Patents

Literature

836 results about "Back-up ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A back-up ring is a rigid ring that holds an elastomeric seal or plastic (such as Polyethylene) connection to its designed shape and in its correct place. Back up rings are commonly used with O-rings, lip seals, and as reciprocating shaft seals. They are also used for piping connections joining two different materials - typically one flexible and one rigid.

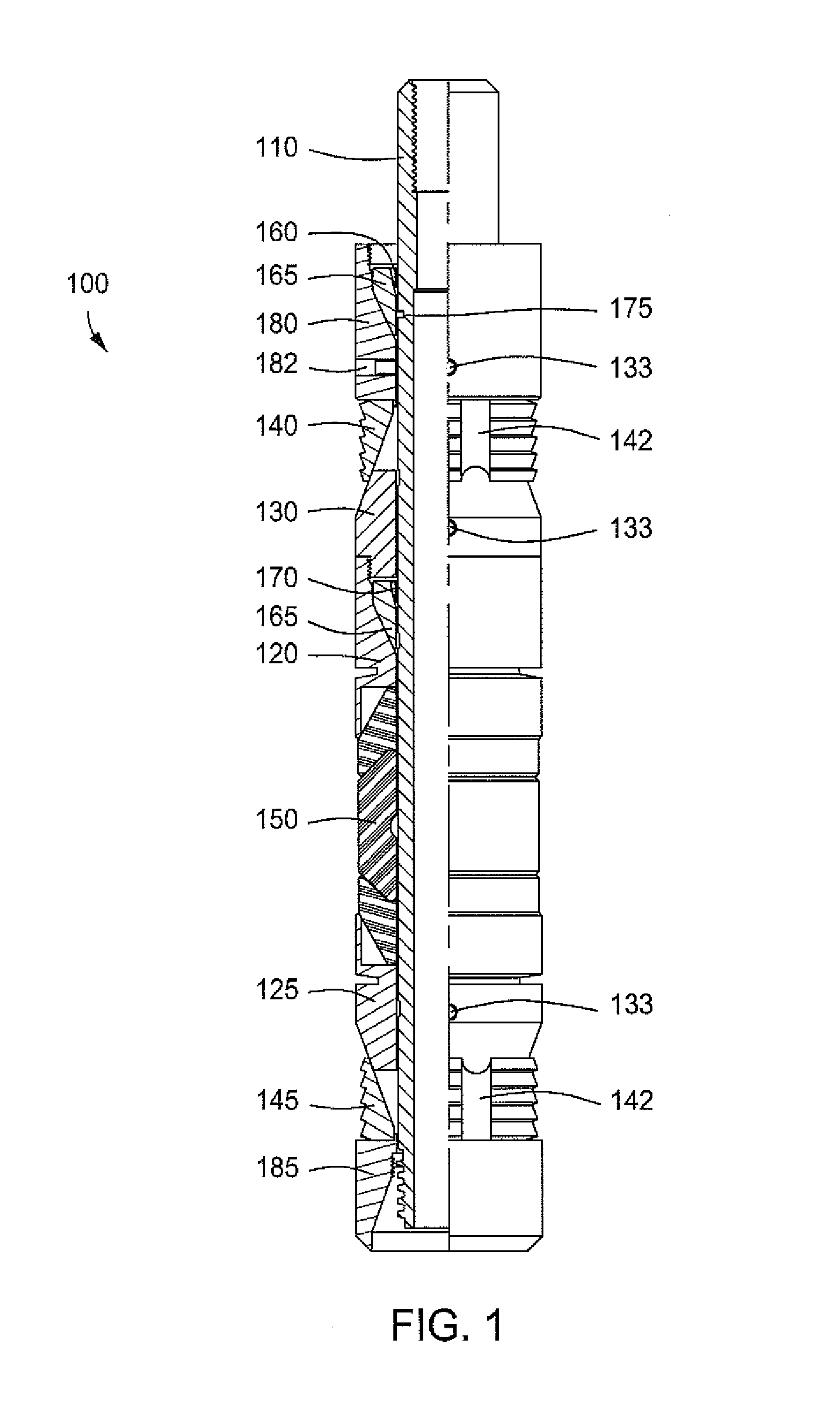

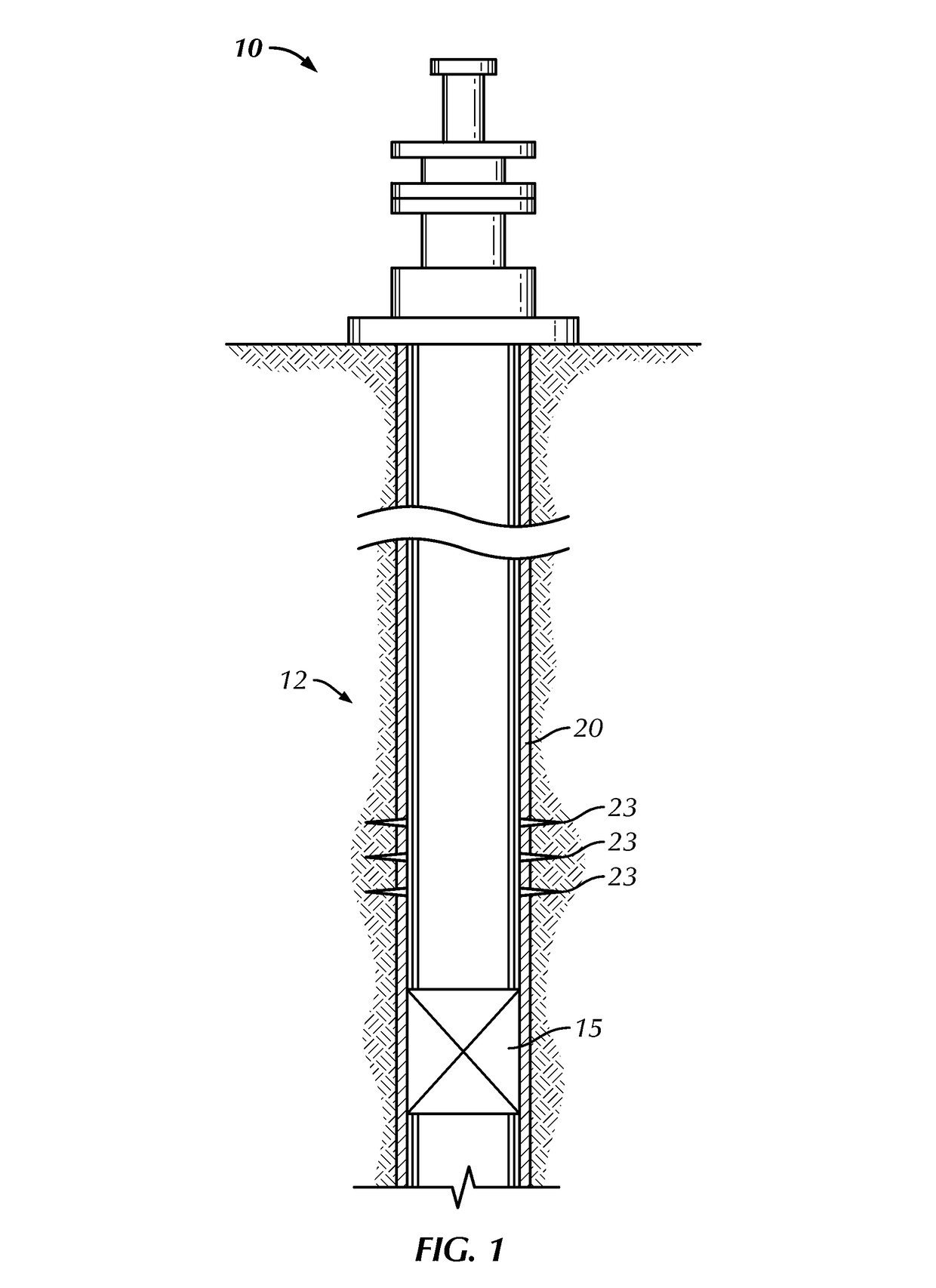

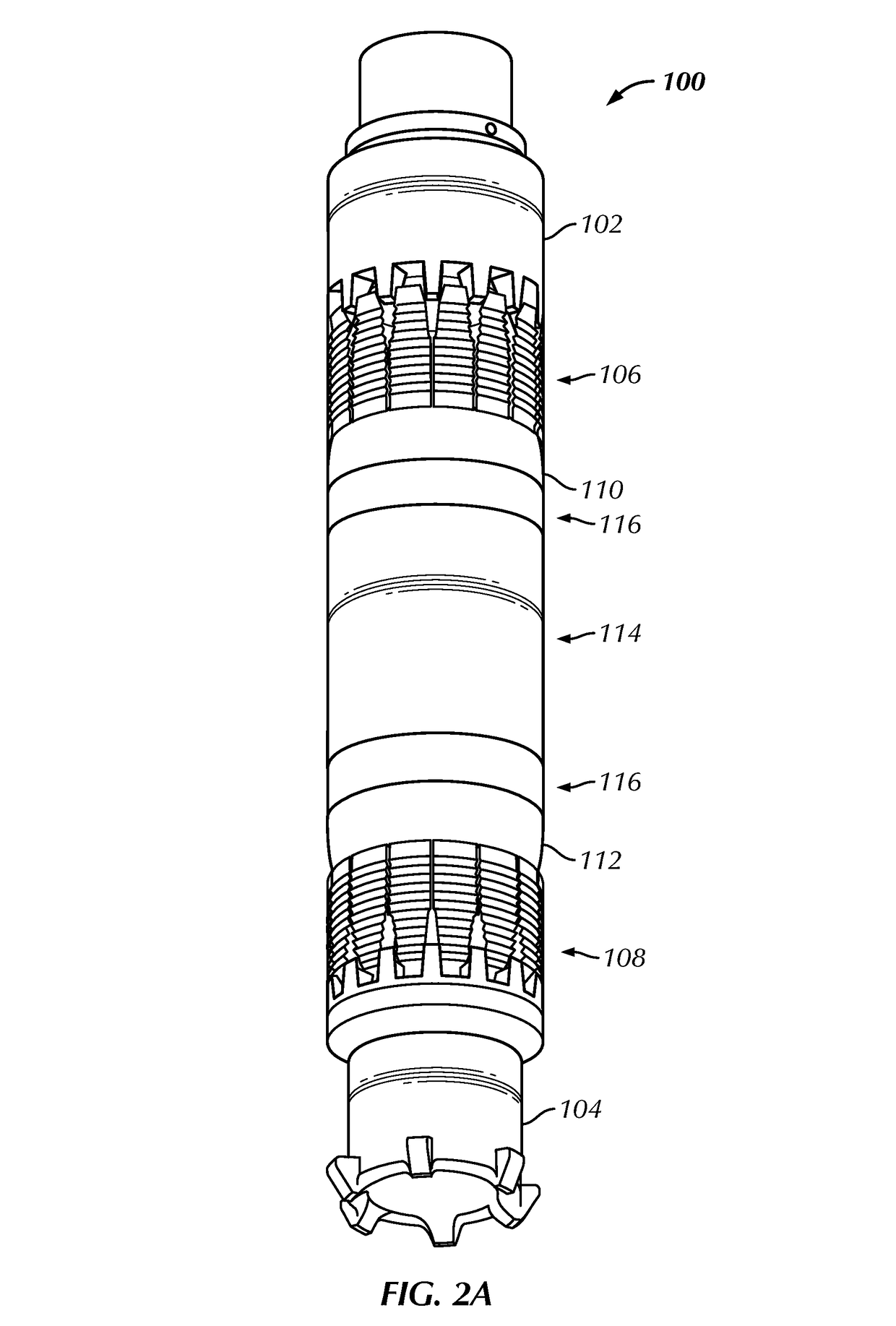

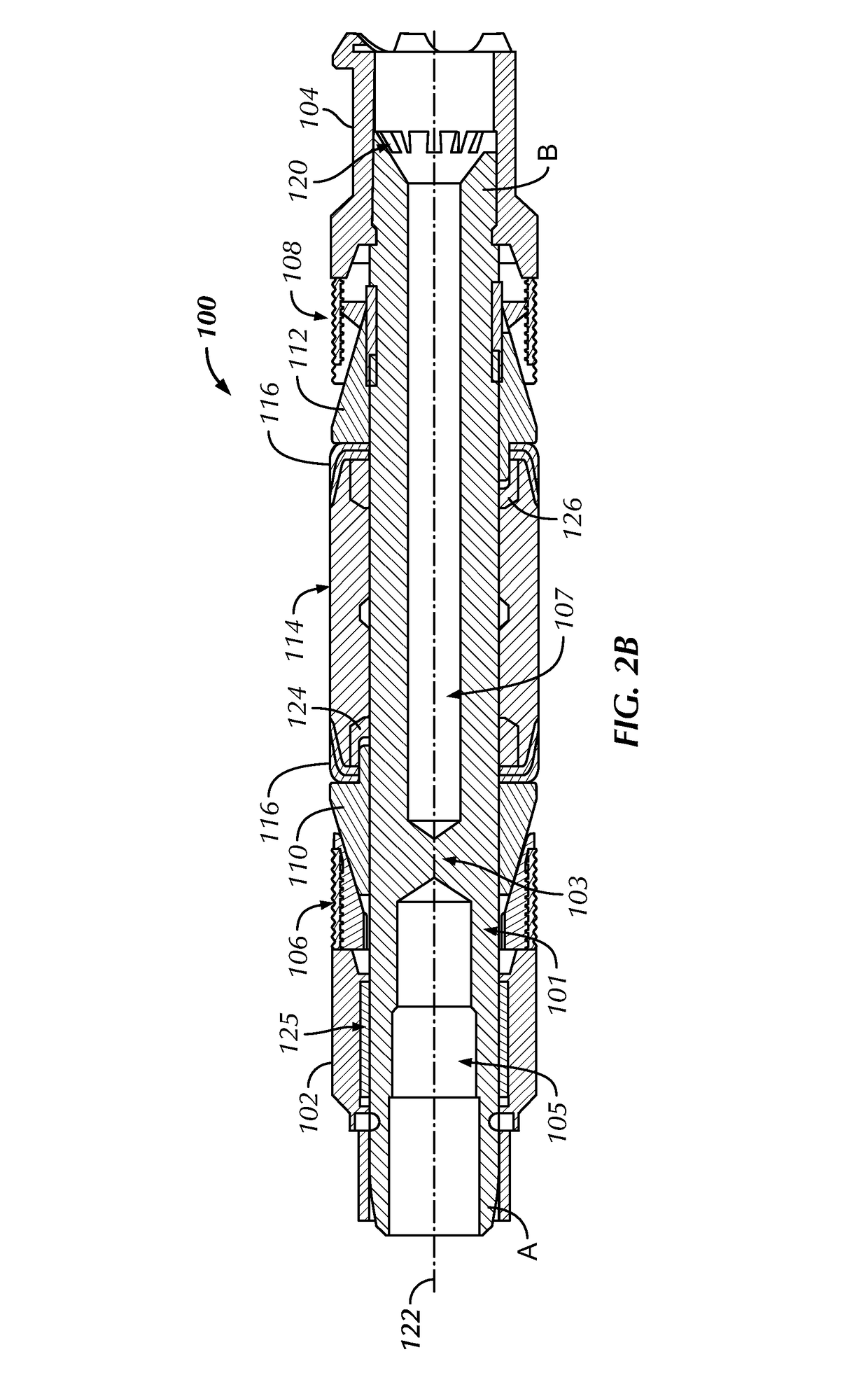

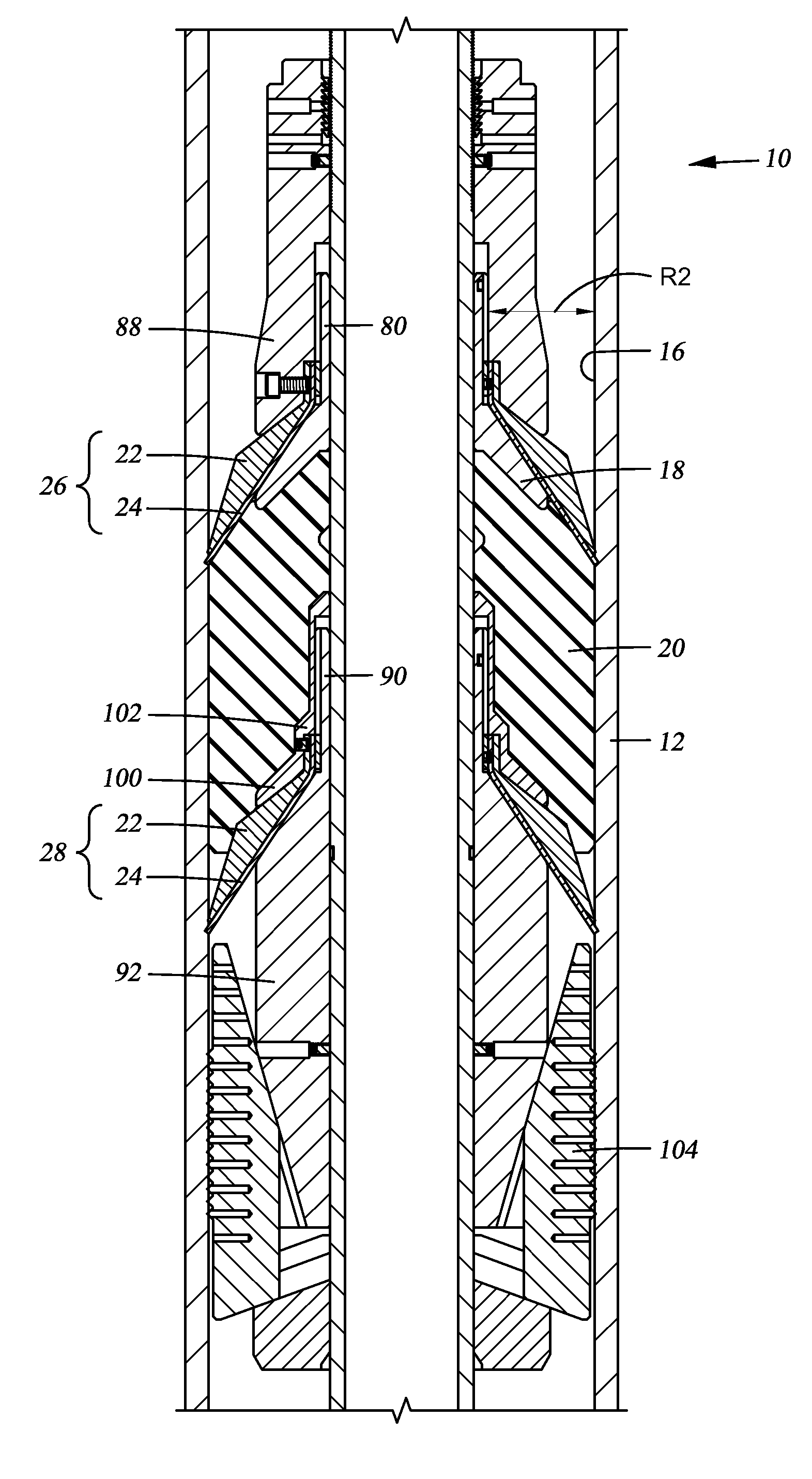

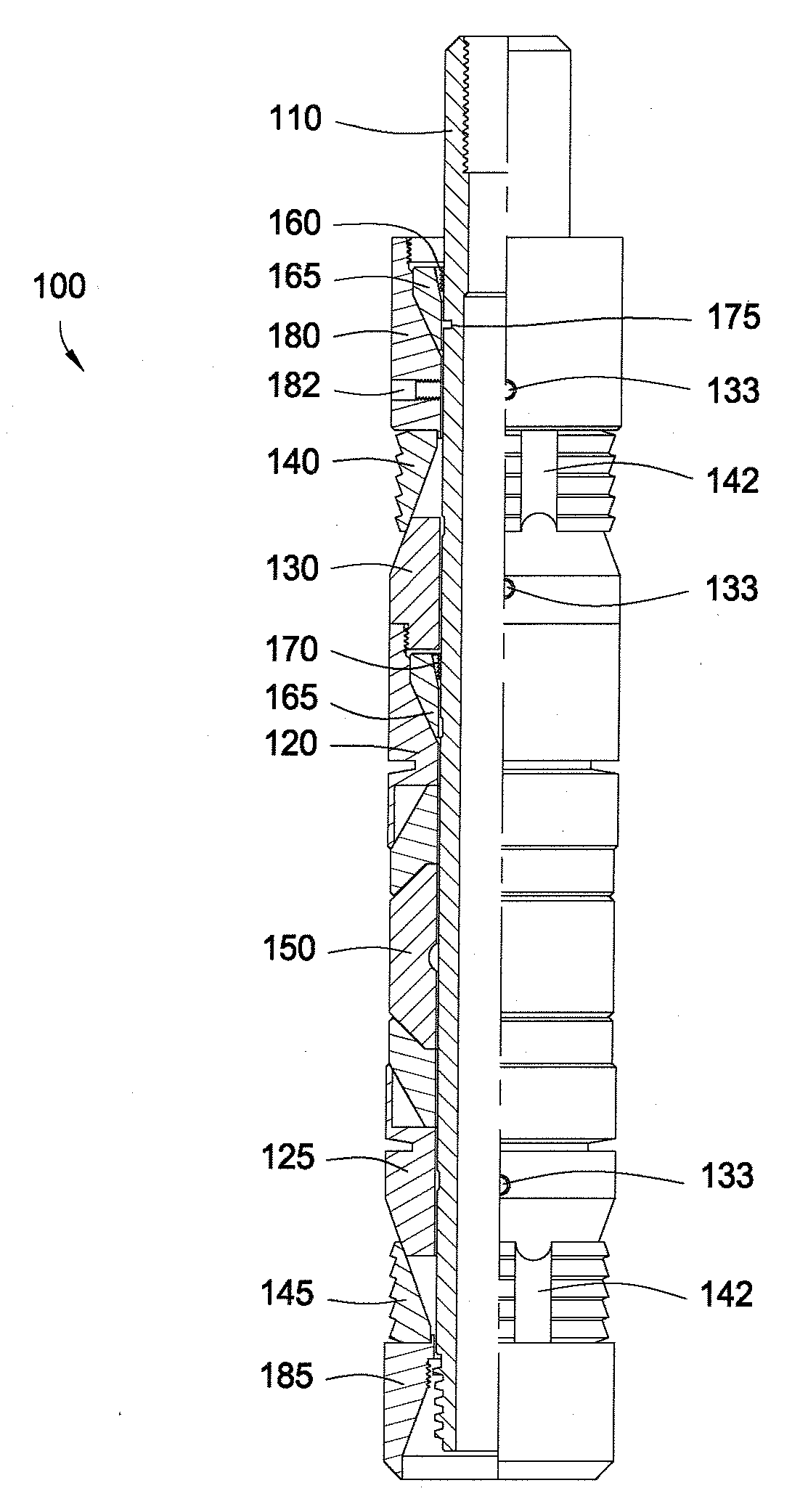

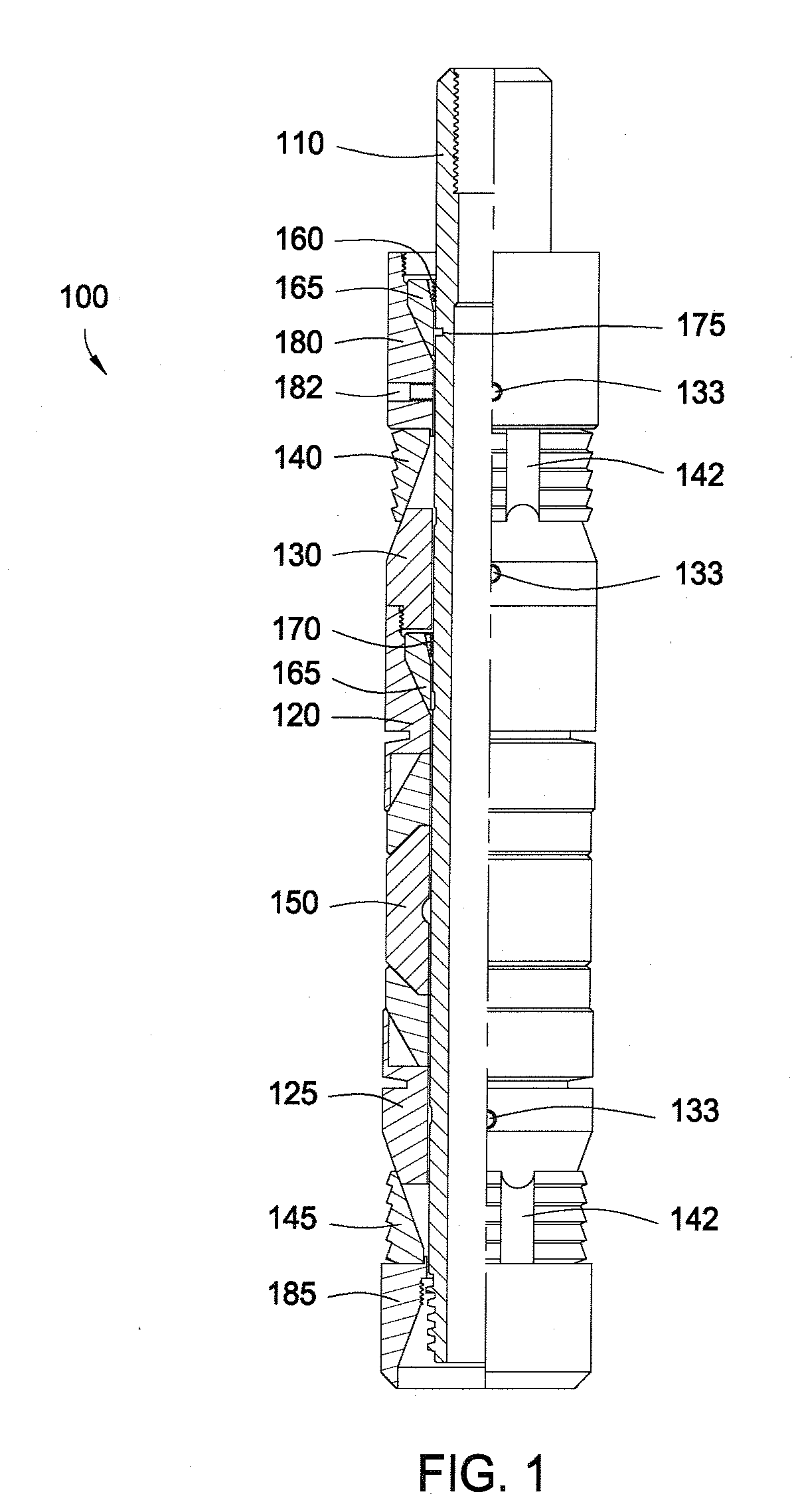

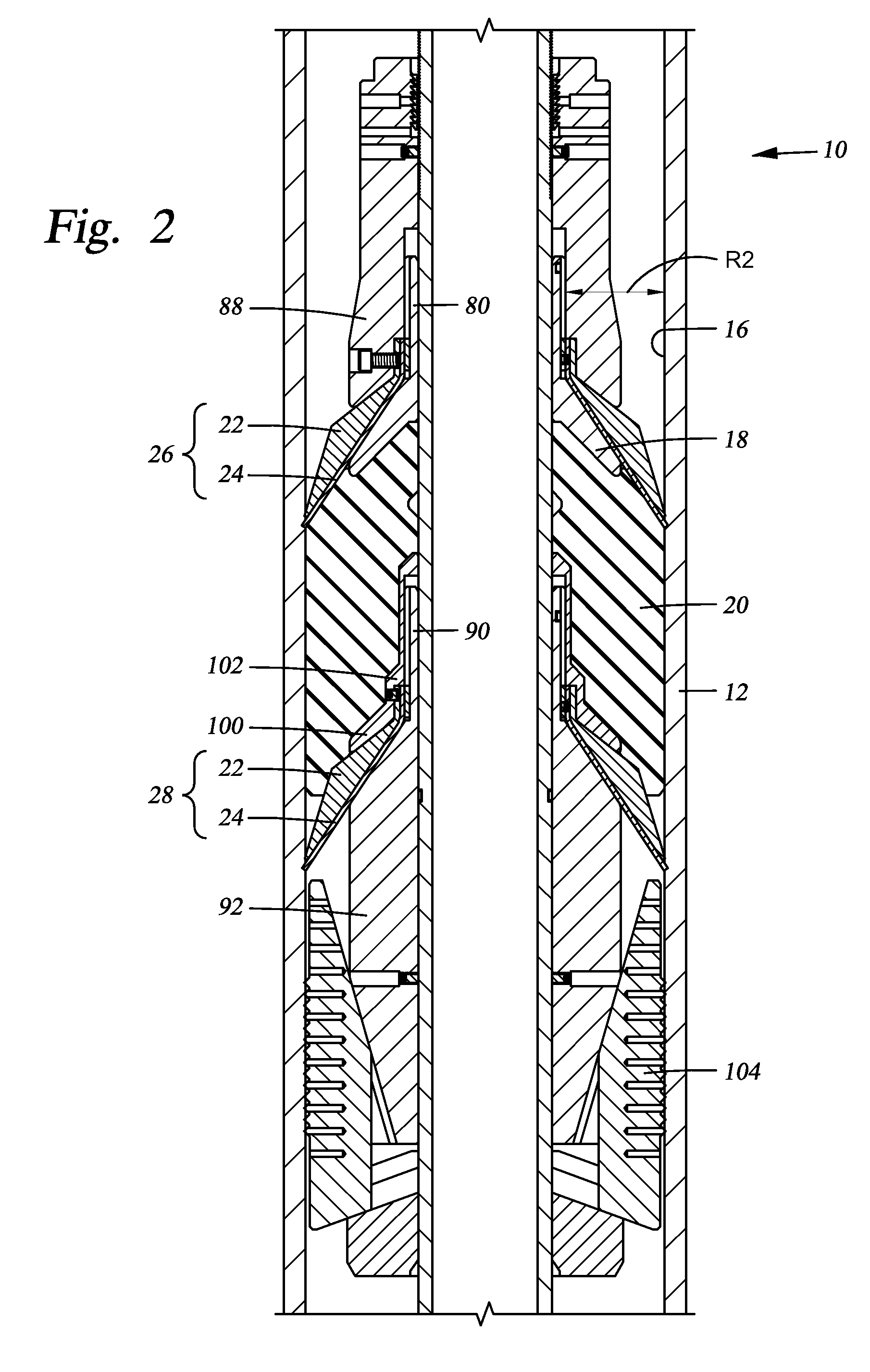

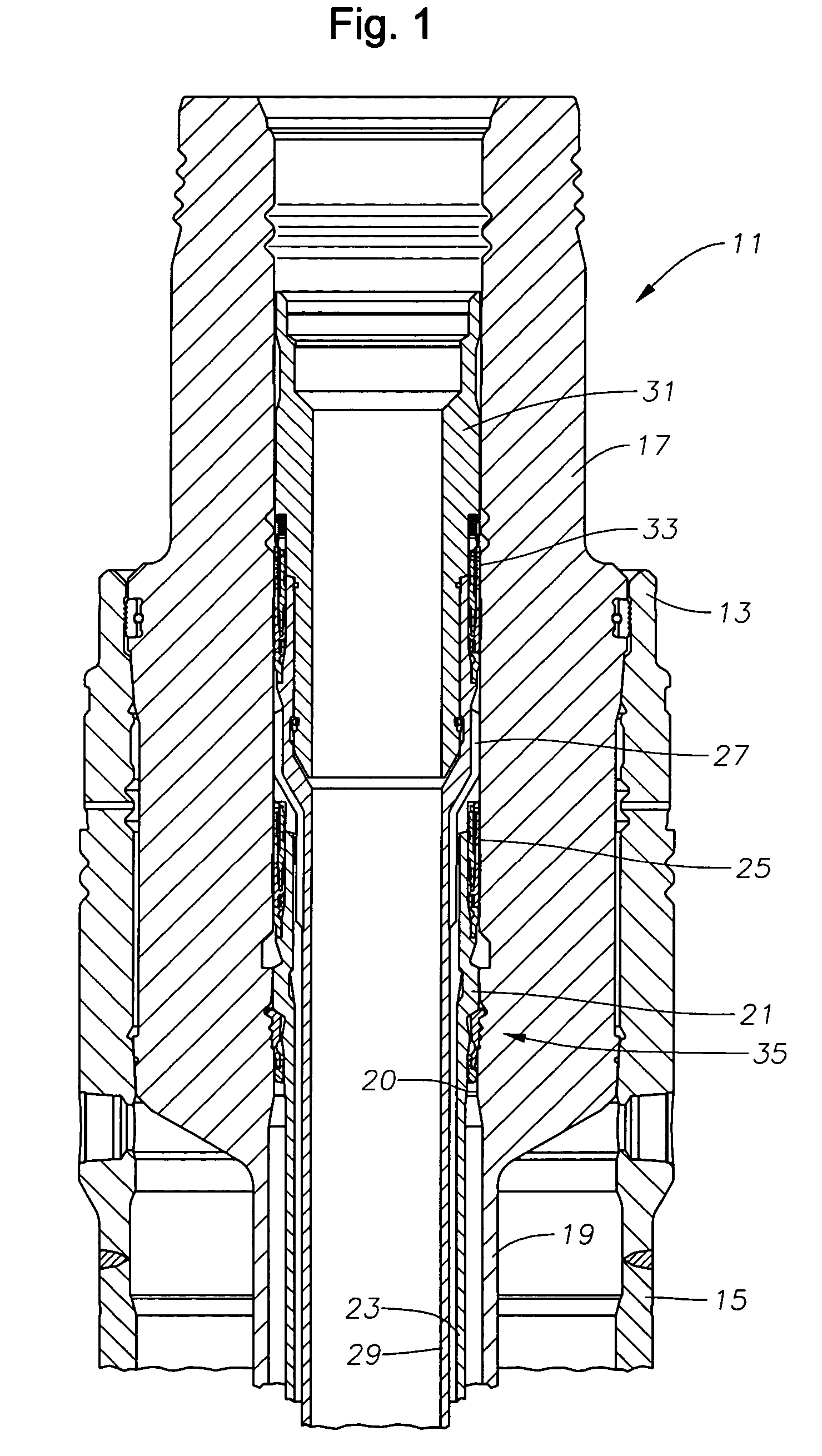

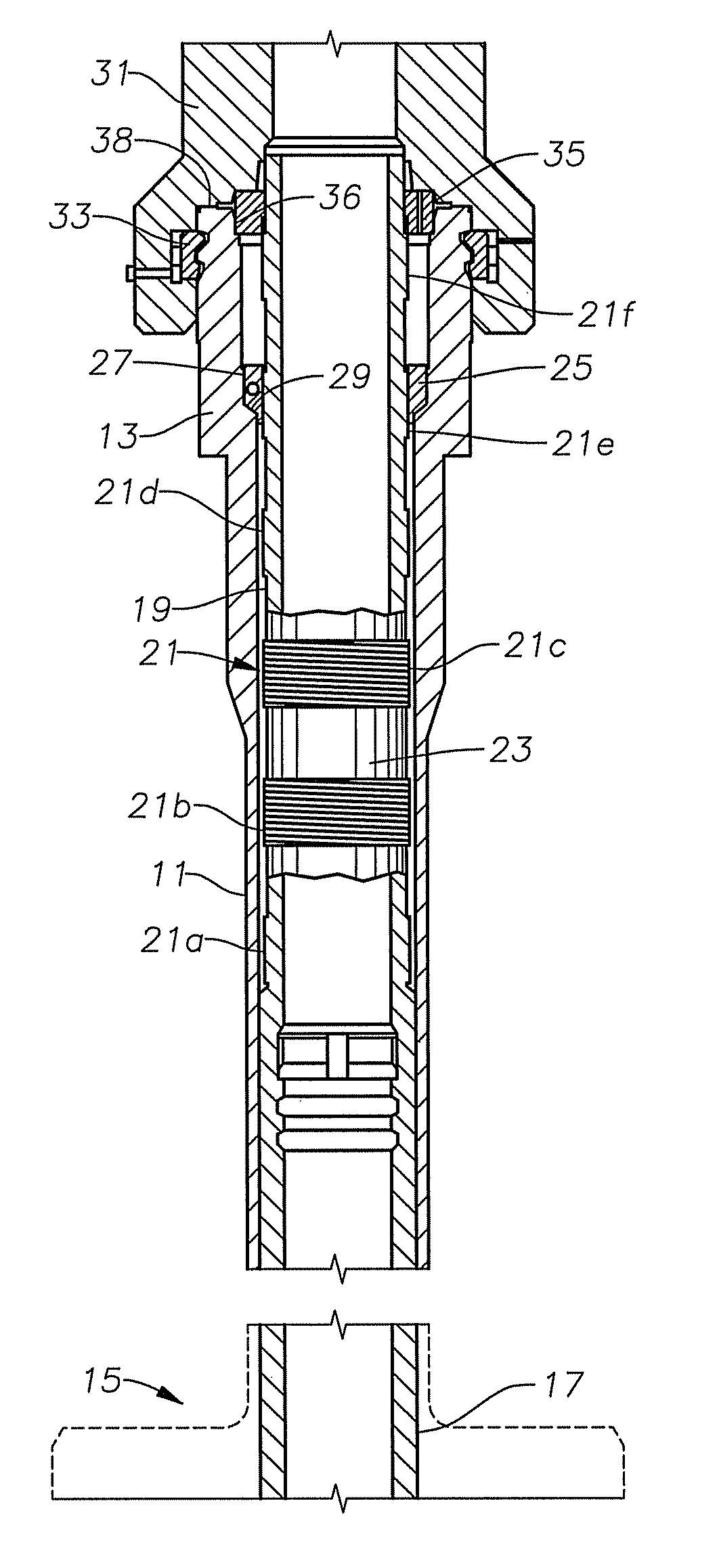

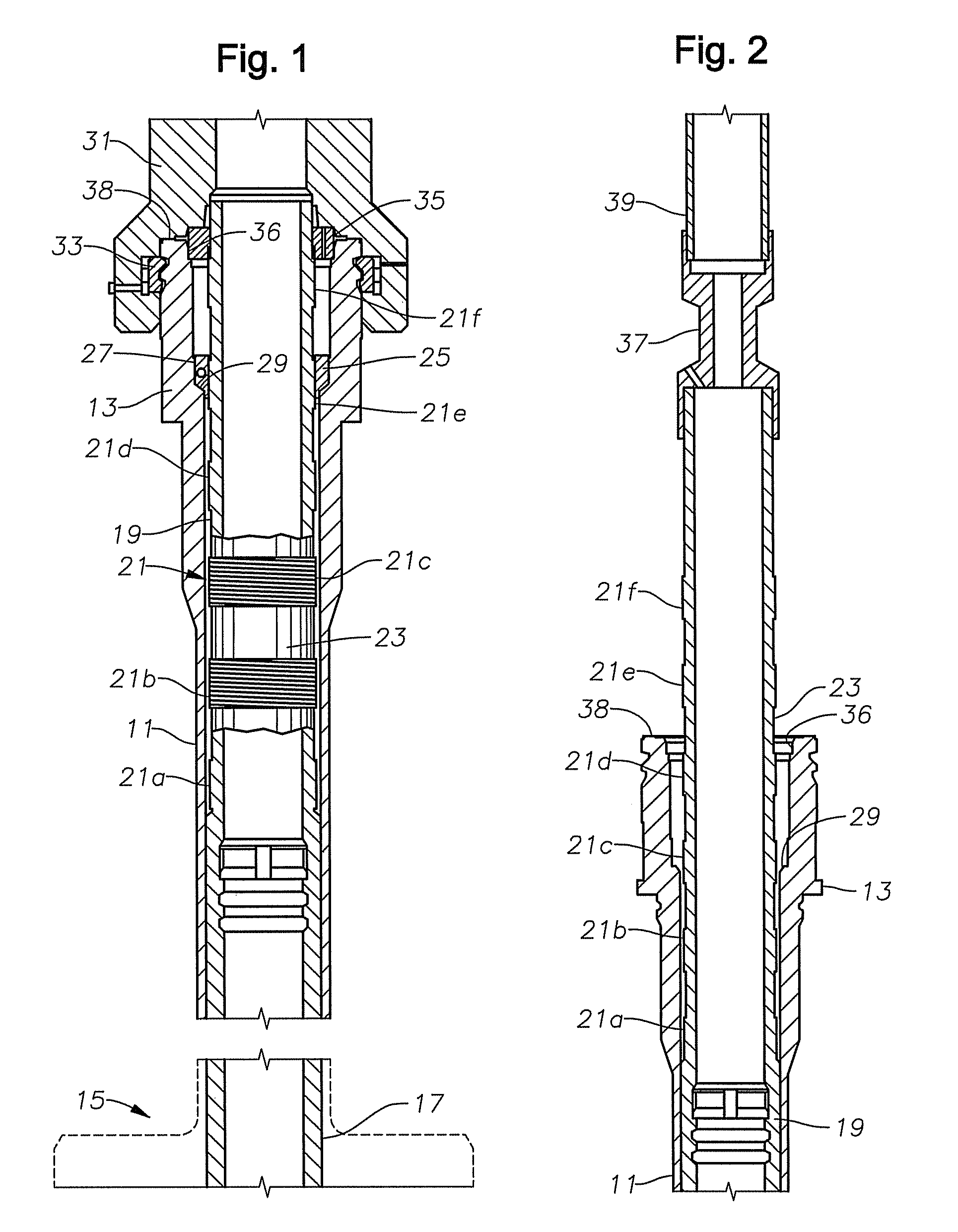

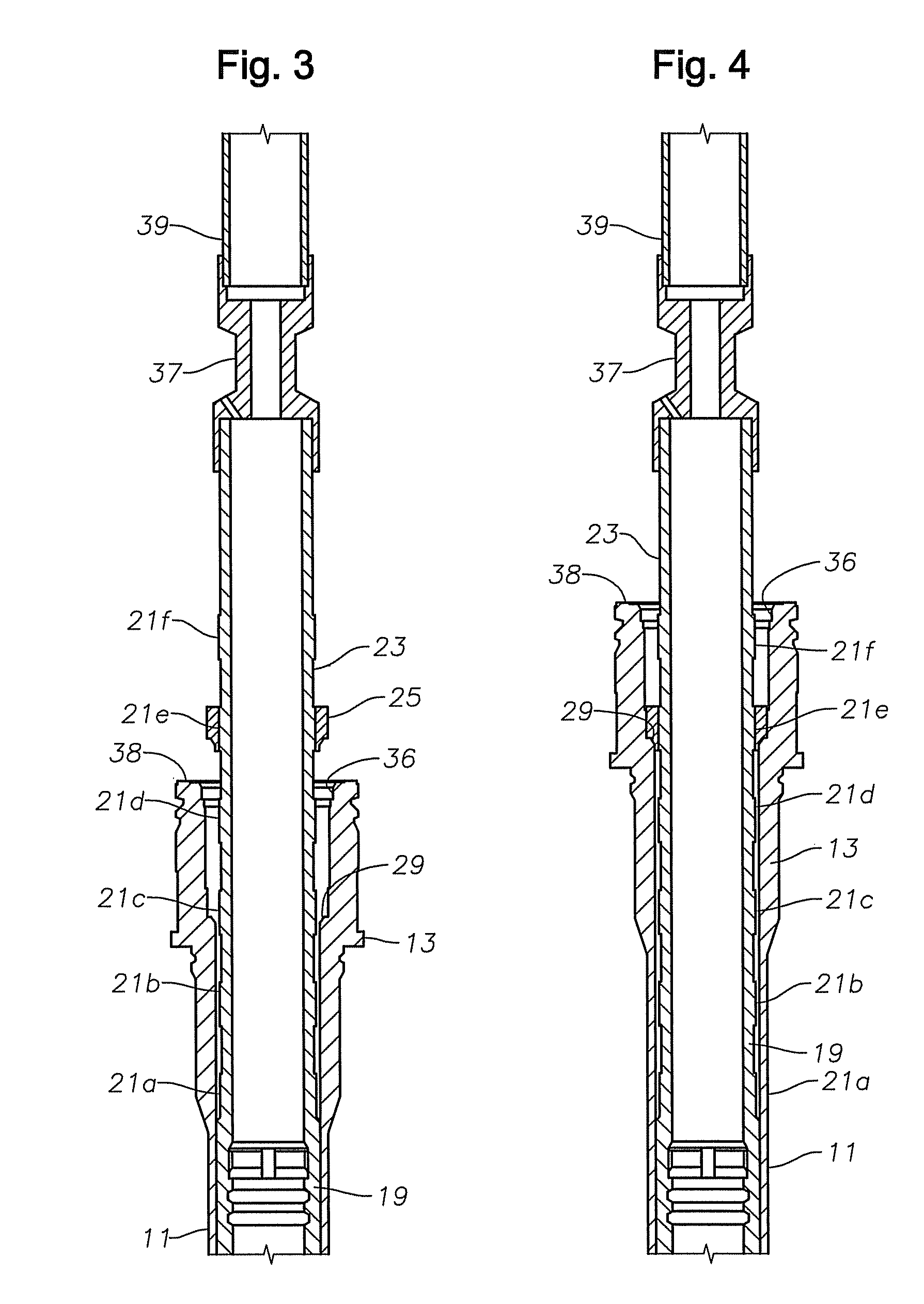

Drillable bridge plug for high pressure and high temperature environments

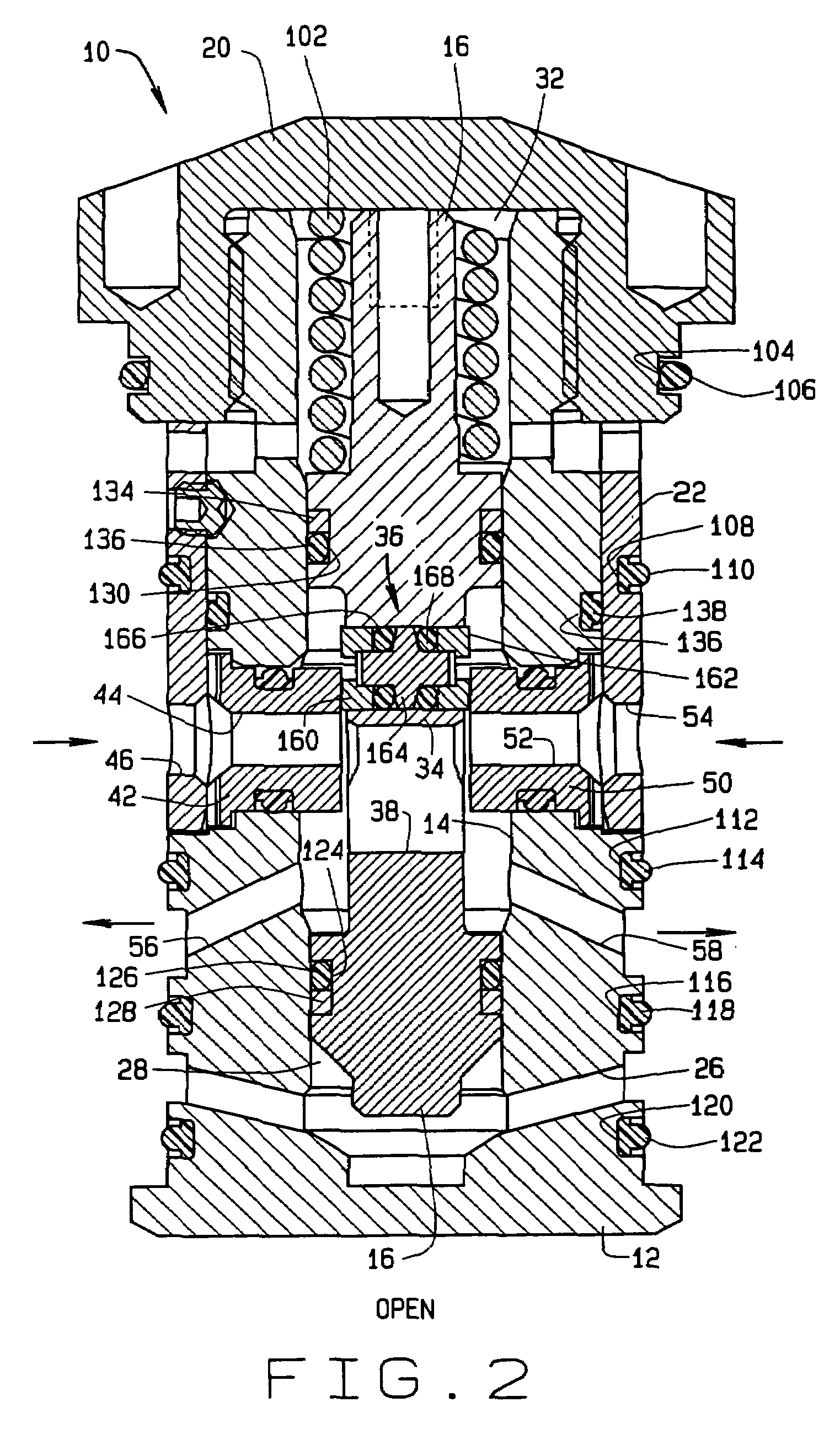

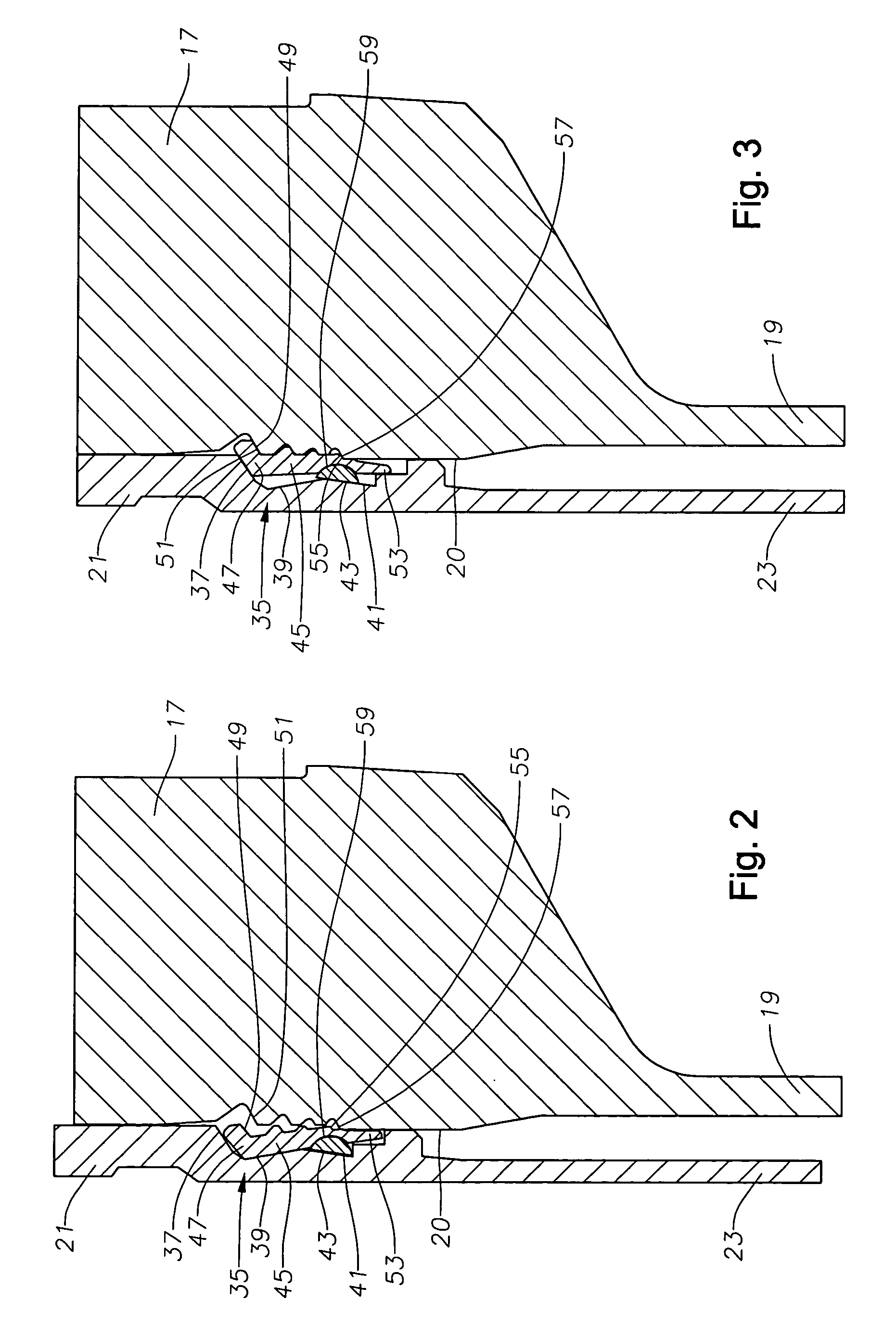

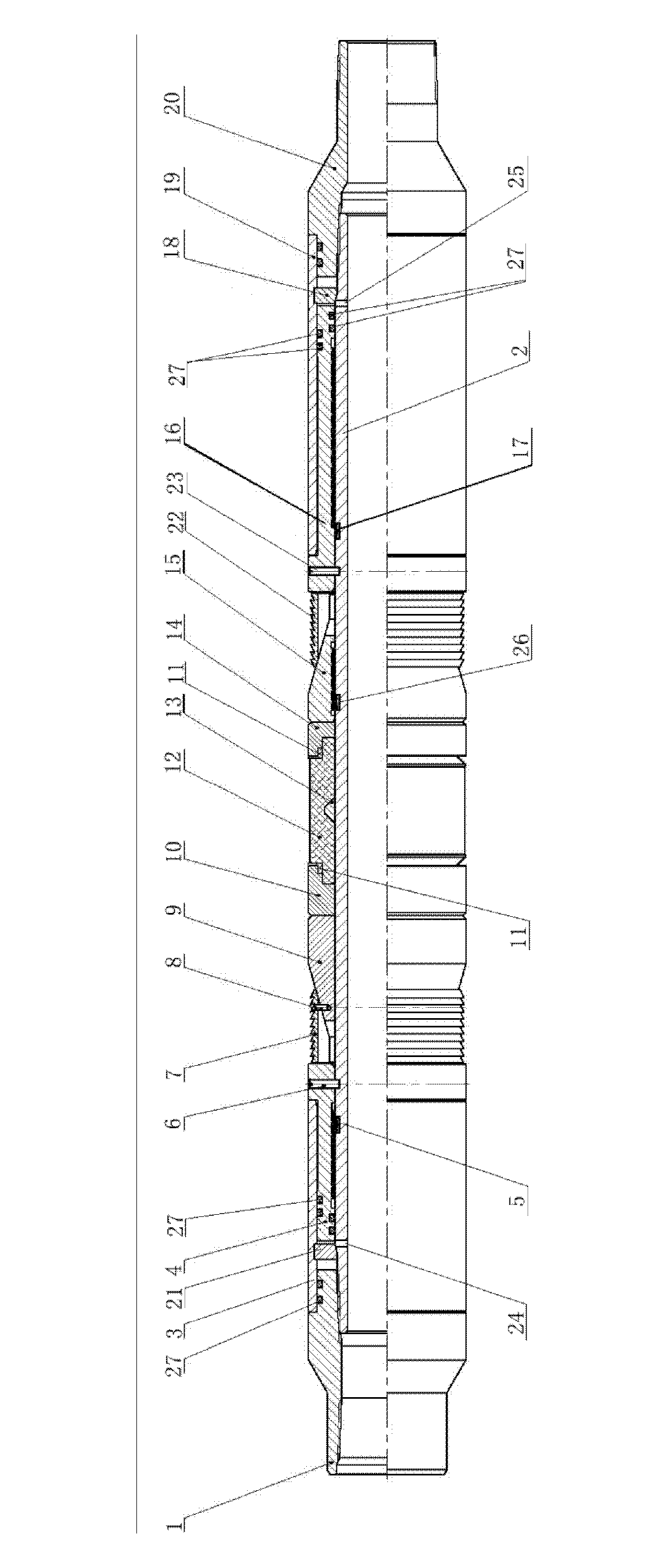

A drillable bridge plug includes a mandrel having external splines disposed on an outer surface of the mandrel, a sealing element disposed around the mandrel, an upper cone disposed around the mandrel proximate an upper end of the sealing element, and a lower cone disposed around the mandrel proximate the lower end of the sealing element, wherein an inner surface of the lower cone comprises internal splines configured to engage the external splines. The drillable bridge plug also includes an upper and a lower slip assembly disposed around the mandrel, and an upper and lower ring assembly each including a first segmented barrier ring, a second segmented barrier ring, and a back-up ring disposed proximate sealing element. A method of setting the drillable bridge plug and a method of removing the drillable bridge plug are disclosed.

Owner:SMITH INT INC

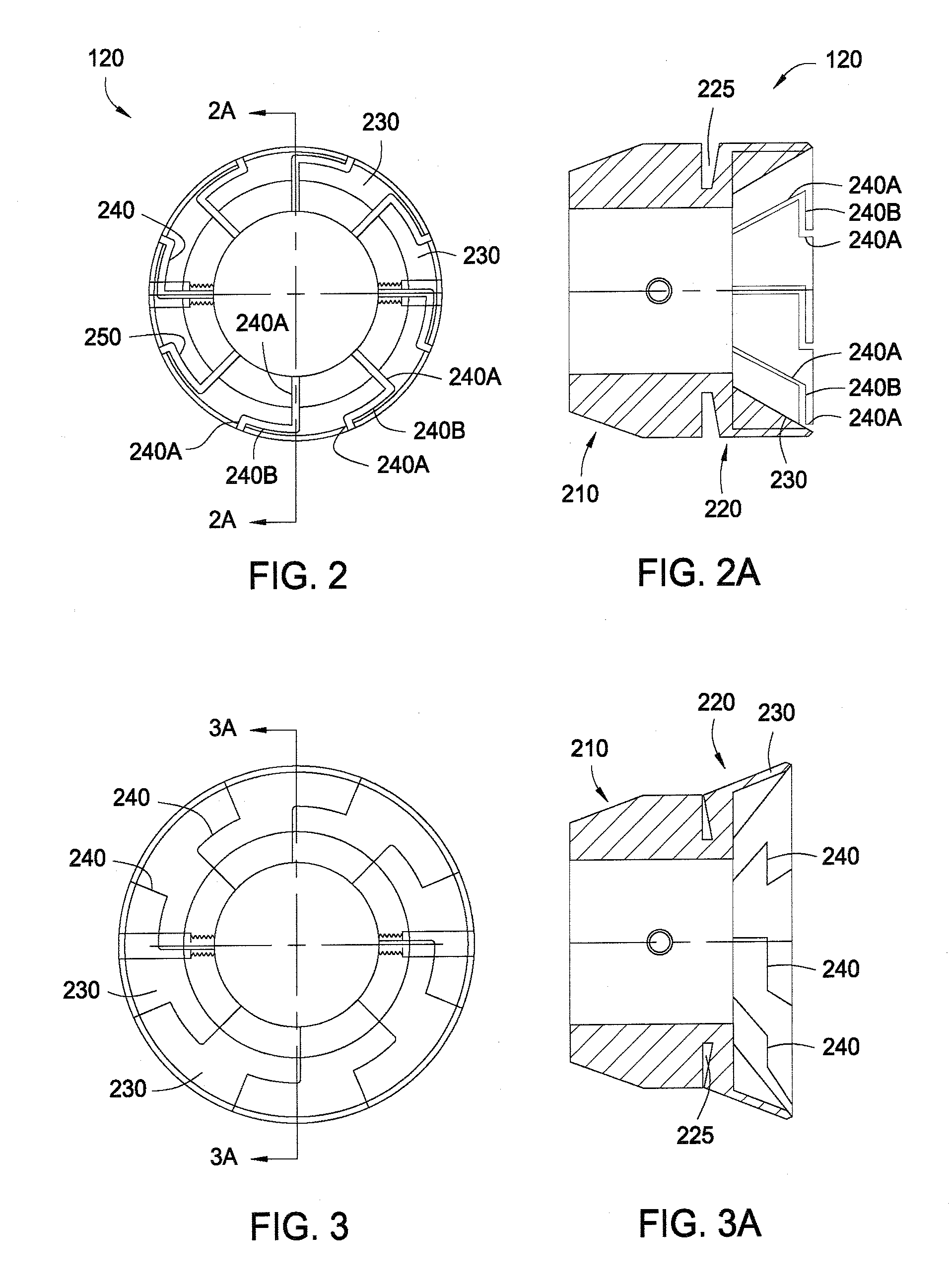

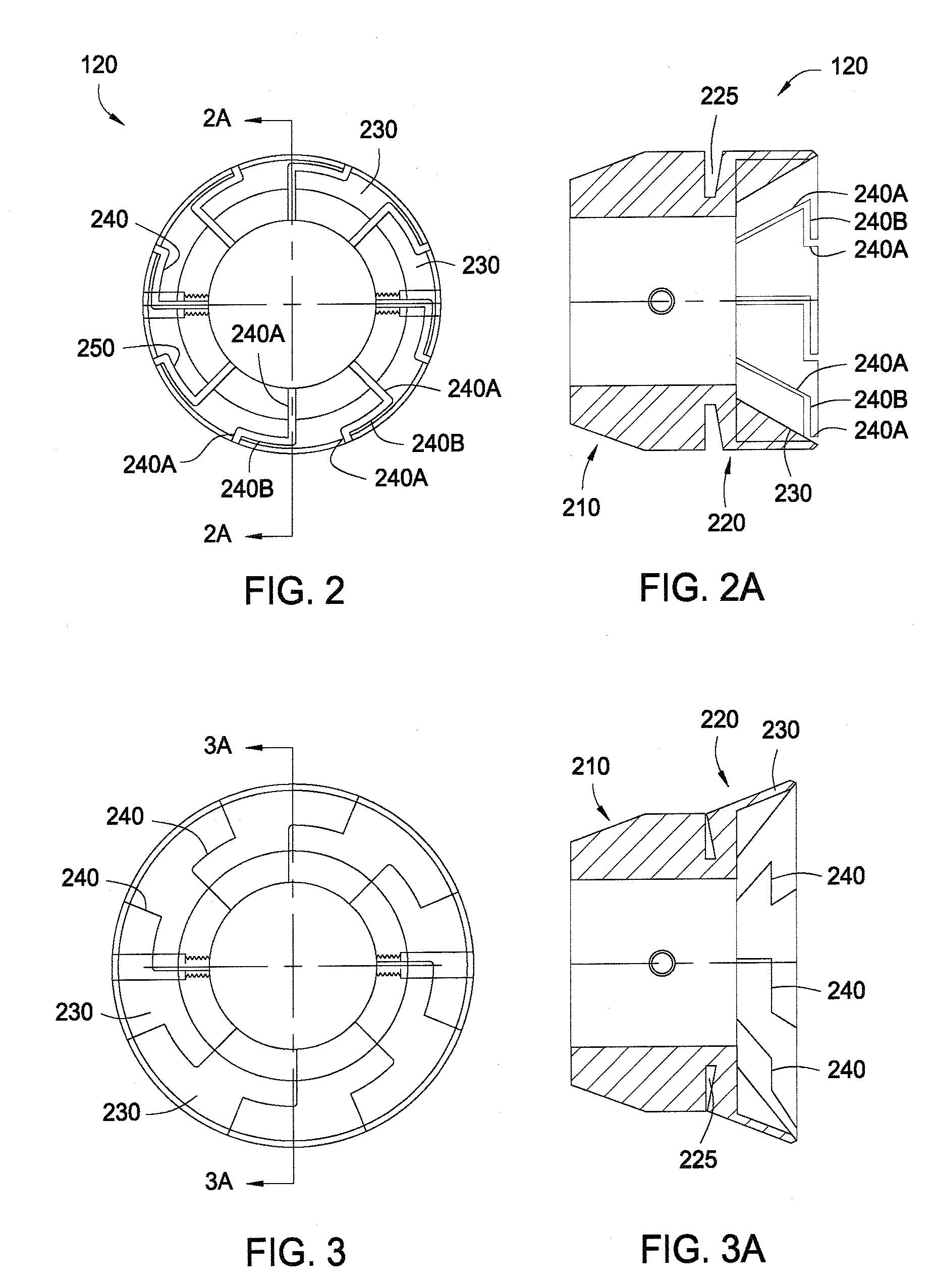

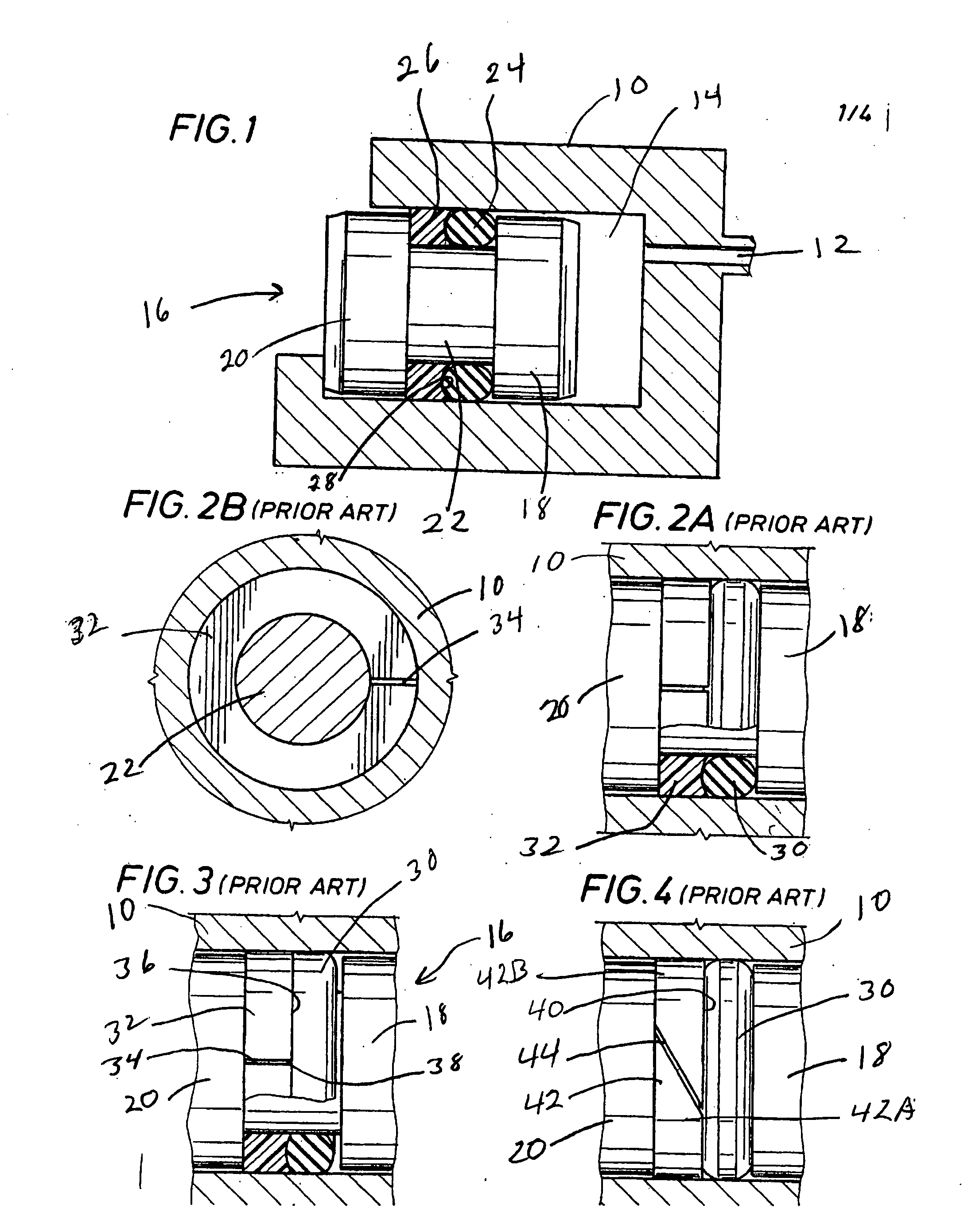

Composite cement retainer

A downhole plug that can include a body and an element system disposed about the body. The plug can further include a first and second back-up ring member having two or more tapered wedges. The tapered wedges can be at least partially separated by two or more converging grooves. First and second cones can be disposed adjacent the first and second back-up ring members.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

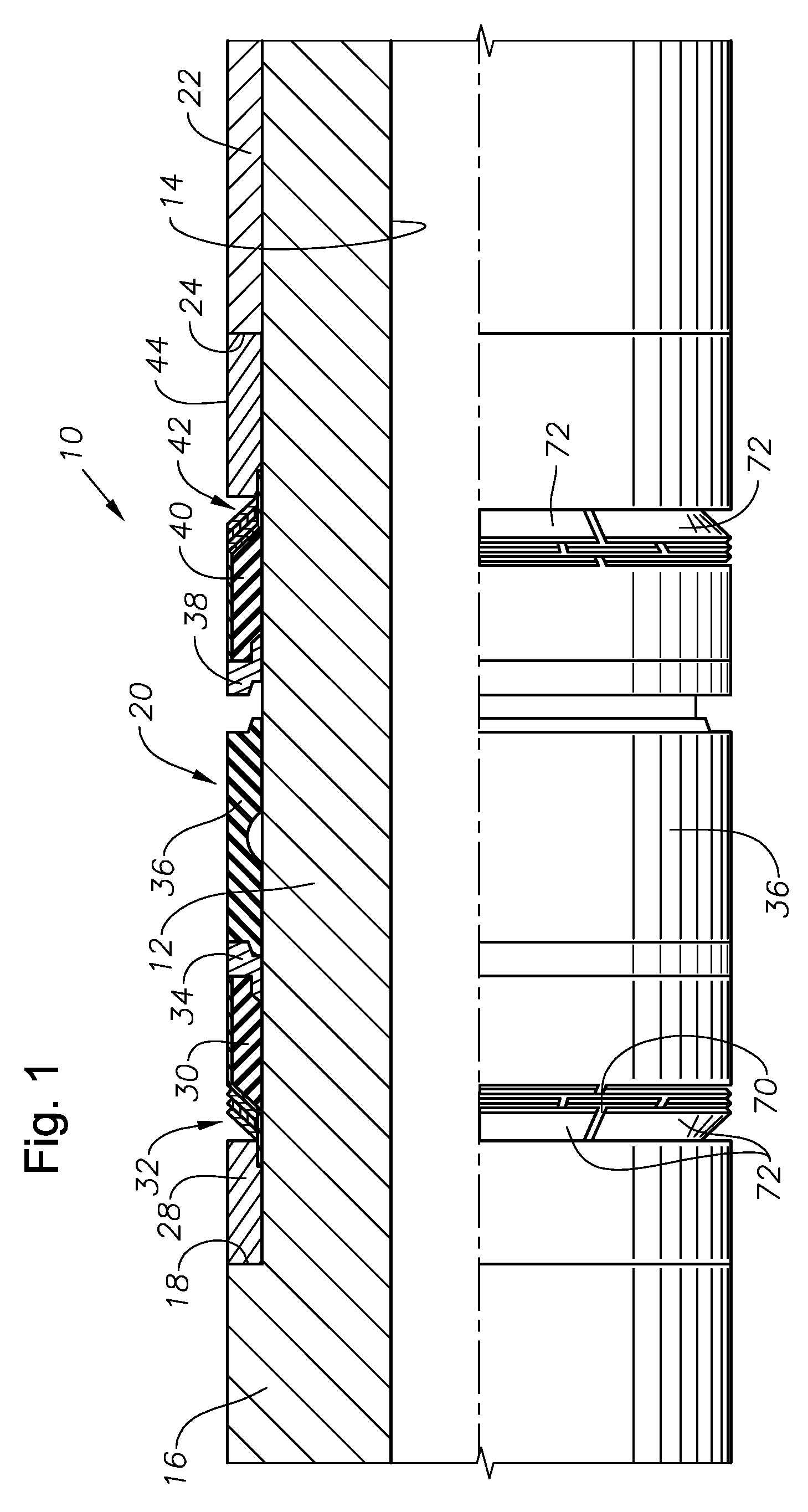

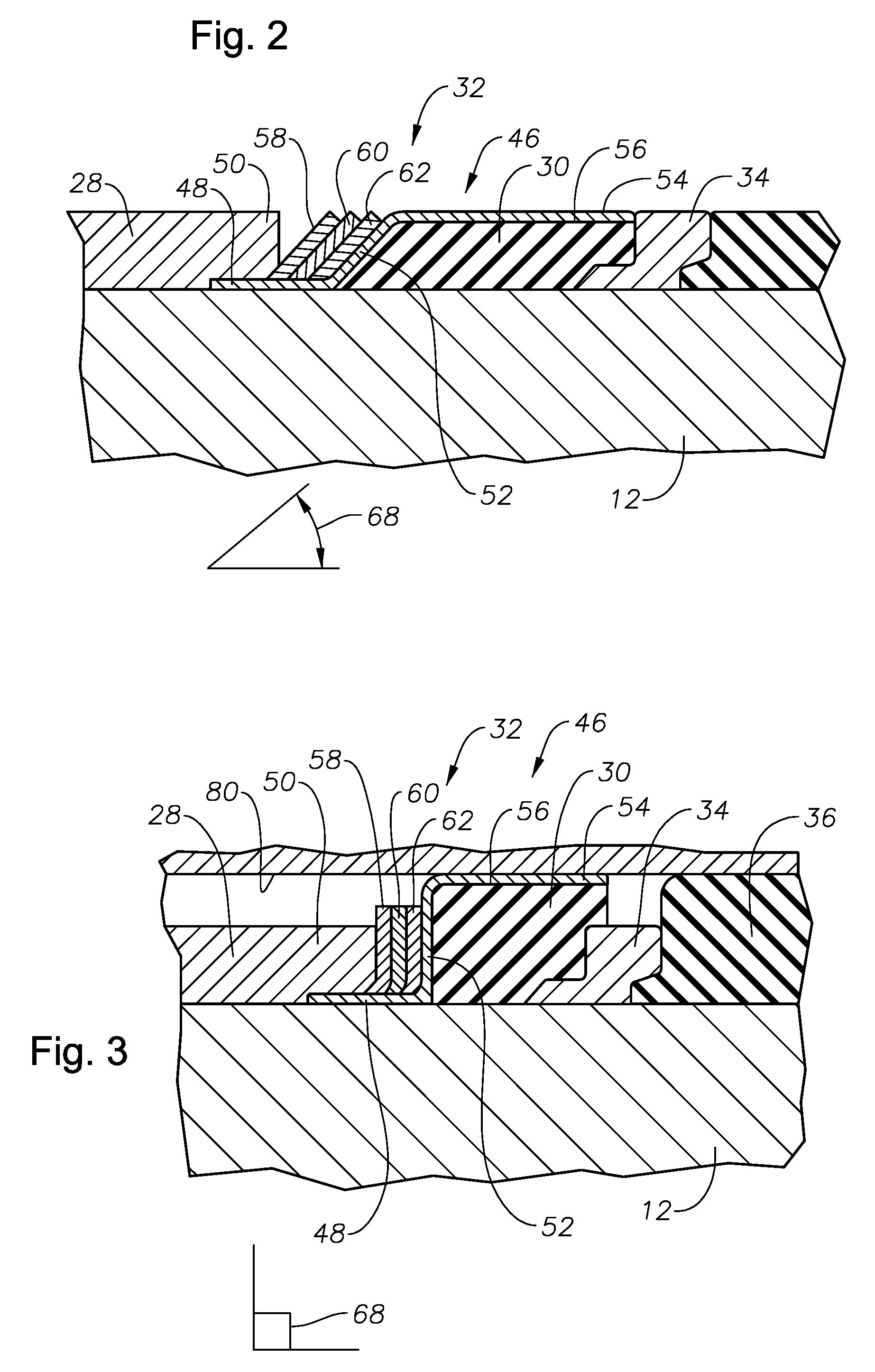

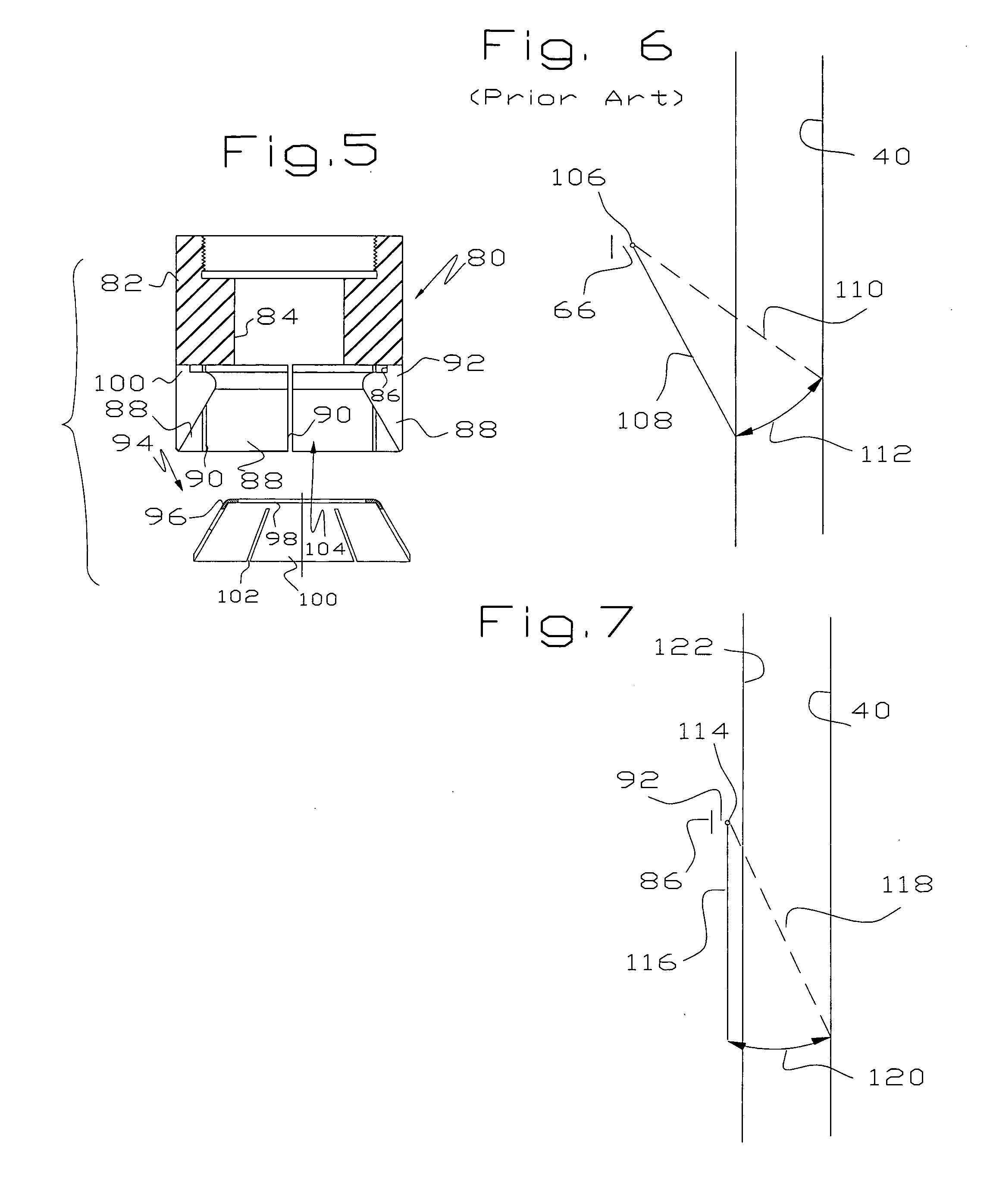

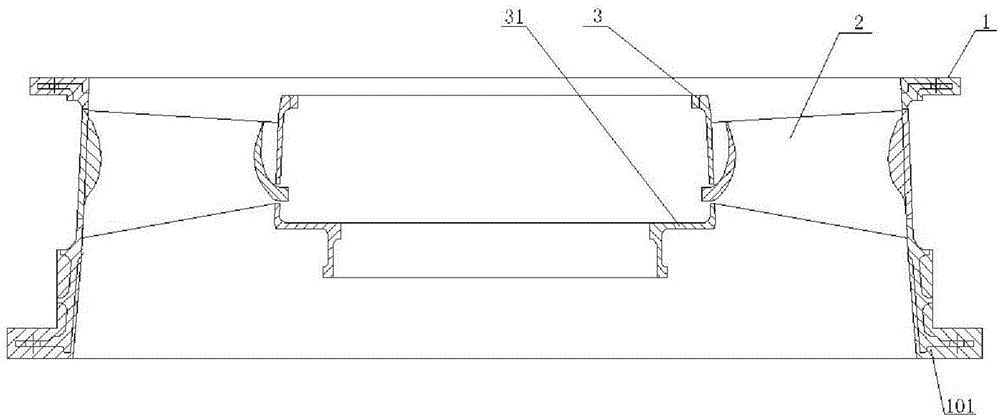

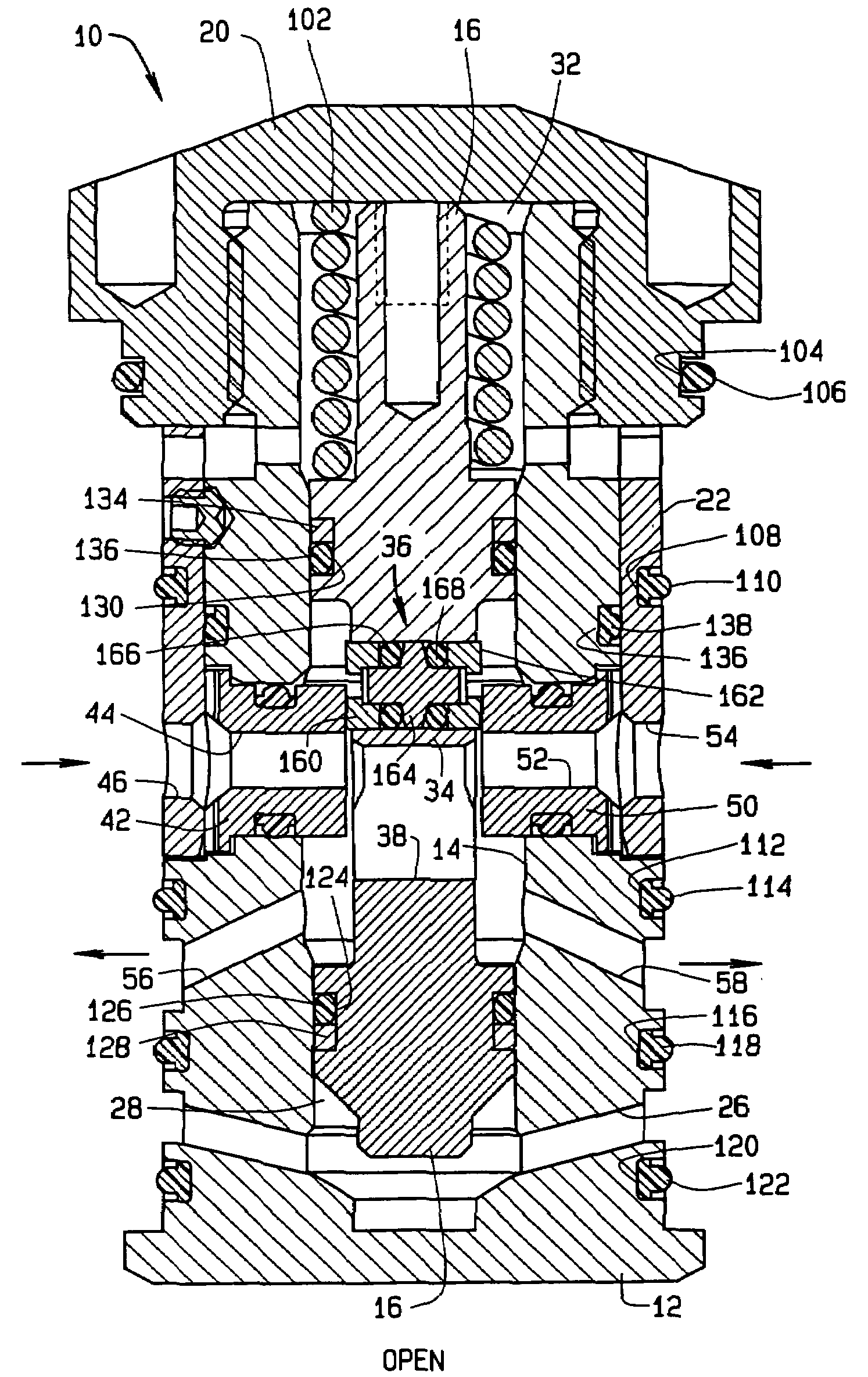

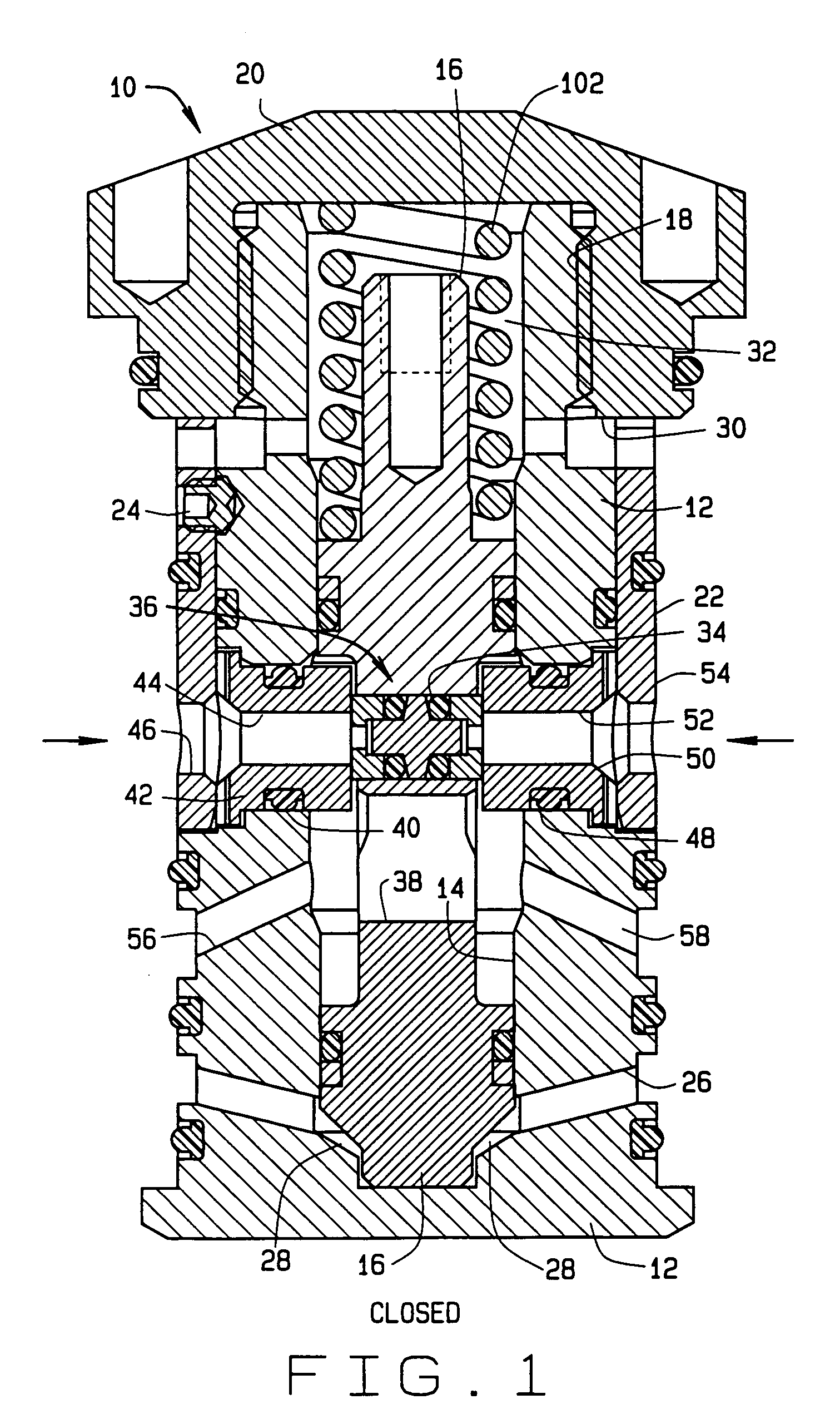

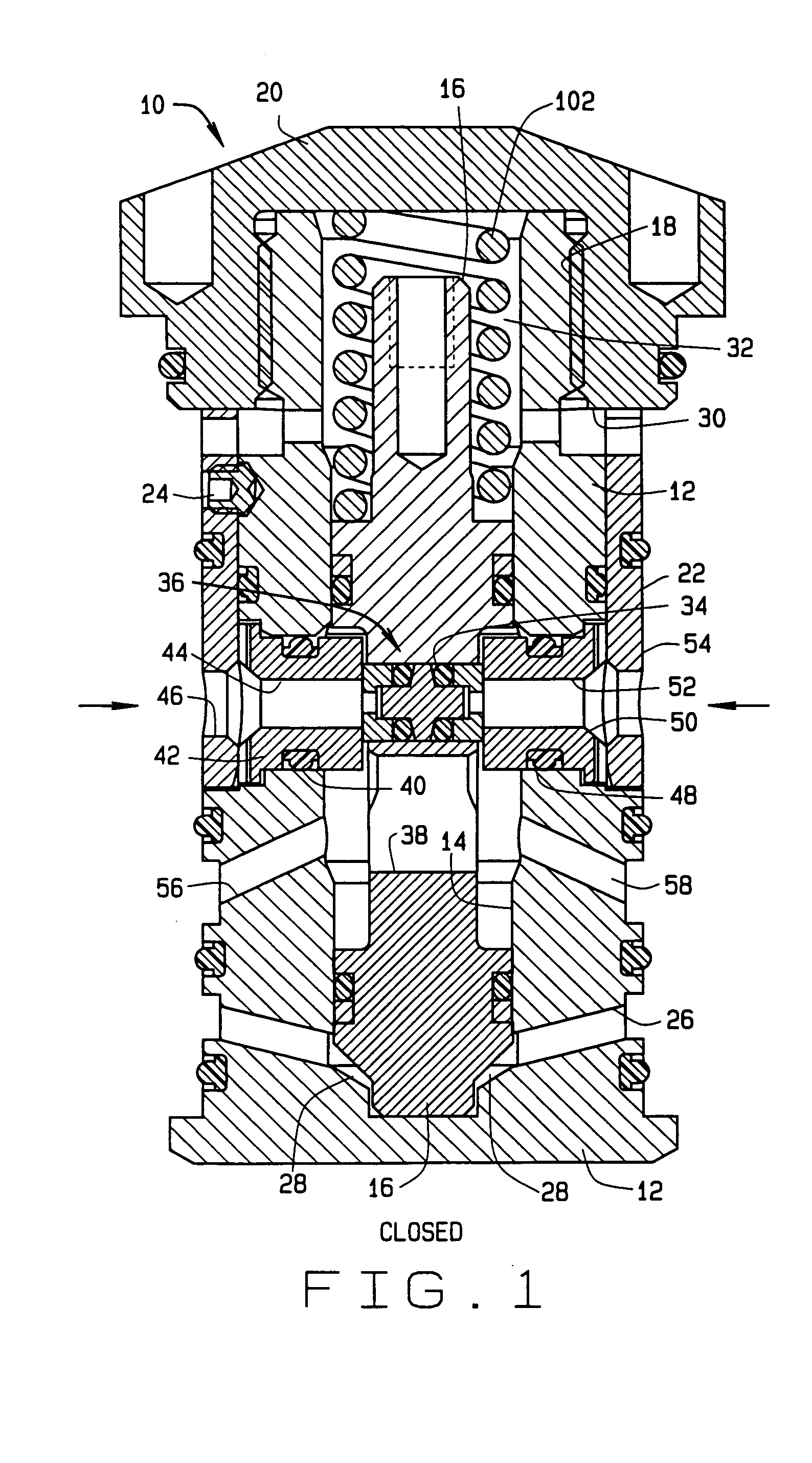

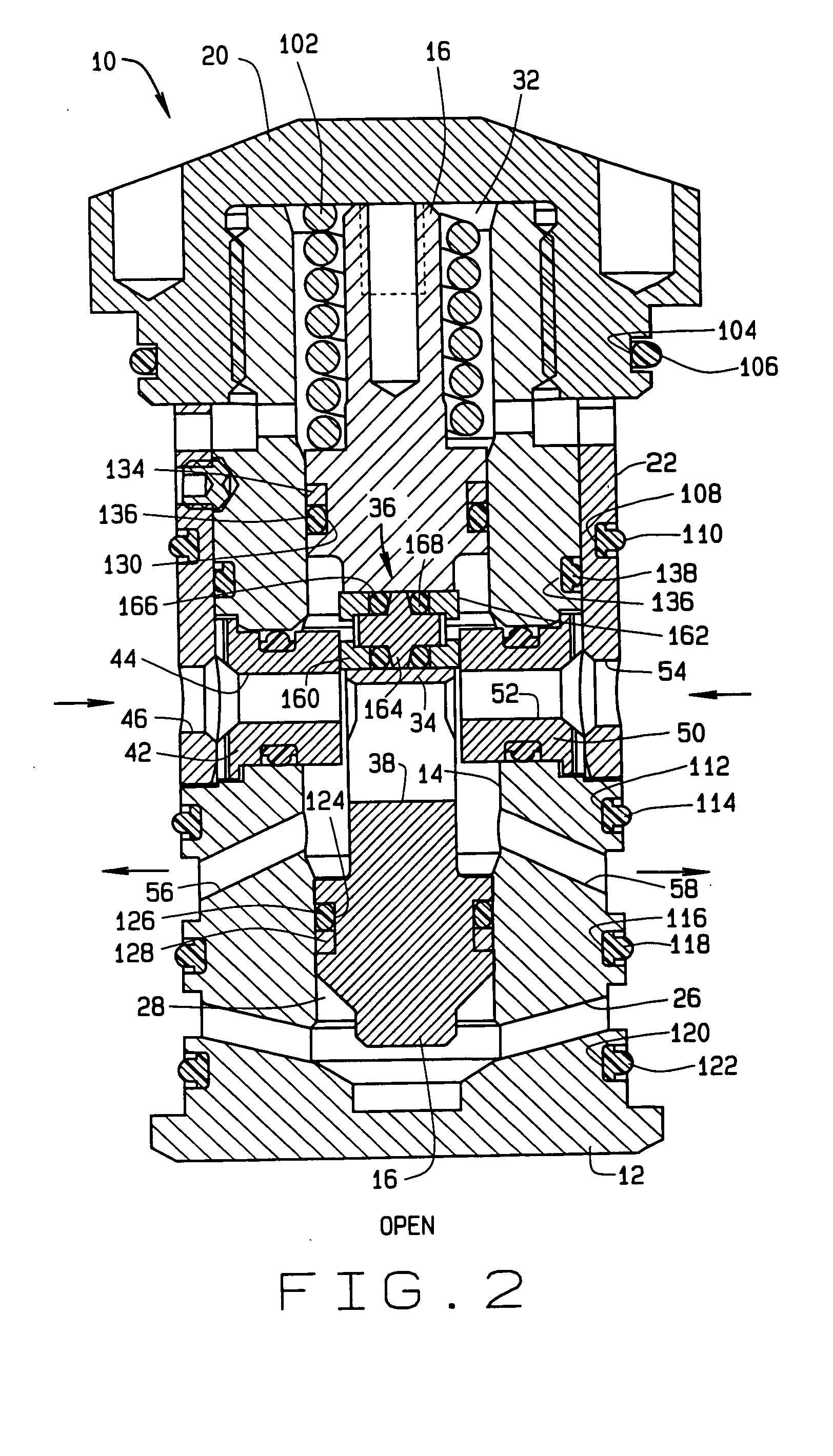

Multi-Piece Packing Element Containment System

InactiveUS20090255690A1Preventing and minimizing extrusionAvoid squeezingFluid removalSealing/packingEngineeringMechanical engineering

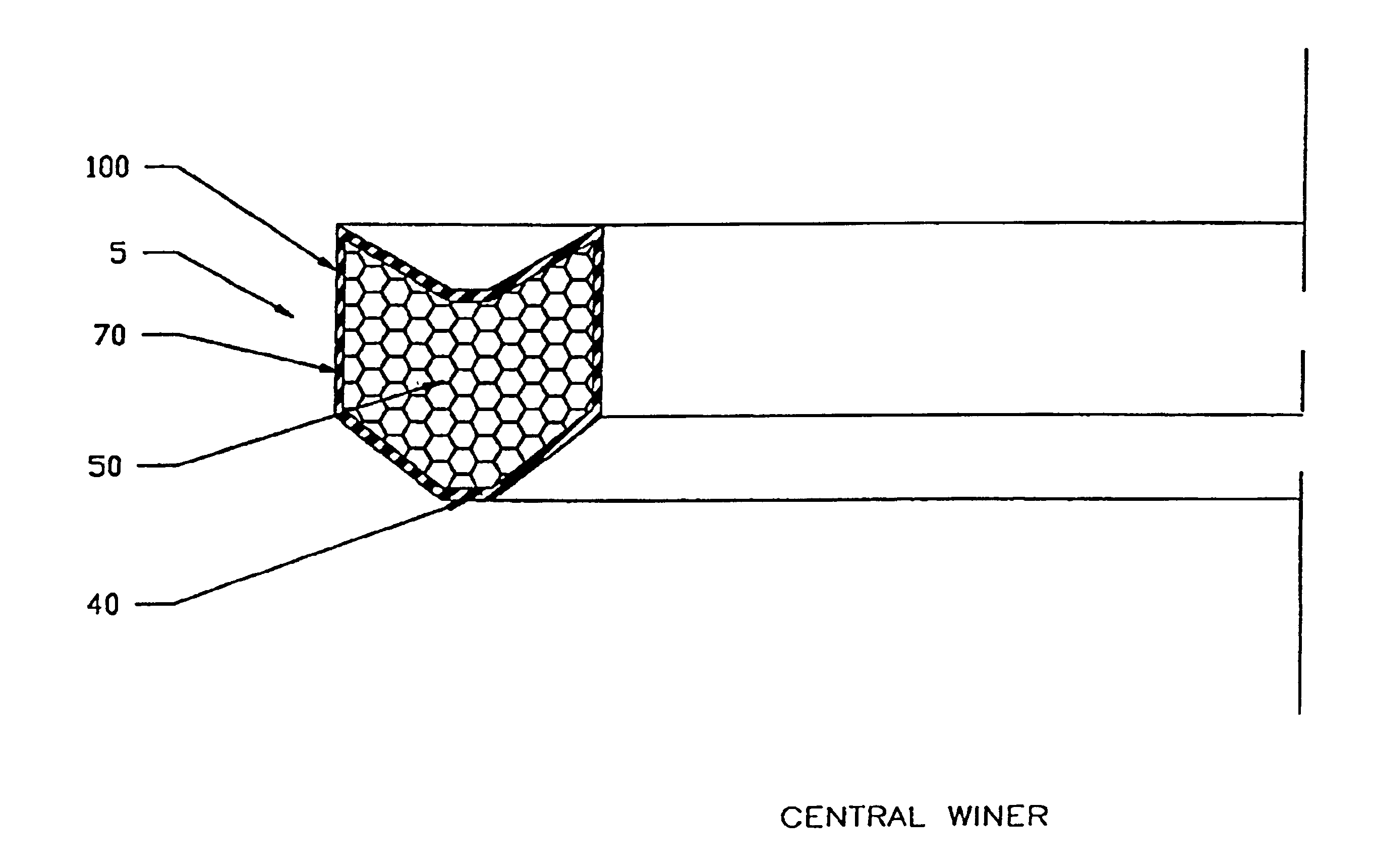

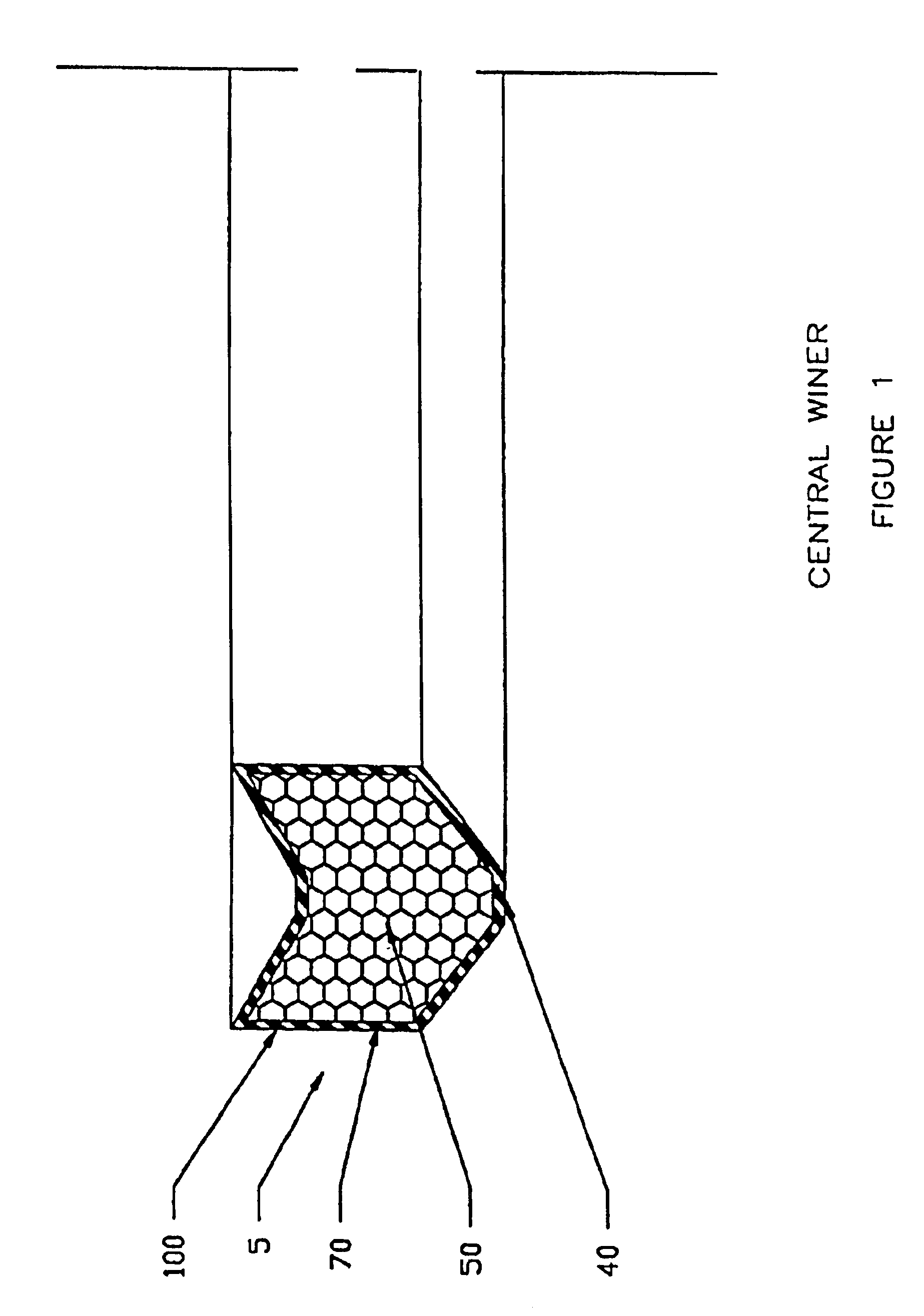

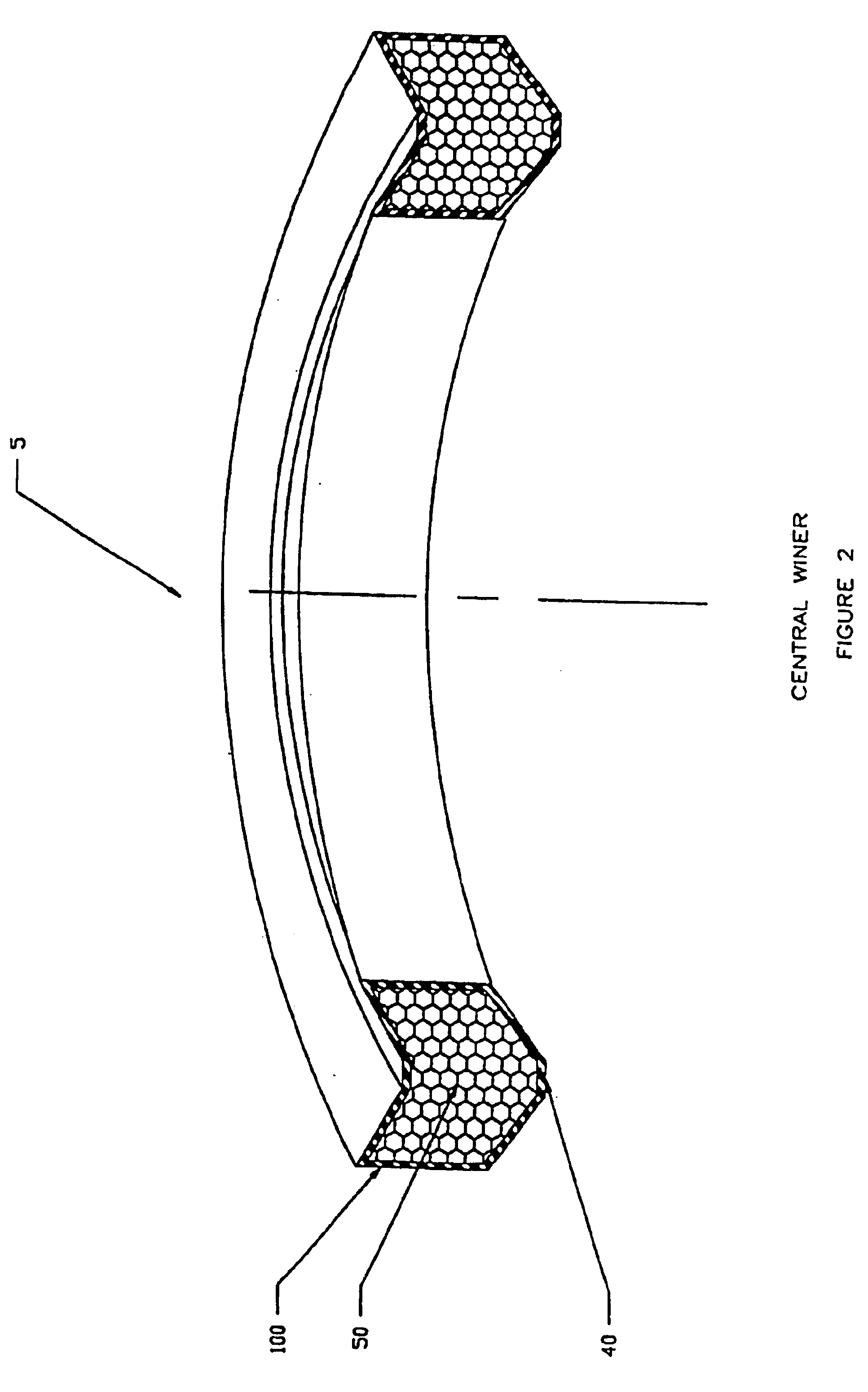

Methods and devices for retaining a packer element in a set condition within a wellbore and for preventing or minimizing extrusion of the packer element after setting. A packer device includes a plurality of deformable packer elements which radially surround a packer mandrel. One or more of the packer elements is contained against axial extrusion using a packer containment system. The packer containment system includes a flexible metal backup ring, which partially encases the packer element by substantially covering at least one axial side and a portion of the exterior radial surface of the packer element. The packer containment system also includes a plurality of annular support rings, or “petal rings” which have petal-shaped radial protuberances with slots between them.

Owner:BAKER HUGHES INC

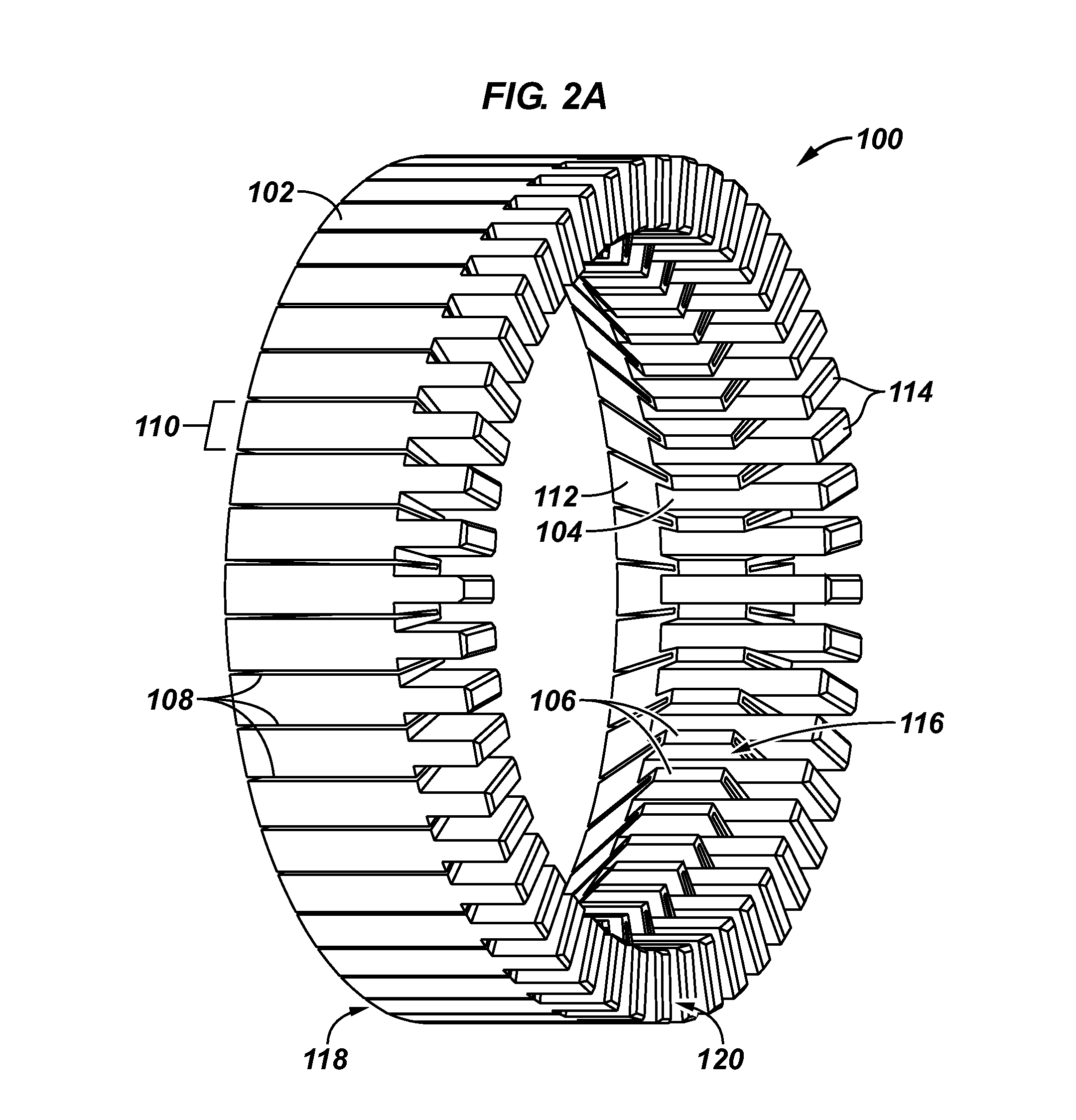

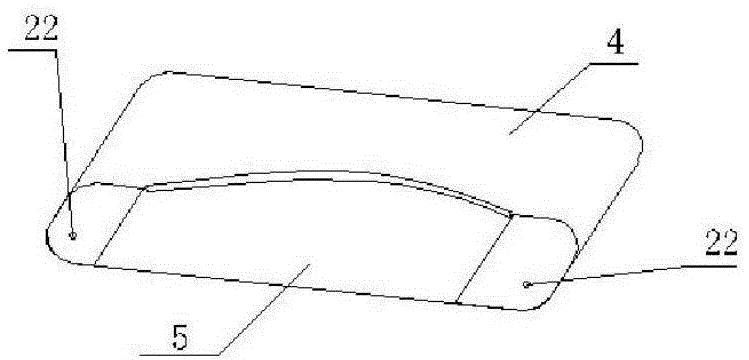

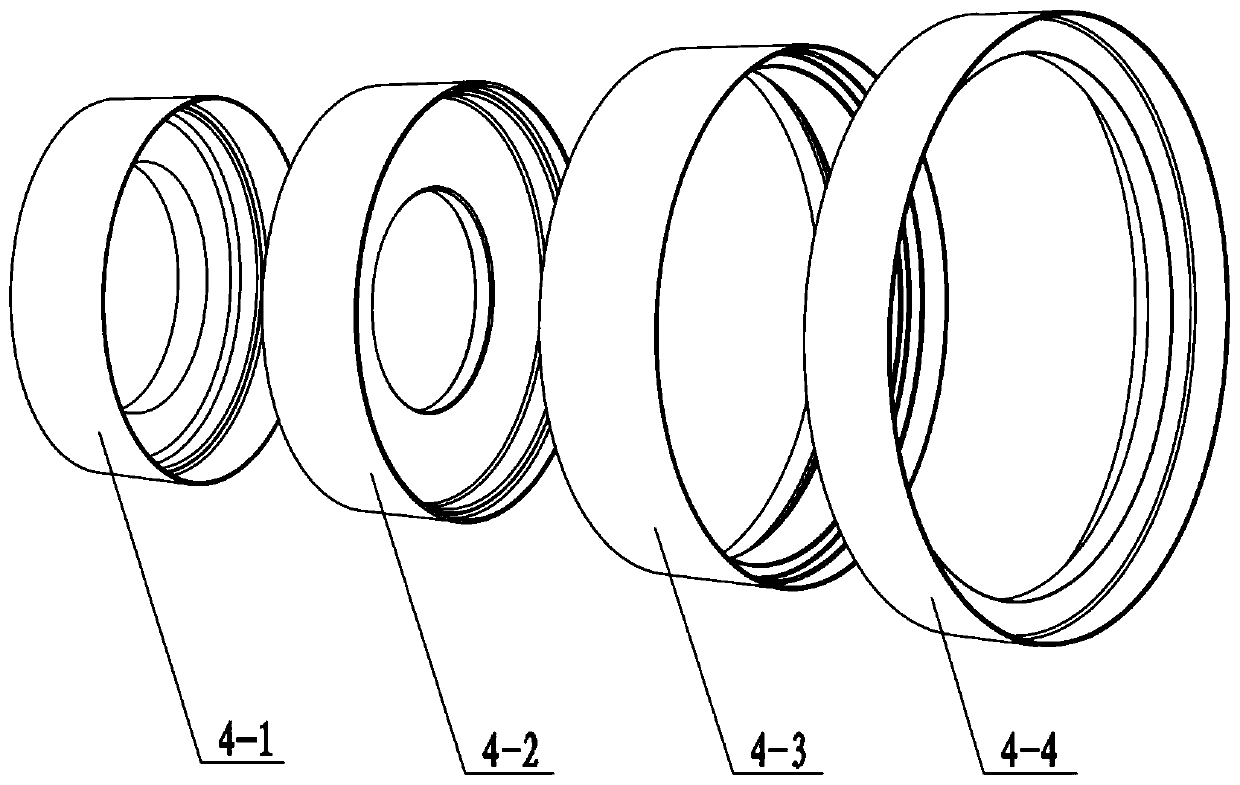

Metal expandable element back-up ring for high pressure/high temperature packer

An expandable backup ring includes an outer surface, an inner surface having a plurality of protrusions projecting radially inwardly, and a plurality of segments, the segments defined by a plurality of outer surface cuts. The plurality of outer surface cuts extends radially inwardly from the outer surface and partially into each of the plurality of protrusions.

Owner:SCHLUMBERGER TECH CORP

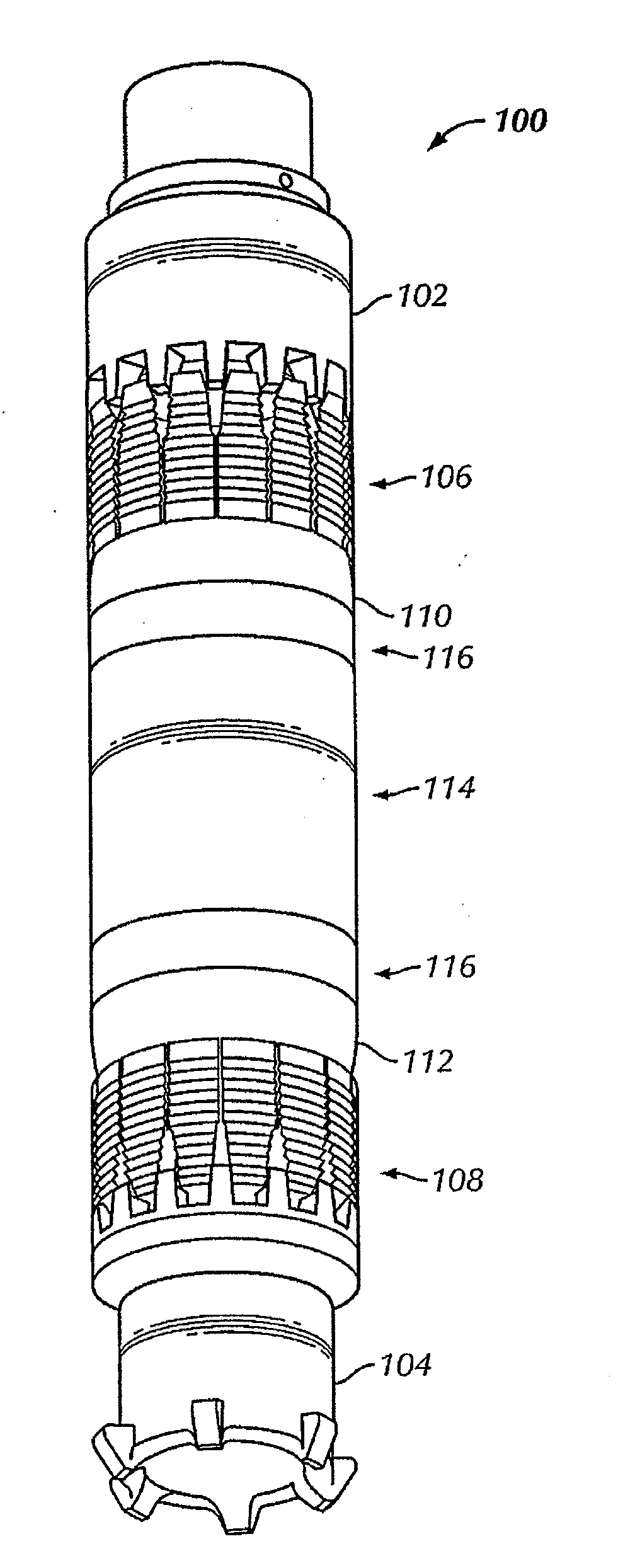

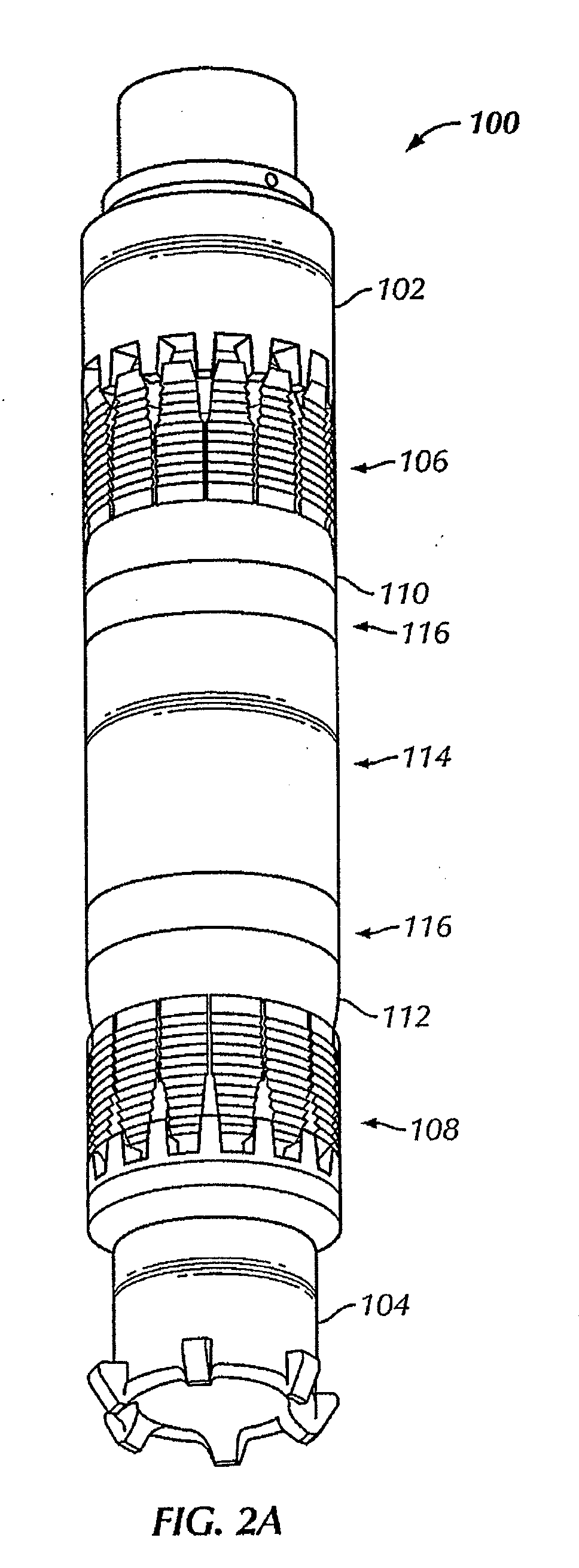

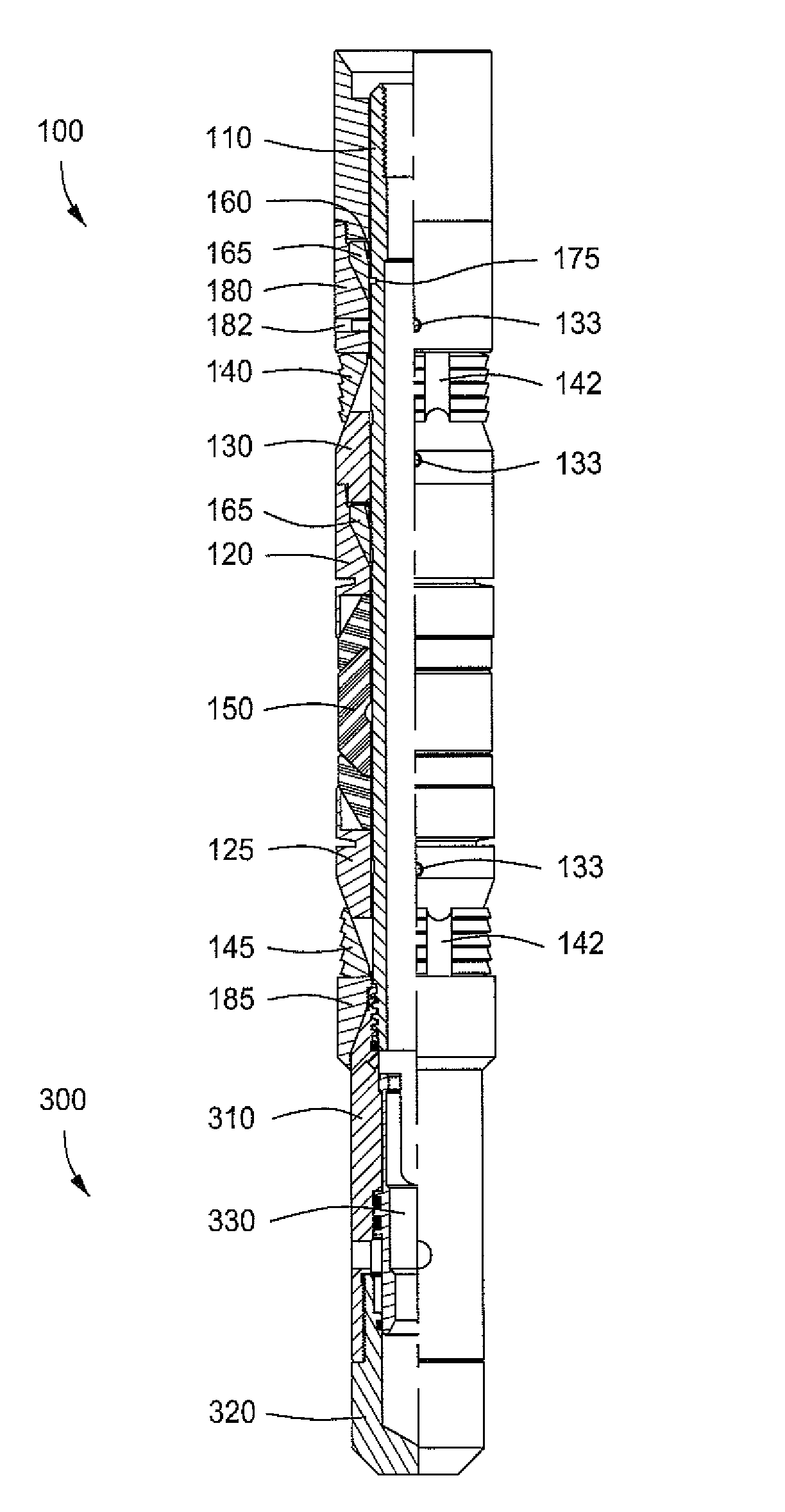

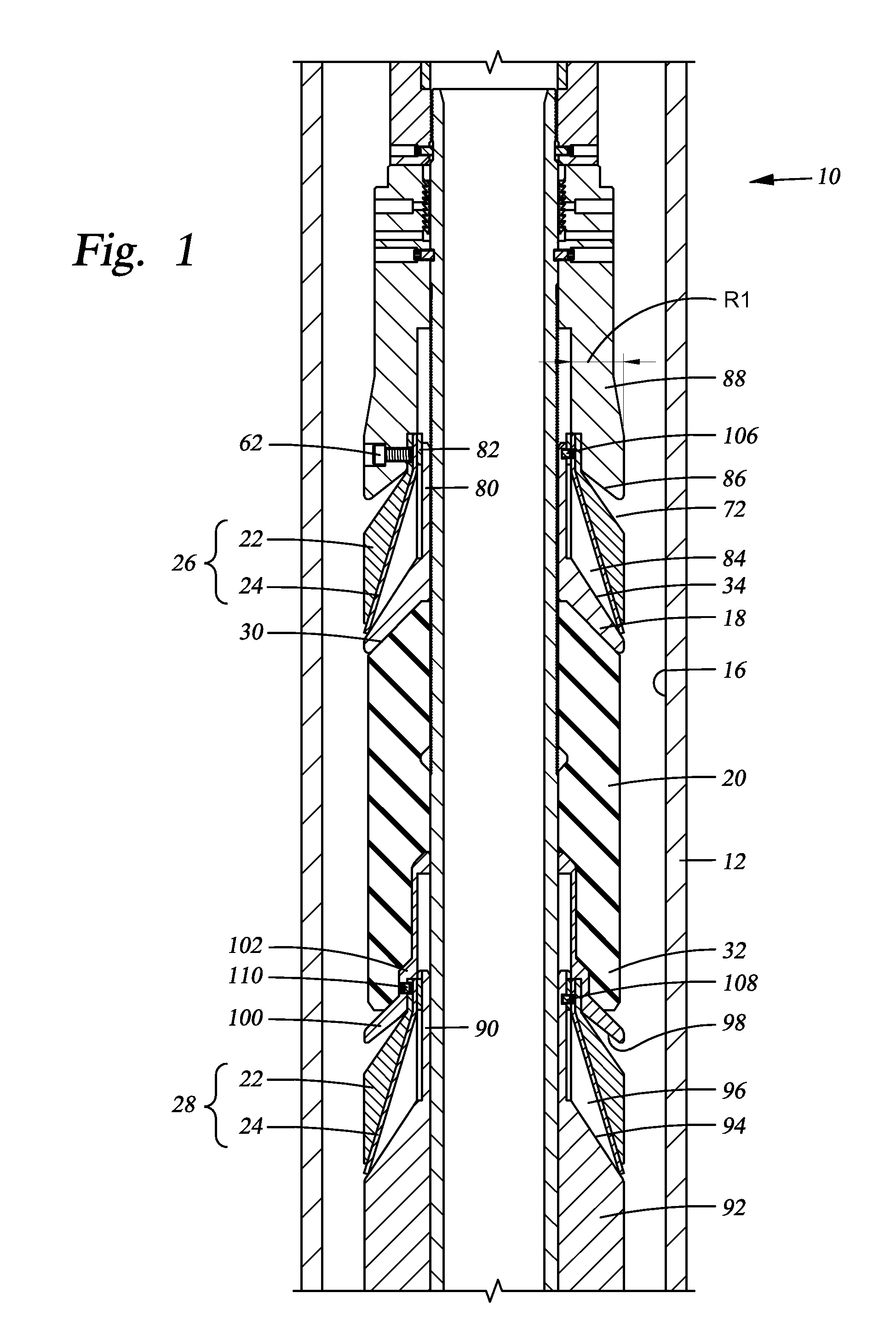

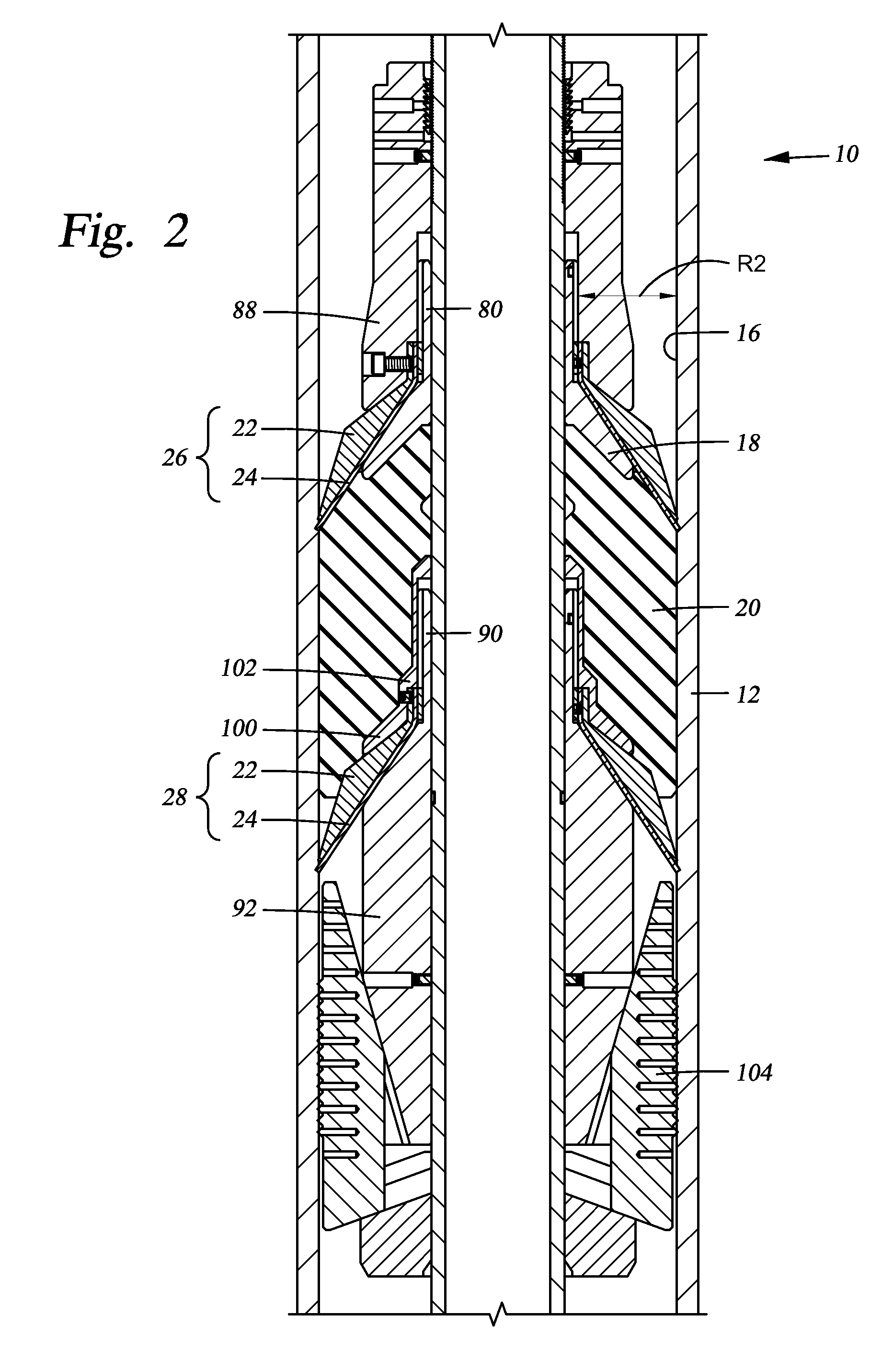

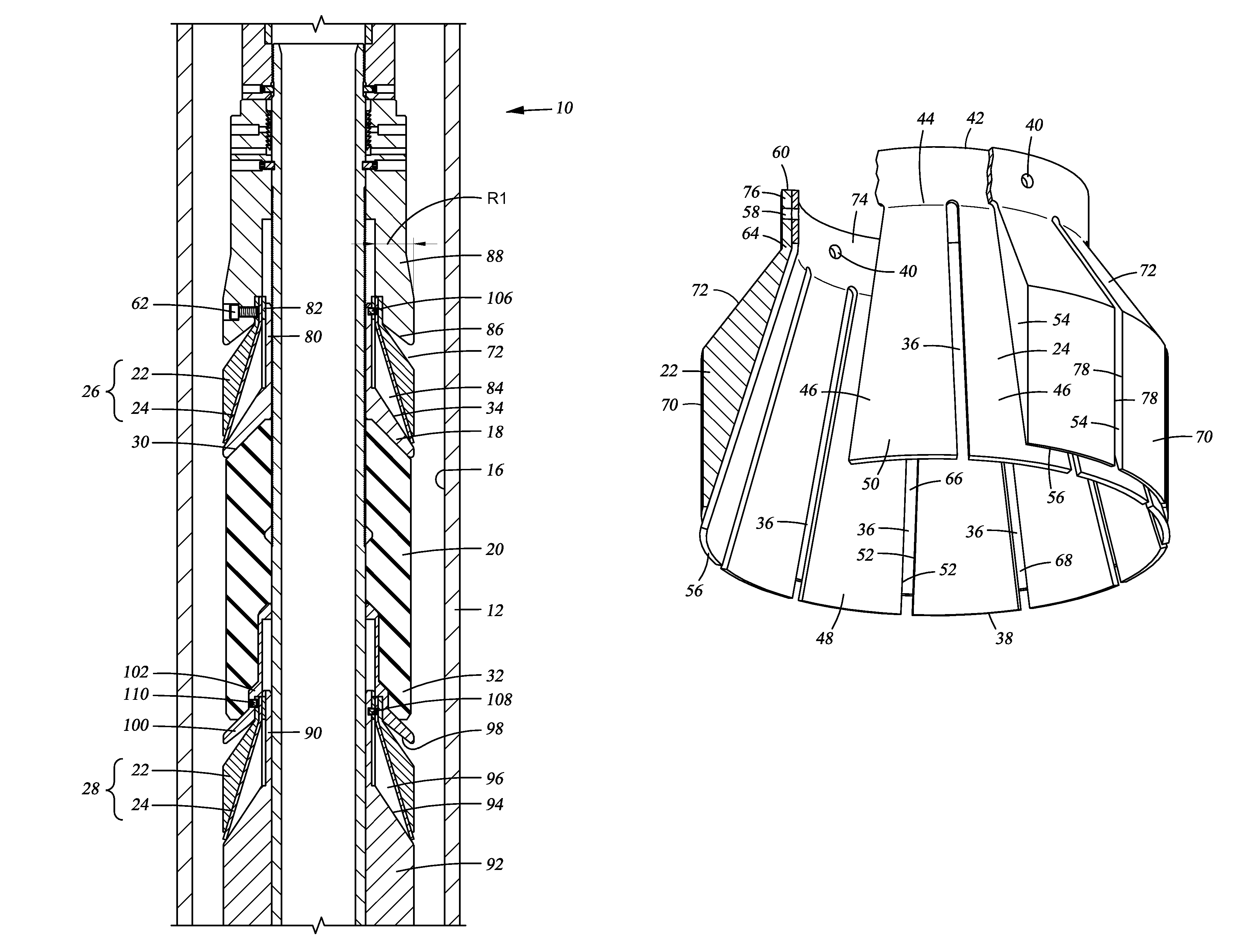

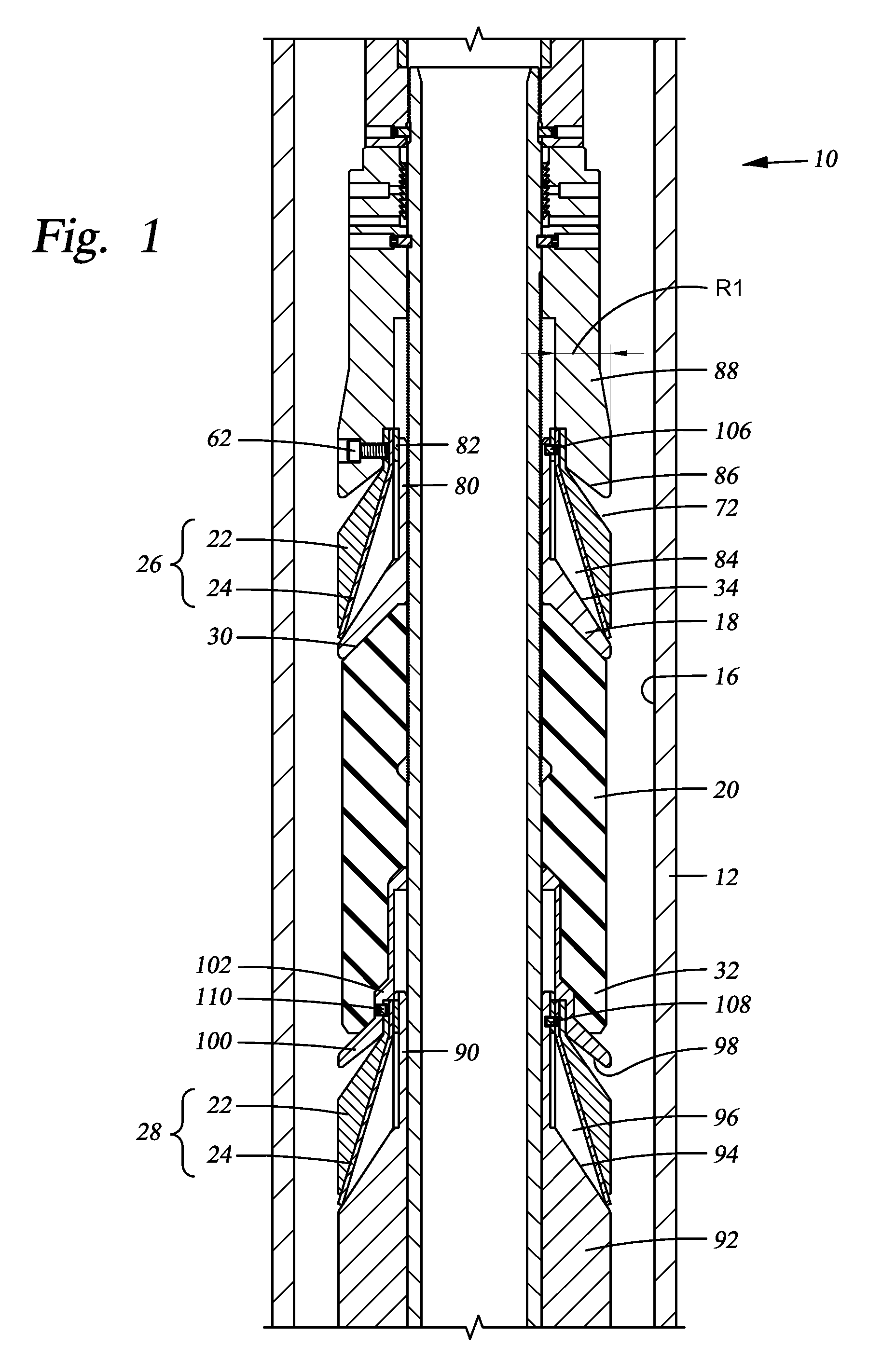

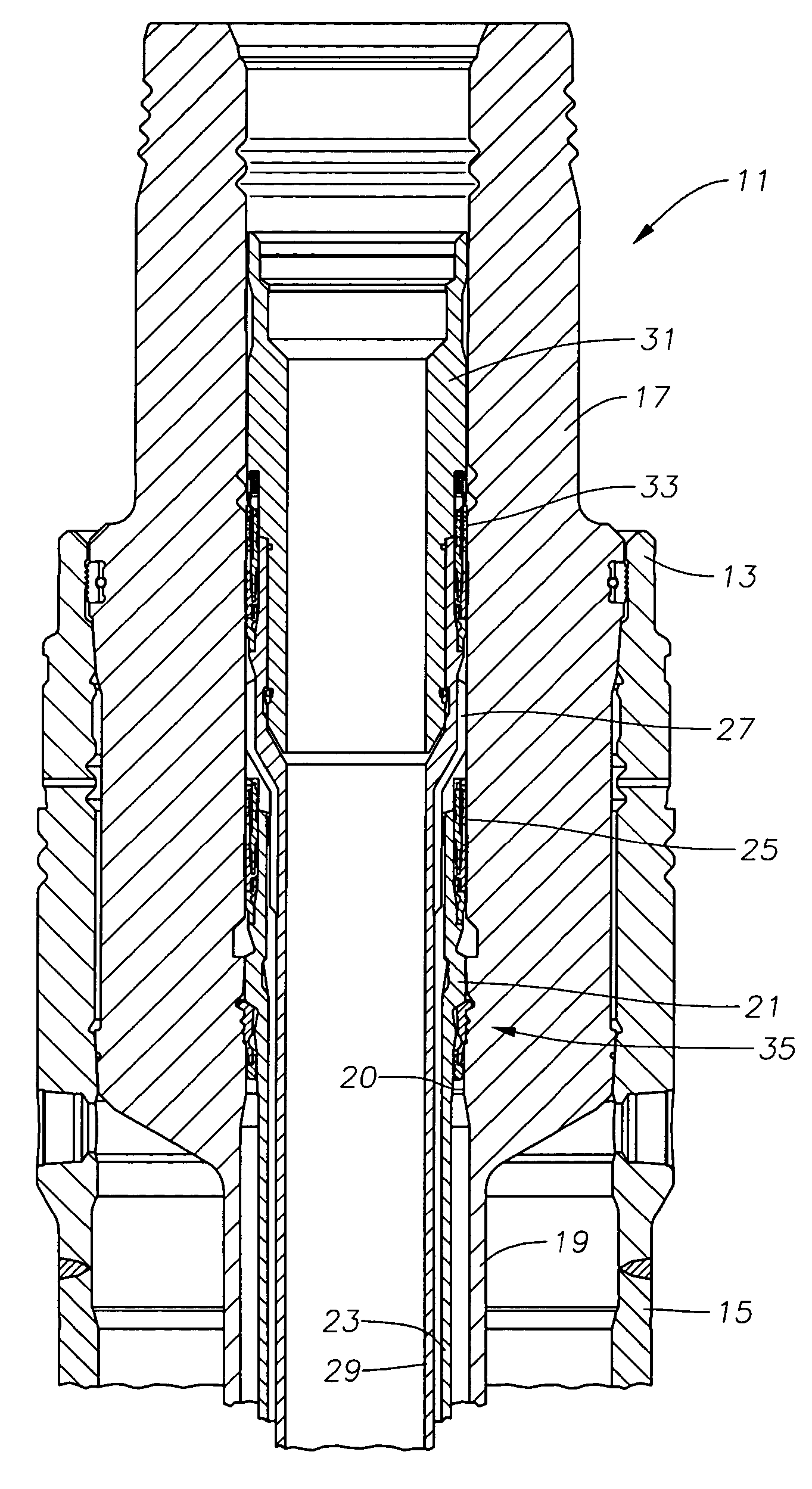

Drillable bridge plug for high pressure and high temperature environments

A drillable bridge plug includes a mandrel having external splines disposed on an outer surface of the mandrel, a sealing element disposed around the mandrel, an upper cone disposed around the mandrel proximate an upper end of the sealing element, and a lower cone disposed around the mandrel proximate the lower end of the sealing element, wherein an inner surface of the lower cone comprises internal splines configured to engage the external splines. The drillable bridge plug also includes an upper and a lower slip assembly disposed around the mandrel, and an upper and lower ring assembly each including a first segmented barrier ring, a second segmented barrier ring, and a back-up ring disposed proximate sealing element. Methods include a method of setting the drillable bridge plug and a method of removing the drillable bridge plug.

Owner:SMITH INT INC

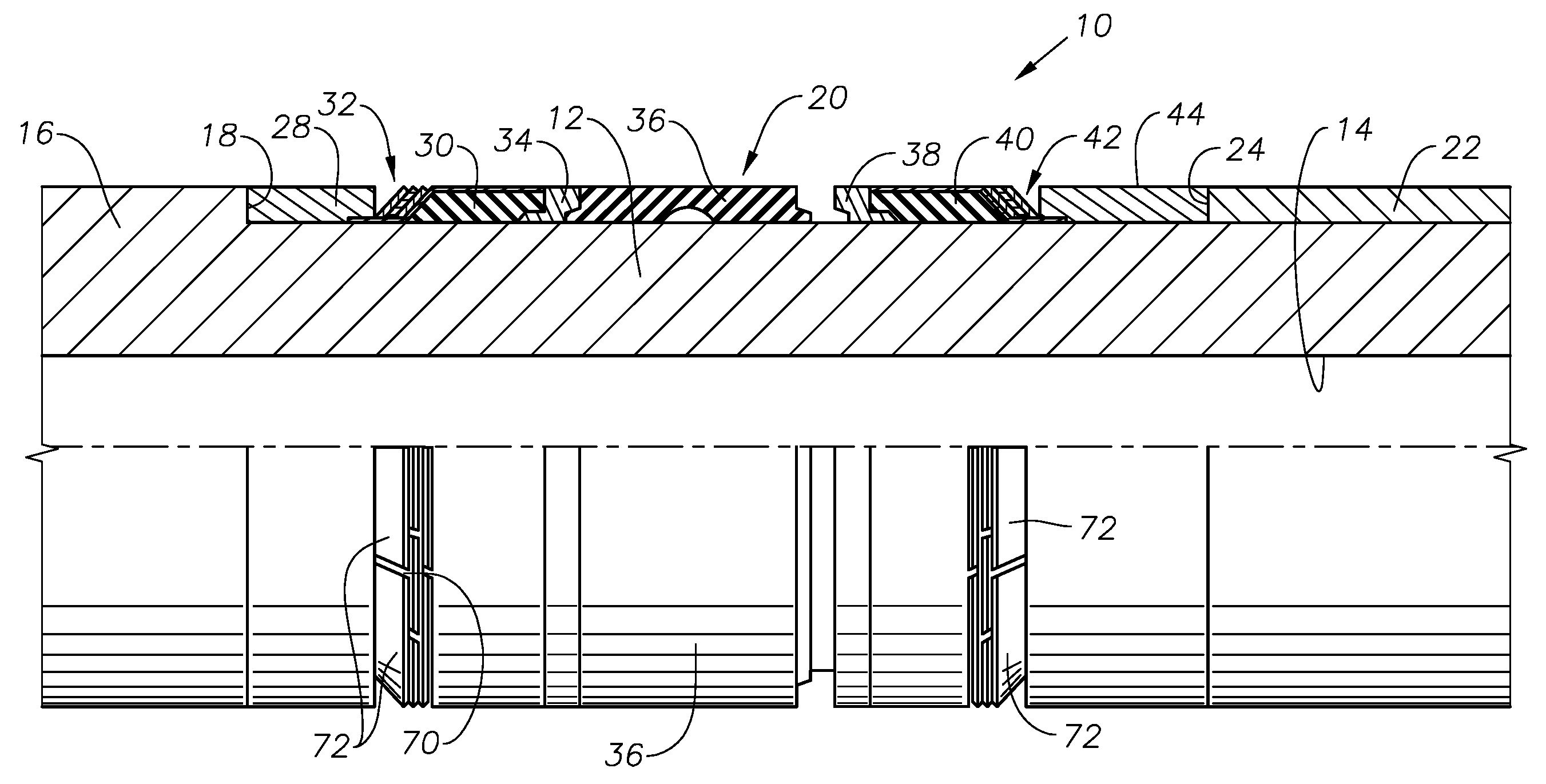

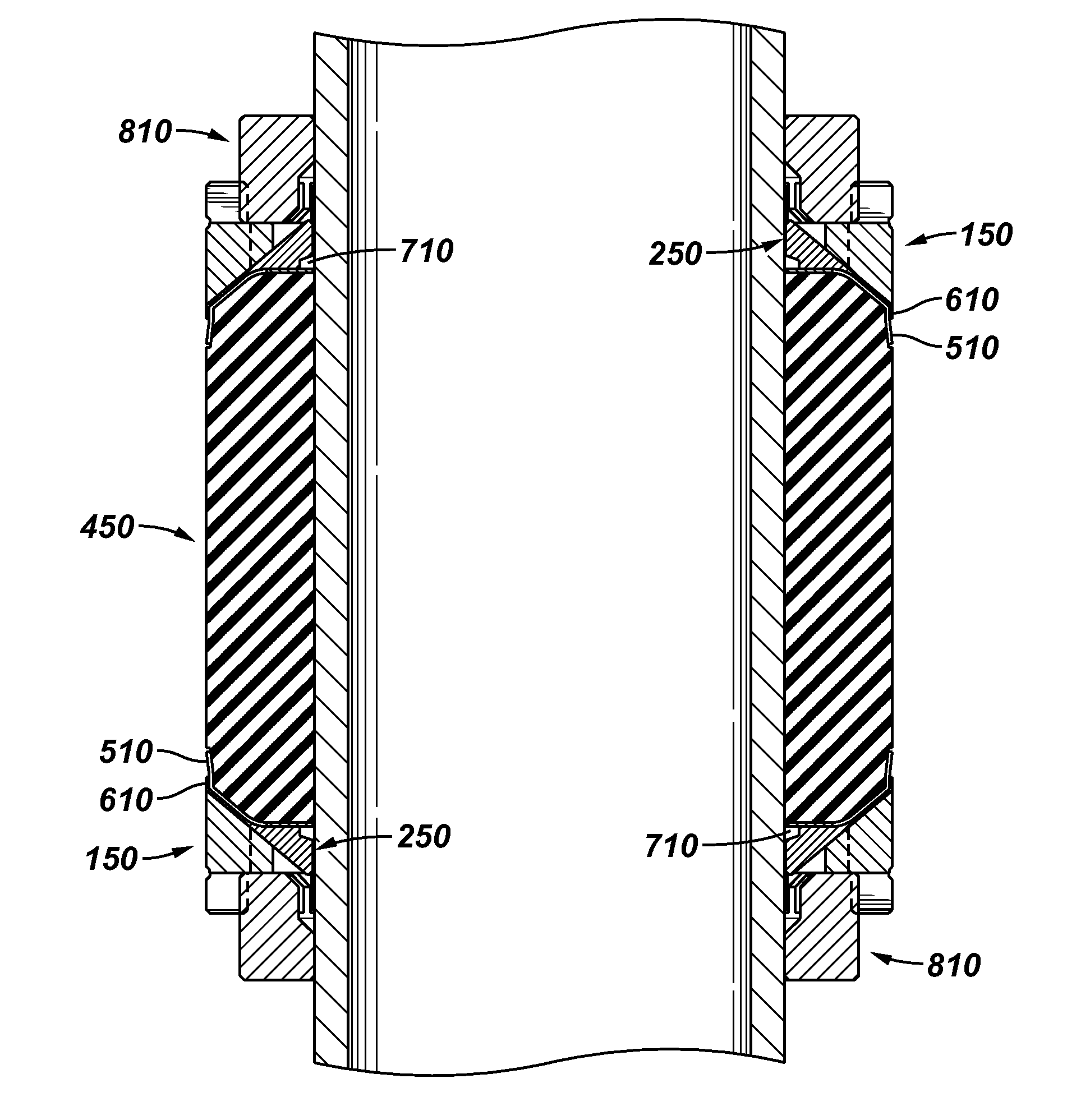

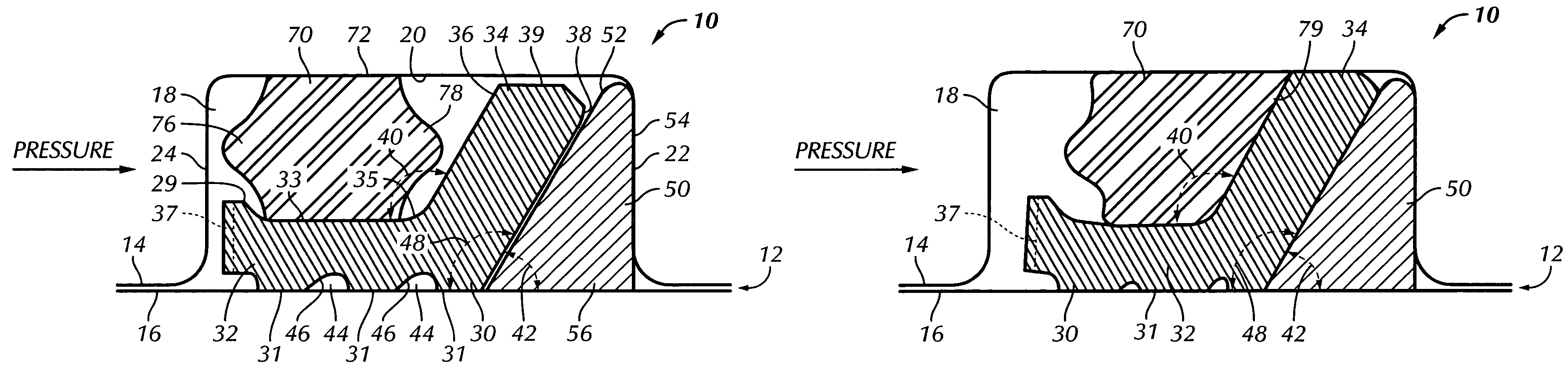

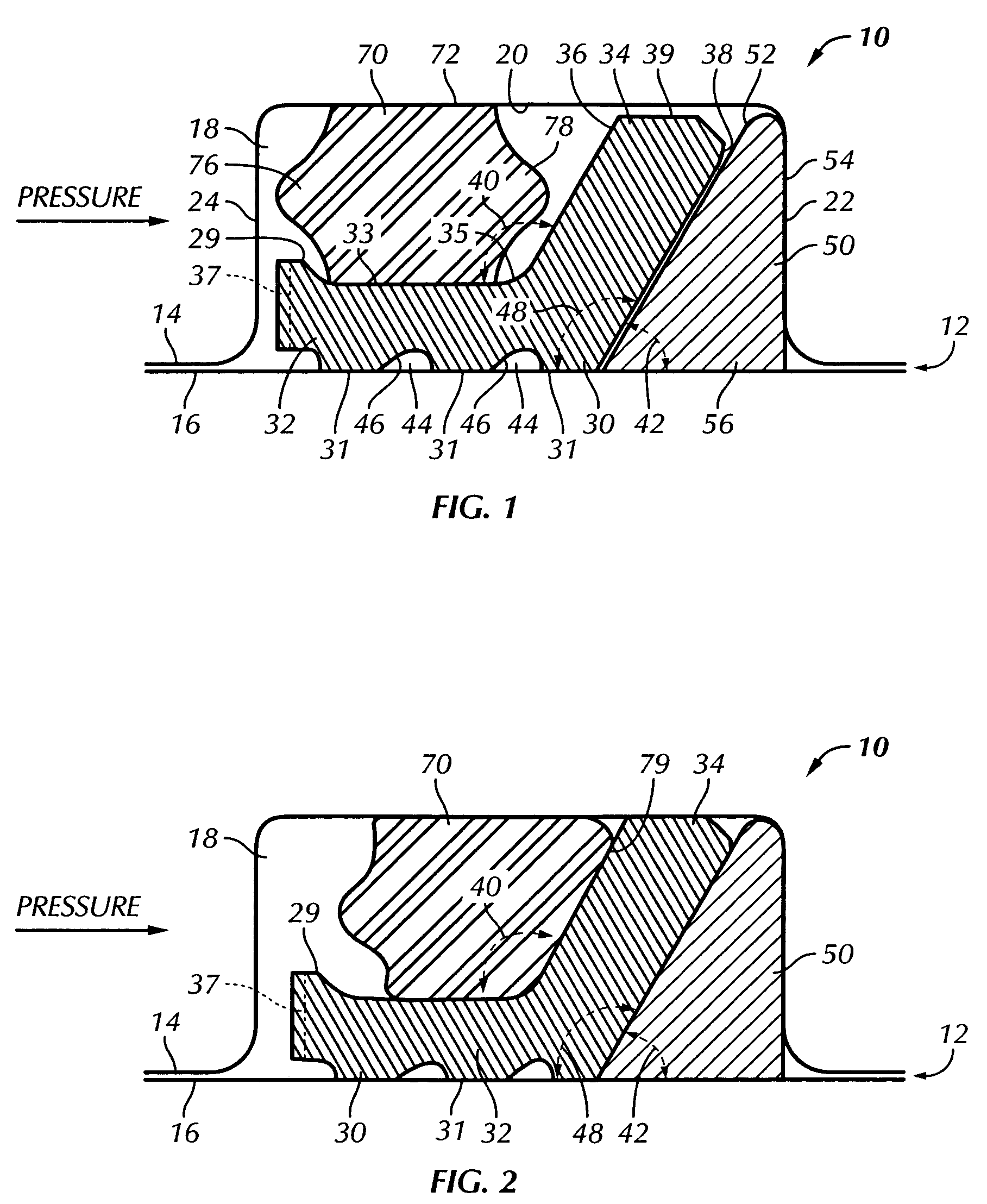

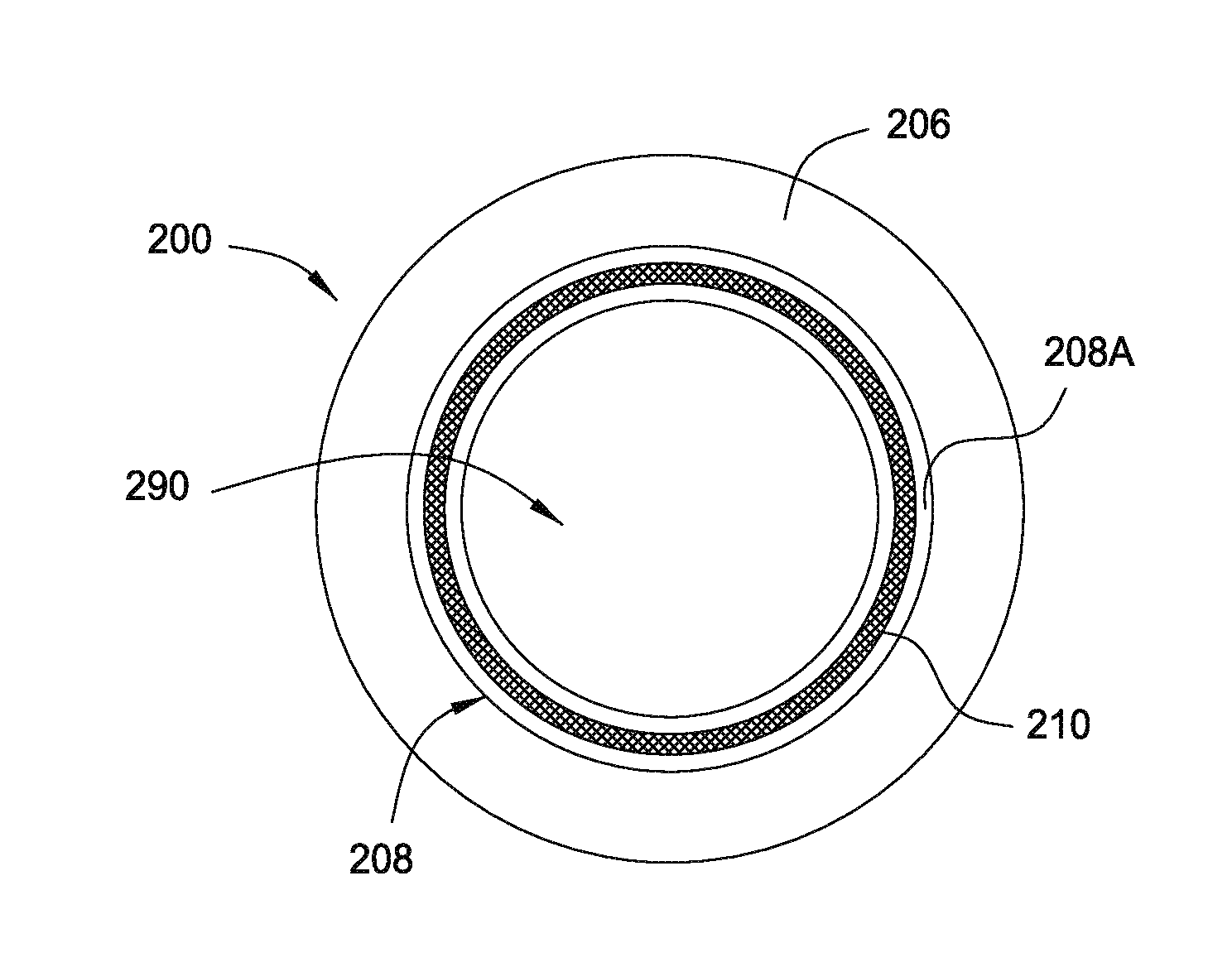

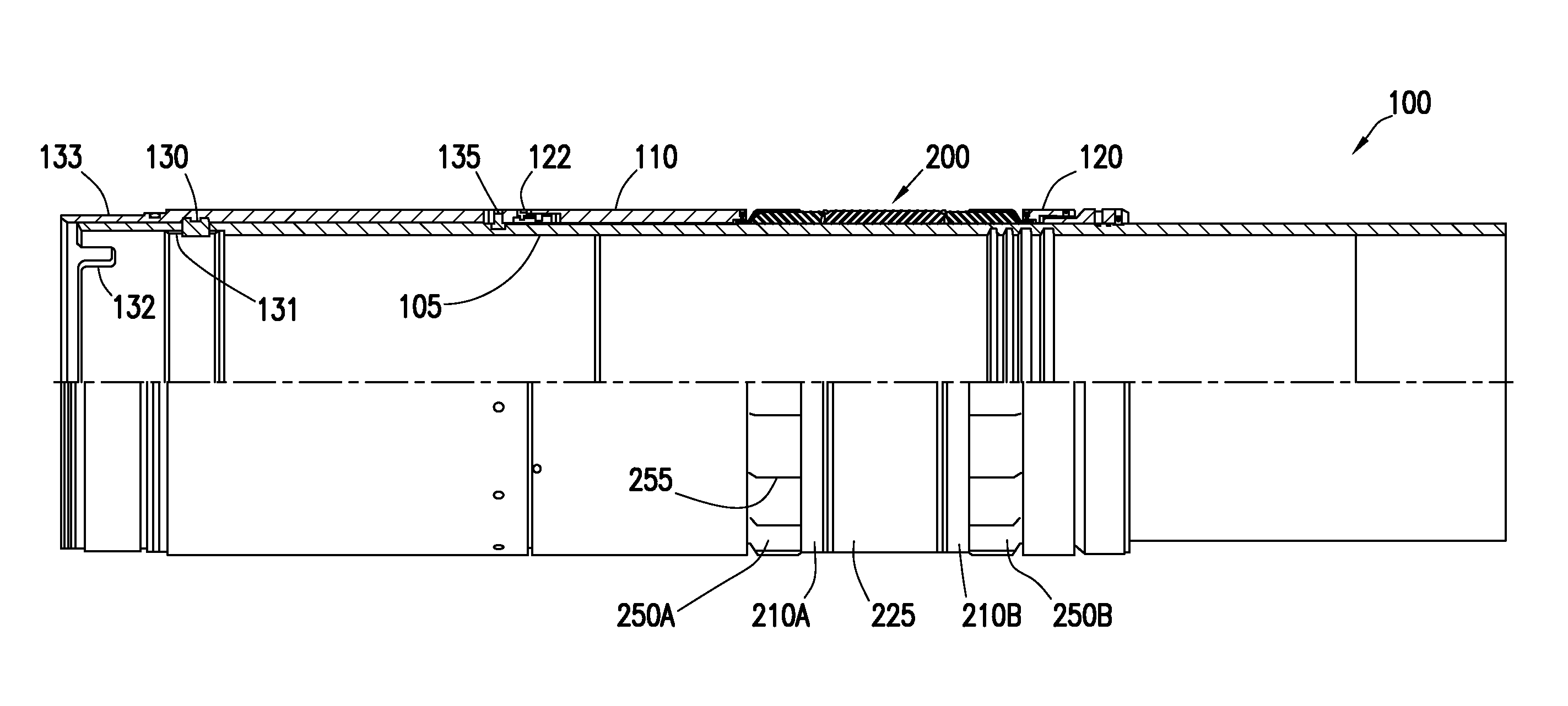

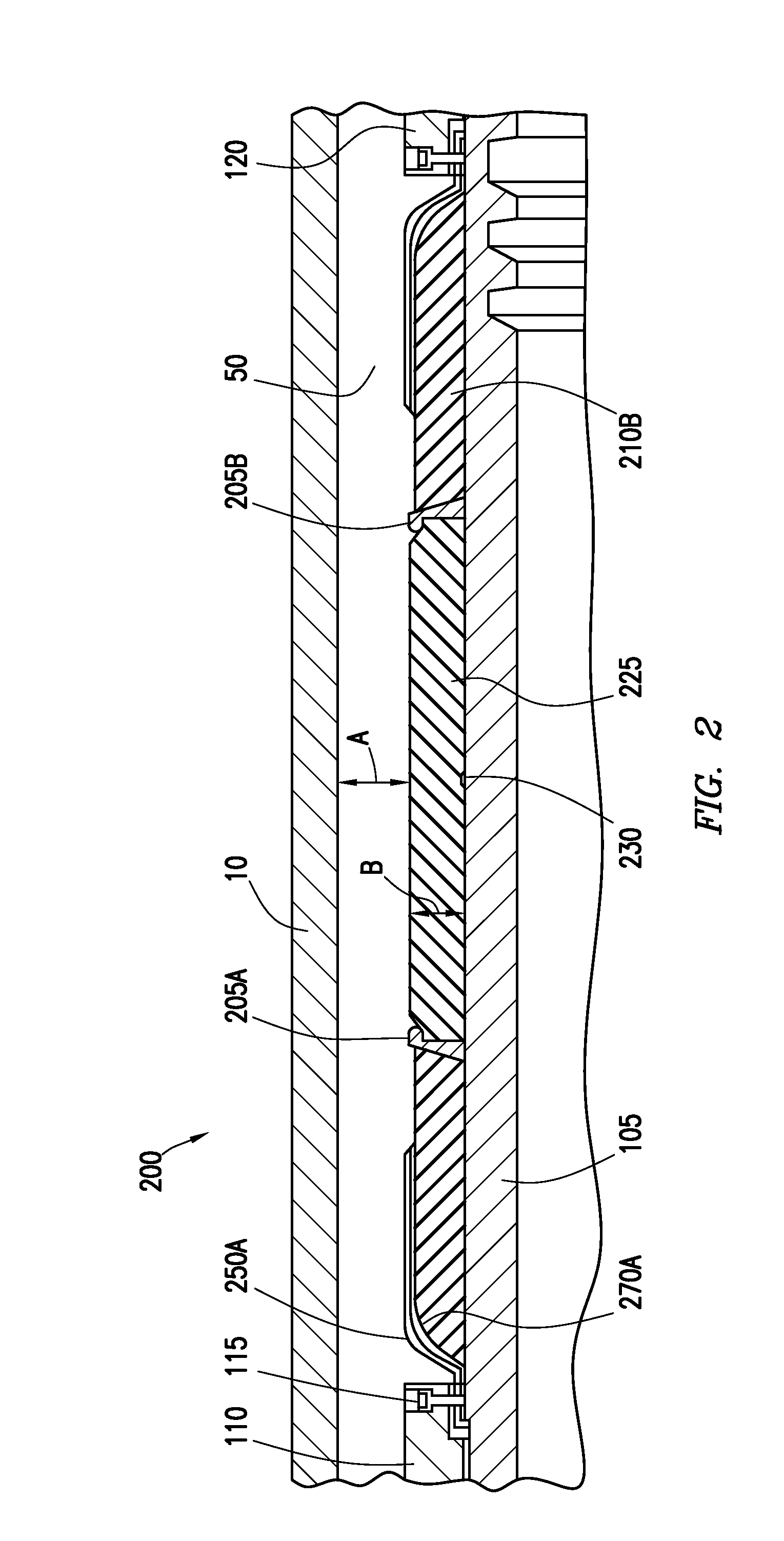

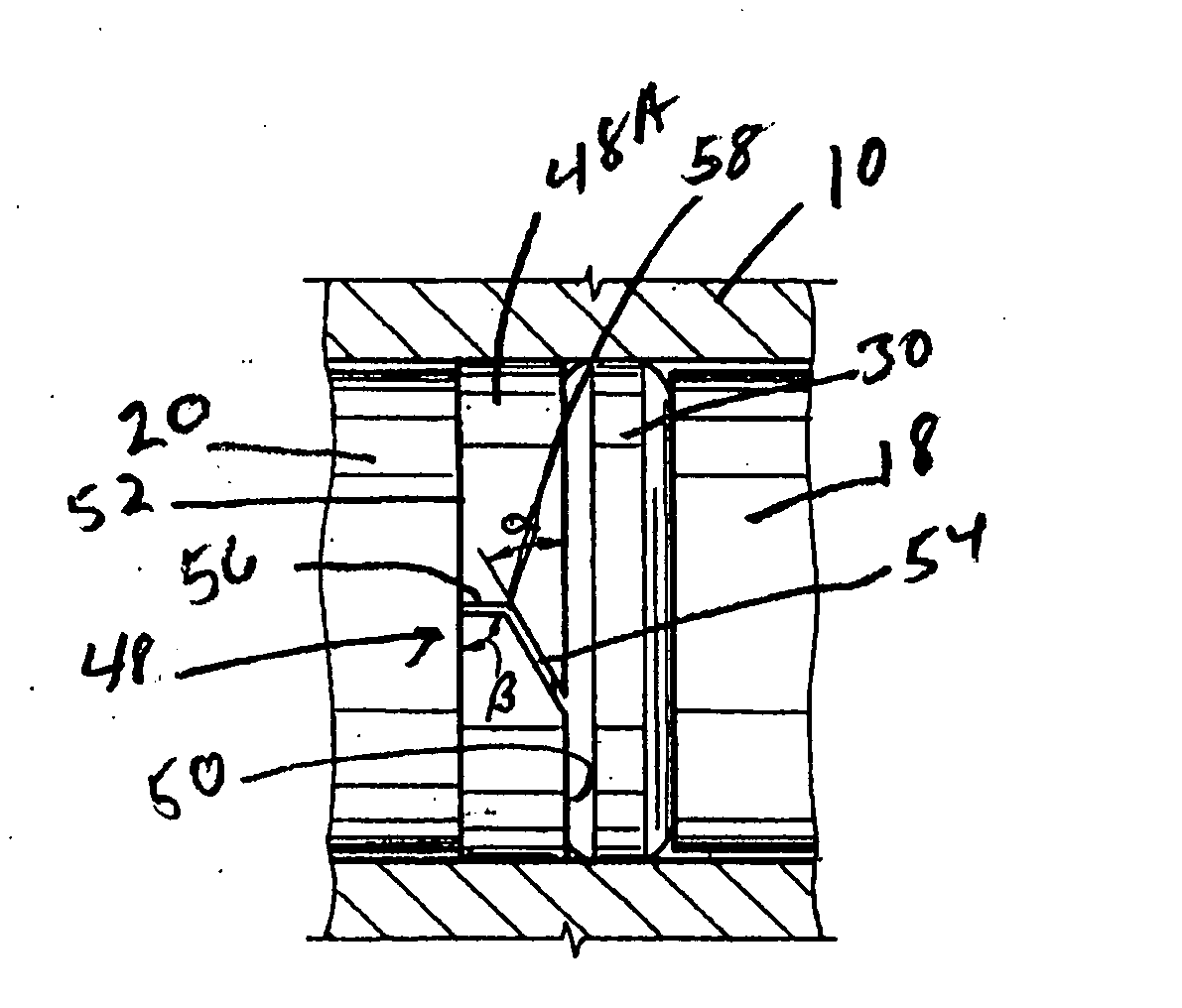

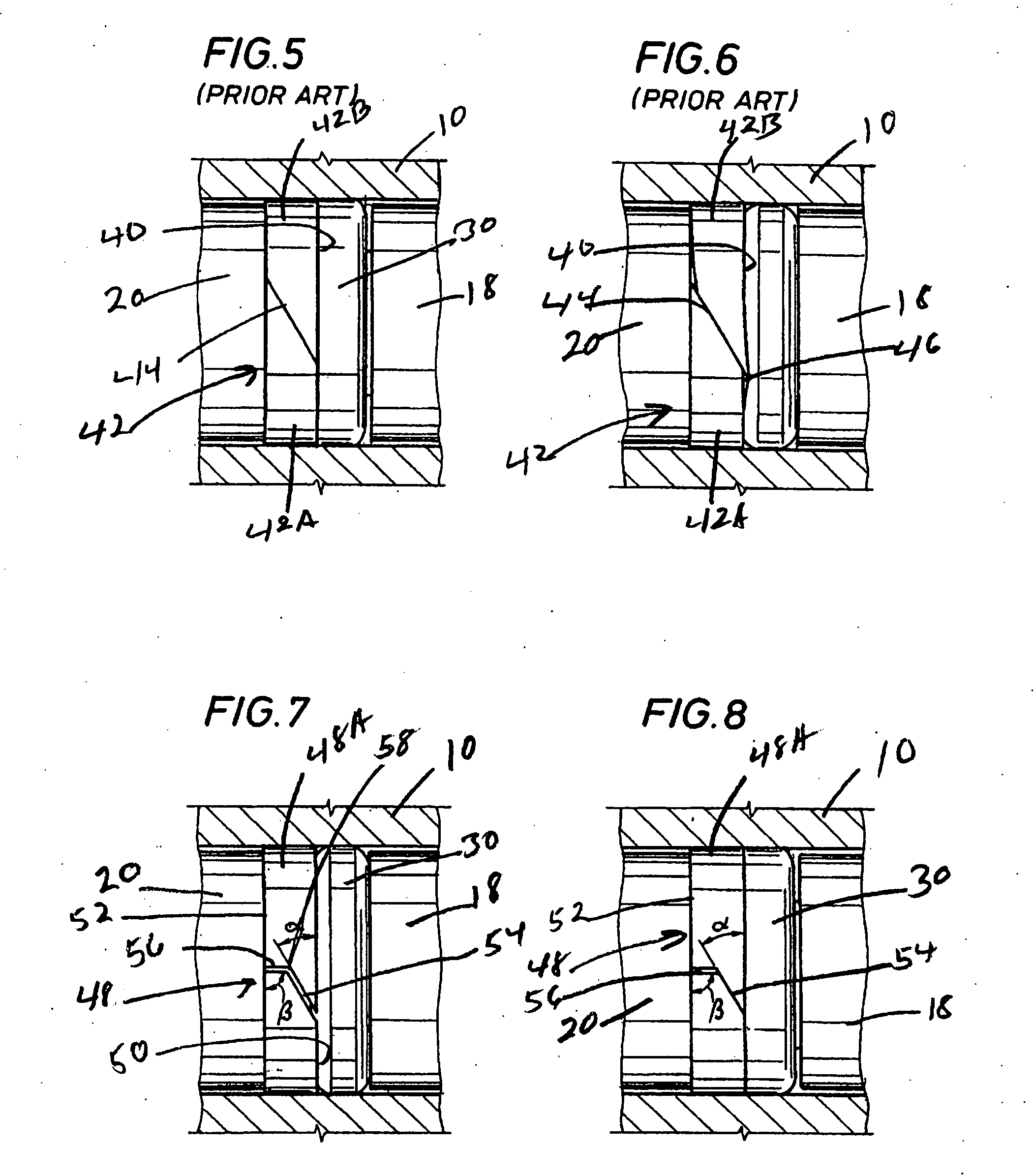

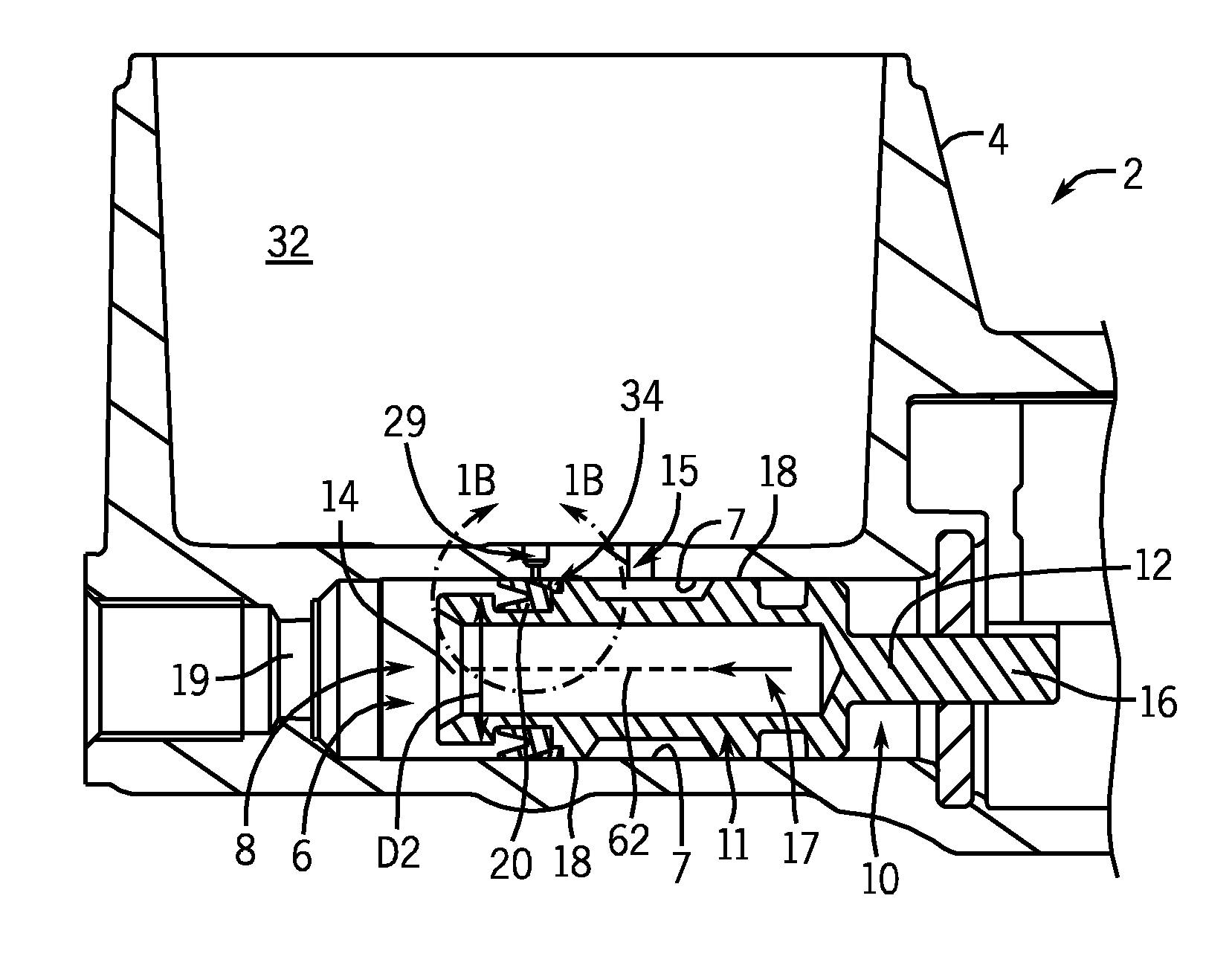

Anti-extrusion backup system, packing element system having backup system, and method

ActiveUS20120133098A1Avoid squeezingSleeve/socket jointsFluid pressure sealed jointsBack-up ringBiomedical engineering

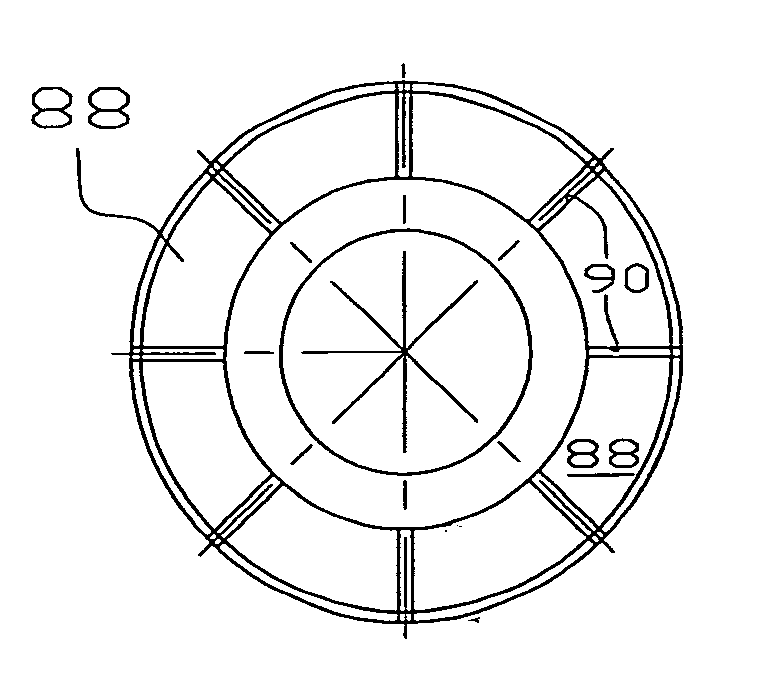

An antiextrusion backup system includes an inner expandable backup ring having a first set of slots. An outer expandable backup ring having a second set of slots wherein the outer expandable back up ring is rotationally locked to the inner expandable backup ring to prevent an extrusion gap in an expanded condition of the backup rings. A method for operating within a tubular is also included.

Owner:BAKER HUGHES INC

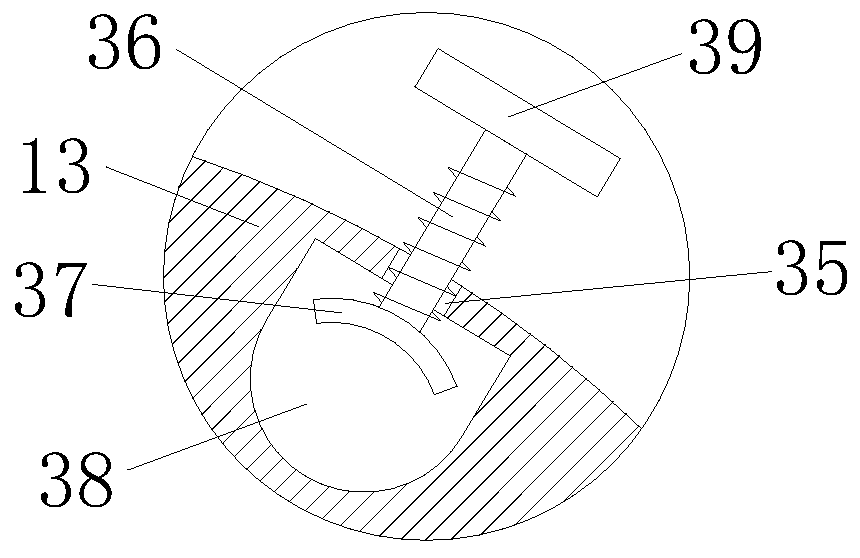

Down hole tool having improved segmented back up ring

ActiveUS20140224476A1Effective expansionAvoid Sealing ProblemsFluid removalSealing/packingCasing stringEngineering

A down hole tool or plug includes a segmented back up ring acting to minimize extrusion of a seal in an axial direction thereby promoting radial expansion of the seal into engagement with the internal diameter of a casing string. The segments of the ring are joined to a ring body having a passage thereby by a junction having, as its outer dimension, the outside diameter of the tool and an inside dimension provided by a groove opening into the passage.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

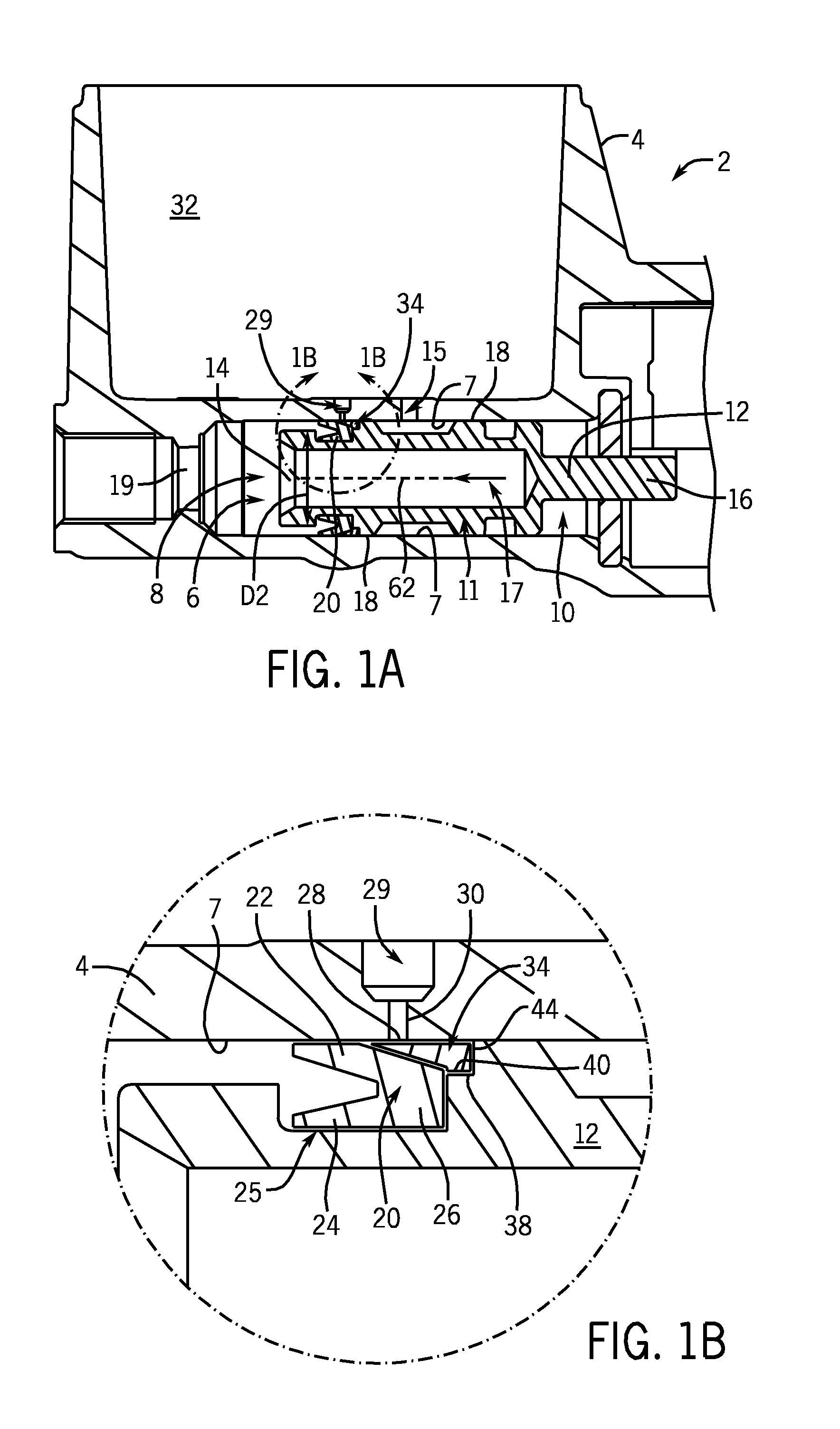

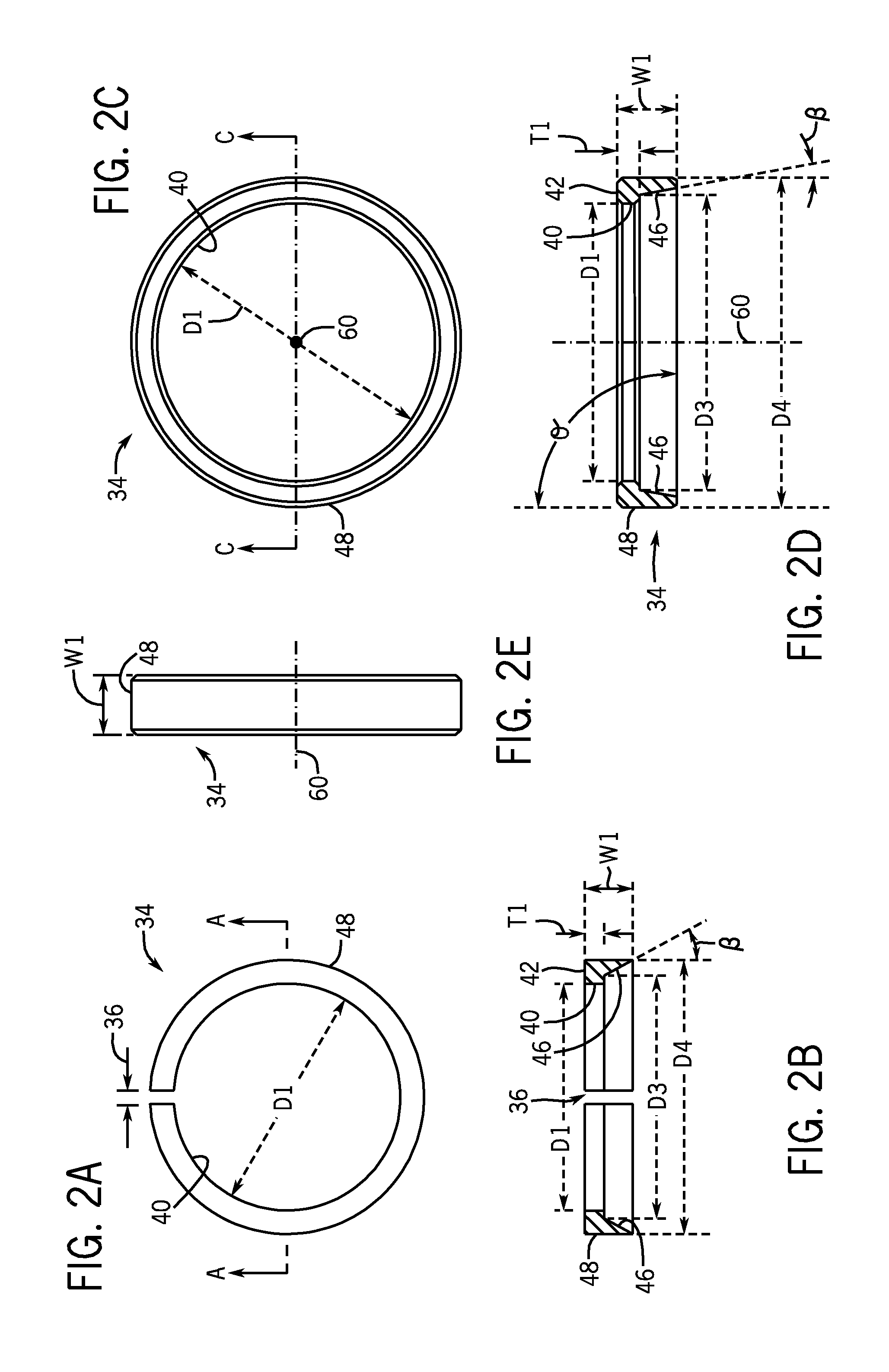

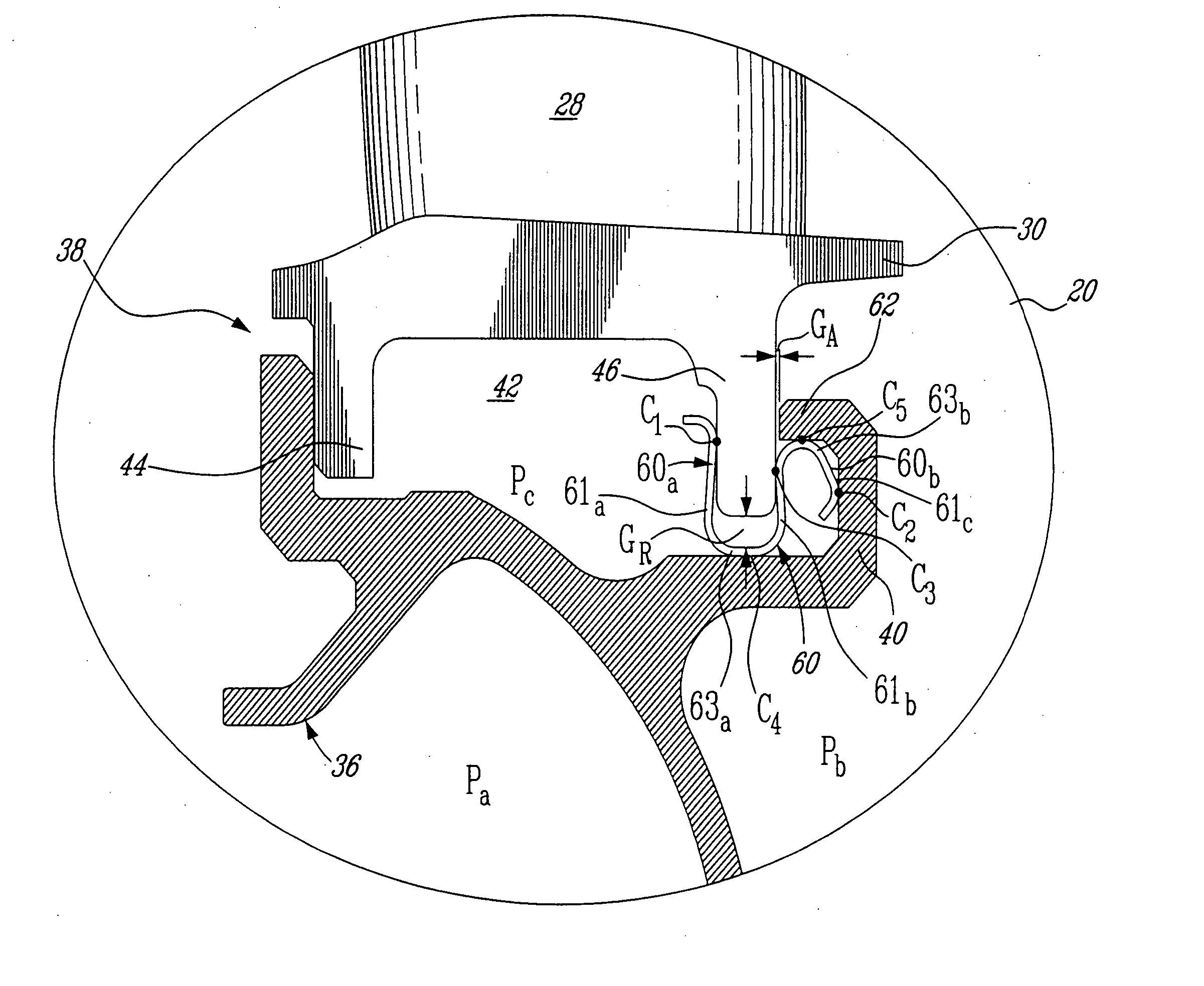

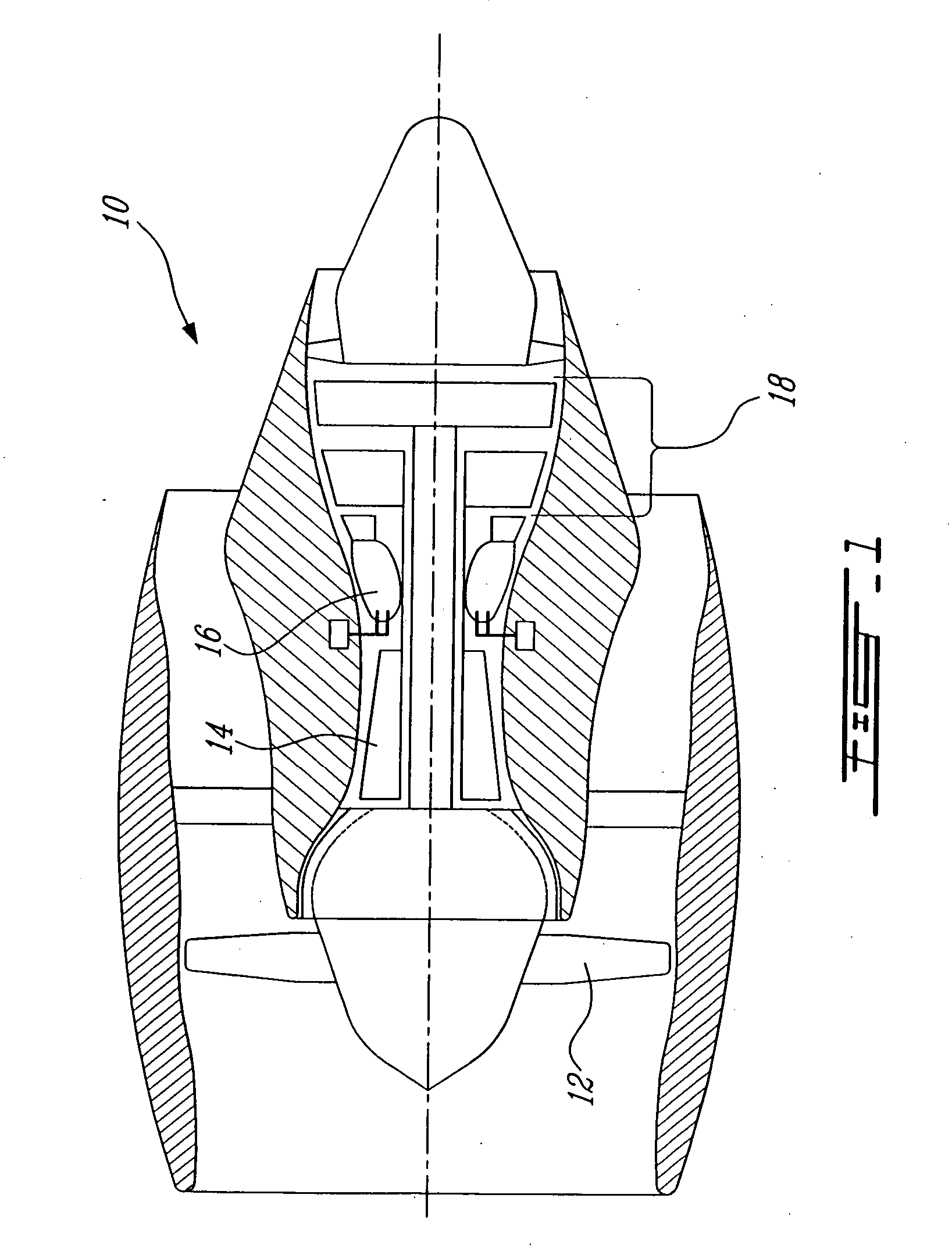

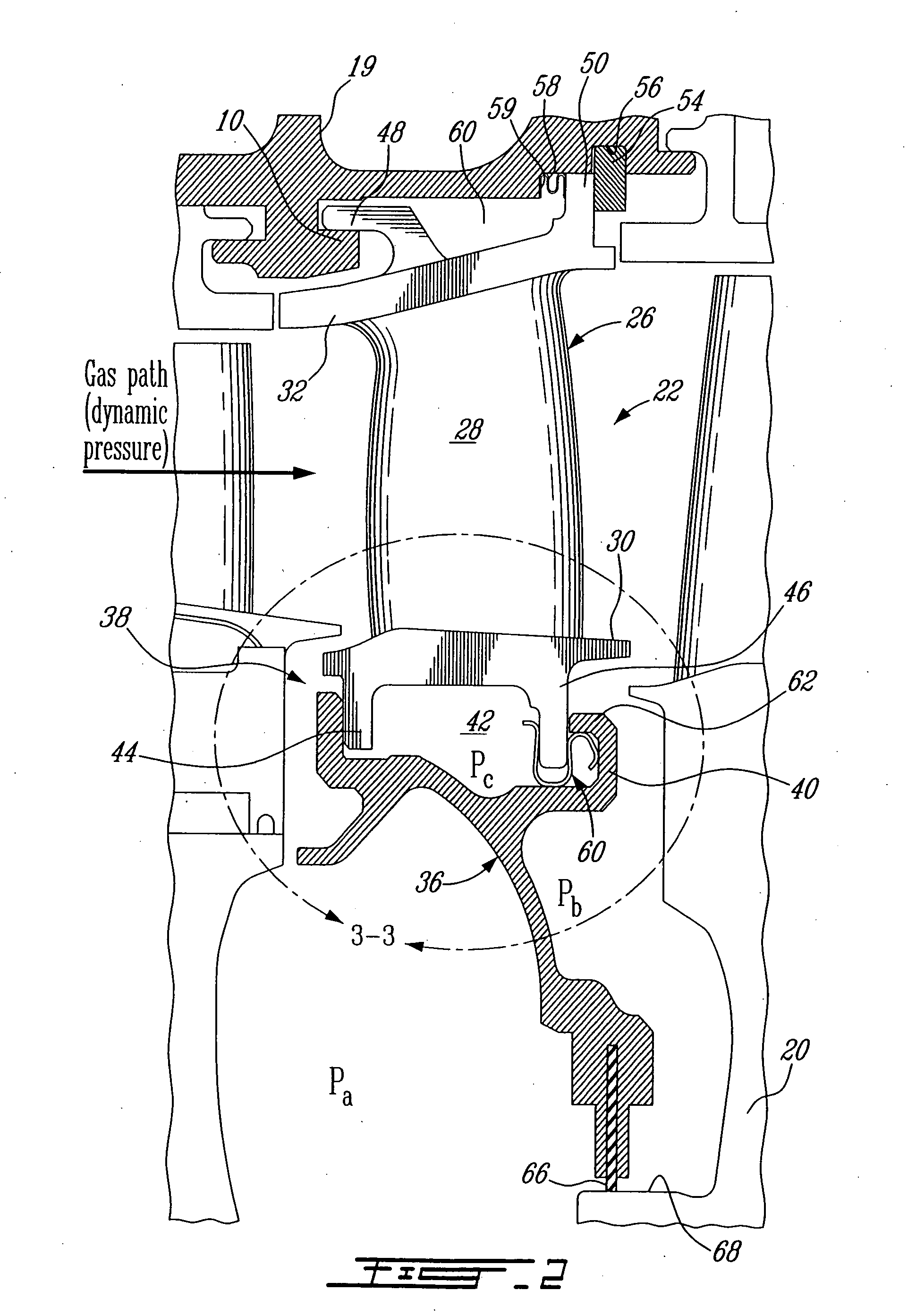

Cammed seal assembly with sealing ring having an angled leg portion and foot portion with elastomeric energizer element

A seal assembly seals first and second operational surfaces spaced apart by a gap. The first surface includes a seal groove having a base surface and first and second side surfaces. A sealing element in the seal groove has a foot portion extending parallel to the base surface which engages the second operational surface. A leg portion extending from the foot portion toward the base surface has first and second surfaces. A back-up ring adjacent to the sealing element prevents extrusion of the sealing element into the gap. A first side of the back-up ring mates with the second surface of the leg portion, and a second side mates with one of the first and second side surfaces of the seal groove. An energizer element located between the base surface and the foot portion applies uniform pressure to the leg and foot portions when the energizer element is compressed.

Owner:GREENE TWEED TECH

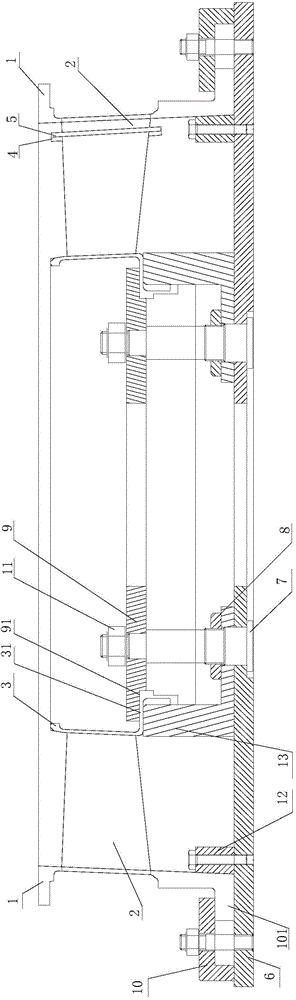

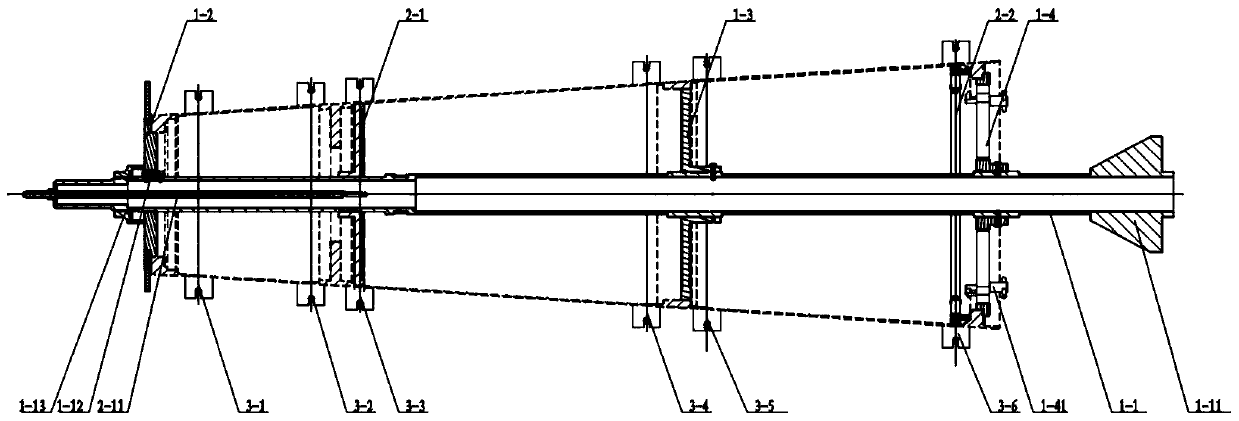

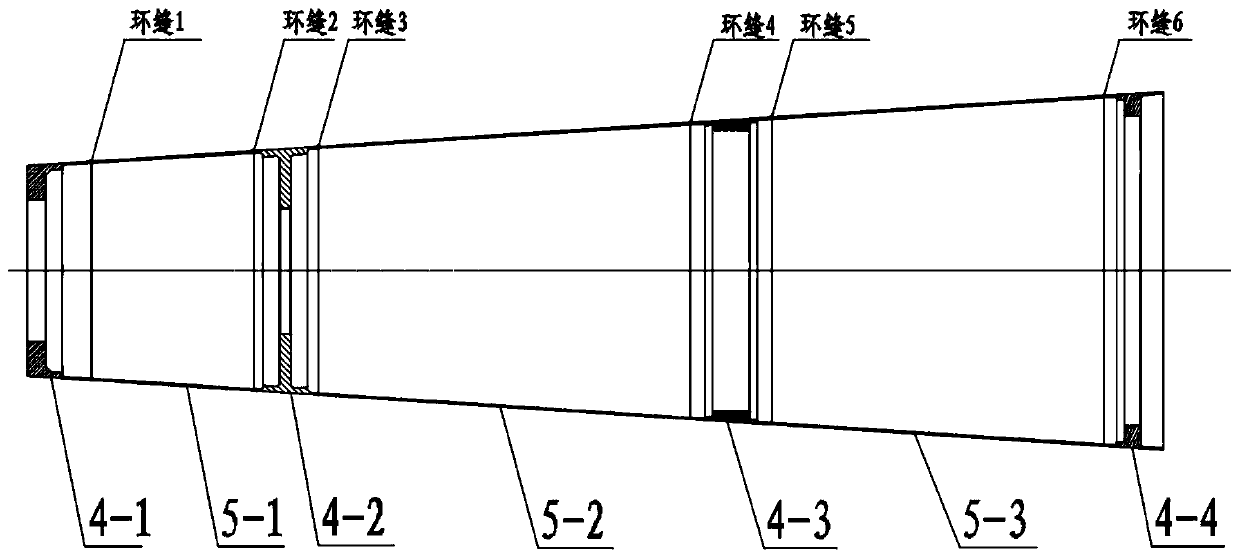

Fan casing assembly welding method and tool for fan casing assembly welding method

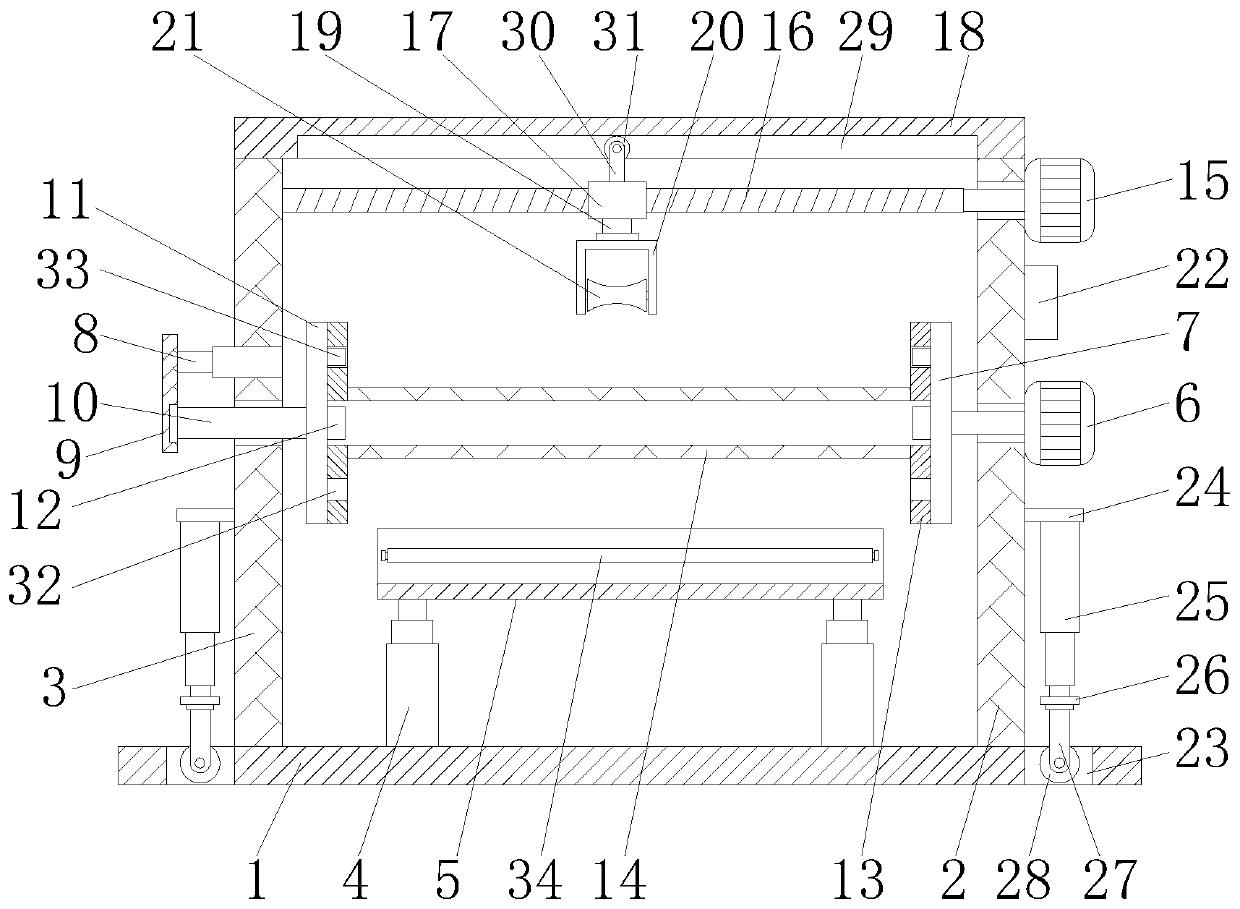

ActiveCN104439730AImprove molding qualityControl heightWelding/cutting auxillary devicesWork holdersEngineeringWelding process

The invention discloses a fan casing assembly welding method and a tool for the fan casing assembly welding method and belongs to the technical field of the welding technology. By the adoption of the fan casing assembly welding method and the tool for the fan casing assembly welding method, the problems that in the welding process, the weld joint forming quality is poor, root reinforcement exists on a weld joint, deformation is serious, dimension errors are large and blade protection is difficult are solved. The fan casing assembly welding method comprises the following steps of preparation before welding, positioning, assembly of a baffle, electron beam welding, inspection after welding, assembly of a heat treatment tool and vacuum heat shaping. The baffle is composed of an upper plate and a lower plate. The fixing tool for welding comprises a base plate, a shaft, a gland, a positioning ring, a supporting ring and a plurality of pressing plates. The heat treatment tool comprises a base plate, a cover plate and a plurality of pressing blocks.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

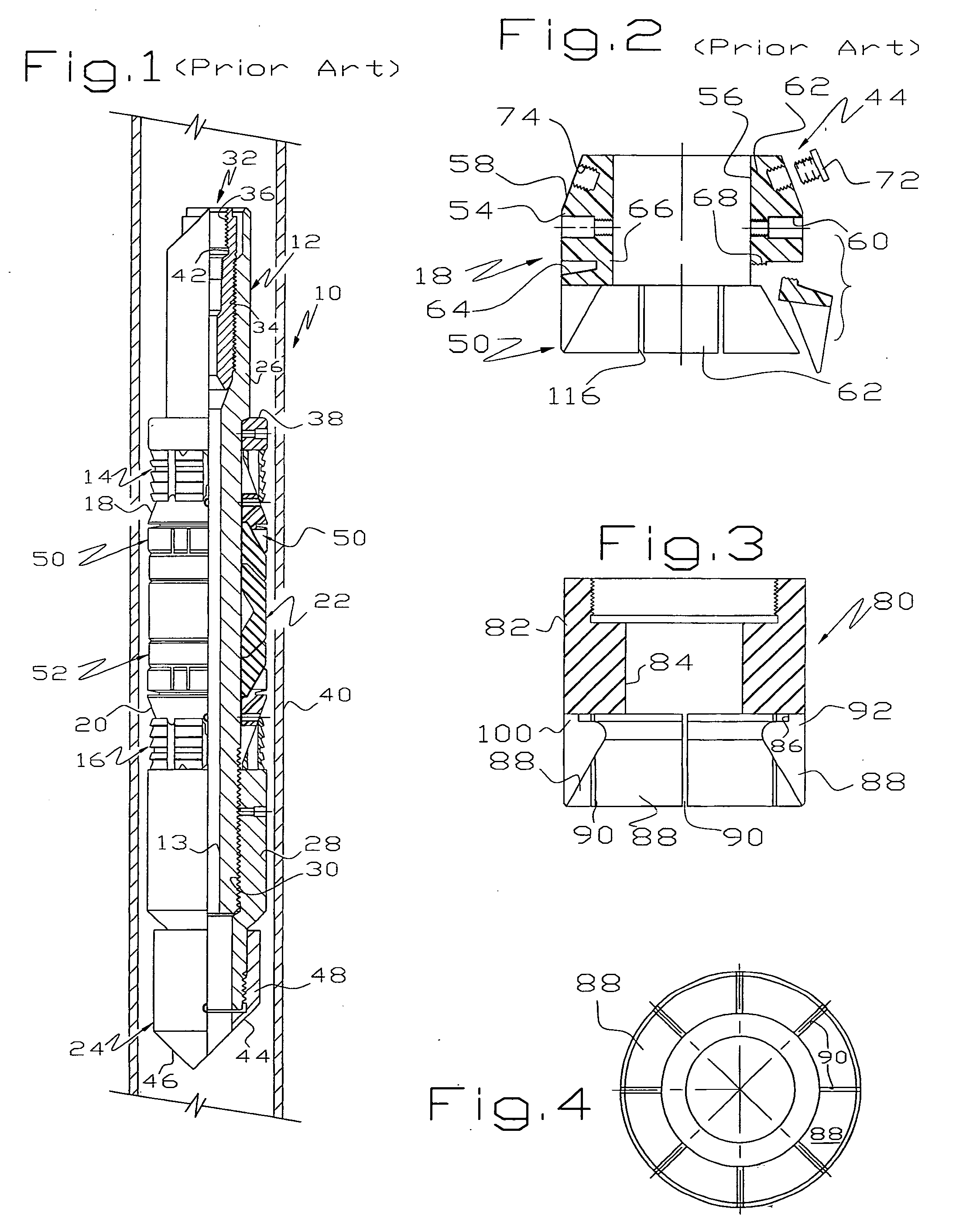

Composite cement retainer

InactiveUS20080073074A1Fluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

A downhole plug is provided. In one or more embodiments, the plug includes a body and an element system disposed about the body. The plug further includes a first and second back-up ring member having two or more tapered wedges. The tapered wedges are at least partially separated by two or more converging grooves. First and second cones are disposed adjacent the first and second back-up ring members.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

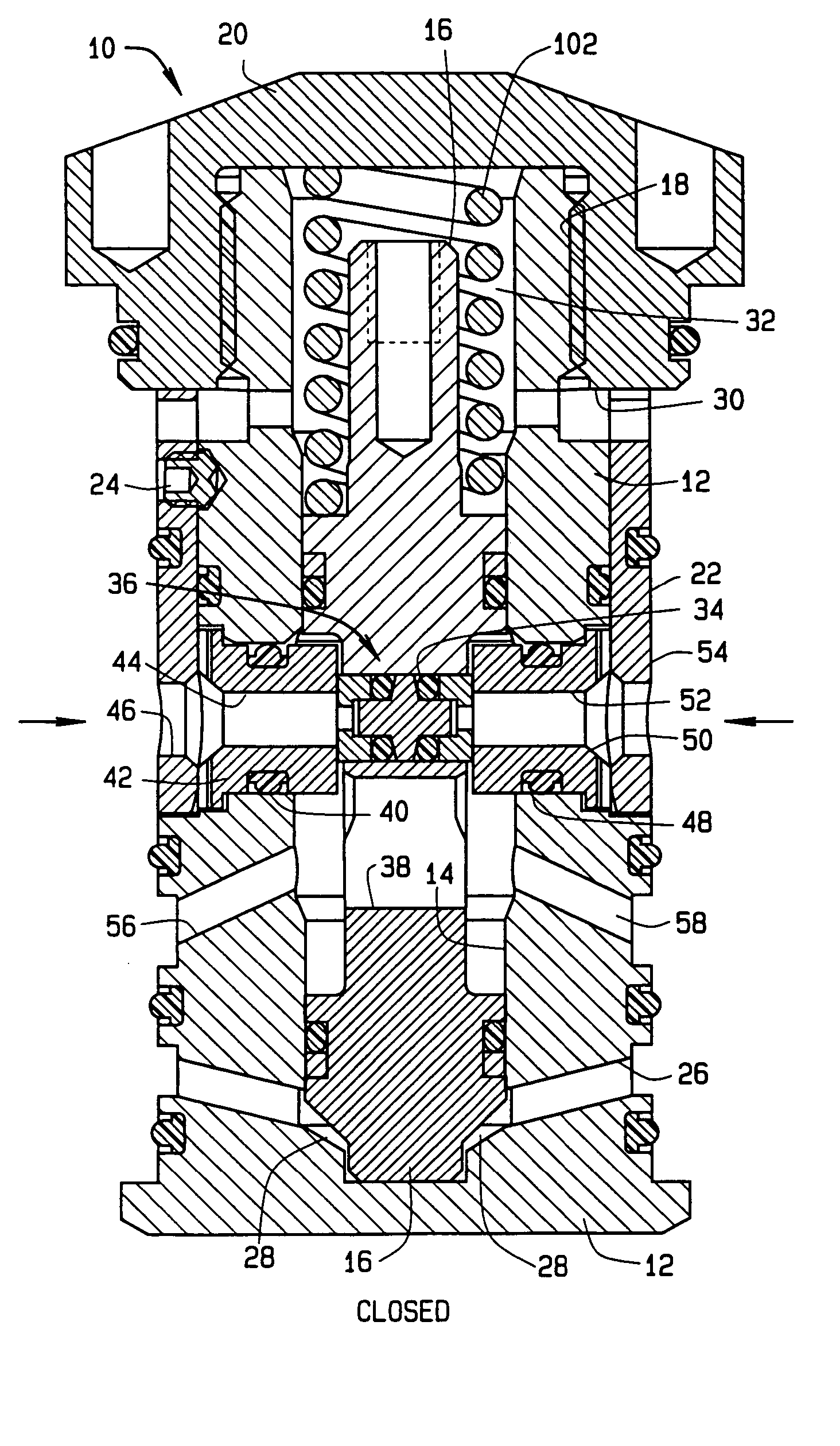

Dual energized hydroseal

A bi-directional seal assembly can be used in various types of cartridge valves including dirty fluid valves and a variety of other valves. The present seal assembly utilizes a seal spool, two O-rings and opposing seal cups. Back-up rings are provided to engage the O-rings to control deformation of the O-rings. The O-rings are compressed during manufacture of the seal assembly and the valve more than typically recommended by O-ring manufacturers. Because of this compression, the O-rings serve a dual function. At lower pressures, the O-rings act as a spring causing the seal cups to contact the opposing seal plates and at higher pressures they act as seals between the seal assembly and the valve.

Owner:PROSERV OFFSHORE INC +1

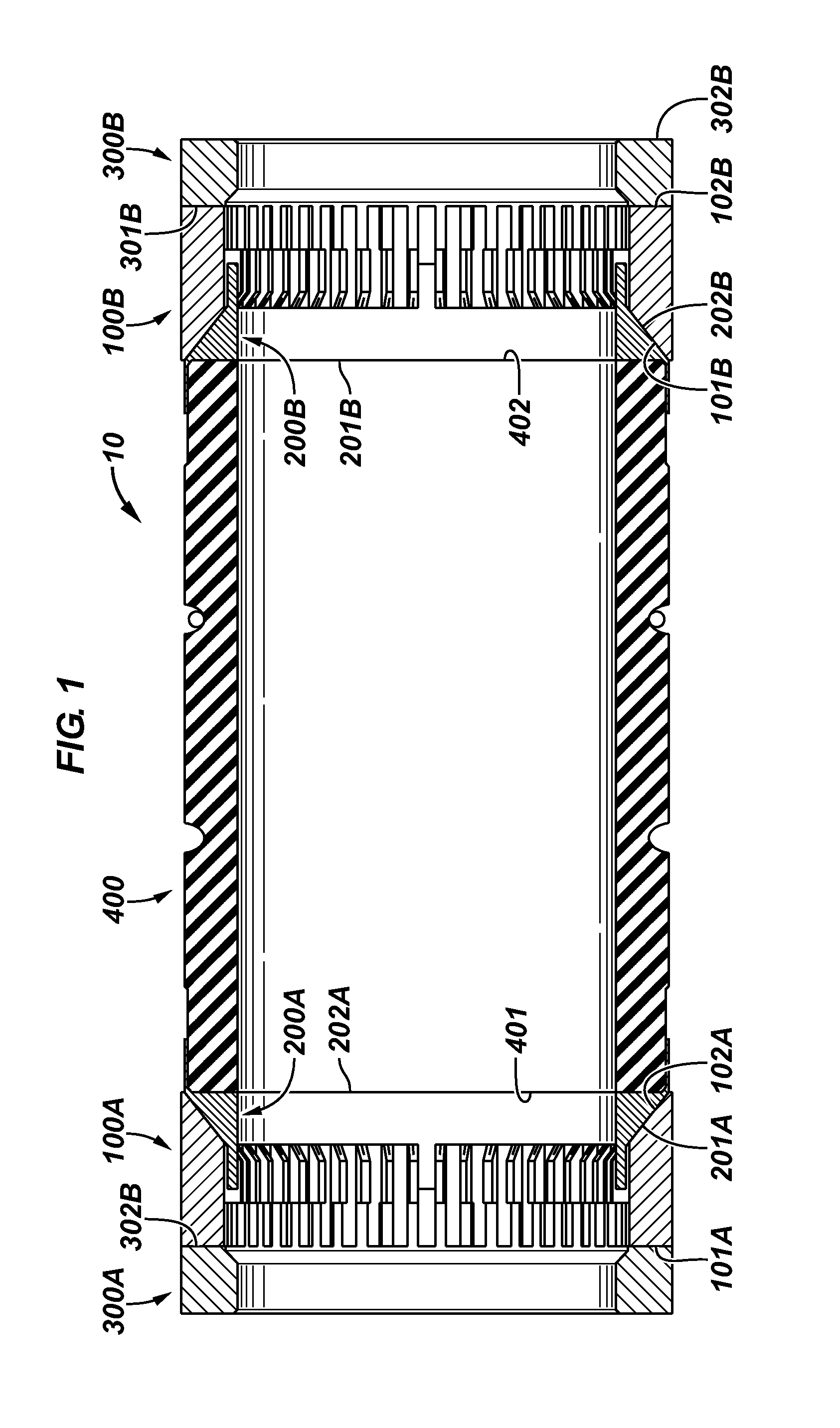

Collet load shoulder

Owner:VETCO GRAY

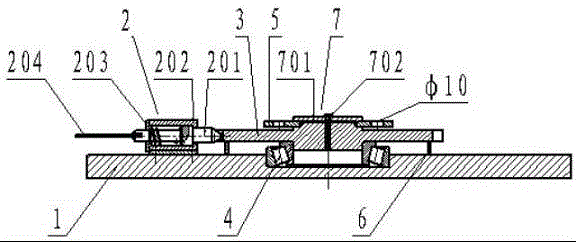

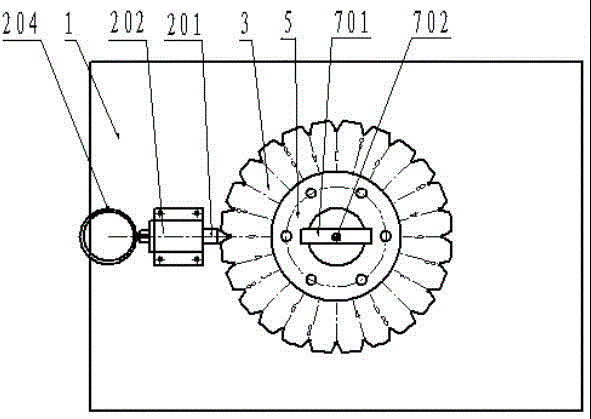

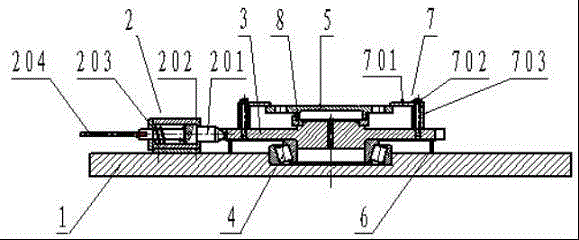

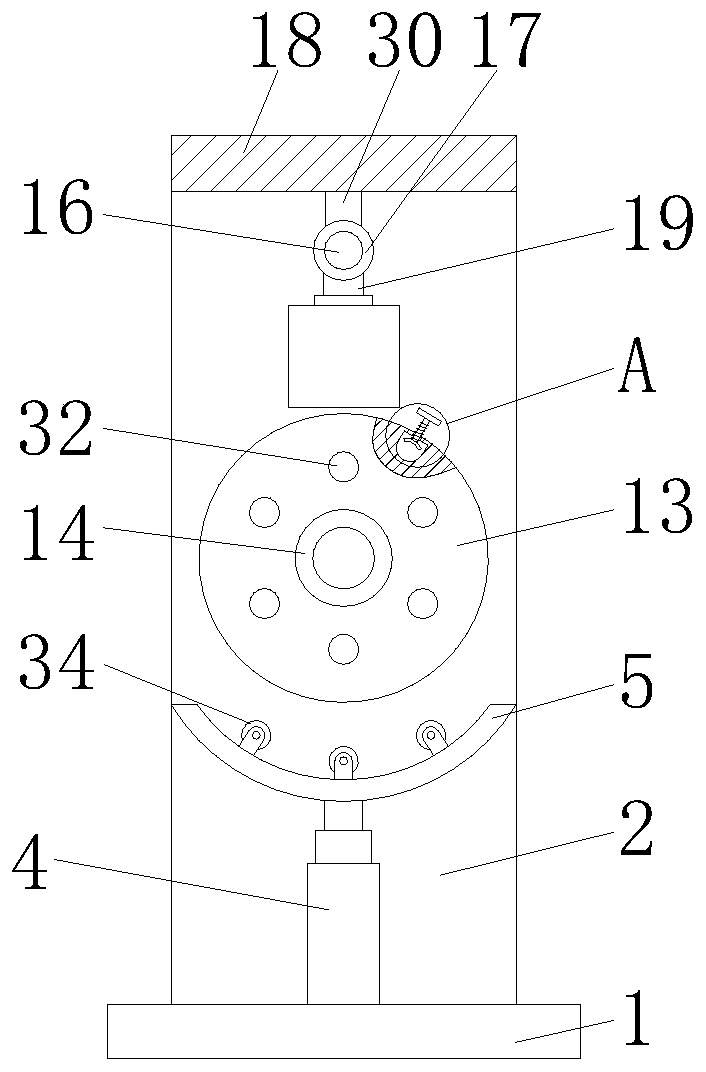

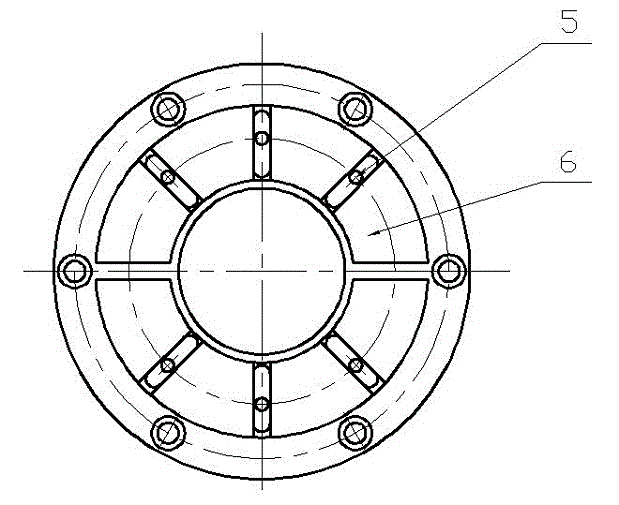

Circumferential drilling hole positioning device for round workpiece

InactiveCN104354017ASimple structureEasy to operatePrecision positioning equipmentPositioning apparatusButt jointClassical mechanics

The invention discloses a circumferential drilling hole positioning device for a round workpiece. The circumferential drilling hole positioning device comprises a bottom plate, a positioning mechanism, a turntable, a bearing, a pressing mechanism and a support ring, wherein the bearing is arranged in a round groove of the bottom plate in a clamping way, the turntable is annularly clamped and arranged in the bearing, the pressing mechanism is arranged on the turntable, the support ring is arranged under the turntable, the positioning mechanism is arranged on the bottom plate, and the front end of a positioning rod of the positioning mechanism is in butt joint with equant V-shaped notches formed in the outer edge of the turntable. The circumferential drilling hole positioning device has the advantages that a drilling hole can be positioned through directly selecting the V-shaped notch corresponding to a bisectrix marked on the turntable, the line drawing or template manufacturing is not needed, the work efficiency is high, the processing cost is reduced, the universality is good, and the product processing precision is high.

Owner:XINYU IRON & STEEL CO LTD

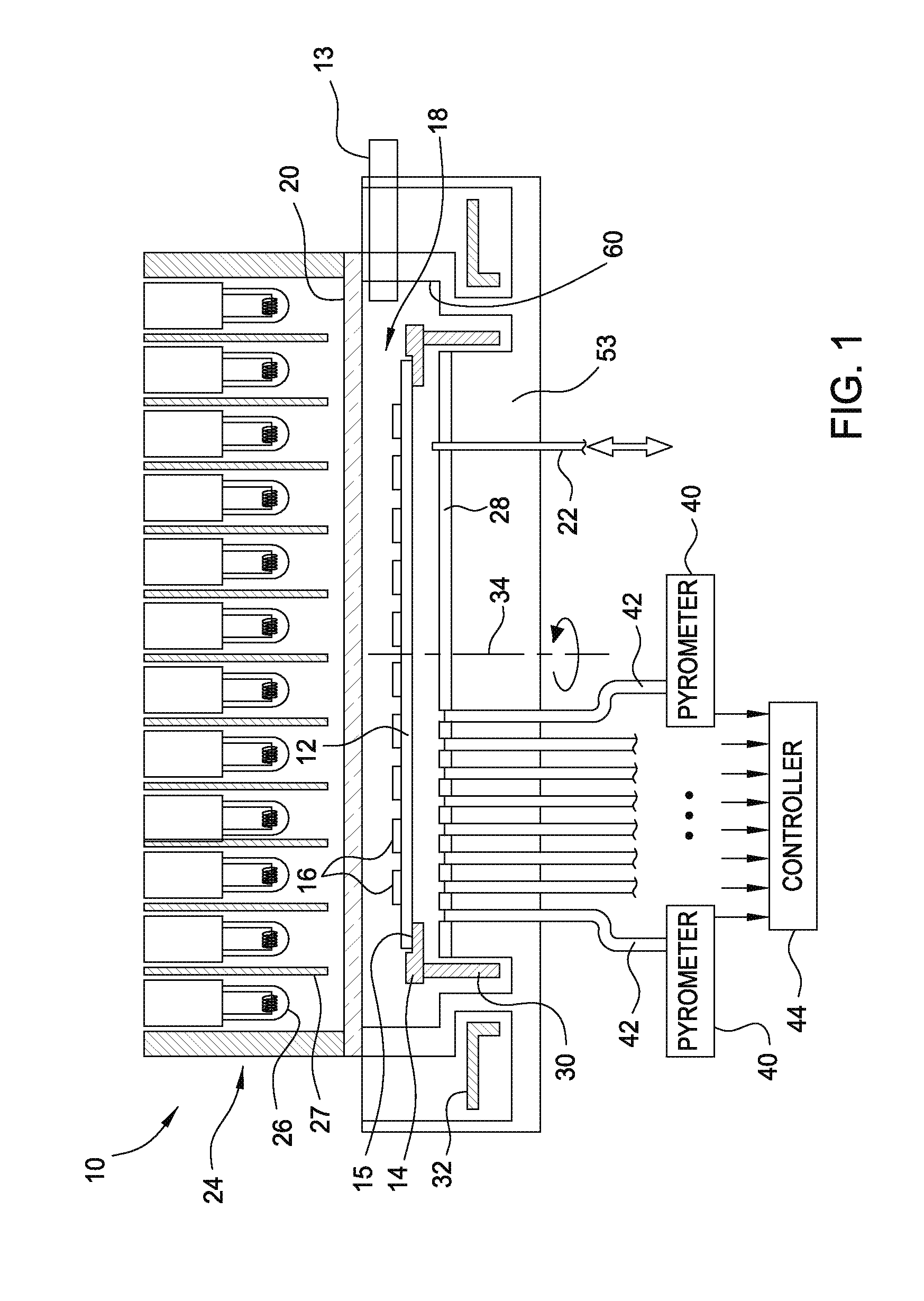

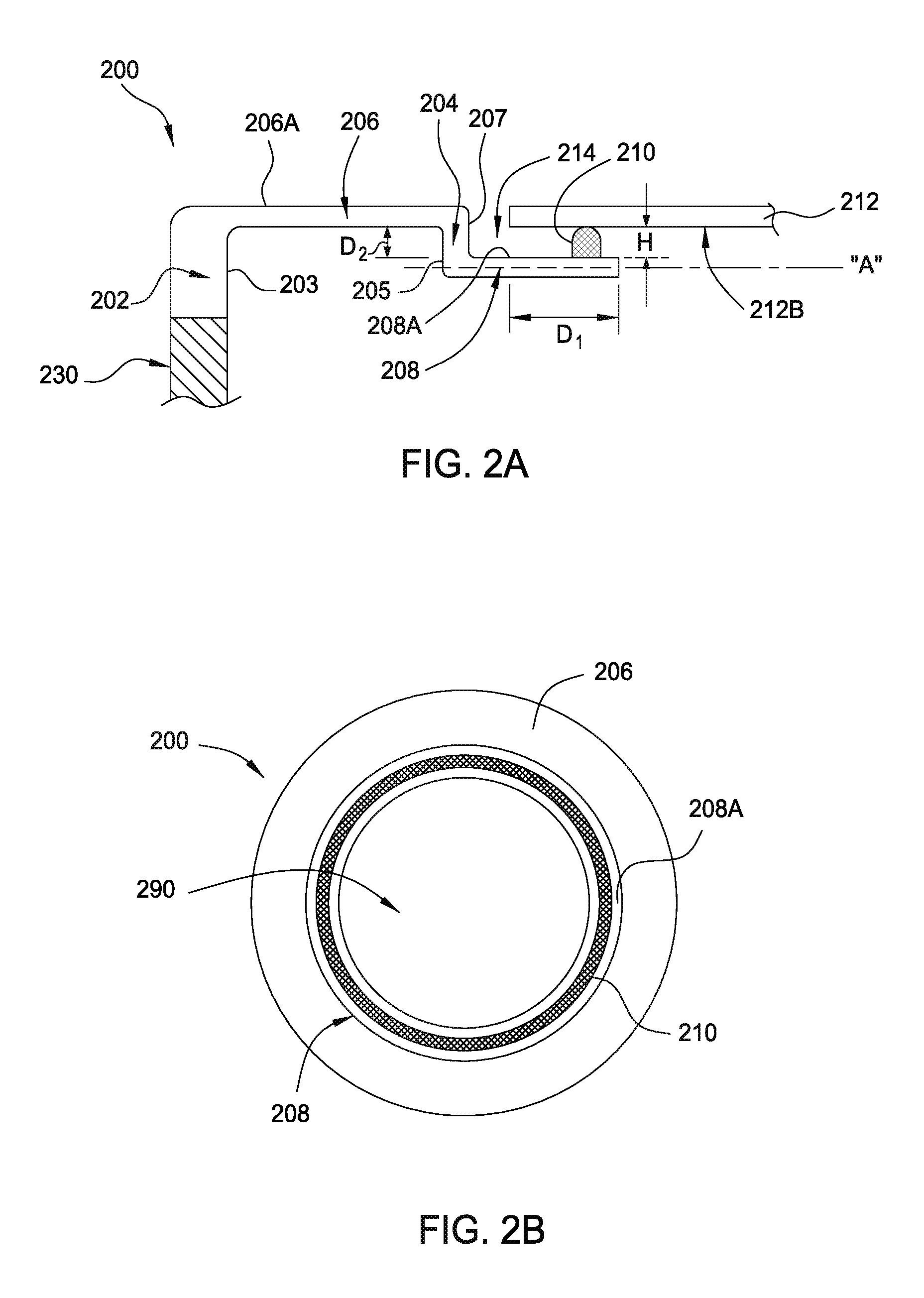

Minimal contact edge ring for rapid thermal processing

ActiveUS20140113458A1Reduce contact areaIncreasing temperature profileSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:APPLIED MATERIALS INC

Anti-extrusion backup system, packing element system having backup system, and method

ActiveUS8479809B2Avoid squeezingSleeve/socket jointsFluid pressure sealed jointsBack-up ringBiomedical engineering

An antiextrusion backup system includes an inner expandable backup ring having a first set of slots. An outer expandable backup ring having a second set of slots wherein the outer expandable back up ring is rotationally locked to the inner expandable backup ring to prevent an extrusion gap in an expanded condition of the backup rings. A method for operating within a tubular is also included.

Owner:BAKER HUGHES HLDG LLC

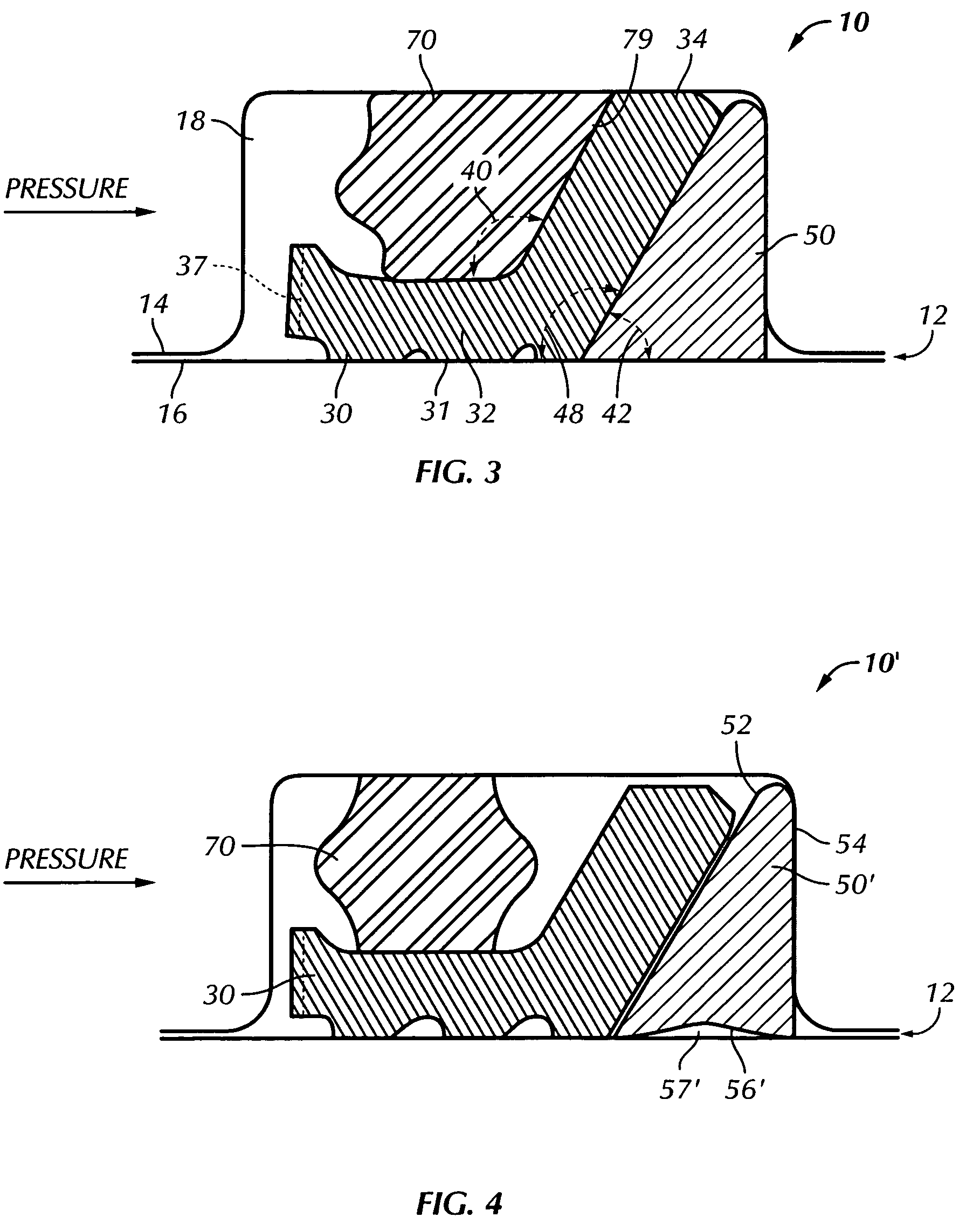

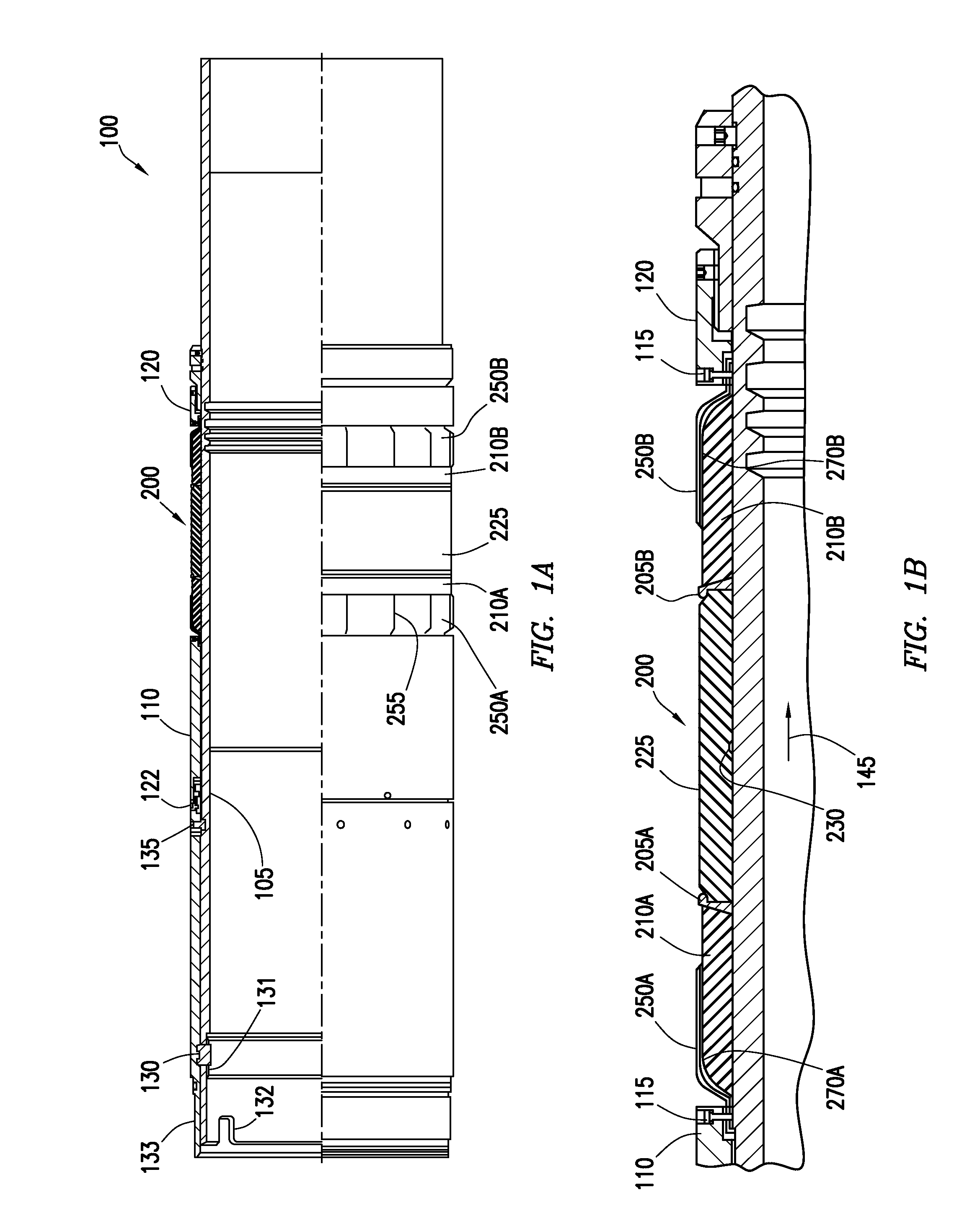

Big gap element sealing system

ActiveUS20140290946A1Sleeve/socket jointsFluid pressure sealed jointsMechanical engineeringBack-up ring

A sealing system includes a packing element having a groove in a surface thereof. The packing element is adapted to form a double hump configuration upon compression. The sealing system may include a first ring member disposed a first end of the packing element, a second ring member is disposed at a second end of the packing element, a first seal ring is disposed laterally outward of the first ring member, and a second seal ring is disposed laterally outward of the second ring member. A first inner back-up ring is disposed laterally outward of the first seal ring. The first inner back-up ring includes slots. A first outer back-up ring is disposed adjacent the first inner back-up ring and includes slots, wherein that slots in the first outer back-up ring are offset from the slots in the first inner back-up ring.

Owner:WEATHERFORD TECH HLDG LLC

Differential pressure instrument support manifold having rotary mode selection system

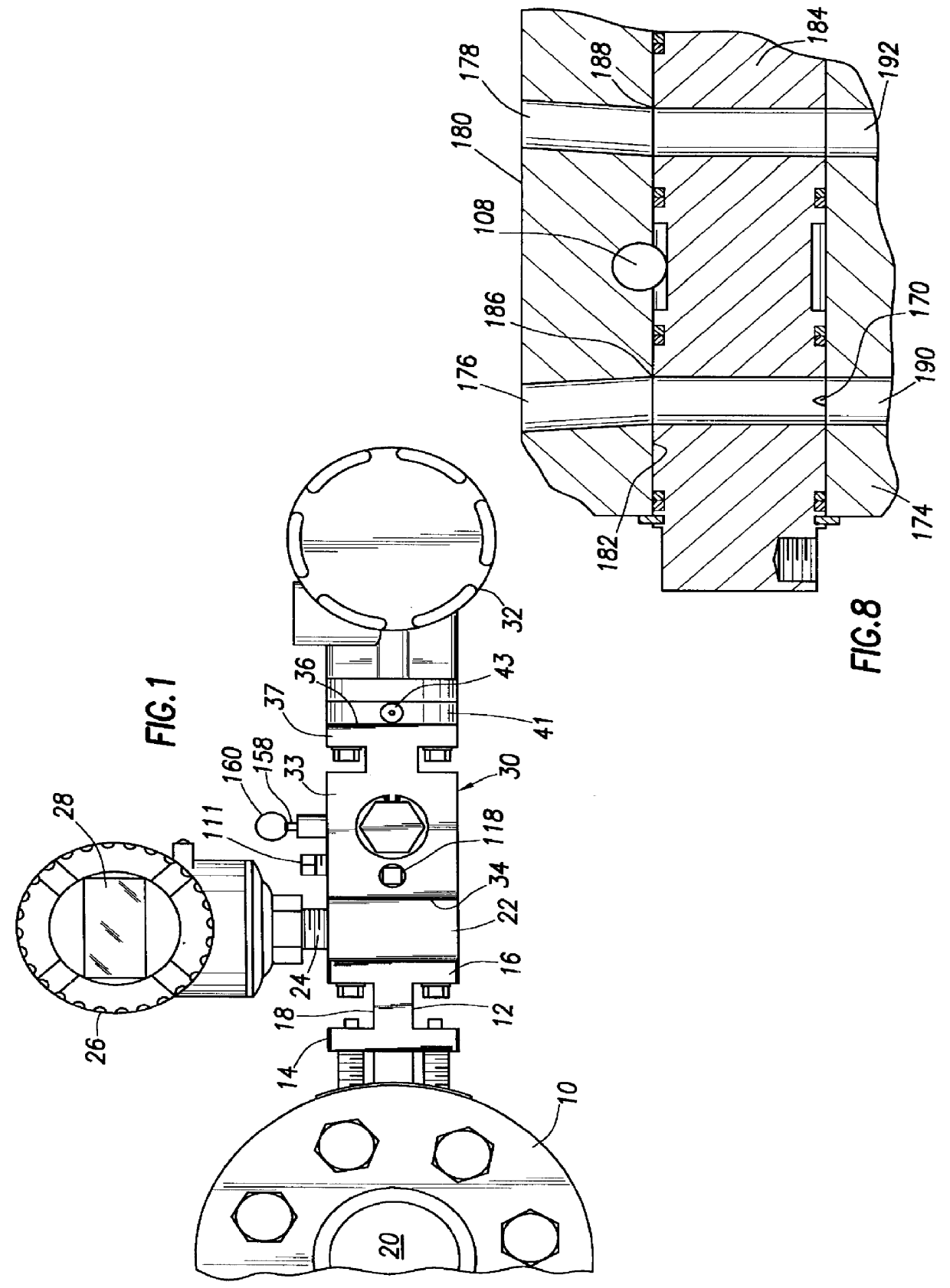

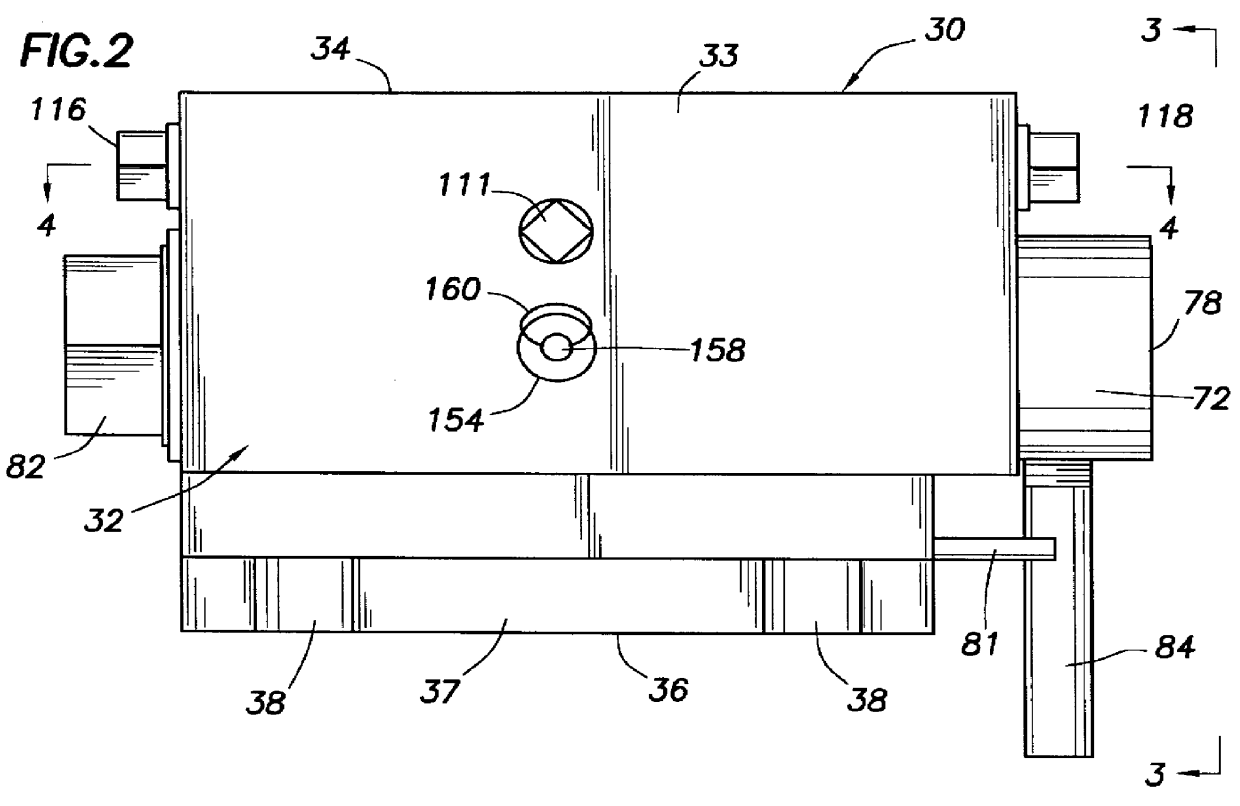

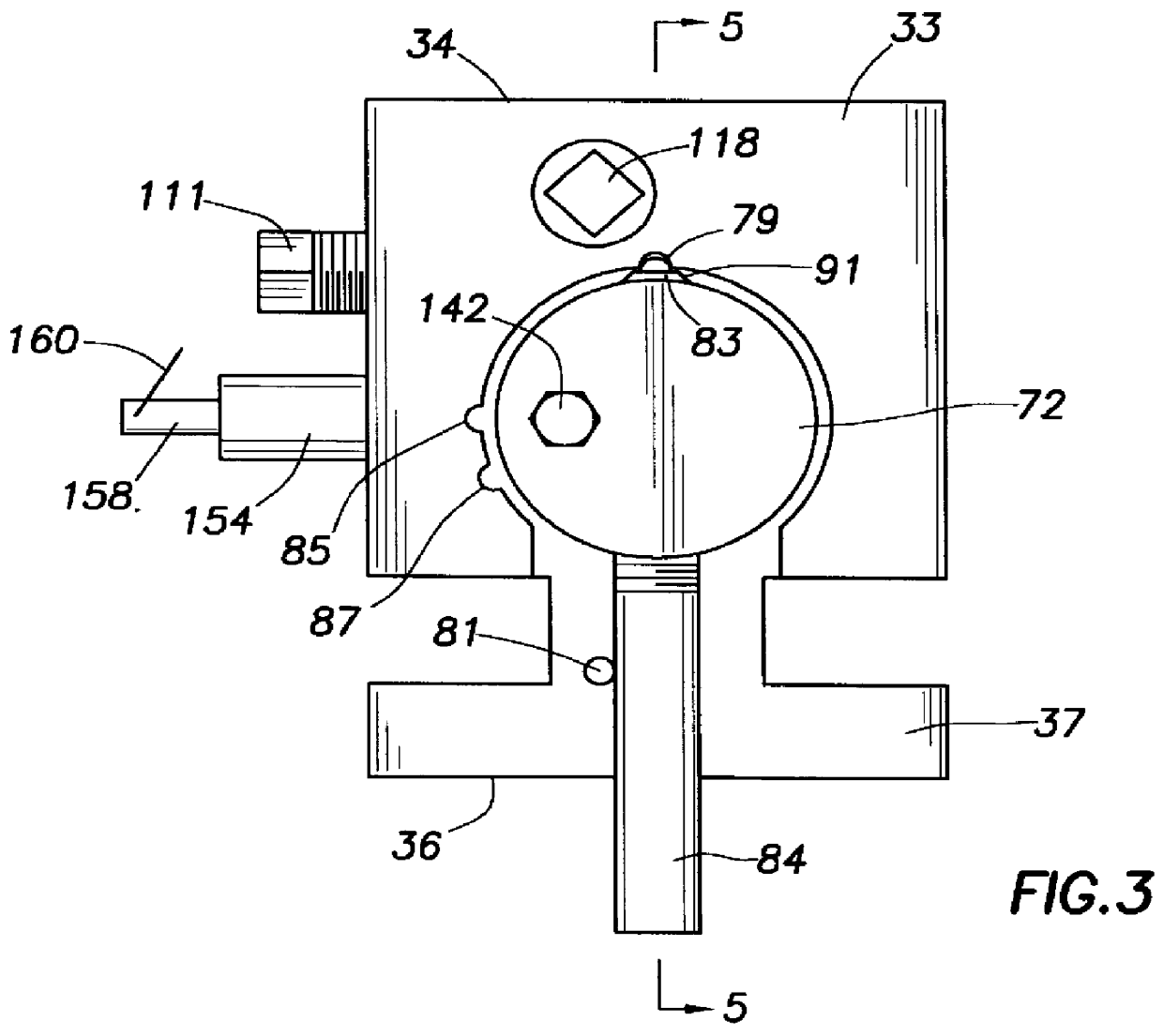

InactiveUS6035724AHarming technician and environmentEliminate dischargeFluid pressure measurement by mechanical elementsDifferential pressureSelection system

A spool type differential pressure transmitter support and valving manifold having a manifold body defining a process face and a transmitter face and having a generally cylindrical internal surface defining an open ended spool chamber and having signal inlet and outlet passages intersecting the process and transmitter faces and being in communication with the spool chamber. The manifold body also defines a vent passage which is in communication with said spool chamber. A spool member is positioned for rotation to "run", "zero" and "off" positions within the spool chamber, has ends extending from the open ends of the spool chamber and has a pair of transversely oriented body passages positioned for selective registry with the signal inlet and outlet passages at the "run" position of the spool member. Circumferential seals each preferably comprising an O-ring and a back-up ring establish sealing between the spool member and the manifold body and serve to isolate the signal passages from one another and to prevent leakage of signal pressure at the open ends of the spool chamber. A plurality of mode seal elements are carried by the outer periphery of the spool member and provide for manifold mode selection to the "run", "zero" and "off" positions responsive to rotational positioning of said spool member relative to said manifold body to permit calibration of the differential pressure transmitter with the pressurized process in operation.

Owner:HEWSON JOHN E

Communication cable winding and protecting device and use method

Owner:西安微城信息科技有限公司

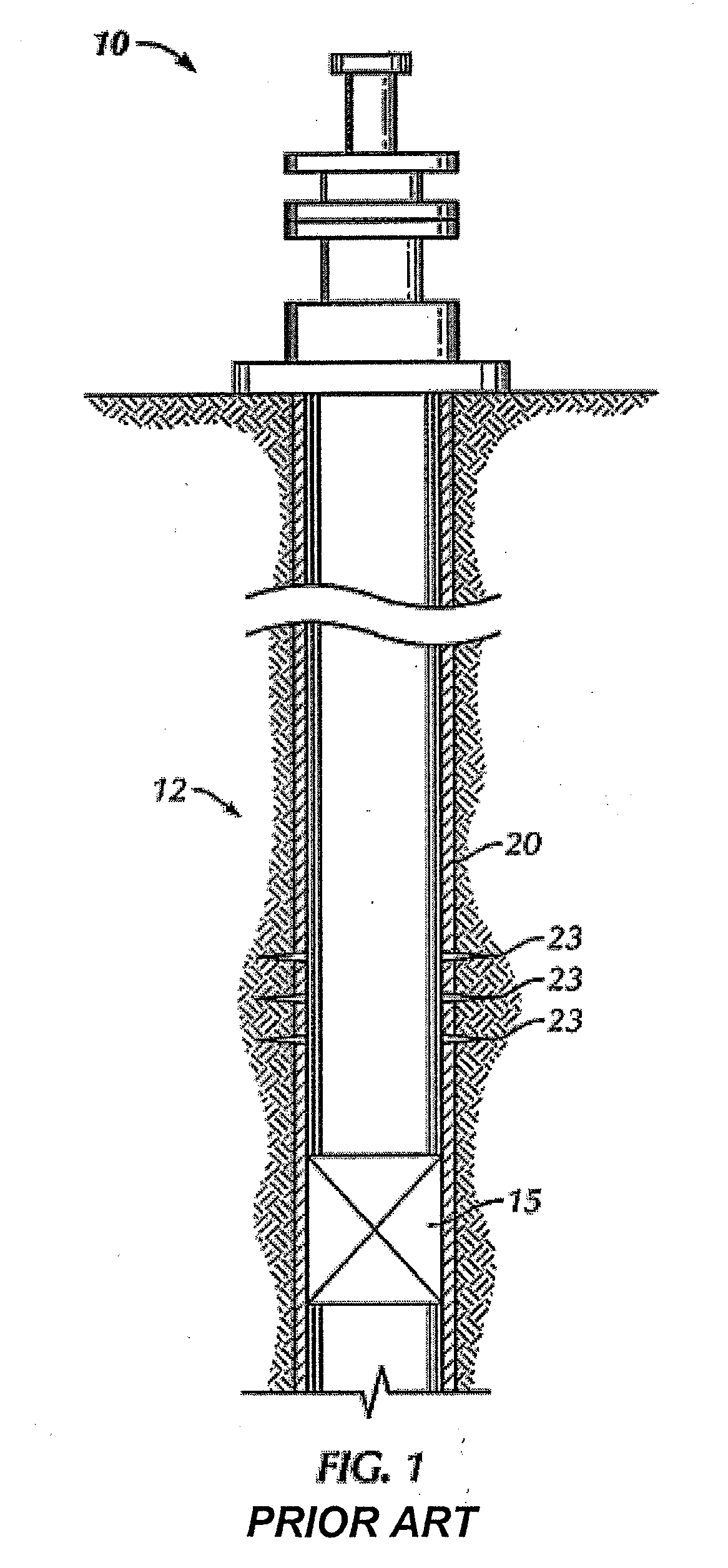

Collet load shoulder

In a subsea wellhead assembly, a collet ring assembly is used with a hanger for suspending a string of conduit in a subsea wellhead assembly. The ring assembly includes a collet that extends around an outer surface of the hanger. The collet has an upper portion that rotates radially between locked and unlocked positions. The ring assembly has a protruding lower portion extending radially outward from the hanger for engaging an interior surface of the wellhead assembly, which causes the upper portion of the collet to rotate radially outward to engage the interior surface of the wellhead assembly in a locked position. The ring assembly includes a back-up ring that engages the interior of the collet, which the collet rotates around between its locked and unlocked positions.

Owner:VETCO GRAY

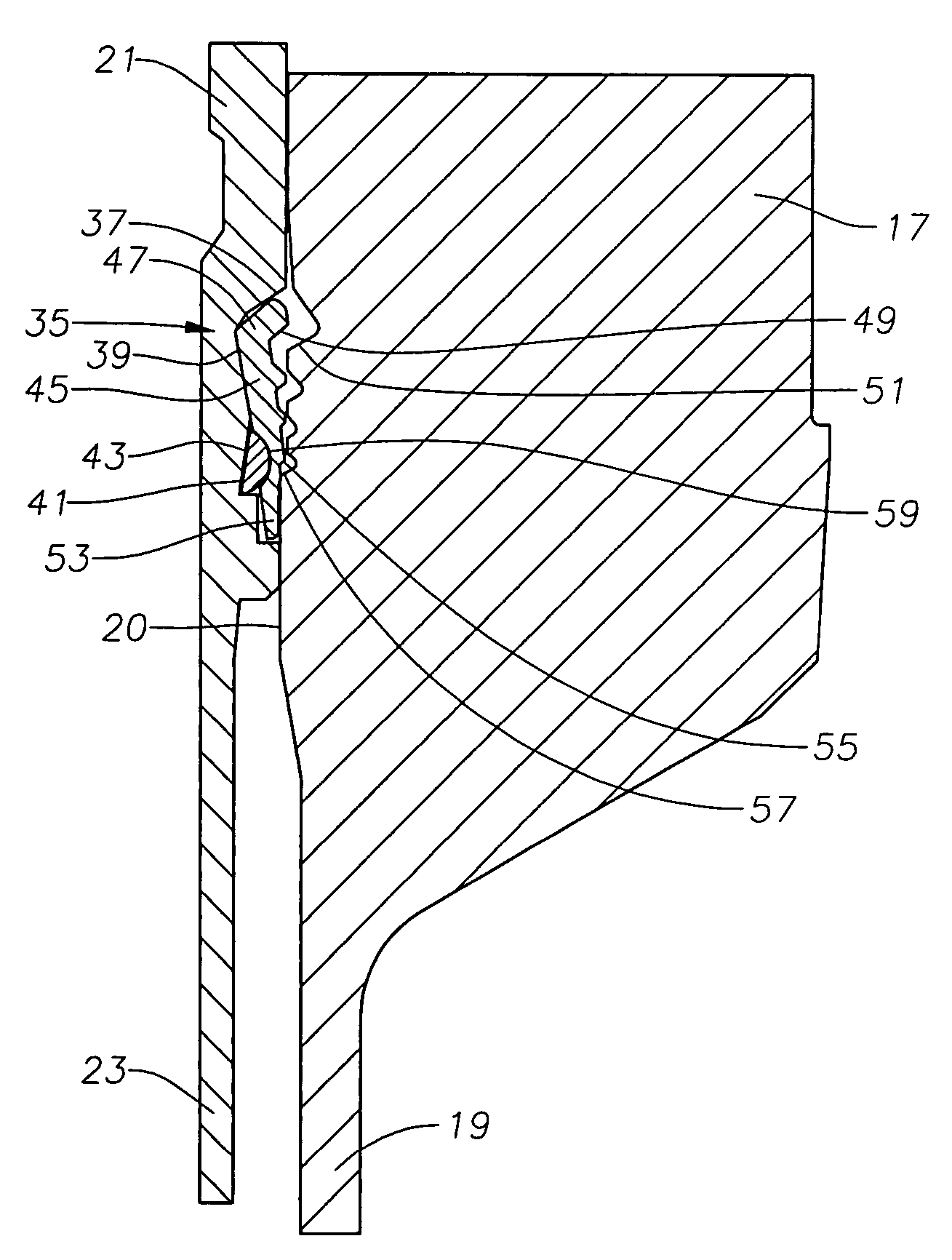

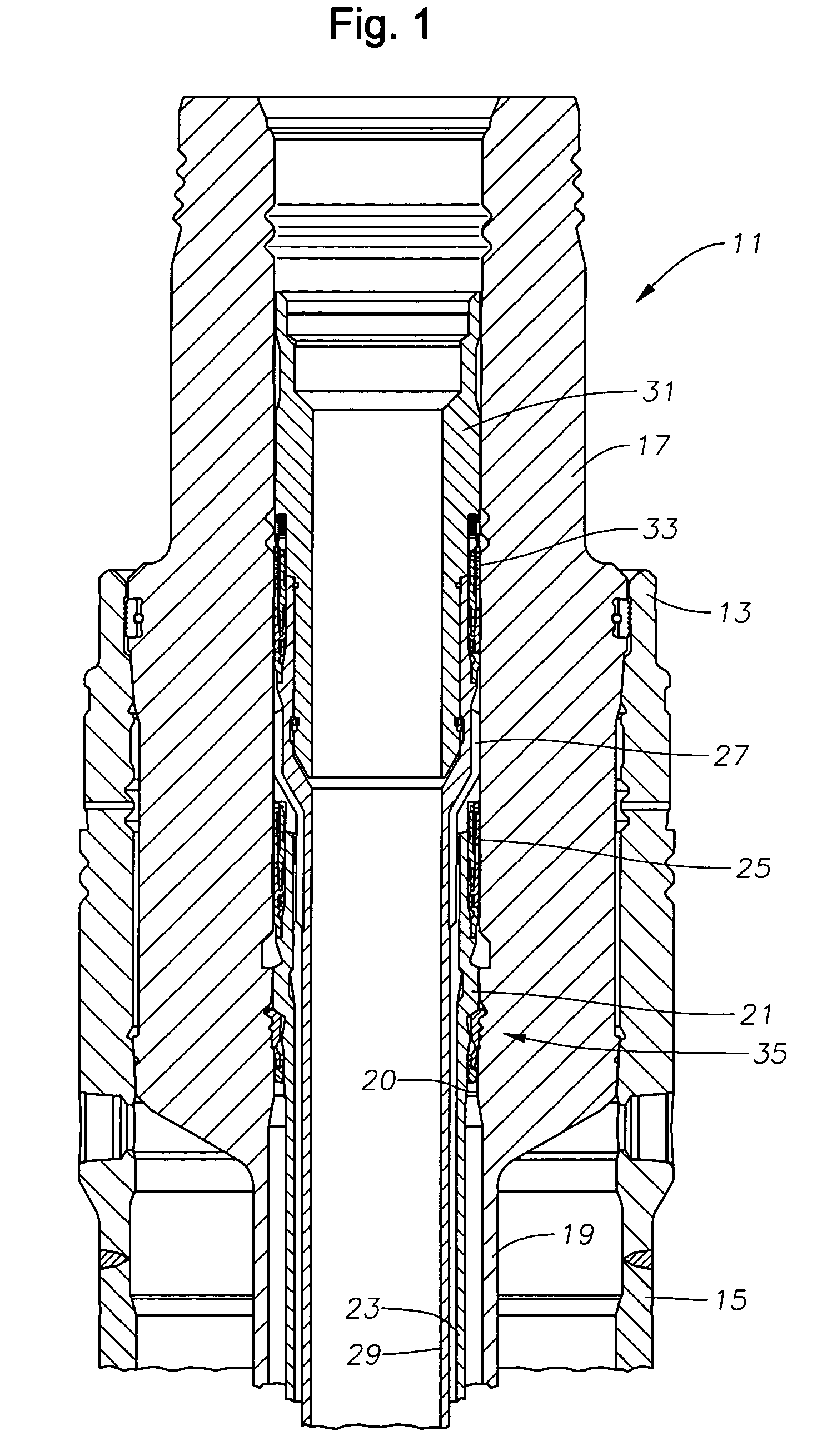

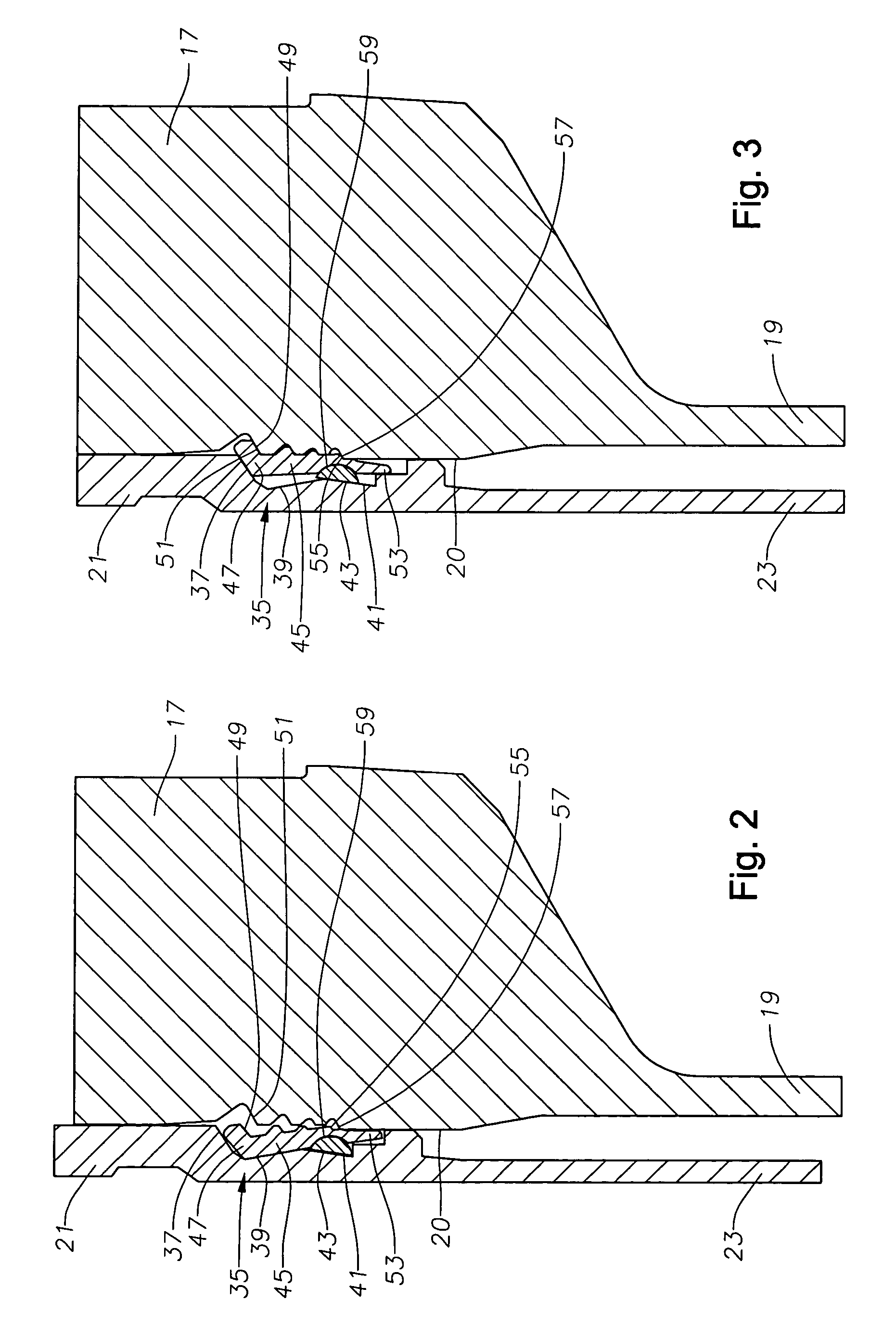

Back-up ring and sealing assembly

A back-up ring for use in a sealing assembly having an annular body with a first face and a second face and defining an axial thickness, the first face being adapted to be engaged by an annular seal ring, a first cut in the first face extending axially inwardly from the first face at an angle of less than 90° but greater than 0° to the first face, a second cut in the second face, the second cut being interconnected to the first cut and being at an angle thereto, the angle of at least a portion of the second cut being 90° or greater but less than 180° to the second face.

Owner:UTEX IND

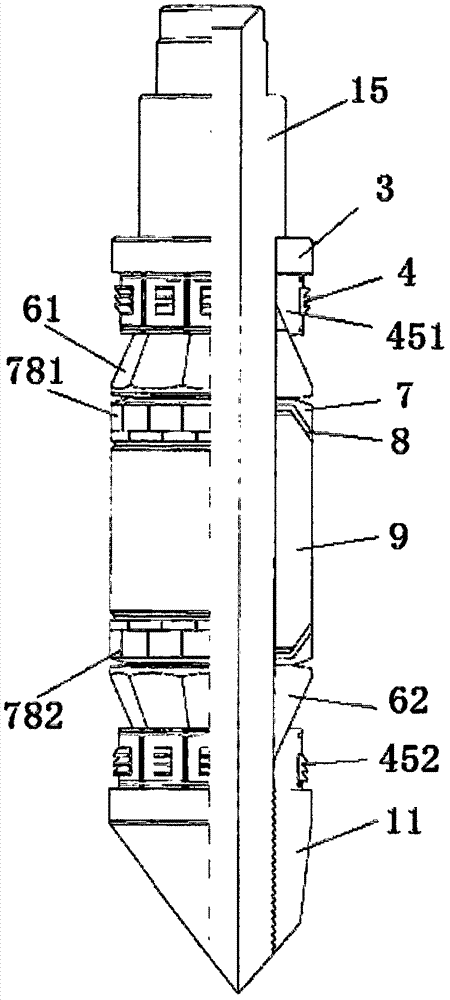

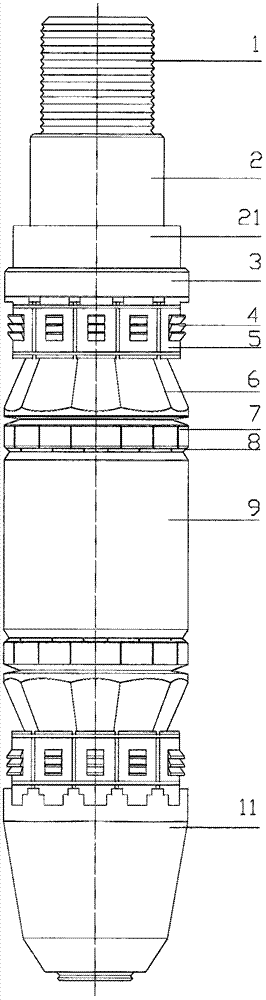

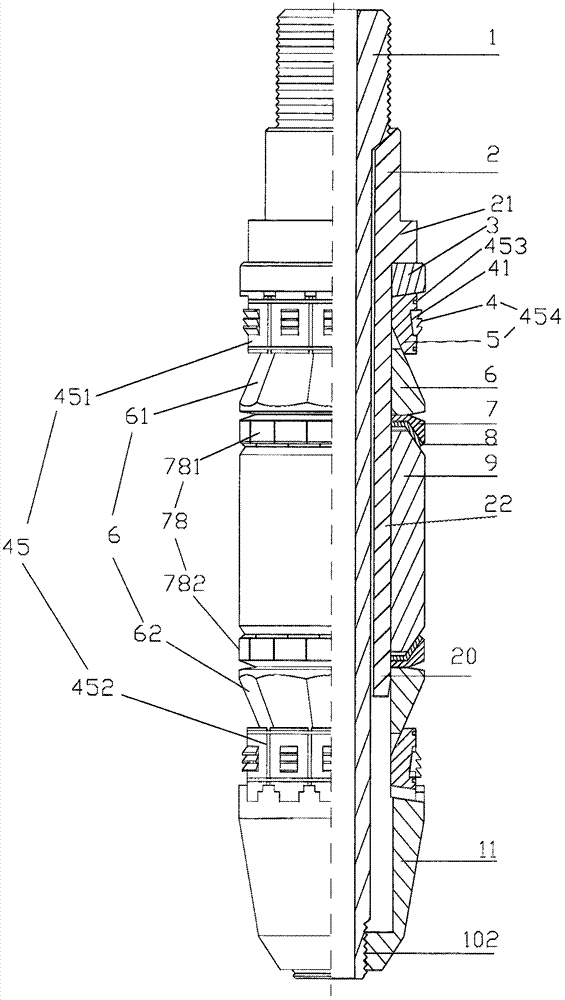

Bidirectional seat seal hook-wall packer, preparation method thereof and shaft circumferential packing method

ActiveCN103184850AImprove reliabilityImprove pressure bearing capacitySealing/packingPistonEngineering

The invention discloses a bidirectional seat seal hook-wall packer, a preparation method thereof and a shaft circumferential packing method. The packer comprises a central tube. The two ends of the central tube are respectively connected with a first joint and a second joint. A first stop collar, a first piston, a first slip, a first cone, a first rubber tube compression ring, a rubber tube, a second rubber tube compression ring, a second cone, a second slip, a second piston and a second stop collar are sequentially sheathed on the central tube from the first joint. A first hydraulic cylinder which is connected with the first joint is sheathed on the external side of the first piston. A first locking slip which is used for preventing the first piston from moving towards the first joint is fixedly arranged on the central tube. A supporting ring is arranged between the central tube and the rubber tube. A second hydraulic cylinder which is connected with the second joint is sheathed on the external side of the second piston. A second locking slip which is used for preventing the second piston from moving towards the second joint is fixedly arranged on the central tube. A first pressure transmission hole and a second pressure transmission hole which respectively correspond to the first piston and the second piston are arranged on the central tube. The packer disclosed by the invention can be reliably anchored.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Hydraulic Brake Master Cylinder with Back-up Ring

Disclosed herein is a hydraulic master cylinder body having a bore defined at least in part by a bore wall, wherein the bore wall includes an opening for hydraulic fluid to be passed into the bore, and a piston assembly situated at least substantially in the bore, the assembly having a piston with a piston body and at least one cup seal situated substantially around the piston body, the cup seal situated adjacent to the bore wall so as to be in sealing engagement therewith, and a back-up ring that is situated about the piston body, wherein the back-up ring is positioned to at least partially cover a portion of the cup seal that is adjacent to the bore wall and to prevent at least a portion of the cup seal from contacting the bore wall and the opening for hydraulic fluid during piston actuation.

Owner:PERFORMANCE SYST

Vane attachment arrangement

Owner:PRATT & WHITNEY CANADA CORP

Dual energized hydroseal

Owner:PROSERV OFFSHORE INC +1

Welding tool and welding method

ActiveCN111037204AEasy to assemble and disassembleImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSpot welding

The invention discloses a welding tool which comprises a positioning assembly, an inner supporting assembly and an outer restraining assembly. The positioning assembly comprises a positioning shaft and a plurality of positioning discs coaxially fixed on the positioning shaft, and a plurality of positioning discs are used for fixing a plurality of end frames; the outer restraining assembly comprises a plurality of outer clamping rings which are used for clamping the joint part of the end frames and the skin, and spot welding grooves used for exposing the joint part are arranged in the outer clamping rings; the inner supporting assembly comprises an inner supporting disc and an inner supporting ring. The inner supporting ring is detachable and is used for internally supporting a seam part atthe rearmost end of the metal shell; and the inner supporting disc is used for supporting the joint part in the metal shell. The tool can be used for continuously welding the seam part without usingmultiple sets of welding tools for multiple times of welding in the prior art, the welded metal shell is convenient to disassemble and assemble through the detachable outer clamping ring and the innersupporting ring and thus the welding efficiency is remarkably improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

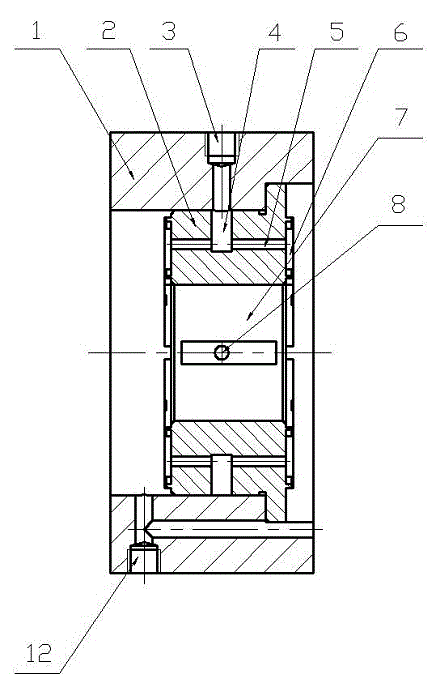

Center shaft for bridge plug, bridge plug and seat sealing method for bridge plug

The invention discloses a center shaft for a bridge plug, a bridge plug and seat sealing for the bridge plug and relates to the technical field of engineering machinery. A technical problem that bridge plugs with large internal drift diameter cannot be made of degradable plastics and degradable metal material in the prior art can be solved. The center shaft for the bridge plug comprises a seat sealing dabber and a seat sealing pipe shaft, wherein the seat sealing pipe shaft is formed by an extrusion shoulder and a bearing trunk; the extrusion shoulder extrude a press ring of the bridge plug or a reducing supporting ring of the bridge plug; after a connection between the seat sealing dabber and a downstream end supporting body is removed, the seat sealing dabber can be extracted out of the center hole of the seat sealing dabber, so the center hole of the seat sealing dabber can form an internal fluid channel for the bridge plug; the strength of the material of the seat sealing dabber is greater than the strength of degradable material or corrosive material; and the material of the seat sealing dabber is degradable or corrosive material. The bridge plug comprises the center shaft for the bridge plug. Internal drift diameter of the bridge plug can be expanded; sealing effect of the bridge plug can be enhanced; and anchoring performance and construction convenience can be improved.

Owner:陈爱民

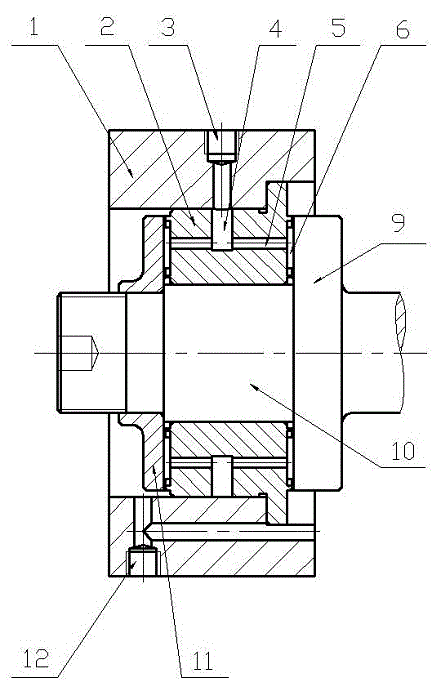

Radially and axially integrated sliding bearing

InactiveCN103335017AOutstanding FeaturesHighlight significant progressSliding contact bearingsBack-up ringAxial load

The invention relates to a radially and axially integrated sliding bearing. The sliding bearing comprises a bearing pedestal, a bearing shell, an oil inlet port, a circumferential oil inlet groove, a thrust bearing oil inlet port, a thrust bearing shell, a radial bearing shell, a radial bearing oil inlet port, a bearing shoulder, a rotating shaft, a back-up ring and an oil outlet port. When the bearing is running, lubricating oil is injected into the circumferential oil inlet groove of the bearing shell through the oil inlet port; then part of the lubricating oil enters into a gap between the rotating shaft and the radial bearing shell through the radial bearing oil inlet port, and an oil membrane is formed as the rotating shaft rotates, and the oil membrane is used for bearing radial load; meanwhile, another part of the lubricating oil enters into a gap among the thrust bearing shell, the bearing shoulder and the back-up ring through the thrust bearing oil inlet port, and an oil membrane is formed as the bearing shell and the back-up ring rotate, and the oil membrane is used for bearing bidirectional axial load. The radially and axially integrated sliding bearing is capable of bearing both radial load and bidirectional axial load.

Owner:SHANGHAI UNIV

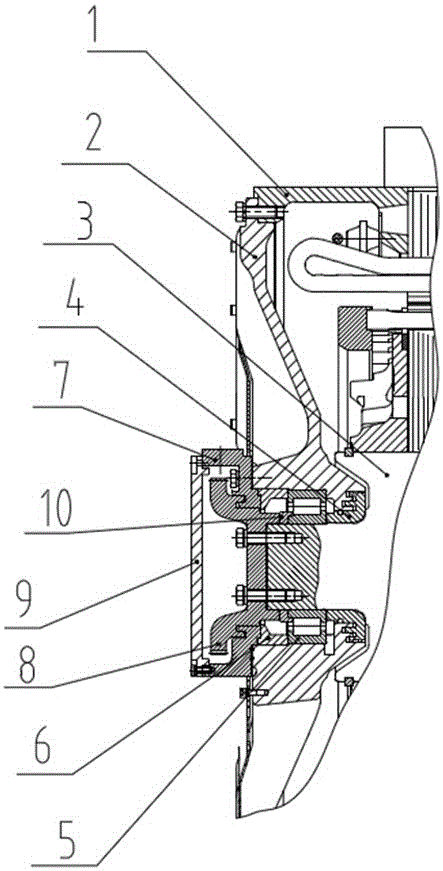

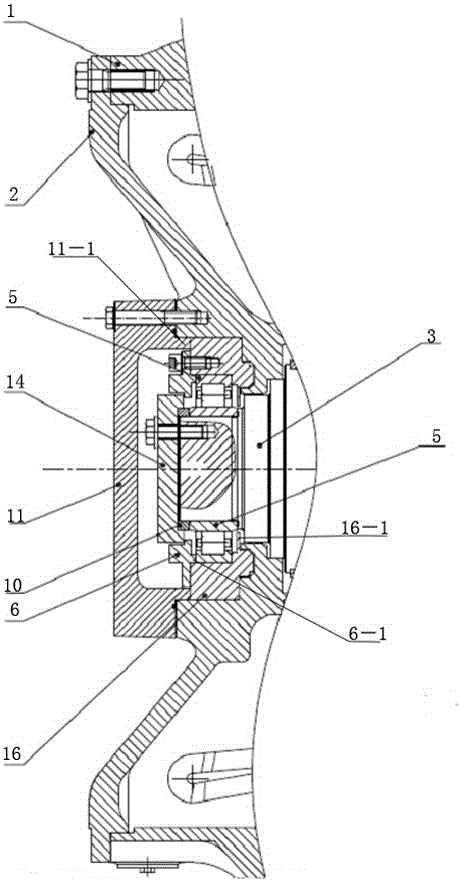

Traction motor capable of online replacement of bearing

ActiveCN106169829AImprove punctualityIncrease profitManufacturing dynamo-electric machinesSupports/enclosures/casingsInterference fitEngineering

The invention relates to a traction motor and specifically relates to a traction motor capable of online replacement of a bearing, for solving the problem of incapability of online replacement of a bearing by use of a conventional locomotive traction motor. The traction motor comprises a support, a non-driving end cover, a rotor, the bearing, a bearing back-up ring and a bearing angular ring, and further comprises a sealing cover, a bearing pedestal and a spindle nose cover plate, wherein the bearing is in interference fit with a bearing hole of a bearing pedestal, the bearing pedestal is in transition fit with the non-driving end cover, and the bearing angular ring is in interference fit with a rotor shaft; the bearing back-up ring is in contact with an outer ring of the bearing and is fixed to the bearing pedestal by use of a bolt, and the spindle nose cover plate is fixed to the end surface of the rotor shaft; the sealing cover and the end cover are in interference fit and are fixed by use of a bolt; and the sealing cover, the spindle nose cover plate, the bearing back-up ring and the bearing pedestal are provided with screw holes. According to the invention, the function of online replacement of the bearing without unloading can be realized, the maintenance time and the maintenance cost of a fault locomotive traction motor are greatly reduced, and the punctuality rate and the utilization rate of locomotive operation are improved.

Owner:CRRC YONGJI ELECTRIC CO LTD

Adjustable hanger for inner production riser

A string of conduit extending from a subsea wellhead assembly to a surface wellhead assembly on a platform has a plurality of grooved profiles on an upper portion of the conduit. Each profile is spaced axially from another of the grooved profiles. After a lower end of the conduit is secured to the subsea wellhead assembly, the operator pulls on the conduit to apply a selected tension to the conduit. The operator attaches a support ring to the profile that was closest to and above a load shoulder in the surface wellhead assembly when the desired tension was reached. After landing the support ring on the load shoulder, the operator may cut off any excess portion of the upper portion of the conduit located above the support ring. A seal ring is set between the upper portion of the conduit and the surface wellhead housing.

Owner:VETCO GRAY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com