Complicate electrode pose pre-adjustment device

A pre-adjustment and electrode technology, which is applied in the field of electrode pose pre-adjustment devices, can solve problems such as long adjustment process time, complex electrode pose pre-adjustment devices, and difficulty in ensuring adjustment accuracy, so as to improve pre-adjustment accuracy and improve processing efficiency , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

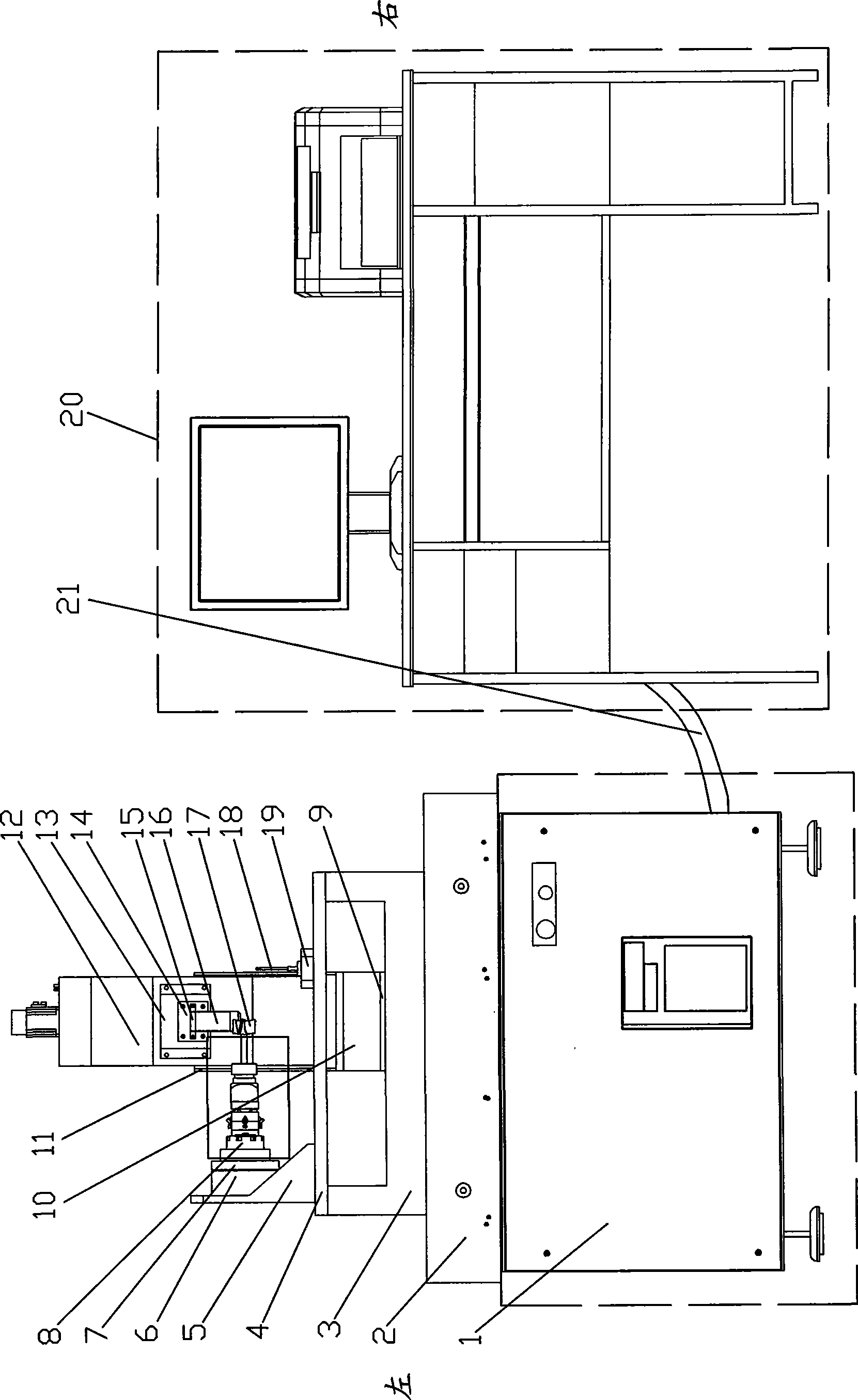

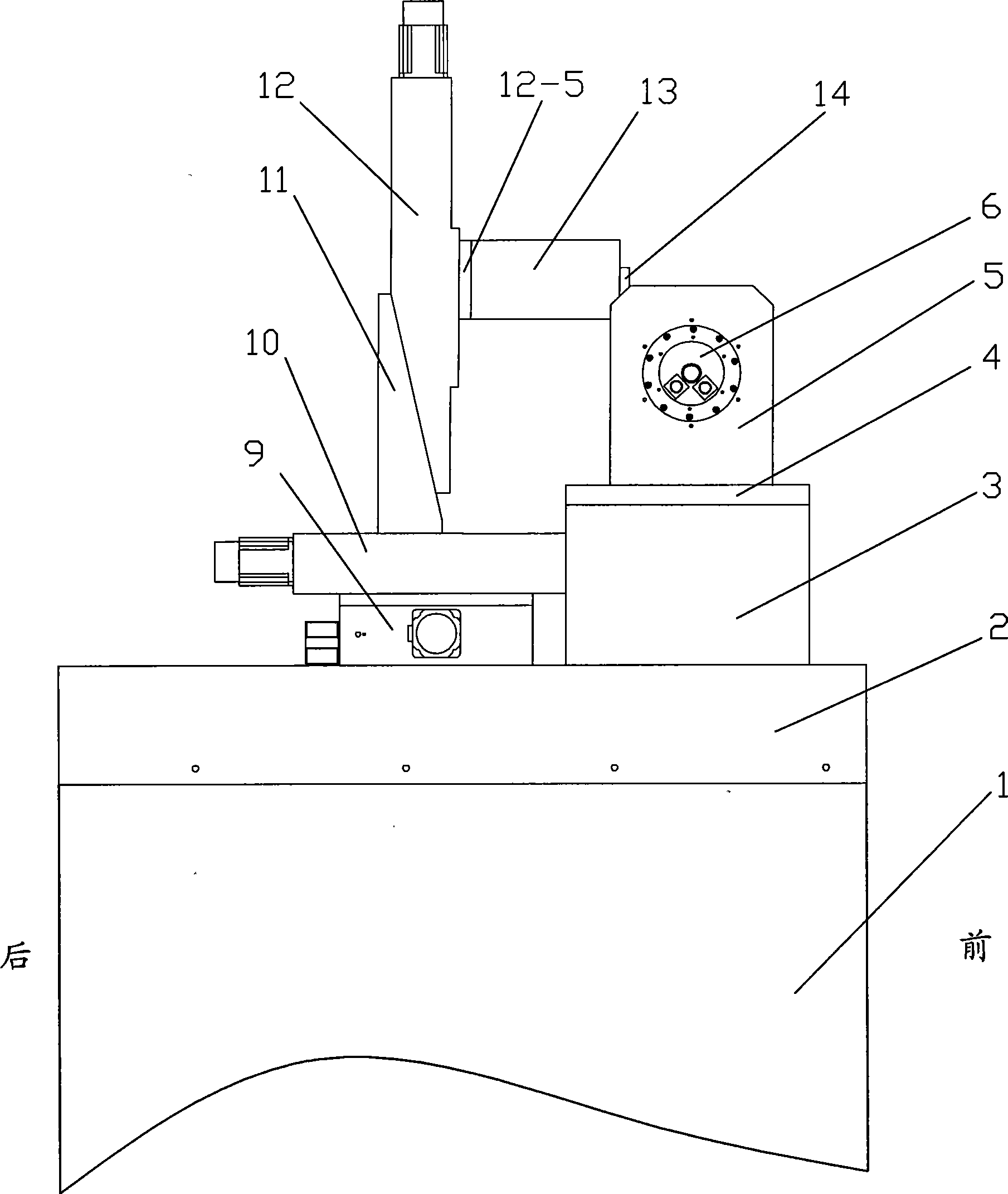

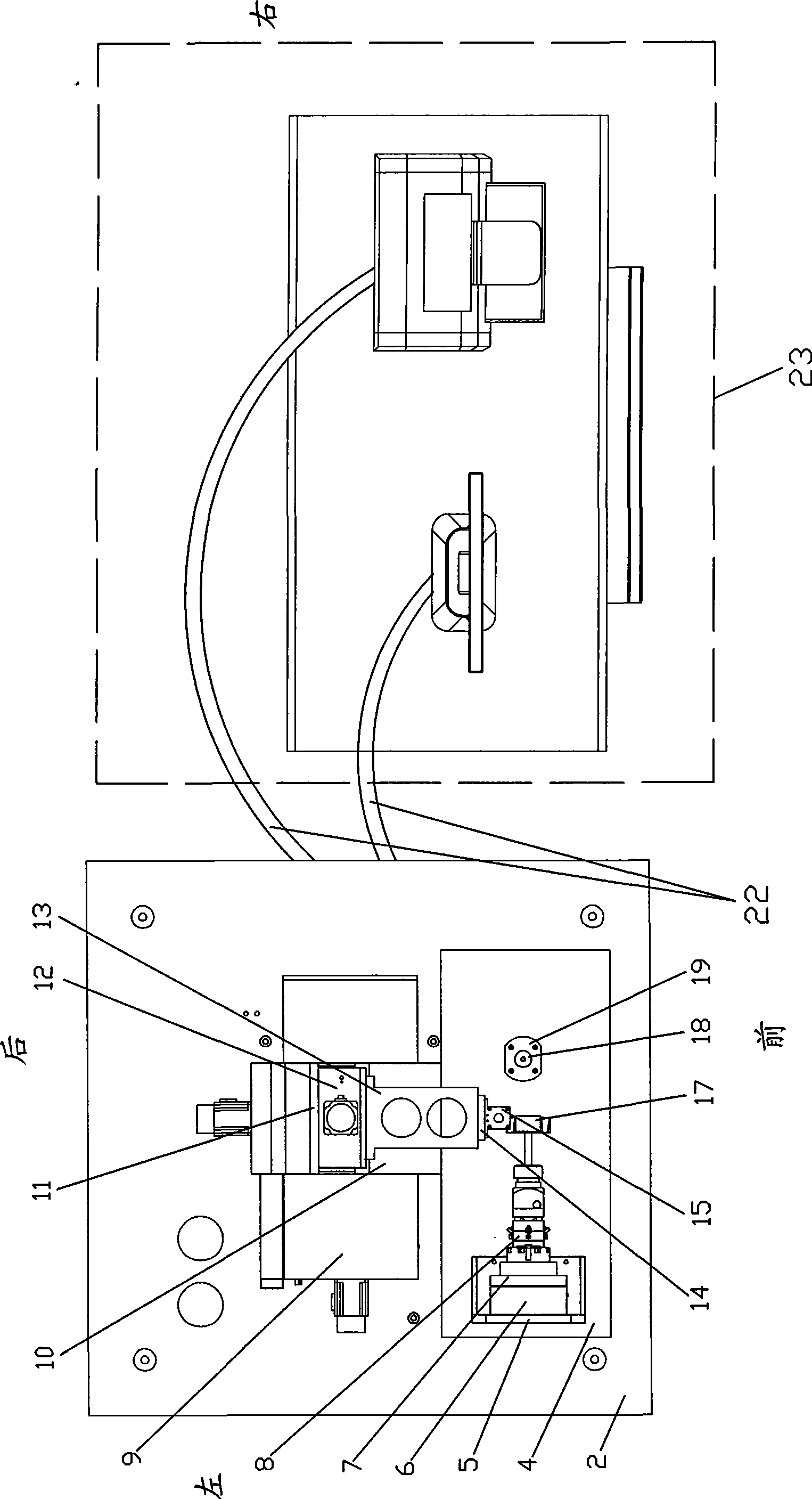

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment. This embodiment includes an electric control cabinet 1, a large platform 2, a U-shaped mounting base 3, a small platform 4, a mounting base 5, a motor 6, an insulating plate 7, a posture adjustment assembly 8, a left and right moving mechanism 9, a front and rear Moving mechanism 10, up and down moving mechanism 12, extension frame 13, insulating plate 14, measuring head mounting seat 15, measuring head 16, standard ball 18, connecting seat 19, human-computer interaction equipment 20 and cables 21, large platform 2 through the connecting piece Installed on the table of the electric control cabinet 1, the U-shaped mounting base 3 is installed on the large platform 2 through the connecting piece, the small platform 4 is installed on the upper end surface of the U-shaped mounting base 3 through the connecting piece, and the motor mounting base 5 is installed through the connecting piece...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 4 and Figure 5 Describe this embodiment, the posture adjustment assembly 8 of this embodiment is composed of a connecting chuck 8-1, a slot spring 8-2, a displacement adjustment plate 8-3, an angle adjustment plate 8-4, a swing plate 8-5, and a spring Chuck body 8-6, lock nut 8-7, grinding electrode rod 8-8, two angle adjustment screws 8-9 and two displacement adjustment screws 8-10, connected with chuck 8-1, card slot The shrapnel 8-2, the displacement adjustment plate 8-3 and the angle adjustment plate 8-4 are connected sequentially from left to right, and the left end of the swing plate 8-5 is provided with a conical surface 8-5-1 and the conical surface 8-5-1 Connect the right end of the angle adjustment plate 8-4 through the connecting piece, the right end of the swing plate 8-5 is connected with the left end of the collet body 8-6, and the lock nut 8-7 is set on the grinding electrode rod 8-8. The left end o...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 6 Describe this embodiment, the left and right moving mechanism 9 of this embodiment is made up of first bottom plate 9-1, two first supporting blocks 9-2, first lead screw 9-3, first lead screw nut 9-4, first The slider 9-5, the first shaft coupling 9-6, the first mounting seat 9-7 and the first motor 9-8 are composed of two first supporting blocks 9-2 fixedly mounted on the first bottom plate 9-1 respectively. On the upper end face of the first lead screw 9-3, the two ends of the first lead screw 9-3 are respectively hinged in the two first support blocks 9-2 and the input end is connected with the output end of the first coupling 9-6, and the first coupling The input end of 9-6 is connected with the output end of the first motor 9-8, and the first motor 9-8 is fixed on the first base plate 9-1 by the first mount 9-7, and the first slide block 9-5 Fixedly mounted on the top of the first leading screw nut 9-4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com