Hydraulic control system of full-hydraulic drill type coal miner

A hydraulic control system and shearer technology, applied in earthwork drilling, slitting machinery, mechanical equipment, etc., can solve the problems of long loading and unloading drill pipes, out-of-synchronization of hydraulic circuits, and large system power loss, etc., to achieve easy operation and maintenance, easy operation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

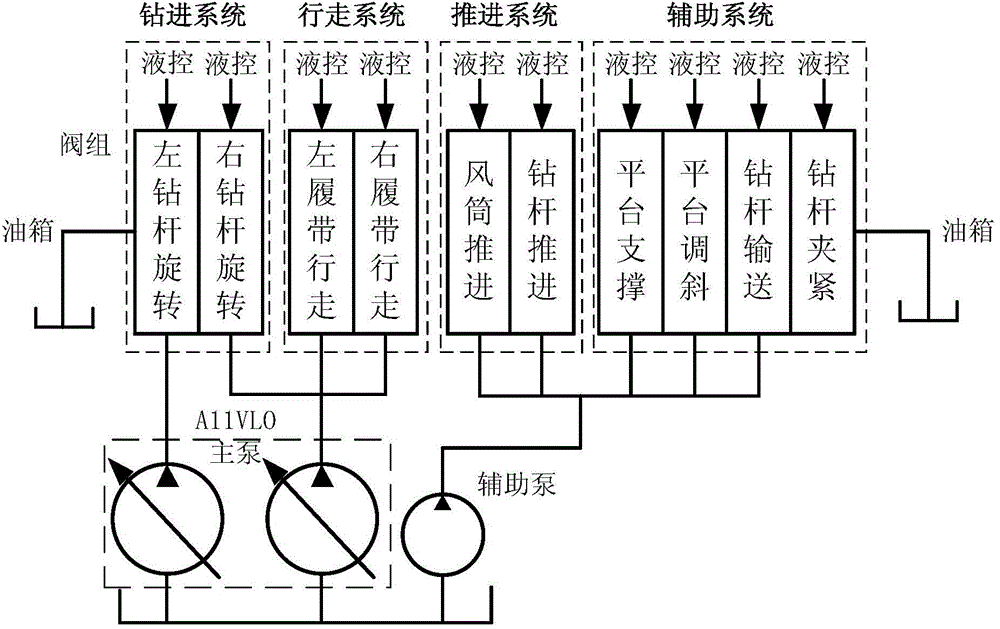

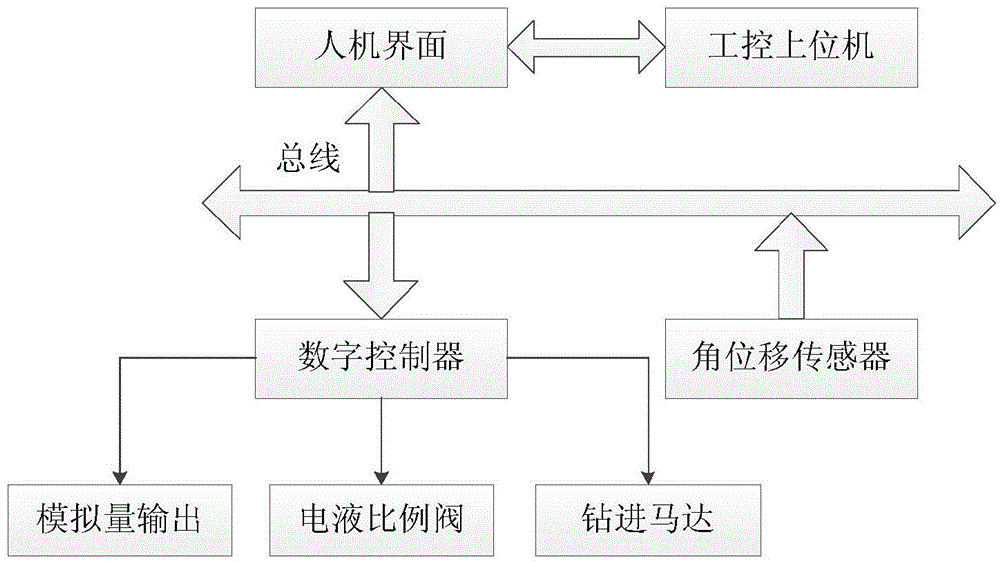

[0023] like figure 1 As shown, the hydraulic control system of the full hydraulic drilling shearer of the present invention includes a drilling system, a walking system, a propulsion system and an auxiliary system;

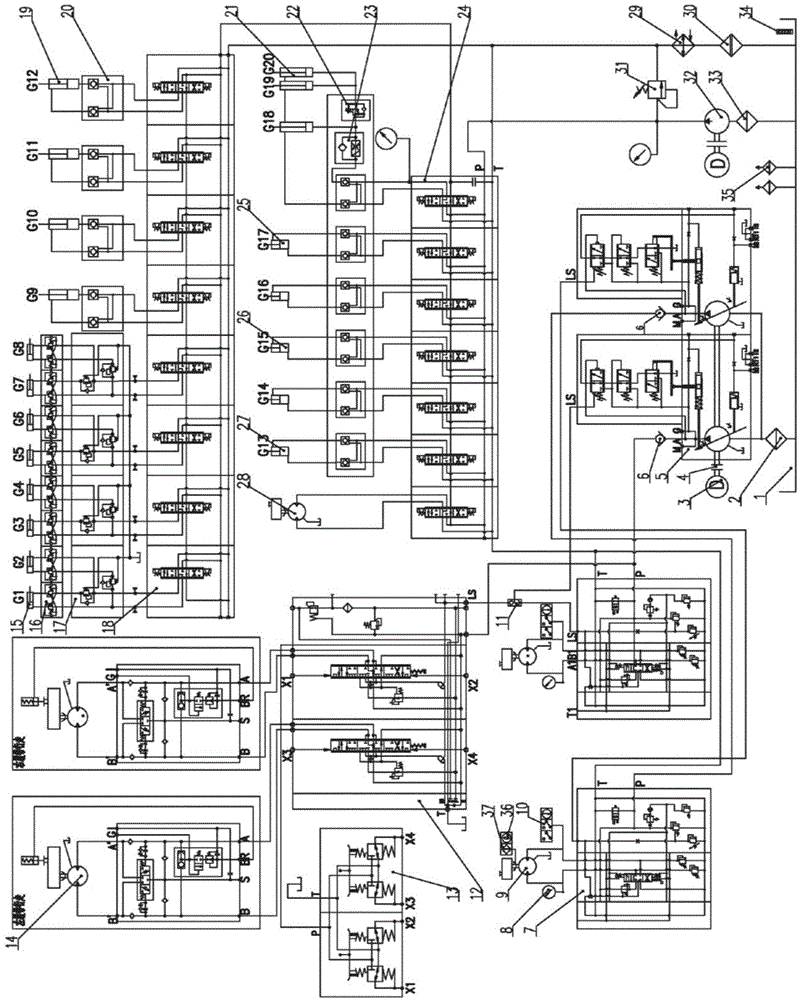

[0024] like image 3 As shown, the drilling system includes a fuel tank, a filter, a dual variable displacement plunger pump, an electro-hydraulic proportional valve, a drilling motor, and hydraulic oil pipes for component connections; The oil outlet of the coupled variable plunger pump is connected to the one-way valve; the oil inlet of the electro-hydraulic proportional valve is connected to the oil outlet of the one-way valve, and the oil outlet is connected to the drilling motor; the LS port of the electro-hydraulic proportional valve is connected to the dual variable column The LS port of the plug pump is connected; a pressure gauge i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com