Solar energy high-temperature heat collecting pipe exhaust method used for generating electricity and horizontal-type exhaust platform

An exhaust method and a technology of heat collecting tubes, which are applied in the directions of solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems that cannot meet the requirements of high temperature heat collecting tubes for solar power generation, and the heat conduction temperature is not high, so as to save auxiliary working time, The production cycle is compact and the effect of ensuring the quality of the workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

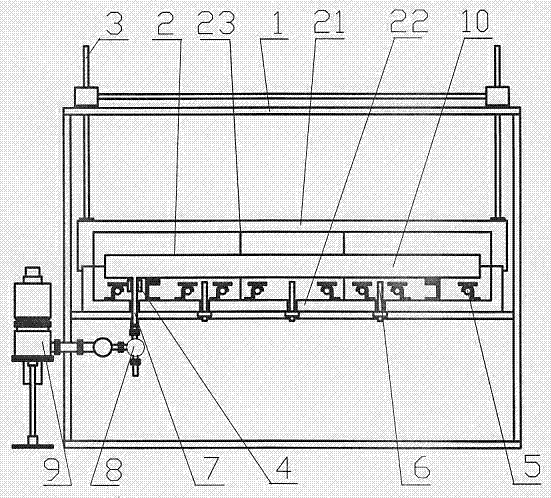

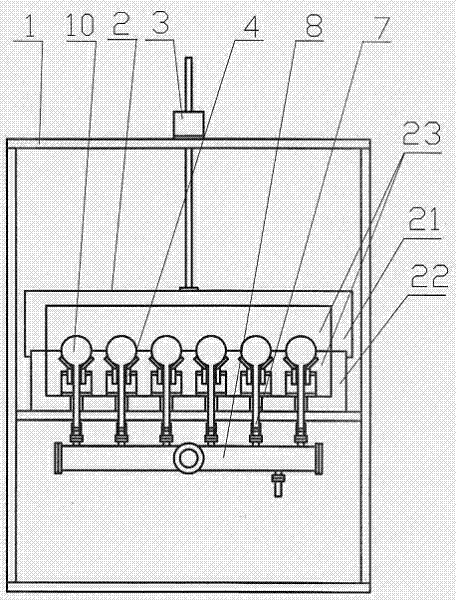

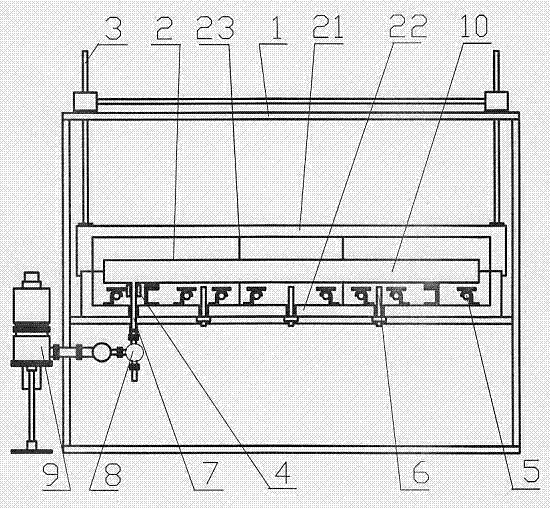

[0023] Such as figure 1 , 2 Shown: A solar high-temperature heat collection tube horizontal exhaust platform for power generation, including a frame 1, an incubator 2, a lifting mechanism 3, an electric heating sealing furnace 4, an electric heating tube 5, a thermocouple 6, a vacuum hose 7, an exhaust The main pipe 8 and the molecular pump vacuum system 9, the insulation box 2 adopts a horizontal rectangular box structure, which has good heat insulation and heat preservation functions, and two layers of stainless steel reflectors are added inside to reduce heat radiation and improve heat preservation performance. The insulation material is filled between them. The insulation box 2 is divided into two parts, the upper box body 21 and the lower box body 22. The inside of the box is separated into three temperature control areas by a partition 23. The temperature of each temperature control area can be set according to the process requirements. and adjustment, the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com