Internal expanding type clamping mechanism of large-caliber hot bend bevelling machine

A technology of hot simmering pipe bending and clamping mechanism, which is applied in the field of metal pipe processing and piping system, and can solve the problems of large size of fixture, difficulty in processing alignment, structural limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

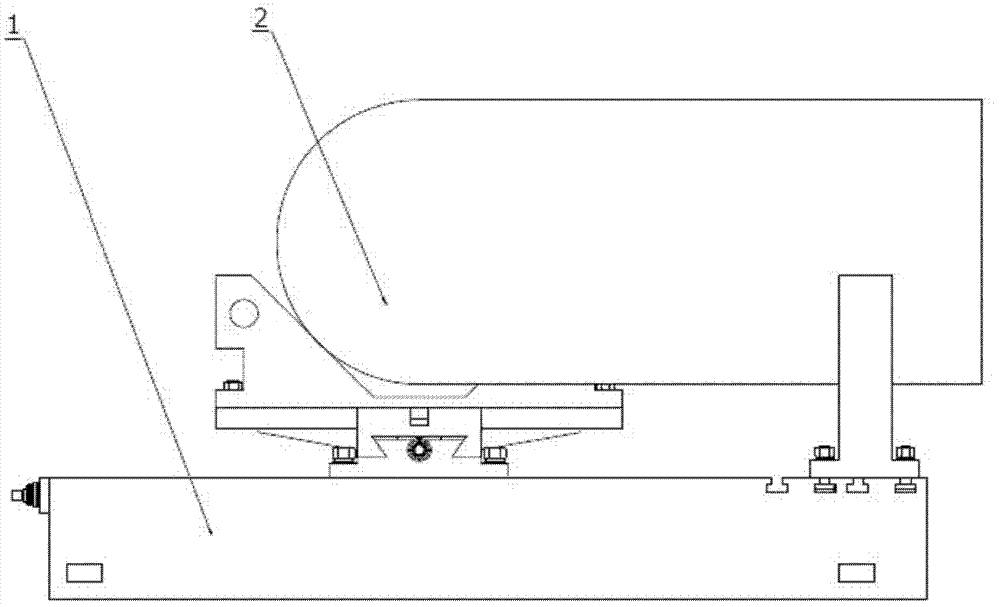

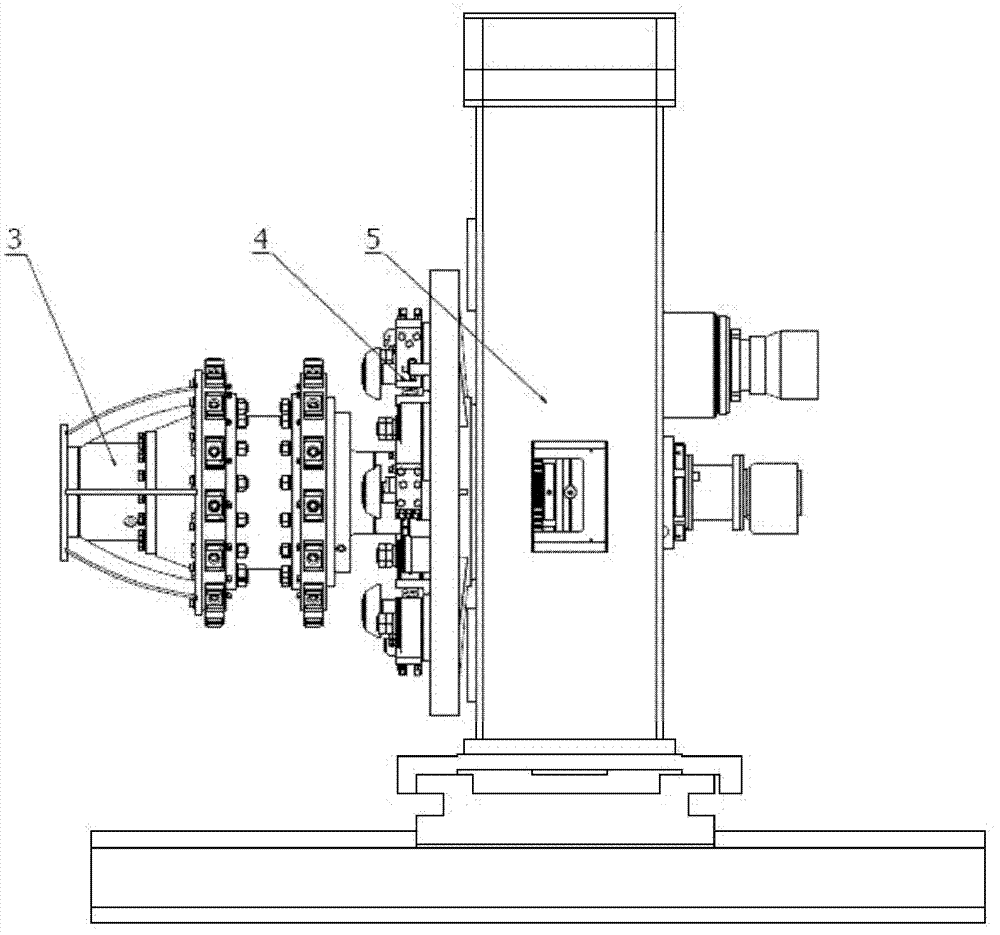

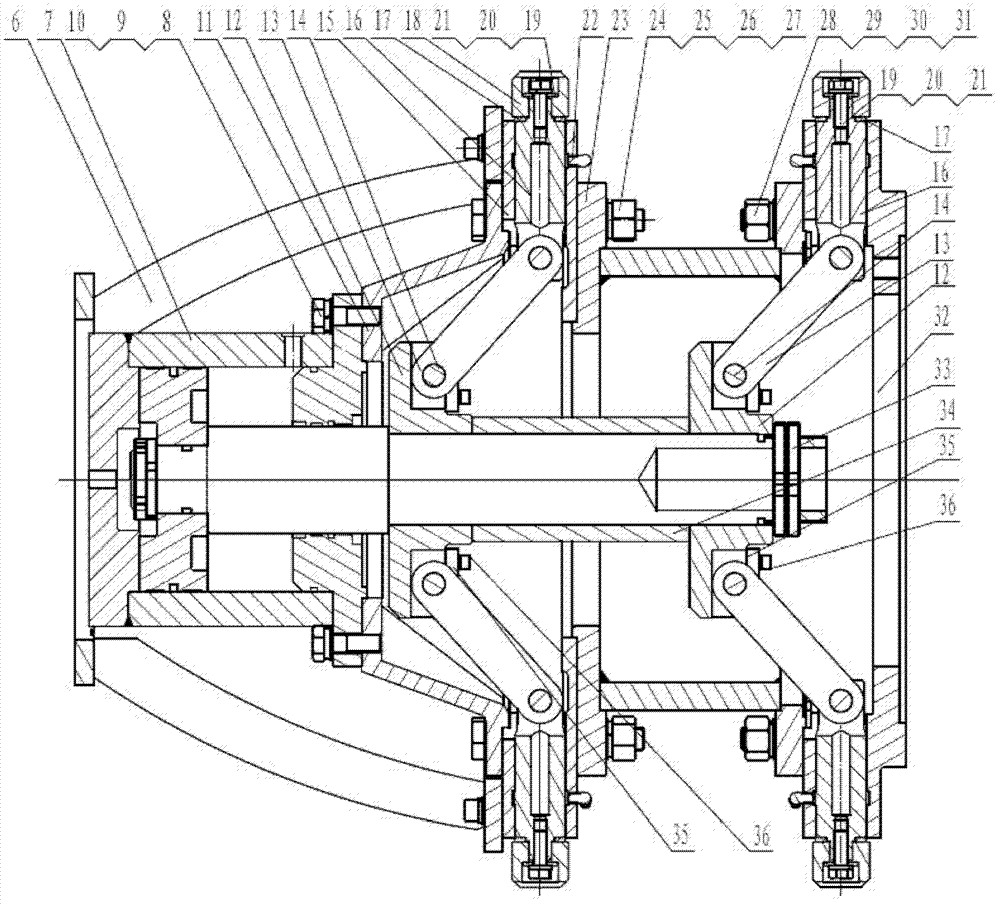

[0063] Example. Taking the processing of Φ1016mm and 90° hot-simmering pipe bending as an example, the structure of the hot-simmering pipe bending beveling machine and its internal expansion clamping mechanism is as follows Figure 1-Figure 4 shown. It mainly includes front cage 6, hydraulic cylinder 7, end plate 11, thrust plate 12, connecting rod 13, cylindrical pin 14, front tightening body 15, ejector rod 16, adjustment pad 17, expansion block 18, grease nozzle 22, Connecting disc 23, rear tension body 32, lock nut 33, axle sleeve 34, pressing bench 35.

[0064] The piston rod end of the hydraulic cylinder 7 is fixedly connected to the end plate 11 by the screw 8 on the flat washer 9 and the spring washer 10, and a thrust plate 12 is installed on the piston rod of the hydraulic cylinder 7 outside the end plate 11; the front cage 6 is set on the hydraulic cylinder After the other end of 7, the mouth of the front cage 6 is connected with the outer edge of the end plate 11 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com