Welding tool and welding method

A welding tooling and tooling technology, applied in the field of welding tooling and welding, can solve problems such as low efficiency of welding metal shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

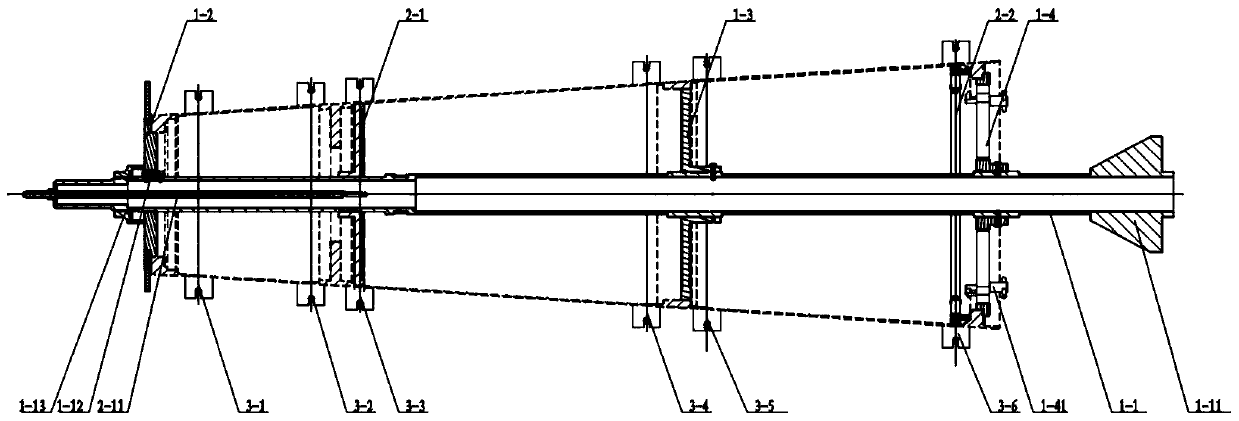

[0044] Such as figure 1 As shown, this embodiment provides a welding tool for welding a metal shell, the metal shell includes a plurality of end frames and a plurality of skins;

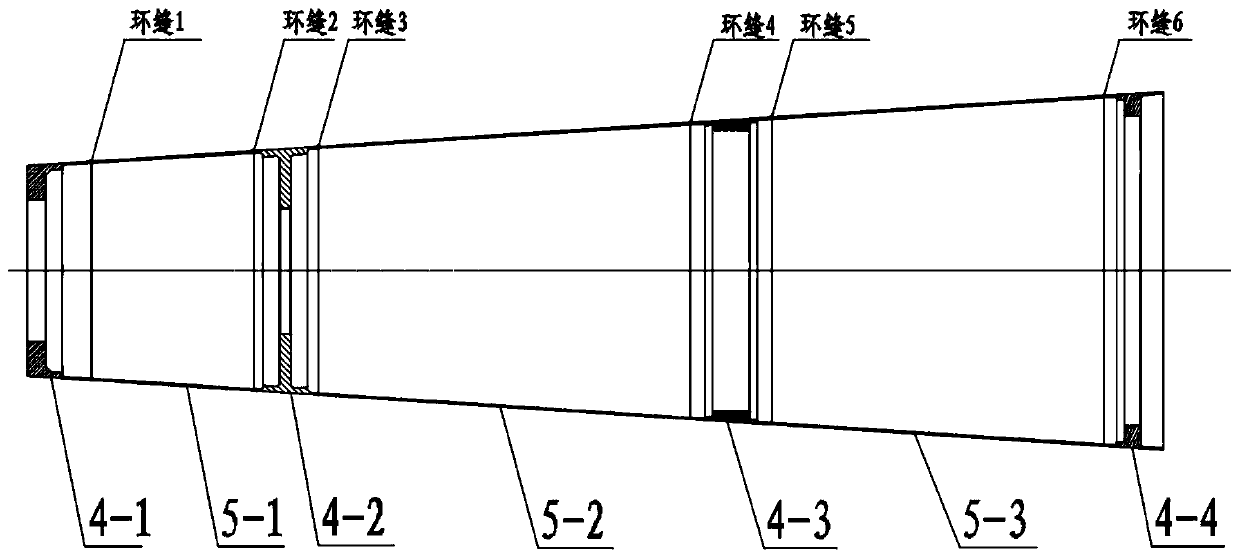

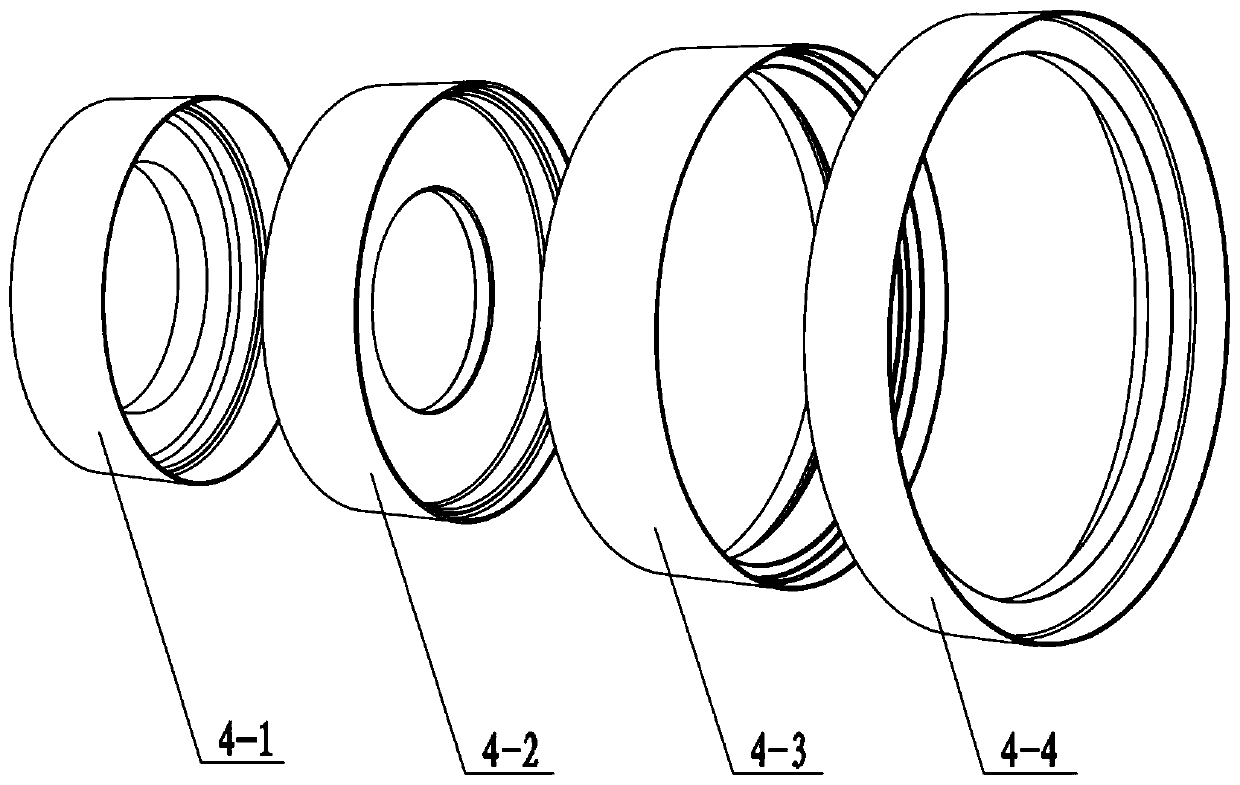

[0045] It should be noted that the metal shell in this embodiment may be a metal shell such as aluminum, iron, copper, or an alloy shell, which is generally welded by multiple end frames and multiple skins. As a typical aluminum alloy shell, see image 3 and Figure 4 , composed of 4 types of end frames + 3 types of skins, a total of 7 parts assembled and welded, including: the first end frame 4-1, the second end frame 4-2, the third end frame 4-3 and the fourth end frame 4-4, and a first skin 5-1, a second skin 5-2 and a third skin 5-3. see figure 2 , involving a total of 6 circular welds (circular seam 1, circular seam 2, circular seam 3, circular seam 4, circular seam 5, circular seam 6, among which, circular seam 1 has the smallest diameter and circular seam 6 has the largest diameter) , th...

Embodiment 2

[0069] Based on the tooling of Embodiment 1, this embodiment provides a welding method for welding a metal shell, the metal shell includes a plurality of end frames and a plurality of skins,

[0070] It should be noted that in practical applications, the outer surface of the aluminum alloy shell as described in Example 1 will be covered with a composite material heat-proof layer, so the requirements for the shape and position tolerance of the shell are relatively strict, and the front and rear end frames of the shell will be It is connected with other compartments, so the requirements for the relative position of the front and rear end frames are relatively strict. These all put forward higher requirements for the quality control of the shell. The existing three-time welding method has a large cumulative error and cannot meet the quality requirements. Require.

[0071] For this, see Figure 8 , the welding method of this implementation, including:

[0072] S101. On the tooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com