Traction motor capable of online replacement of bearing

A technology for traction motors and bearings, which is applied in the field of traction motors for online replacement of bearings. It can solve the problems that locomotive traction motors cannot replace bearings online, and achieve the effects of reducing maintenance time and cost, avoiding leakage, and improving punctuality and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

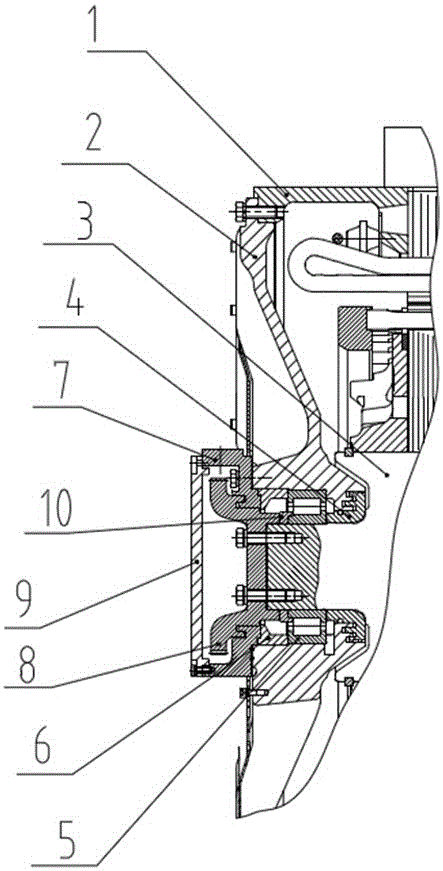

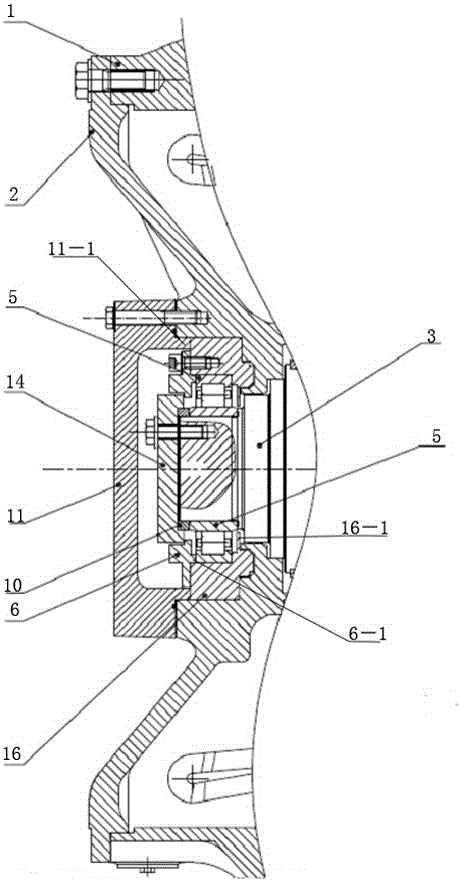

[0011] A traction motor with online bearing replacement, including machine base 1, non-drive end cover 2, rotor 3, bearing 5, bearing retaining ring 6, bearing angle ring 10; also includes cover 11, bearing seat 16, shaft head cover plate 14. The bearing hole on the bearing seat 16 is a stepped hole that tapers from the outside to the inside; the outer ring of the bearing 5 withstands the stepped surface of the bearing hole of the bearing seat 16, and is interference fit with the bearing hole of the bearing seat 16. The inner ring of the bearing 5 bears against the shoulder of the rotor shaft and has an interference fit with the rotor shaft; the bearing seat hole on the end cover 2 of the non-drive end is a stepped hole tapered from the outside to the inside, and the inner end surface of the bearing seat 16 tops The stepped surface of the bearing seat hole of the non-drive end cover and the transition fit with the stepped seat hole, the bearing hole wall at the inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com