Integrated arm type in-hole perforator

A down-the-hole drilling rig and arm-type technology, which is applied in the field of integrated arm-type down-the-hole drilling rigs, can solve problems such as inability to satisfy multi-directional drilling, inability to adjust the drilling angle, and small adjustment angle range, so as to save auxiliary operation time, Improve the drilling accuracy and prevent the vibration of the drill frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

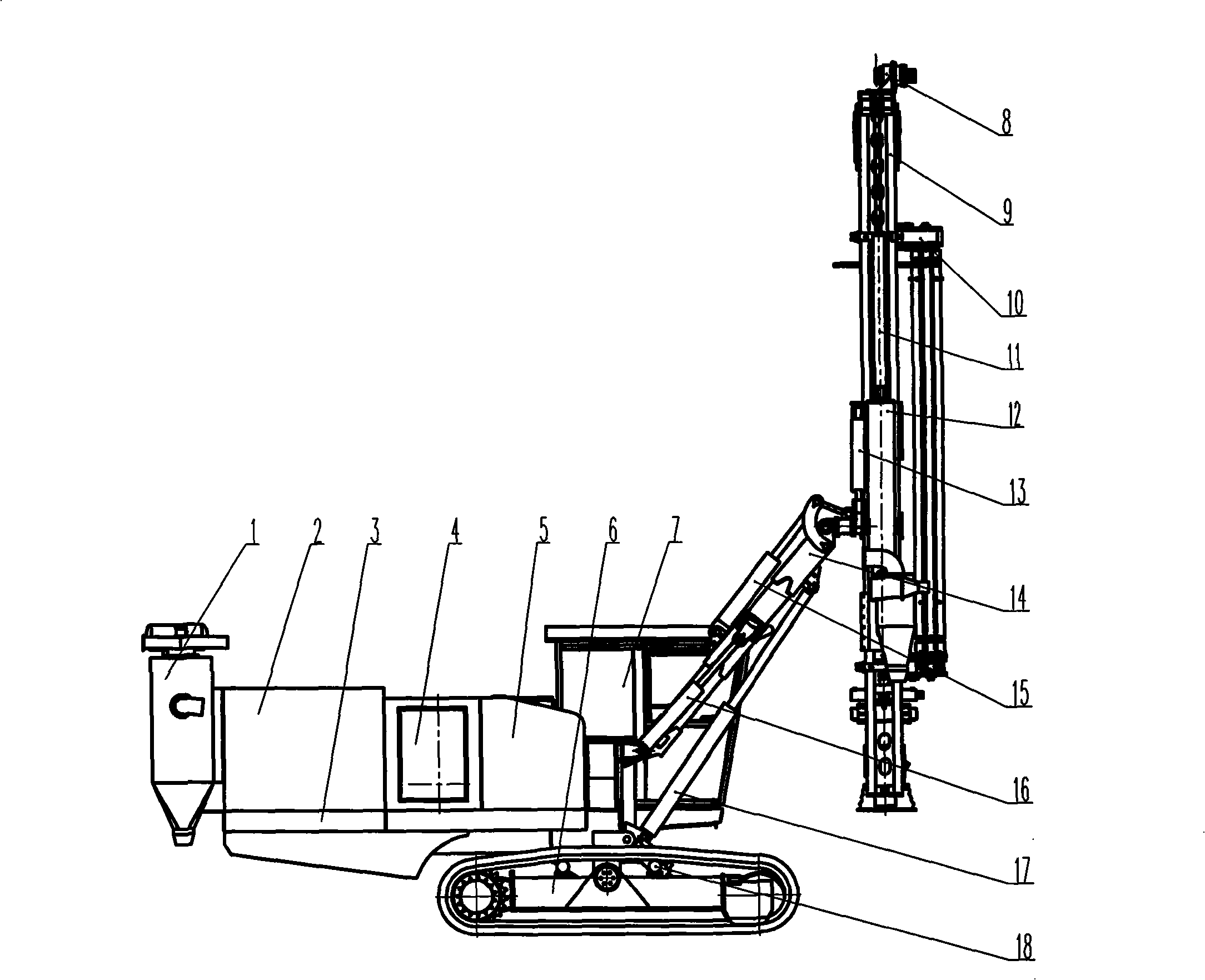

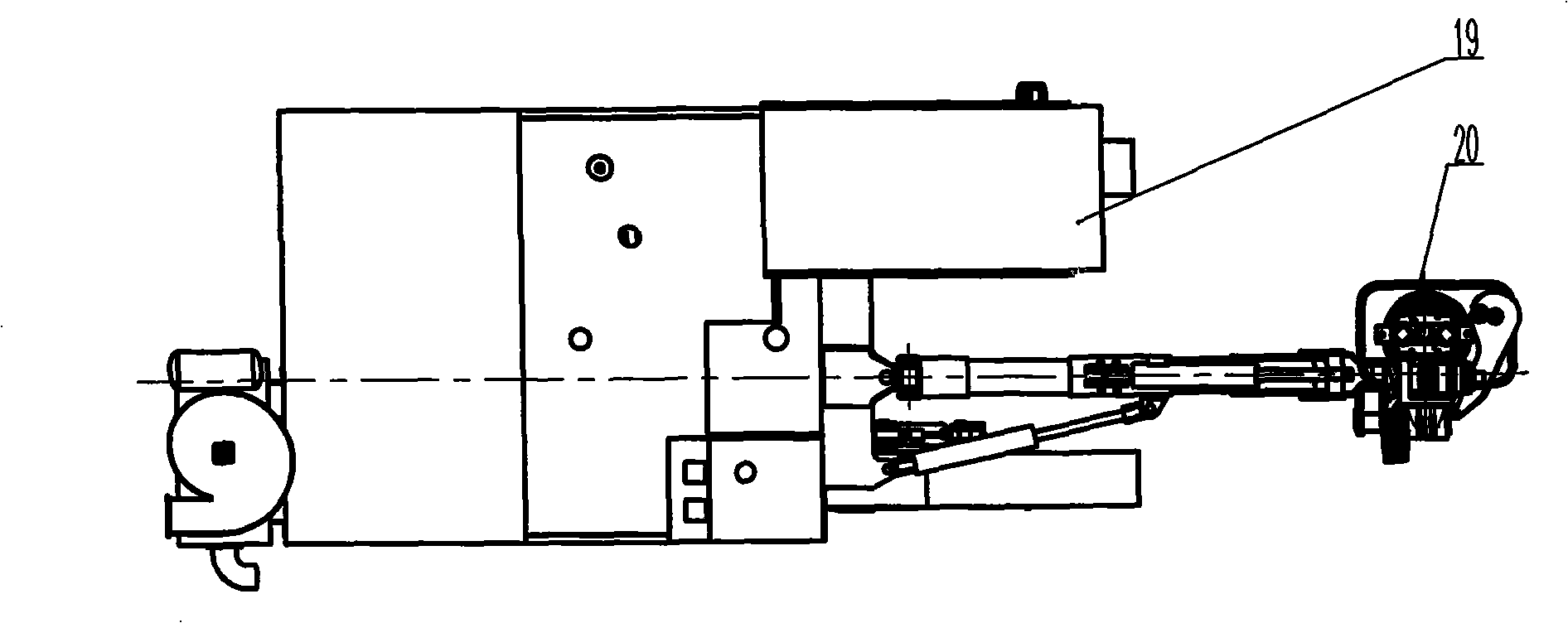

[0012] see figure 1 and figure 2 , the frame 3 is provided with a crawler floating chassis 6, the frame 3 is provided with an air compressor 2, a dust removal system 1, a power system 4, a hydraulic system 5, a driver's cab 7 and an operating system 19, and the drilling arm 14 is hinged on the On the frame 2, the drill frame 9 is hinged on the drill boom 14, and the drill frame 9 is provided with a propulsion system 8, a drill rod store 10, a sliding frame 12 and a rotary system 20, and between the sliding frame 12 and the drilling frame 9 Compensation oil cylinder 11, drill boom lifting cylinder 17 and drill boom deflection cylinder 16 are installed between the drill boom 14 and the frame 9, and drill frame lifting cylinder 15 and drill frame deflection cylinder are arranged between the drill boom 14 and the drill frame 9 13.

[0013] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com