Center shaft for bridge plug, bridge plug and seat sealing method for bridge plug

A central shaft and bridge plug technology, applied in the field of construction machinery, can solve the problems of inability to make inner diameters and bridge plugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

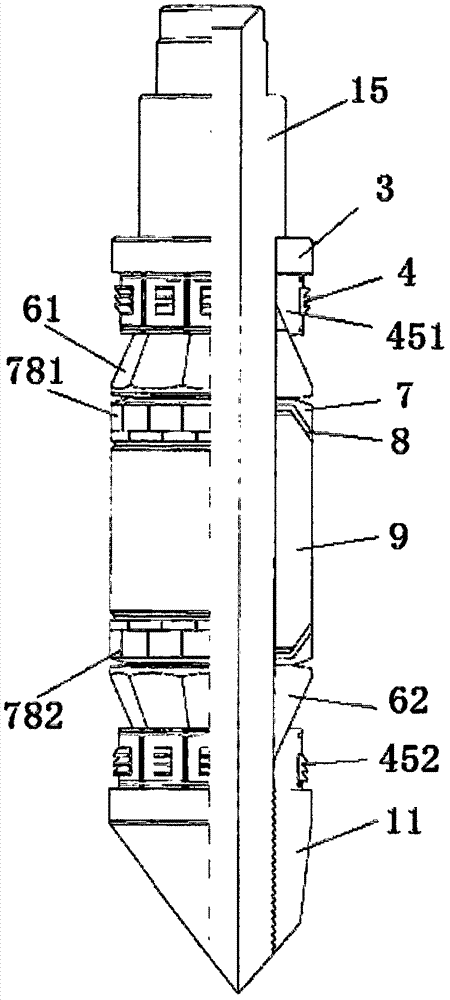

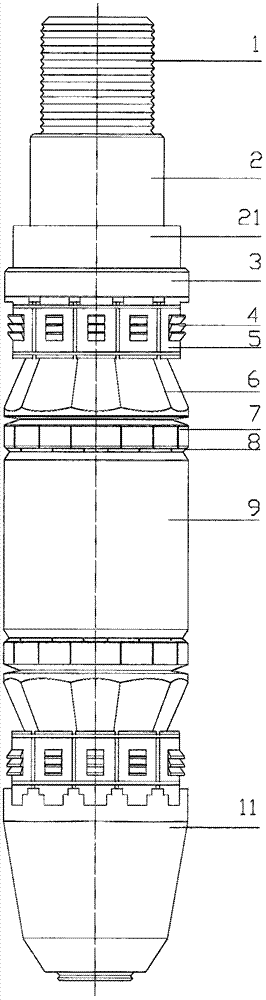

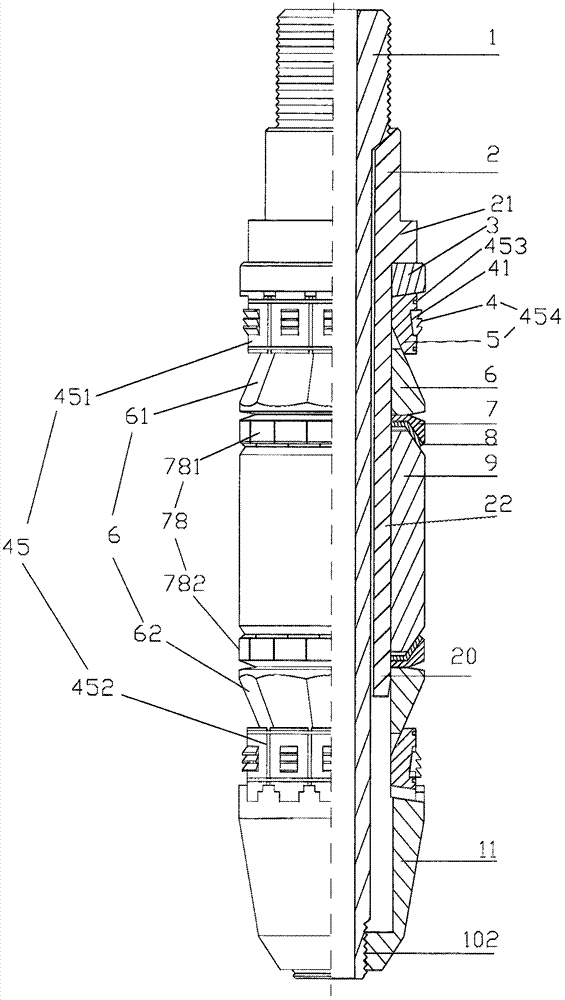

[0082] Below you can refer to the accompanying drawings Figure 1 to Figure 21 And the content of the text to understand the content of the present invention and the differences between the present invention and the prior art.

[0083] The embodiment of the present invention provides a bridge plug with the advantages of large internal diameter, stable plugging effect, good anchoring reliability, no midway setting problem, good degradable performance, no need for drilling plugs, and convenient construction. The central axis of the bridge plug, the bridge plug using the central axis and the setting method of the bridge plug.

[0084] Such as Figure 2 to Figure 21 As shown, the central shaft for the bridge plug provided by the embodiment of the present invention includes a seating mandrel 1 and a seating tubular shaft 2, wherein:

[0085] There is a central hole in the sealing pipe shaft 2, and the sealing pipe shaft 2 includes an extrusion shoulder 21 and a bearing trunk 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com