Main winch rapid-descent and confluent return oil regeneration system of rotary drilling rig

A technology of rotary drilling rig and regeneration system, which is applied in hoisting devices, drill pipes, drill pipes, etc. It can solve problems such as complex pressure changes, BVD balance valve block 9 cannot be effectively closed, and drill pipes stall and drop, etc., to achieve system Good controllability, reduced hole-forming auxiliary operation time, and the effect of preventing drill pipe and drilling tools from being damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

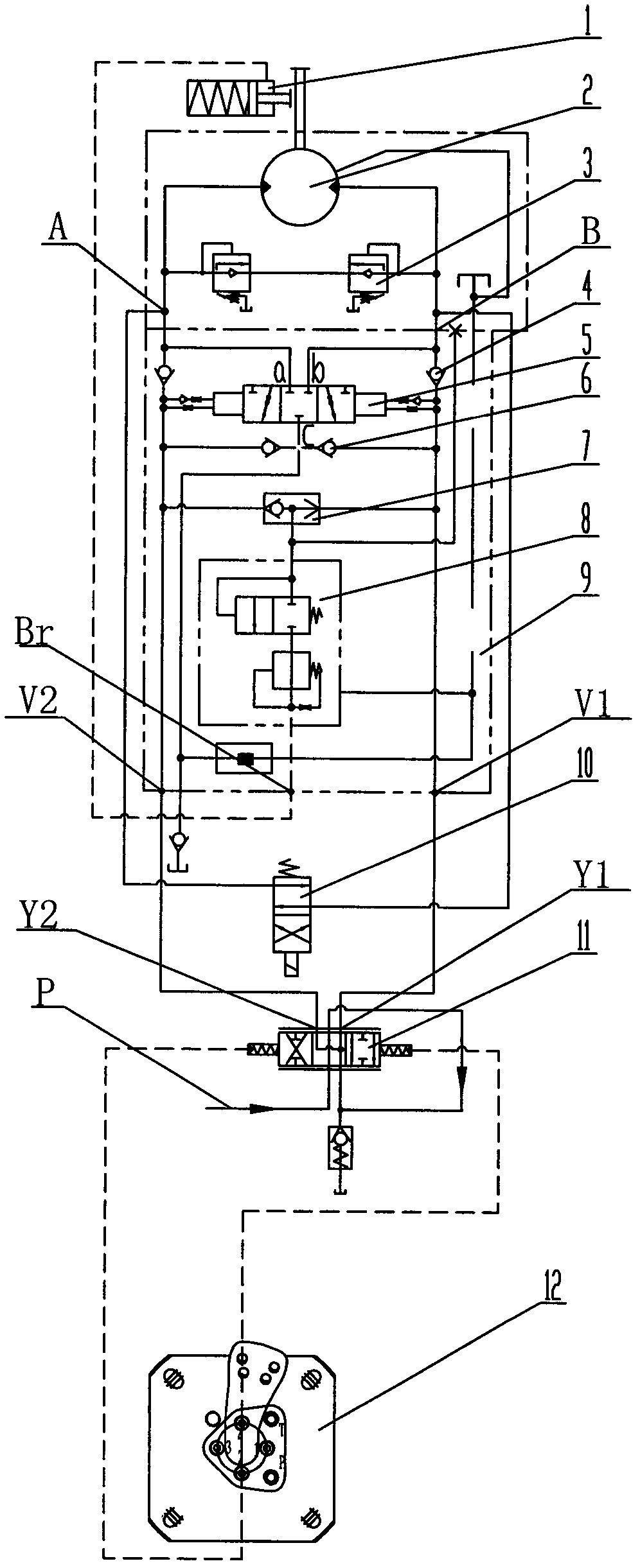

Image

Examples

Embodiment Construction

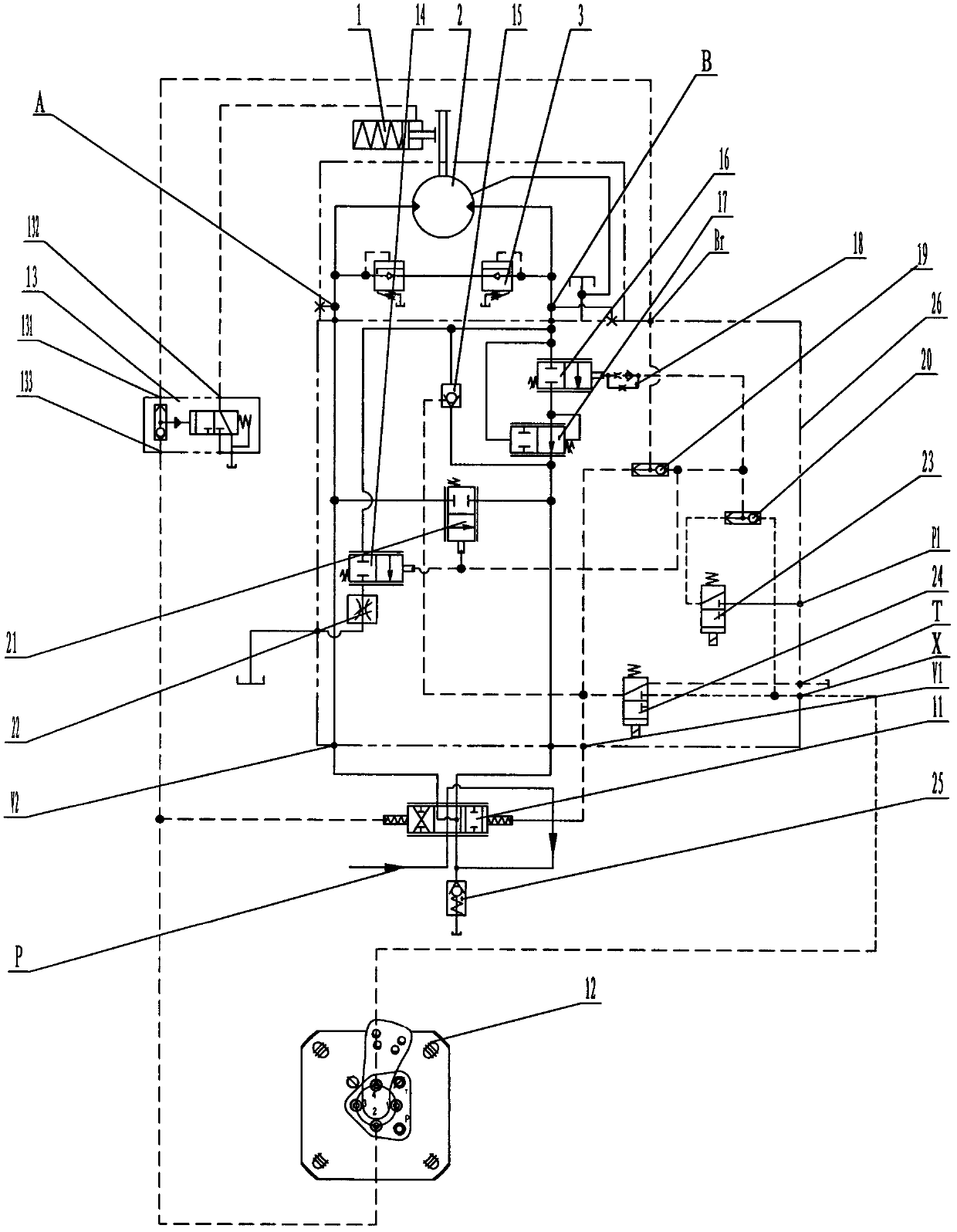

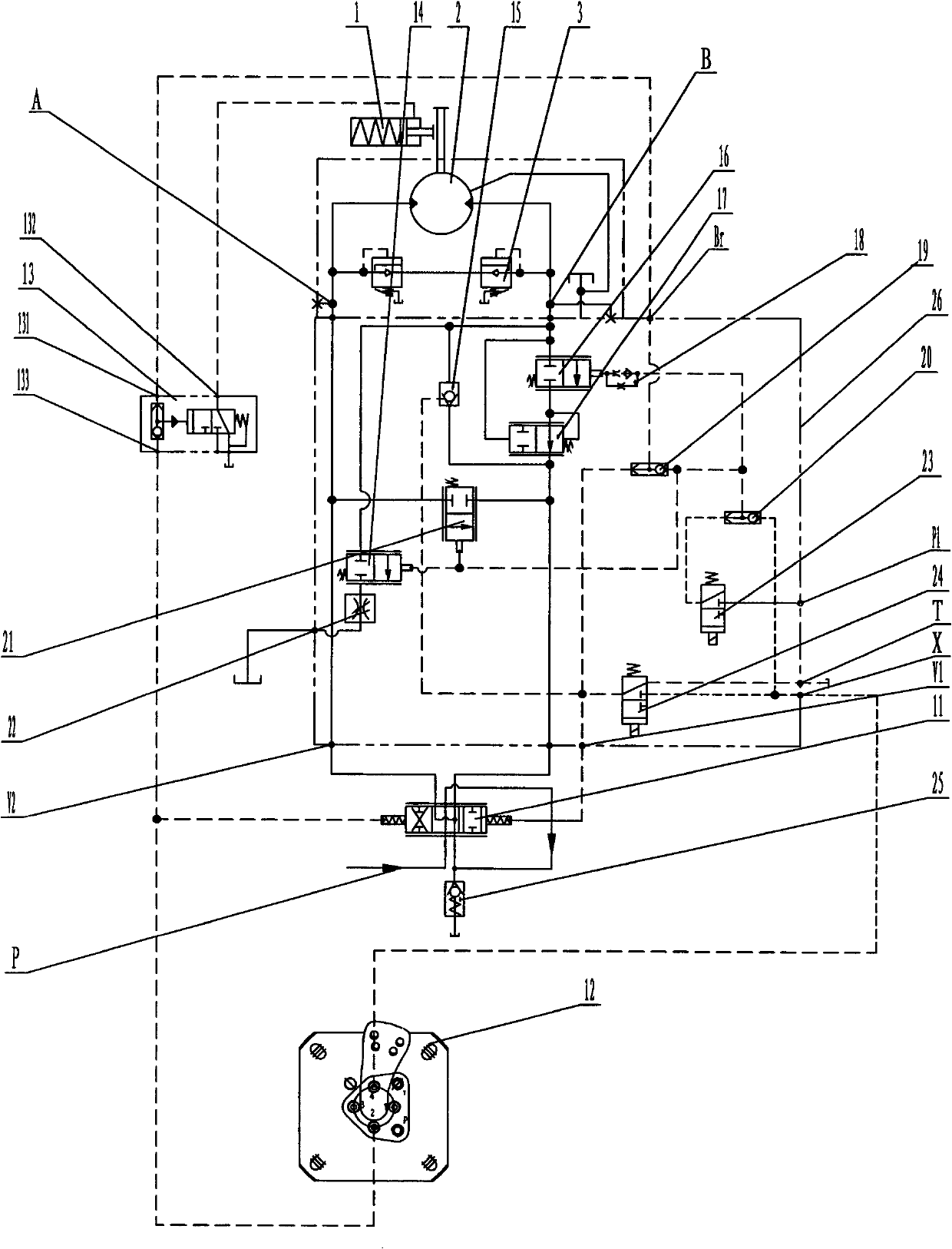

[0052] Examples such as figure 2 As shown in the figure, a main winch of a rotary drilling rig is quickly lowered to merge and return oil regeneration system, which includes a main winch motor 2, a brake 1, a main valve 11 and a pilot handle 12, and the pilot handle 12 communicates with the main valve 11 through an oil circuit , the main winch motor 2 and the main valve 11 are connected through pipelines with a special balance valve block 26 for oil return regeneration, and the special balance valve block 26 for oil return regeneration is controlled and regulated by the control device.

[0053] The special balance valve block 26 for oil return regeneration is provided with an oil inlet line and an oil return line, and the special balance valve block 26 for oil return regeneration is provided with a pilot pressure outlet P1, a control port X, an oil drain port T and a braking port. Port Br and the first oil inlet V1 of the valve block and the second oil inlet V2 of the valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com