Quick roll changing device for working roll or supporting roll of hot rolling production line, and changing method

A roll changing device and work roll technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of complex structure design of the transmission device, immature roll changing process, complicated roll changing steps, etc., and improve the equipment Efficiency of use, shortening of working time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

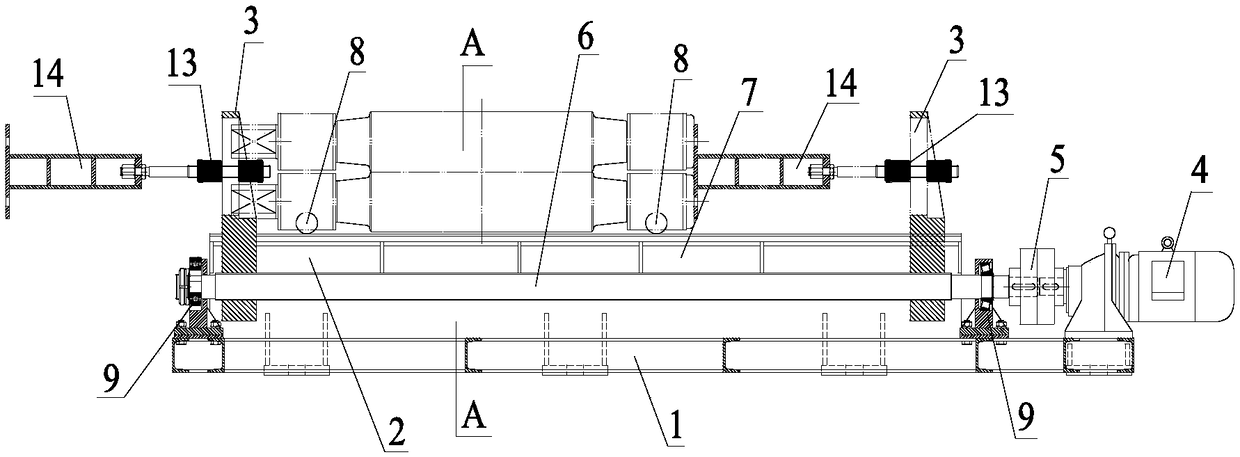

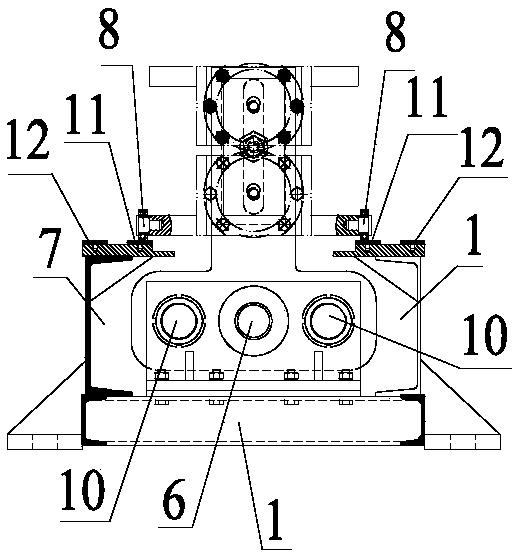

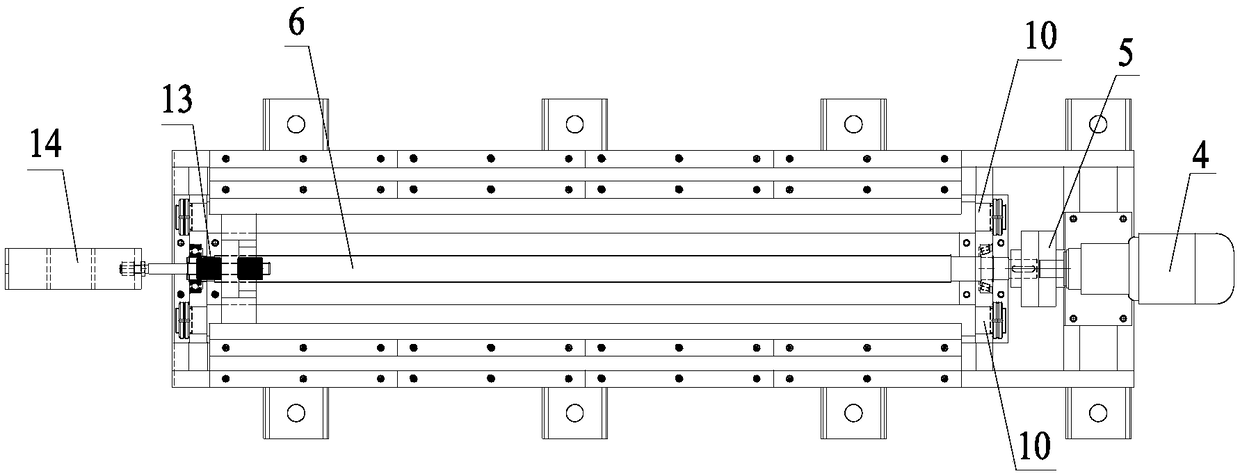

[0034] Such as figure 1 As shown, a quick roll changing device for work rolls or back-up rolls in a hot rolling production line includes a frame 1 on which a sliding frame 2 for placing the working rolls or backup rolls is arranged. The sliding frame 2 includes two symmetrical sliding frames The baffle 3 and the frame 1 are fixed with a cycloidal pinwheel reducer 4, and the cycloidal pinwheel reducer 4 is connected with a screw rod 6 through a column pin coupling 5, and the screw rod 6 passes through two screw rods in sequence. The lower part of the sliding baffle 3, such as figure 2 As shown, the carriage 2 also includes two roll changing platforms 7 parallel to the screw mandrel 6, the two roll changing platforms 7 are respectively located on both sides of the screw mandrel 6, and the upper surfaces of the two roll changing platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com