Snow-melting and deicing integrated maintenance equipment

A technology for equipment and snow melting, which is applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of not being able to work on urban roads, not being able to work on urban roads, and the technology can only be cleared at fixed points, so as to achieve high snow removal efficiency and work operation Low cost, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

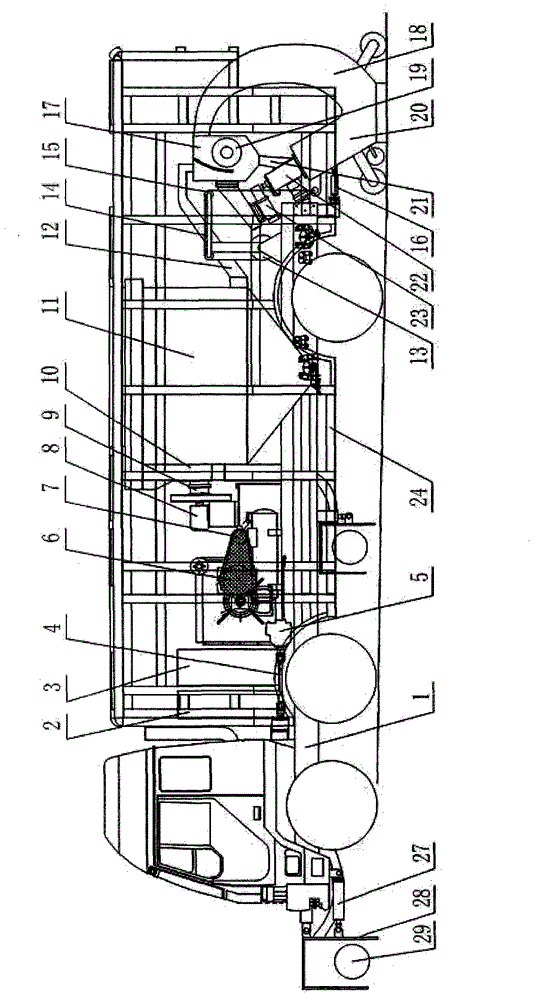

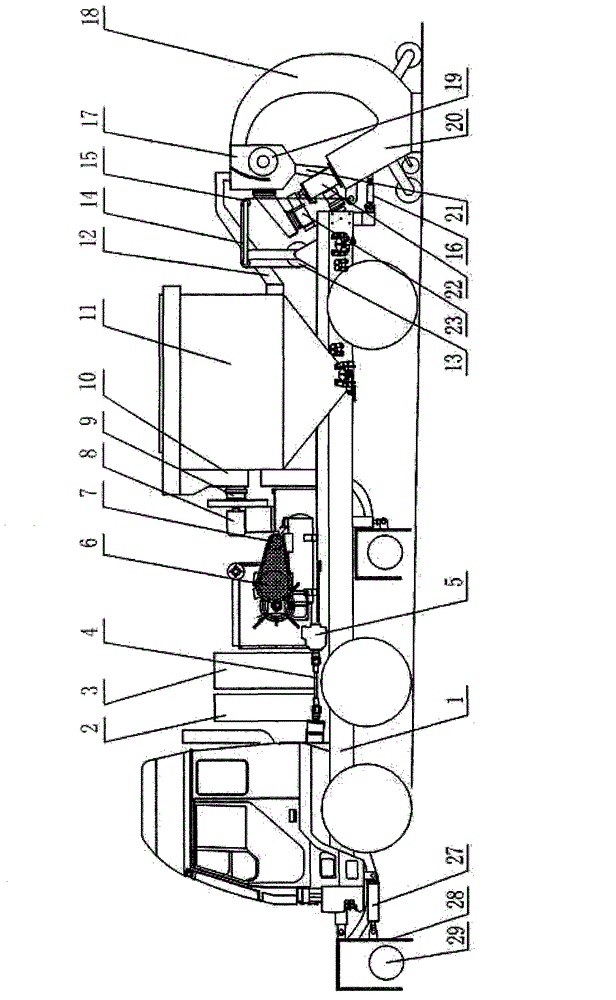

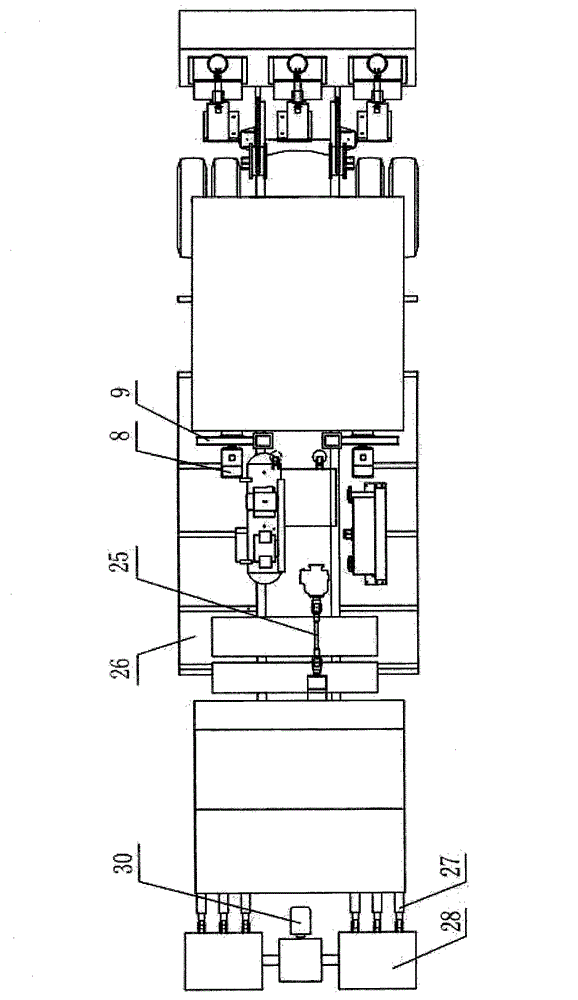

[0023] Such as figure 1 , 2 . As shown in 3, a snow melting and deicing comprehensive maintenance equipment includes a car body with a chassis, a compartment and a front, and also includes an ice crushing device, a snow removal device and a snow cleaning device.

[0024] Automobile chassis 1 adopts domestic and foreign standard chassis. Its function is to carry and install ice crushing device, snow removal device, air source device, snow removal device, hydraulic system and electrical control system.

[0025] The ice crushing device is composed of a distribution bin 17, a recovery channel 18, a shot blasting box 20, a discharge gate valve 21, and a shot blasting device 22. There are three shot blasting devices 22, all of which form an angle of 120° with the horizontal plane and are respectively fixed on the blasting device. On the shot box 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com