Surface blasting mechanization continuous powder charging system

A charging system and open-air technology, applied in blasting and other directions, can solve the problems of inability to use emulsion explosives, poor operation safety, high labor intensity, etc., and achieve the effect of eliminating the phenomenon of drug breakage, convenient operation, and improving the economic benefits of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

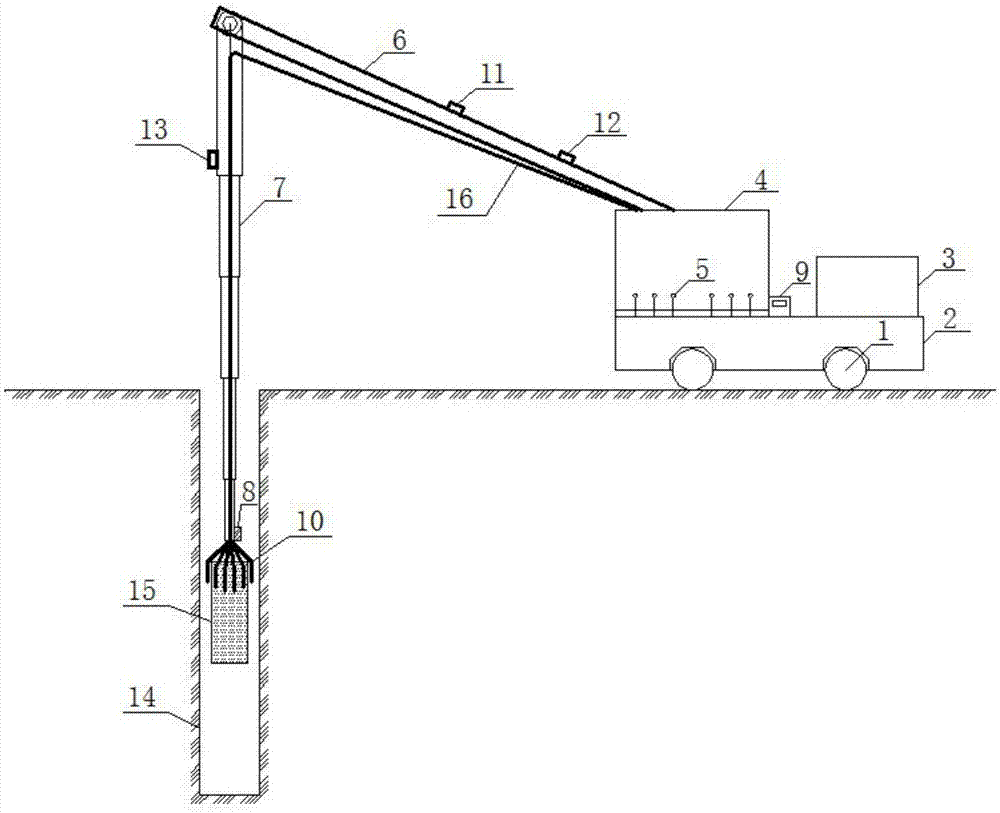

[0019] In order to better describe the present invention, the mechanized continuous charging system for surface blasting of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Depend on figure 1 As shown in the schematic diagram of the structural connection of the mechanized continuous charge system for open-air blasting of the present invention, the mechanized continuous charge system for open-air blasting of the present invention includes a traveling mechanism 1, a frame 2, a power system 3, a hydraulic system 4, and a control system 5 , support arm 6, combined telescopic arm 7, hydraulic oil pipe 16, frame 2 is supported on the running mechanism 1, power system 3, hydraulic system 4, control system 5 are all installed on the frame 2, and described power system 3 adopts Diesel engines. One end of the support arm 6 is fixed on the walking mechanism 1, and the other end of the support arm 6 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com