance workload and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

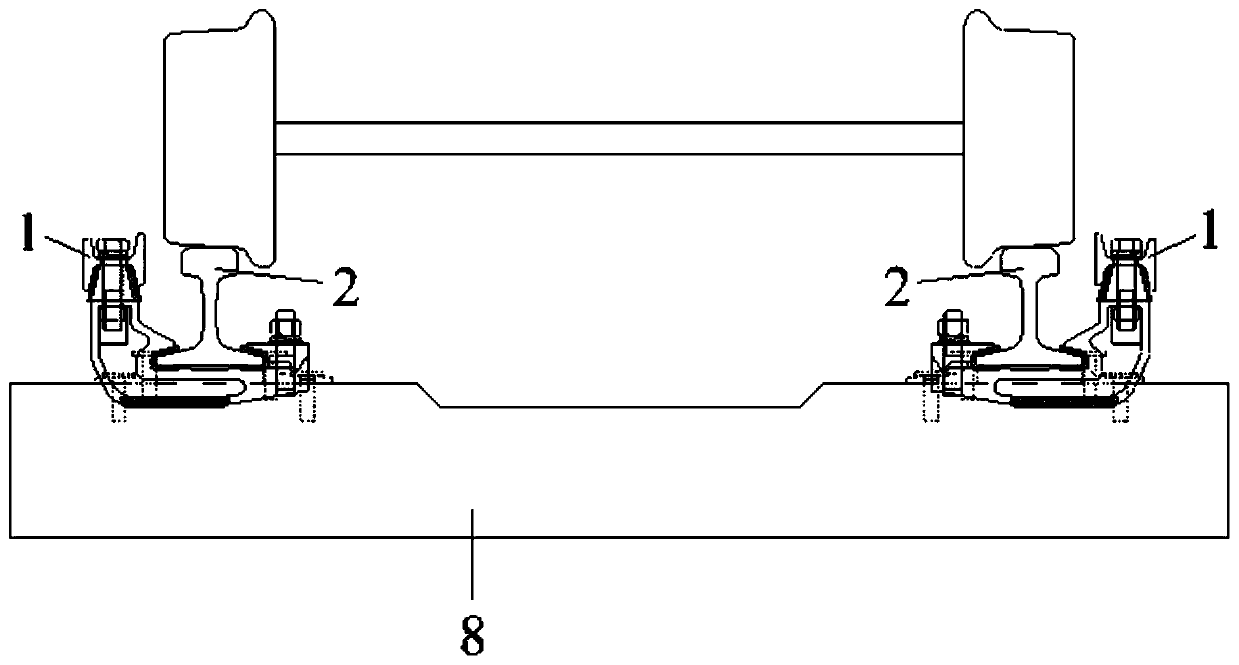

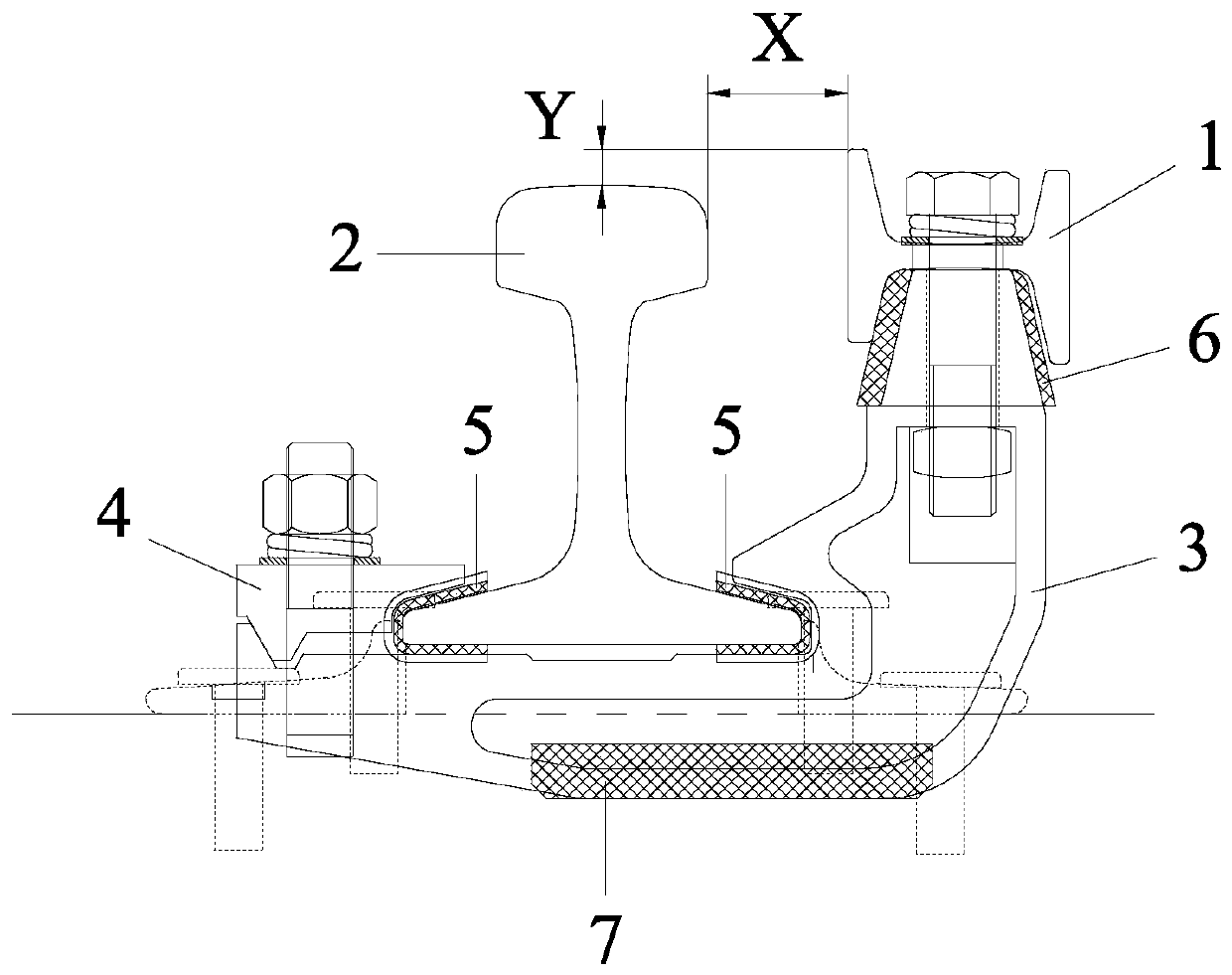

[0048] Such as Figure 1-6 As shown, the design method of a railway flexible guard rail device according to the present invention, the guard rail device includes a guard rail 1, and the guard rail 1 is located outside the rail 2, and the distance between the guard rail 1 and the rail 2 The distance X between and the distance Y between the top of the upper edge of the guard rail 1 higher than the top surface of the steel rail 2 are determined by the following equation:

[0049]

[0050]

[0051]

[0052]

[0053] Wherein, X is the design distance between the guard rail 1 and the rail 2, is the average value of the distance between the guard rail 1 and the rail 2, D is the rim width, L is the rail head width of the rail 2, d is the rim thickness, σ is the mean square error, N is the guarantee coefficient, Y is the design distance that the upper edge top of the guard rail 1 is higher than the top surface of the steel rail 2, H 1 is the effective height of the anti-...

Embodiment 2

[0057] Such as Figure 1-6 As shown, a railway flexible guard rail device according to the present invention is designed and manufactured using the design method of the railway flexible guard rail device as described in Embodiment 1.

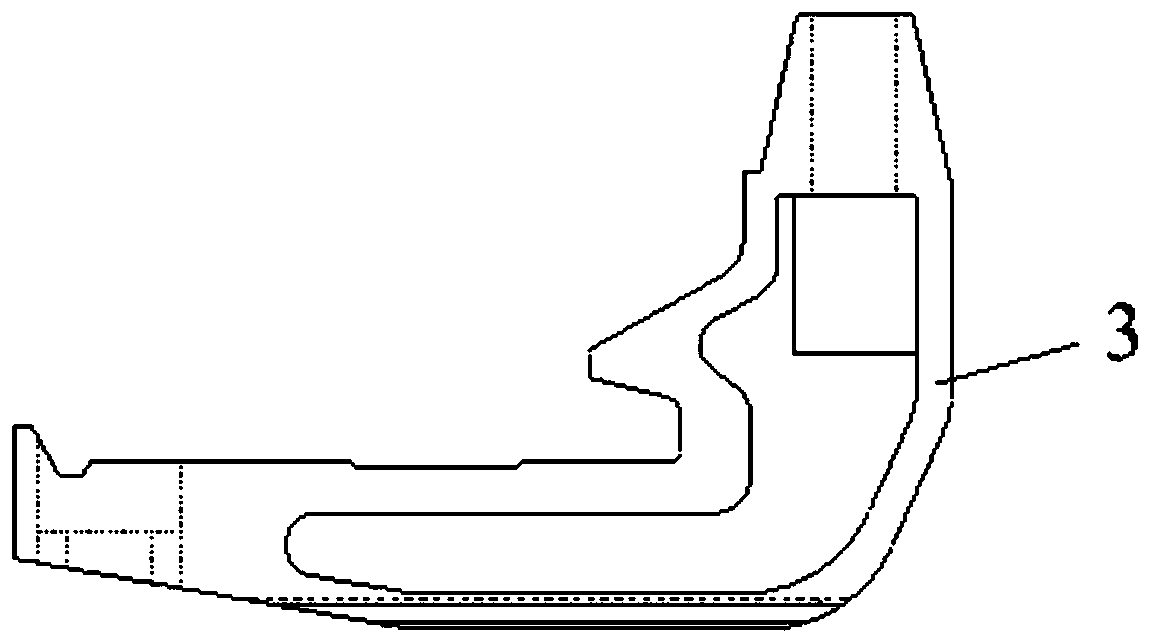

[0058] The guard rail device includes several supports 3 and several pressure plates 4, each of the supports 3 is a cantilever structure, each of the pressure plates 4 corresponds to one of the supports 3, and each of the pressure plates 4 is connected by bolts Corresponding to the support 3, the support 3 is clamped on the rail 2, between the support 3 and the rail 2, between the pressure plate 4 and the rail 2 are provided with The insulating sheet 5, the rail 2 is arranged on the sleeper 8.

[0059] The guard rail 1 is connected to the cantilever end of each support 3 by bolts, and a rubber sleeve 6 is arranged between the guard rail 1 and the support 3, such as Figure 5 As shown, the grade thicknesses of the front and rear working faces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com