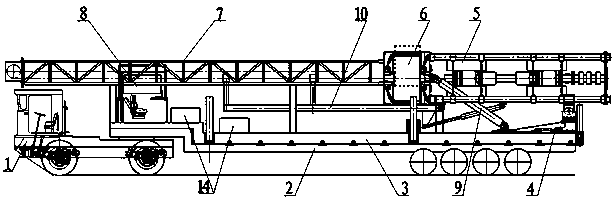

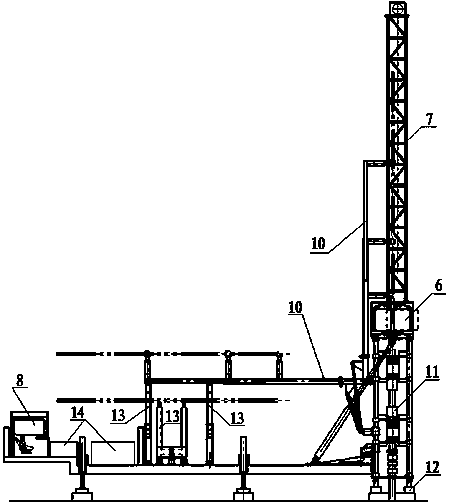

Integrated high-temperature pressure balance workover rig

An integrated, high-temperature technology, applied in wellbore/well components, drilling equipment, drilling equipment and methods, etc., to facilitate equipment transportation and operation, reduce auxiliary operation time, and provide a degree of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The car body system of the present invention is composed of a tractor 1 and a trailer 2. The length, width and height of the work vehicle should meet the requirements of the special vehicle road transportation standard and meet the requirements of on-site operation. All components and operation systems are installed on the work platform 3 to facilitate transportation and operation. The work platform 3 can be connected with the trailer 2 through the slot, so that it has only one degree of freedom up and down, so as to prevent slipping during transportation. There are six hydraulic support feet on the work platform 3, the work platform 3 is supported during operation, and the trailer 2 can be driven away. When the ground conditions at the wellhead are complicated, such as a large raised platform at the wellhead, the trailer 2 cannot deliver the operation platform 3 to the position at one time, and the trailer 2 can be separated from the operation platform 3 first, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com