Coupler buffering mechanism

A buffer device and coupler technology, applied in traction devices, transportation and packaging, railway car body parts, etc., can solve problems such as poor performance, derailment, and no anti-off function, so as to improve transportation safety, improve reliability, and prevent The effect of accidental uncoupling of the coupler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

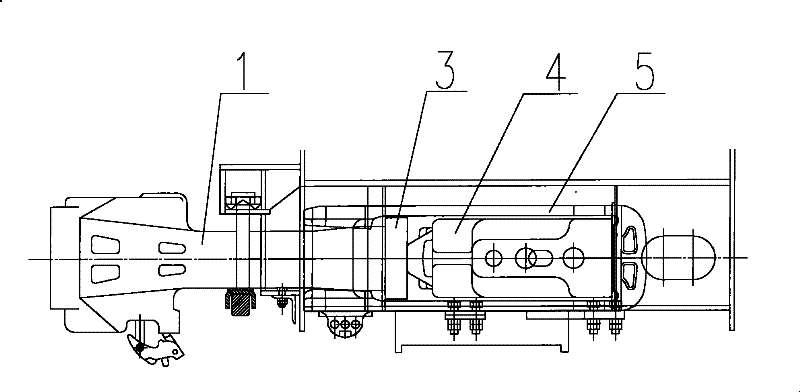

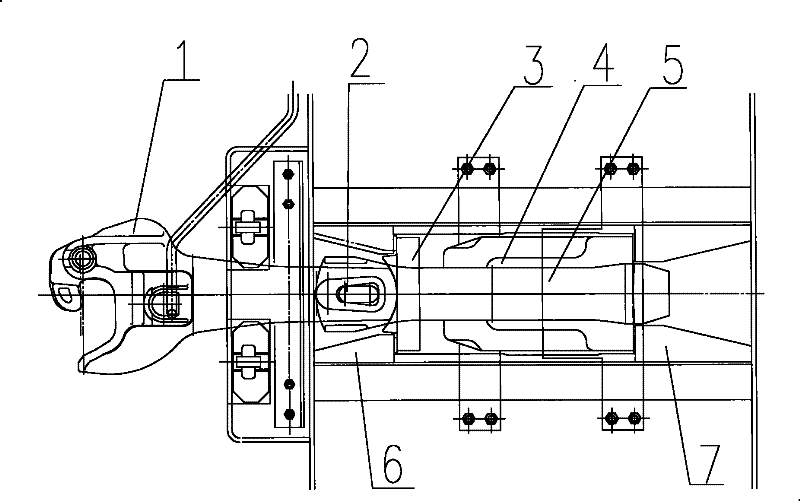

[0053] The basic idea of the present invention is that the tail end surface of the coupler is designed as a cylindrical surface plus a symmetrical shoulder structure, and the slave plate is also designed as a cylindrical surface plus a symmetrical shoulder structure, so as to enhance the automatic centering function of the coupler.

[0054] The following will be described in detail in conjunction with the accompanying drawings and embodiments.

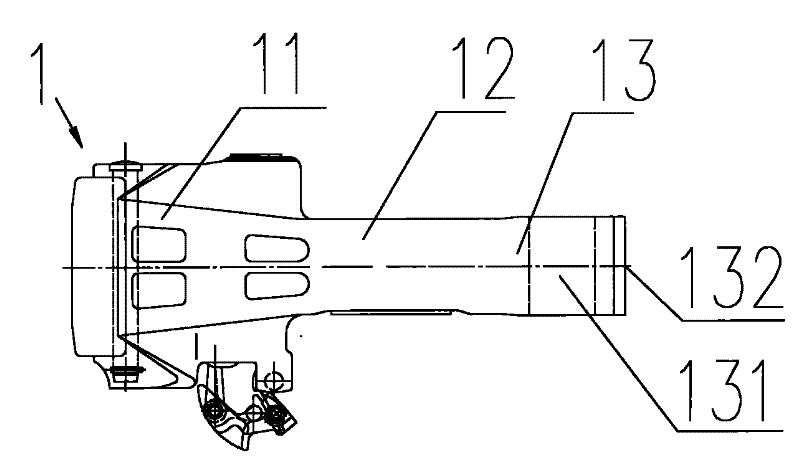

[0055] See Figure 10-11 ,in: Figure 10 It is the structural representation of the coupler of the present invention; Figure 11 yes Figure 10 top view. In the coupler 1, the coupler head 11 includes a knuckle tongue 111, a knuckle tongue pin 115, a knuckle tongue push iron 117, a coupler lock 116, a lower lock pin (including a lower lock pin, a lower lock pin rod 113), and a lower lock pin. Rotating shaft 119; when the lower locking pin rotating shaft 119 rotates, the lower locking pin forms an action to make the hook lock 116 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com