Method for quickly moving fully mechanized mining face under special geological condition

A technology of fully mechanized mining face and special geology, applied in underground transportation, mining equipment, earthwork drilling, etc., can solve the problems of slow speed and low efficiency, reduce moving time, improve safety, and save auxiliary work time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

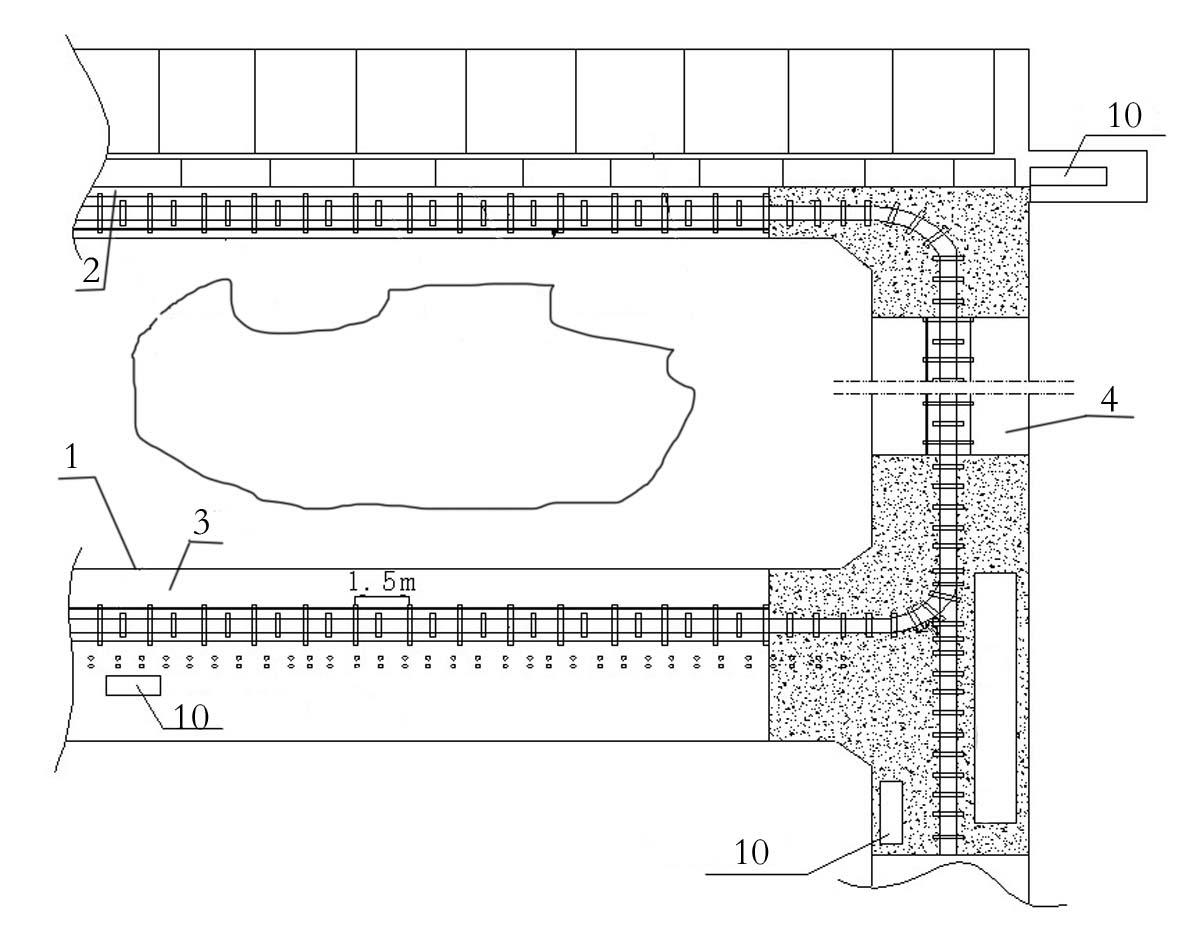

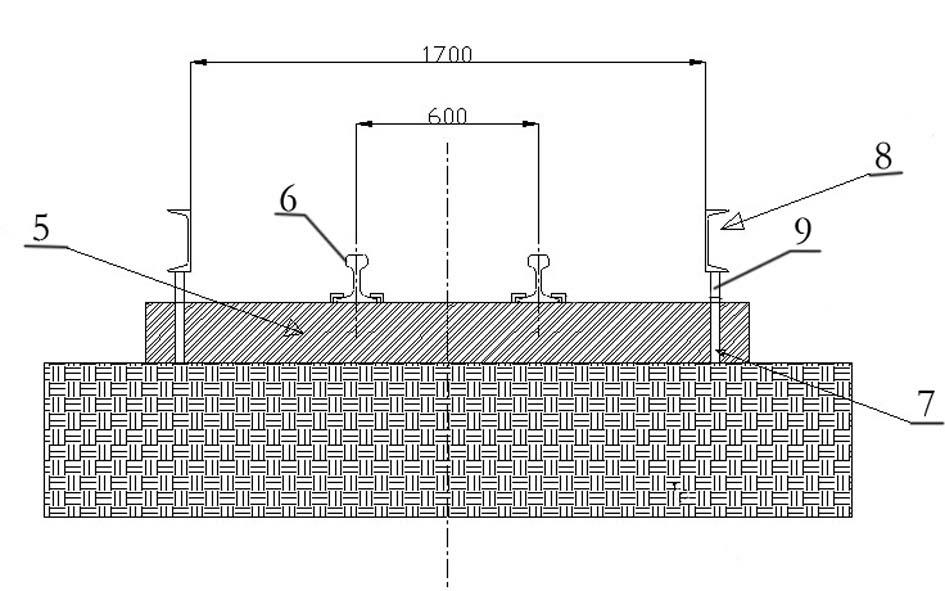

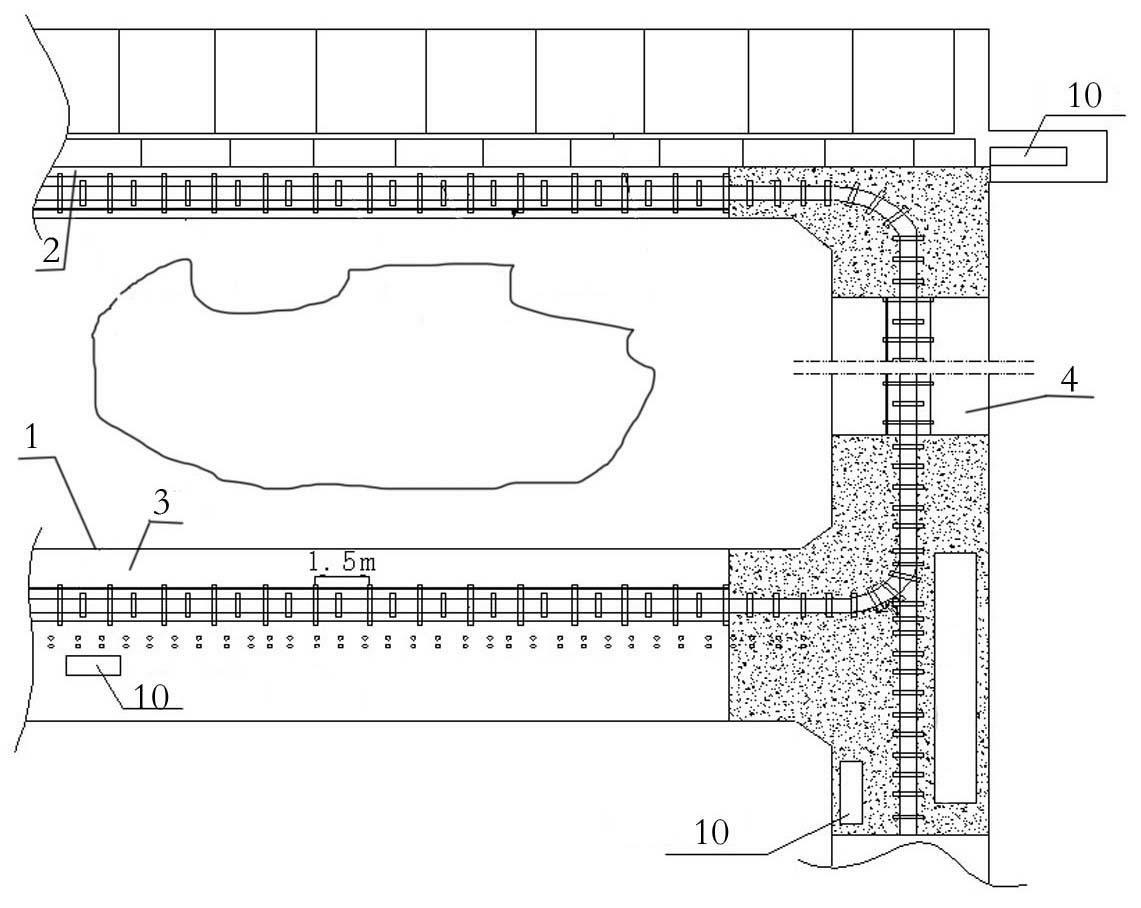

[0010] The method of rapid relocation of the fully mechanized mining face under special geological conditions is realized by the following steps: 1. The working face is pushed to the stop line position 1, and a new (jump face) cut hole 2 is excavated in advance (that is, bypassing the collapsed column , faults, etc. to excavate a new working face); during specific implementation, the section size of the new cut is 7.5m in clear width and 2.95m in clear height, which meets the conditions for equipment installation. After the working face is pushed to the position of the scheduled stop production line, the old cut hole is expanded and supported in time, which meets the conditions for equipment removal. 2. Harden the ground of the new incision 2, the old incision 3, and the trough lane 4 connecting the new and old incisions (such as laying concrete or other materials); 3. Along the old incision, the trough lane, and the new incision Lay wooden sleepers and add a steel sleeper 5 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com