Multi-Piece Packing Element Containment System

a technology of containment system and packing element, applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve problems such as sealing failure, and achieve the effect of preventing or minimizing extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

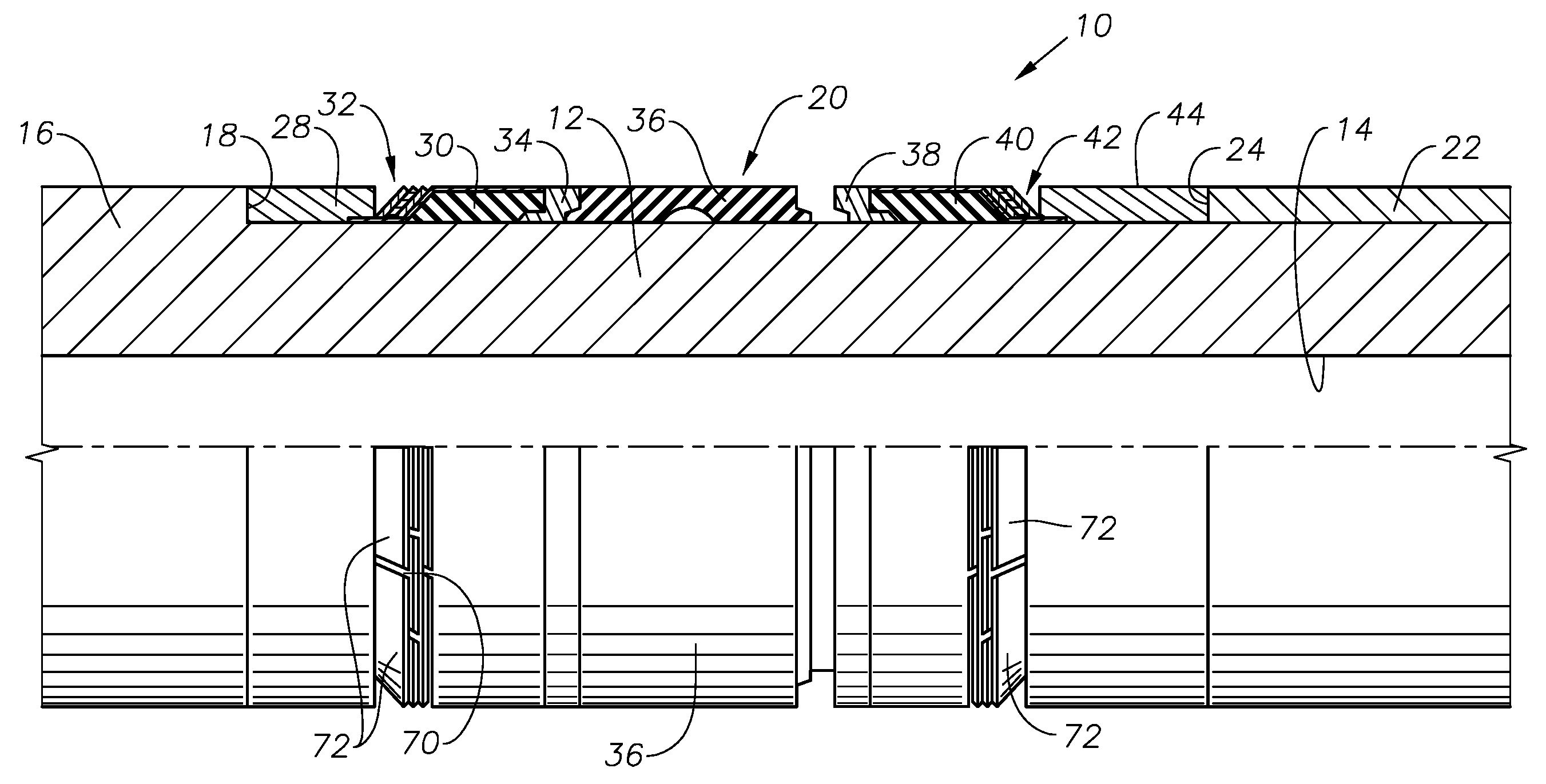

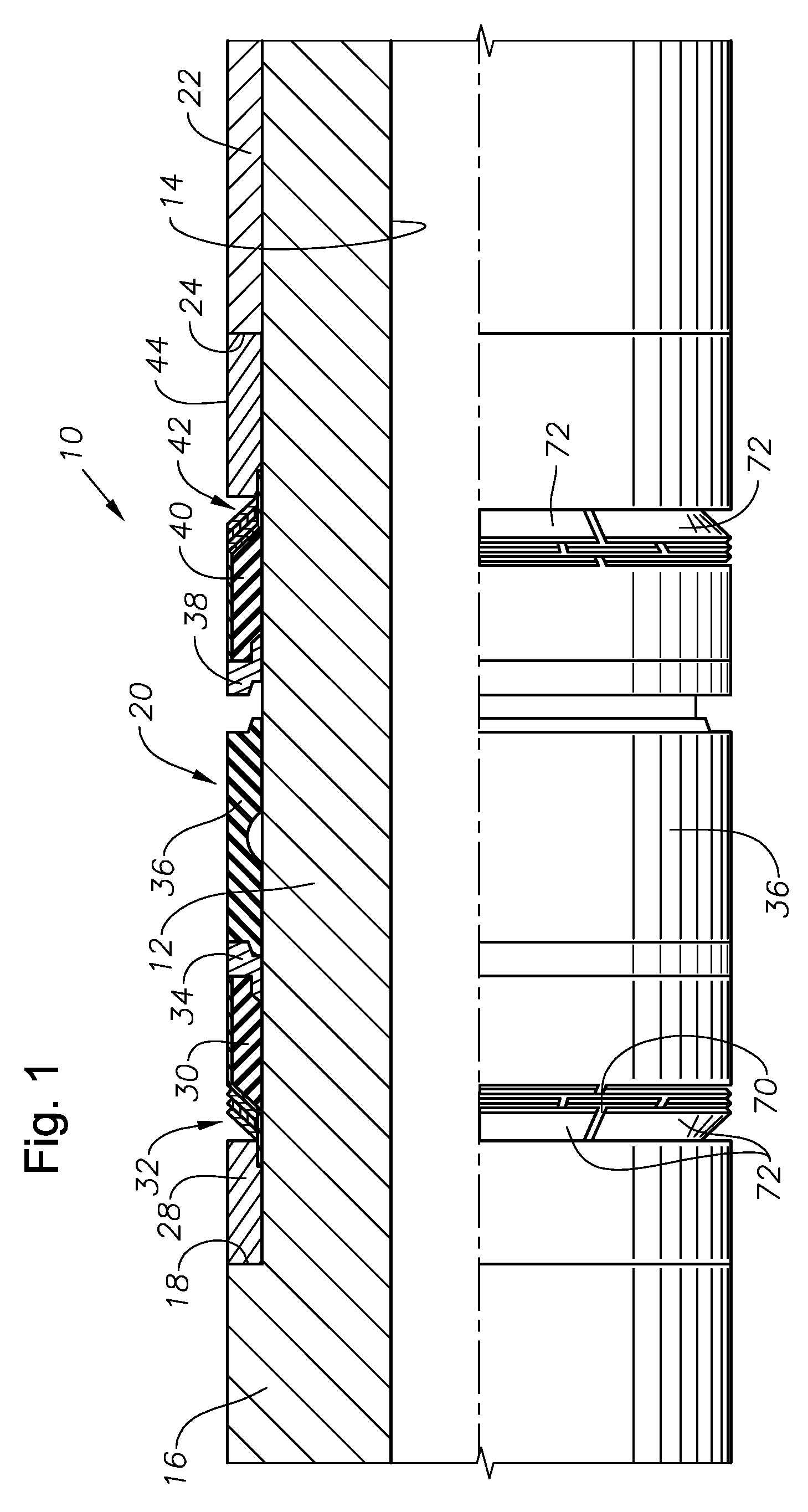

[0015]FIG. 1 illustrates an exemplary packer assembly 10 which includes a central packer mandrel 12. The packer mandrel 12 can be incorporated into a production tubing string or other work string (not shown), in a manner known in the art. A flowbore 14 is defined within the mandrel 12. The outer radial surface of the mandrel 12 has an expanded diameter portion 16 which presents a stop shoulder 18. Radially surrounding the packer mandrel 12 and immediately below the stop shoulder 18 is a packer element portion, generally indicated at 20, the structure of which will be described in greater detail shortly. A setting sleeve 22 radially surrounds the packer mandrel 12 below the packer element portion 20. The setting sleeve 22 is axially moveable with respect to the mandrel 12 and presents a compression end 24.

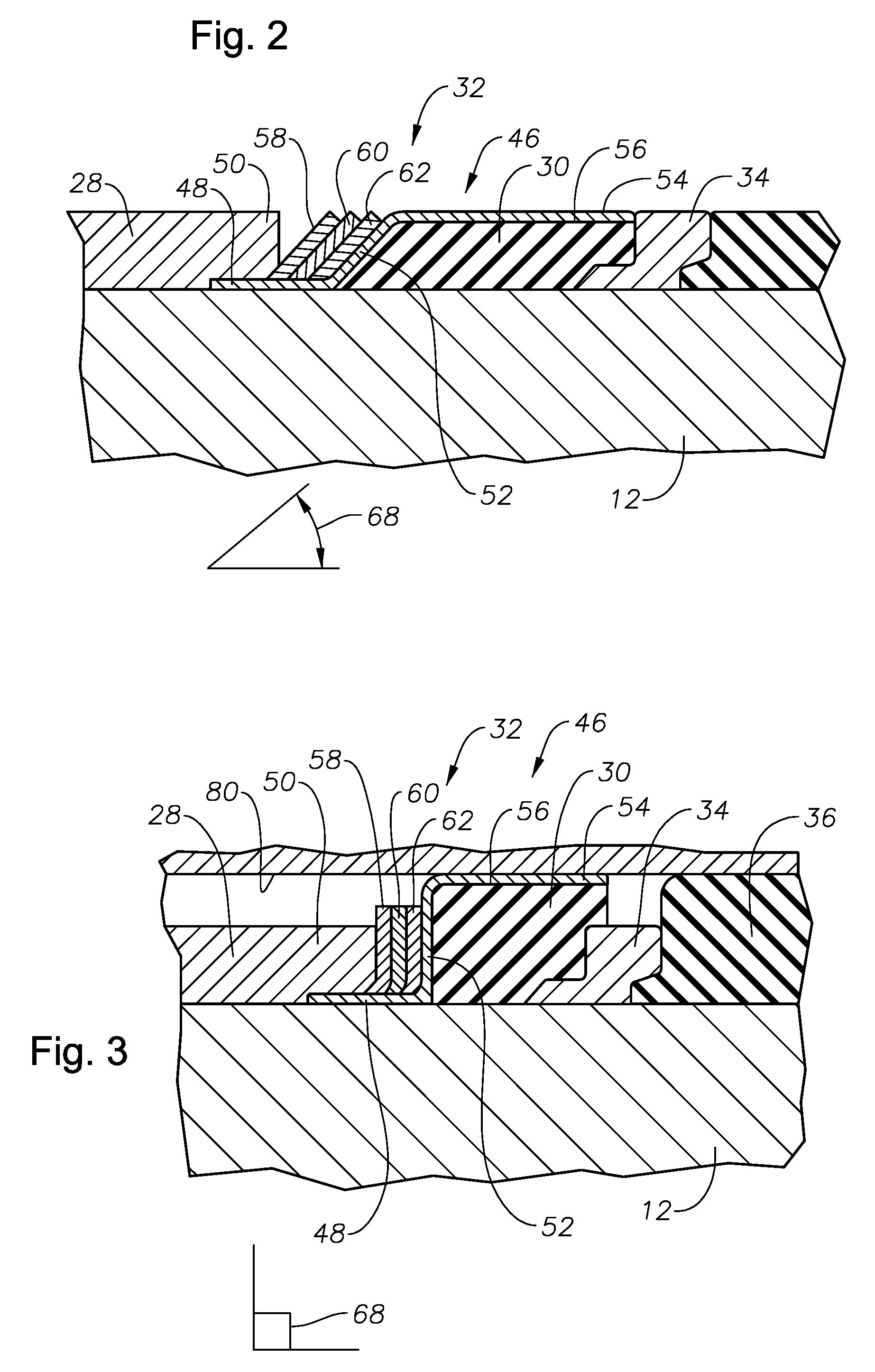

[0016]The exemplary packer element portion 20 depicted in FIG. 1 includes an upper end cone 28 which surrounds the mandrel 12 and abuts the stop shoulder 18. The packer element port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com