Novel tunneling process

A technology for excavating working face and process, which is applied in mining equipment, earth-moving drilling, pillars/supports, etc., can solve problems such as the speed of tunnel excavation can not keep up, restrict coal mining output of coal mines, hinder the progress of excavation work, etc. Conducive to safety management, convenient operating environment, limiting and preventing deformation and damage of surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

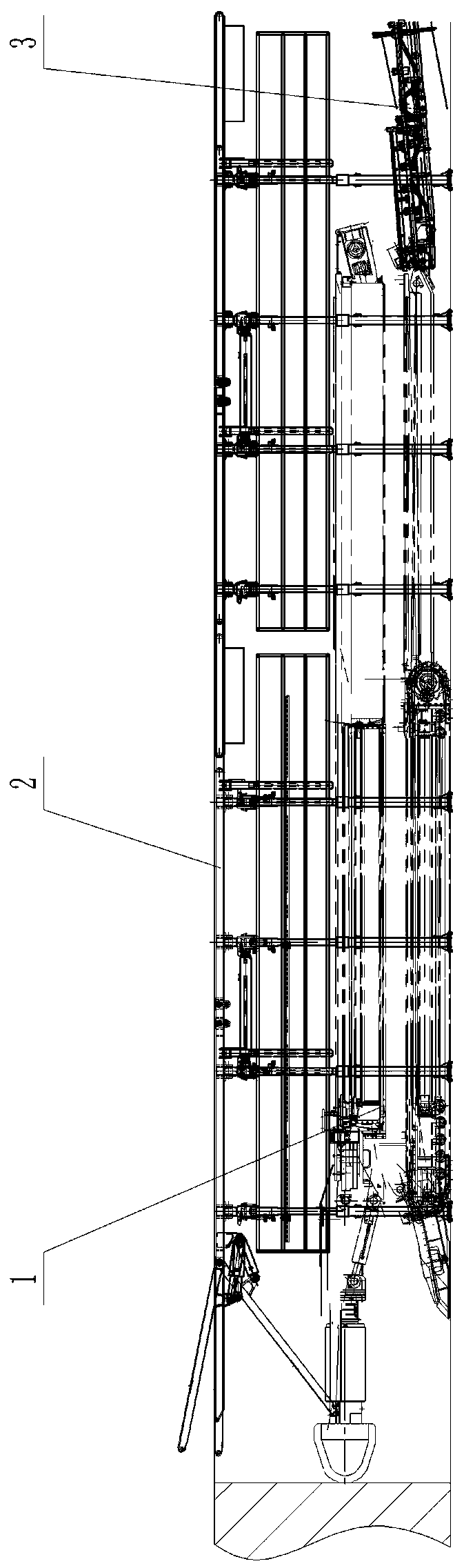

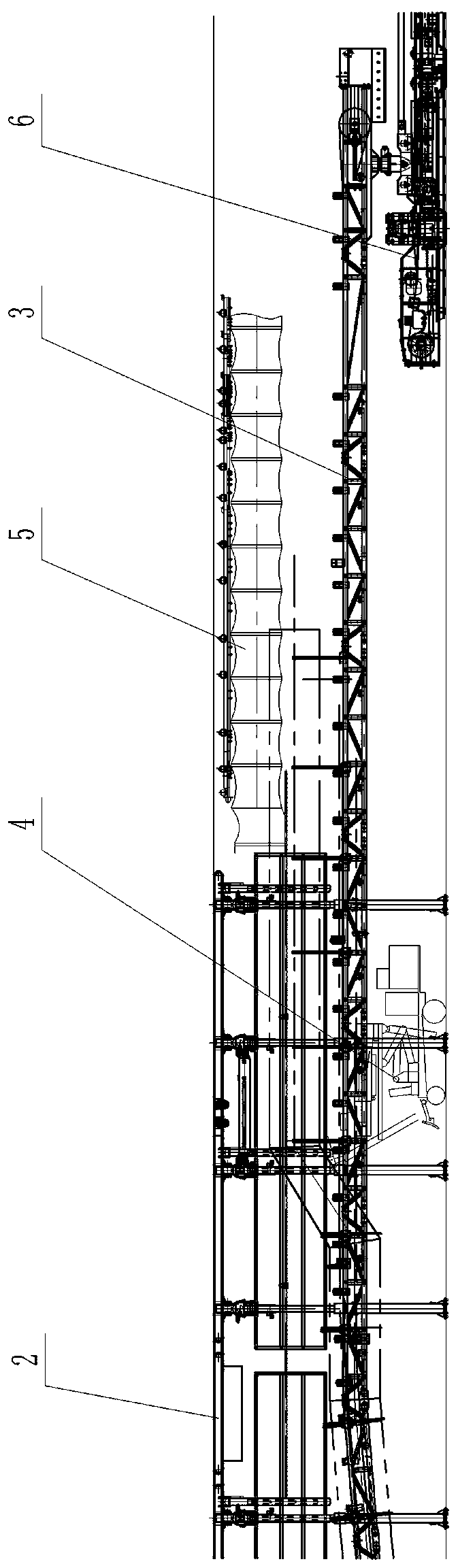

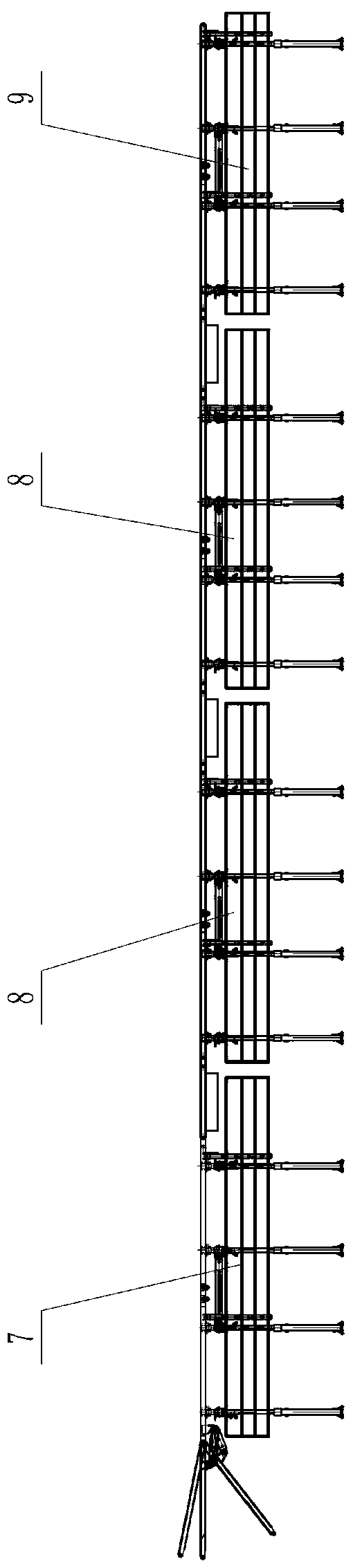

[0033] according to Figure 1-12 The specific steps of the present invention are described in detail. The novel tunneling process includes the following steps:

[0034] Step 1. Arrange the roadheader 1 at the front end of the excavation face of the underground roadway. The rear part of the roadheader 1 is connected with the front belt frame of the bridge type conveyor belt conveyor 3, and the rear belt frame of the bridge type conveyor belt conveyor 3 is connected to the The front end of self-moving belt machine tail 6 slides and links to each other. And, the self-moving belt conveyor tail 6 is also provided with a wet dust removal fan and an emulsion pumping station. Afterwards, an excavation temporary support device 2 that can move forward synchronously with the fully mechanized excavation operation is installed on the outside of the roadheader 1, and then the surrounding rock of the excavation working face of the entire roadheader 1 and the front half of the bridge convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com