Mechanical airplane jack

A kind of jack and mechanical technology, applied in the direction of mechanical equipment, supporting machines, mobile frames, etc., can solve the problems that the center of gravity of the aircraft is not very convenient, the maintenance of the aircraft is inconvenient, and the rising speed is slow, so as to shorten the auxiliary working time and increase the Field adaptability and effects of shortened working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

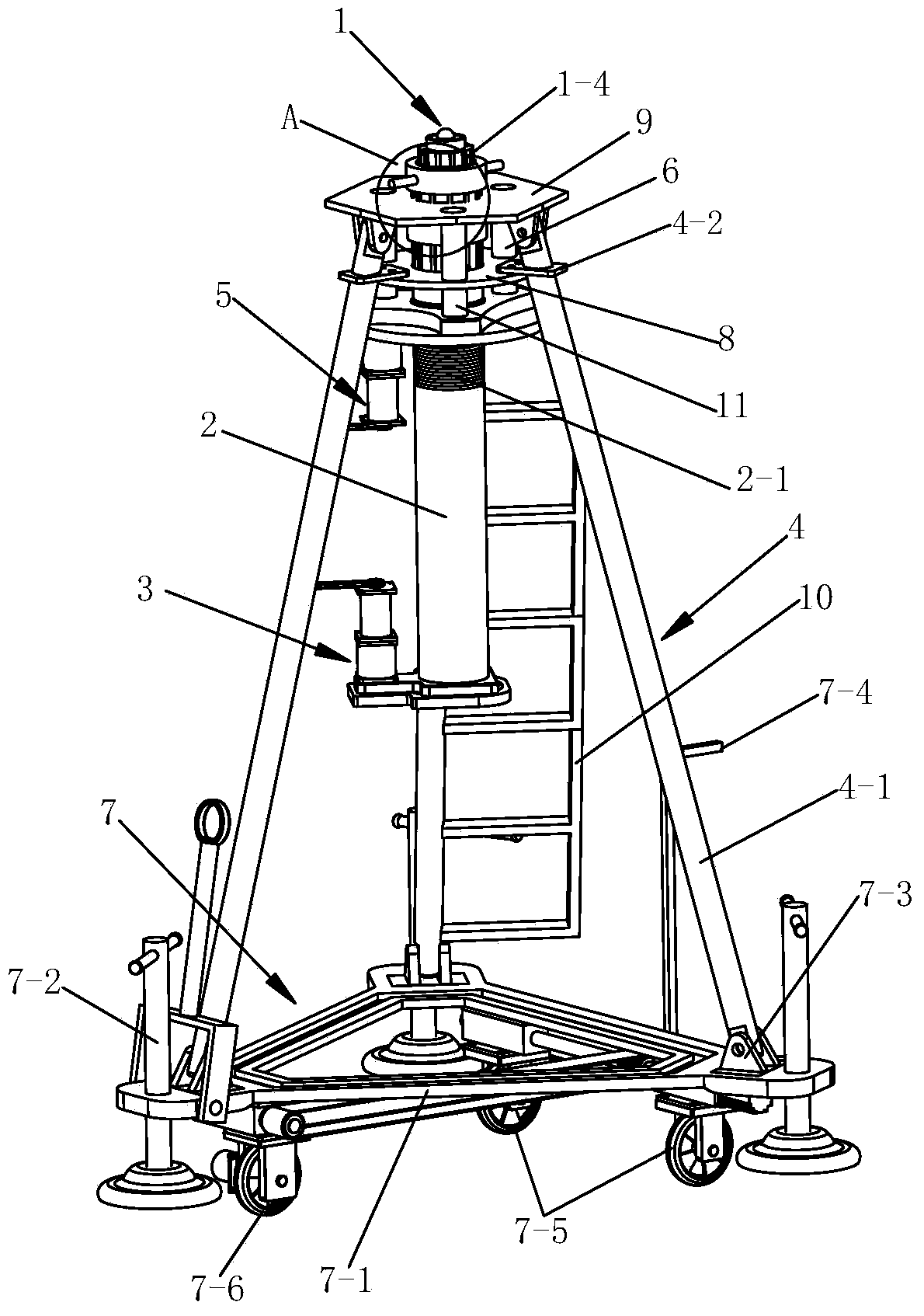

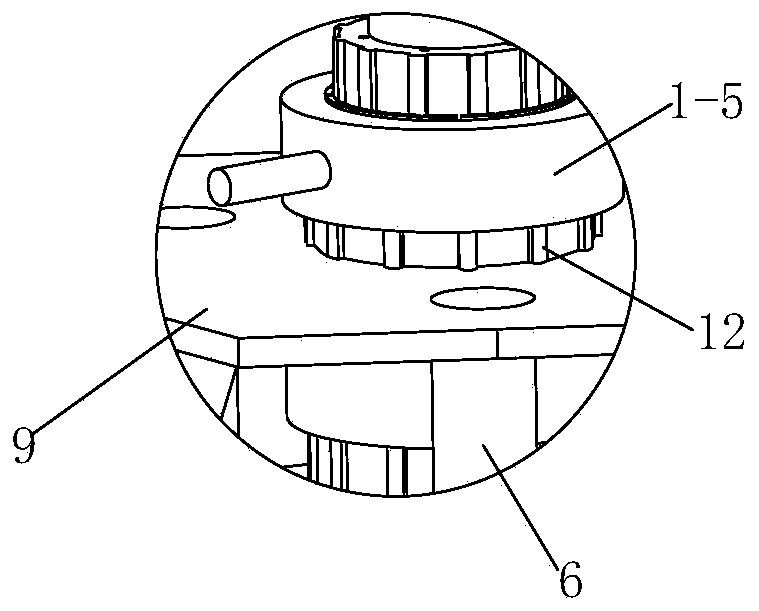

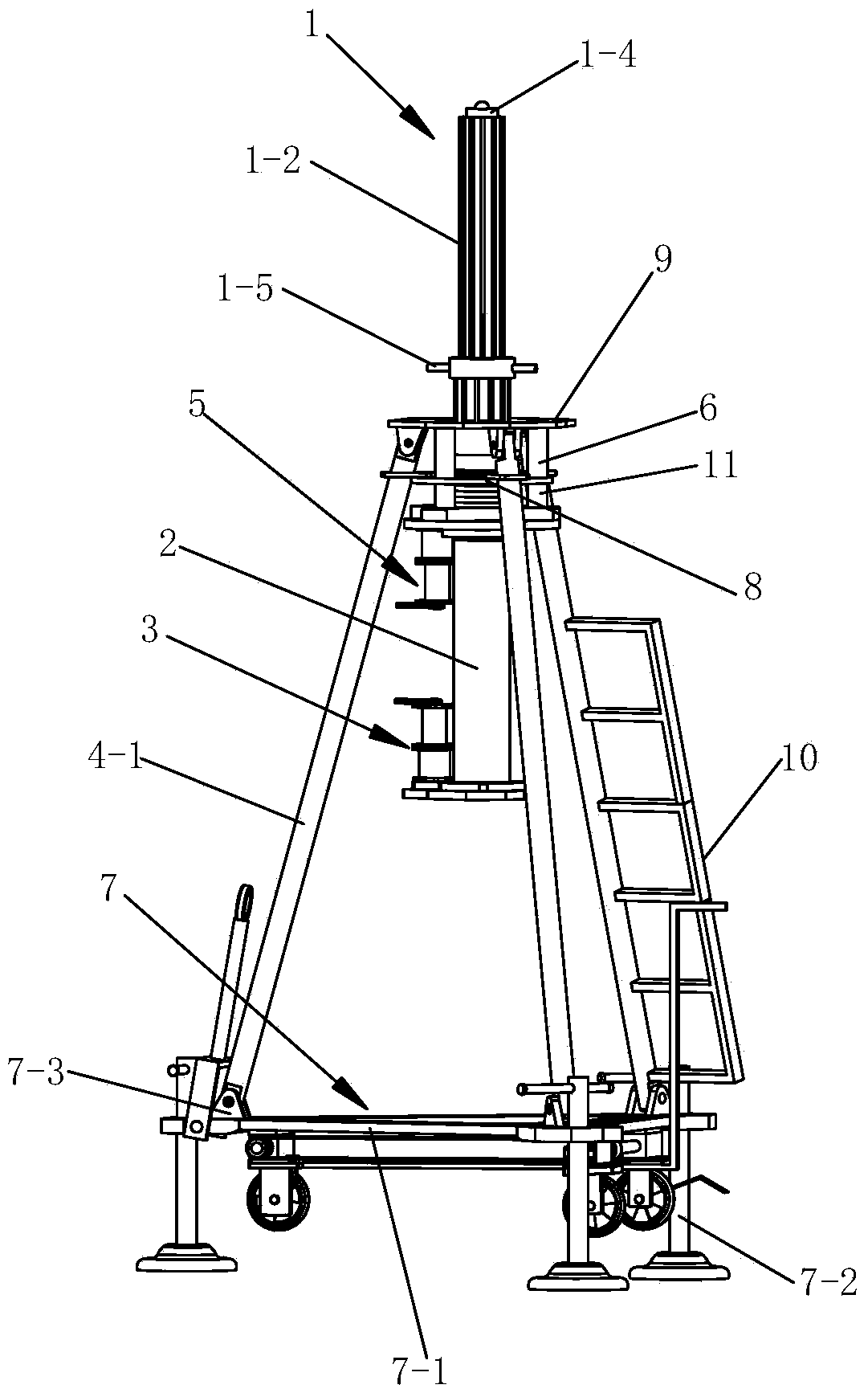

[0071] Such as figure 1 and image 3 A mechanical aircraft jack shown includes a support frame 4, a fast jacking mechanism 1, a fast driving mechanism 3 for driving the fast jacking mechanism 1 to move or position in the no-load stroke, a bearing sleeve 2 and a The heavy-duty drive mechanism 5 that drives the load-bearing sleeve 2 to move or position in the load stroke; the fast drive mechanism 3 is installed on the load-bearing sleeve 2, and the lower end of the fast jacking mechanism 1 extends into the load-bearing sleeve 2 And it is in transmission cooperation with the fast driving mechanism 3 , and the heavy-duty driving mechanism 5 is installed on the support frame 4 and in transmission cooperation with the bearing sleeve 2 .

[0072] In this embodiment, the mechanical aircraft jack is provided with a fast jacking mechanism 1 and a fast driving mechanism 3 that drives the fast jacking mechanism 1, so that the fast jacking mechanism 1 can quickly complete the no-load stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com