Narrow-gauge electric motor car

A technology for electric locomotives and bullet trains, applied to electric locomotives, locomotives, motor vehicles, etc., can solve the problems of slow locomotive driving, long transportation time, and reduced production efficiency, so as to reduce the height of the center of gravity, increase the length of the car body, and prevent derailment The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

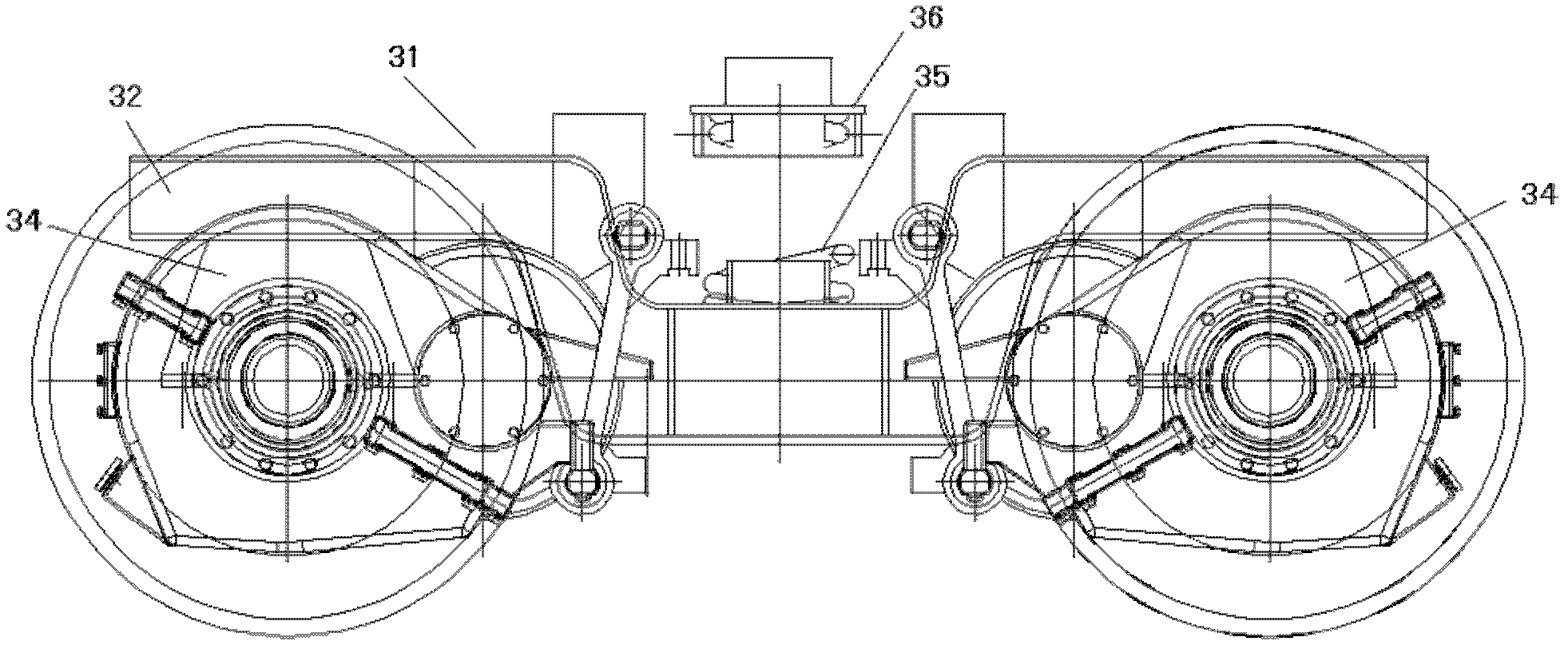

[0019] The present invention will be described in detail below with reference to the drawings and embodiments.

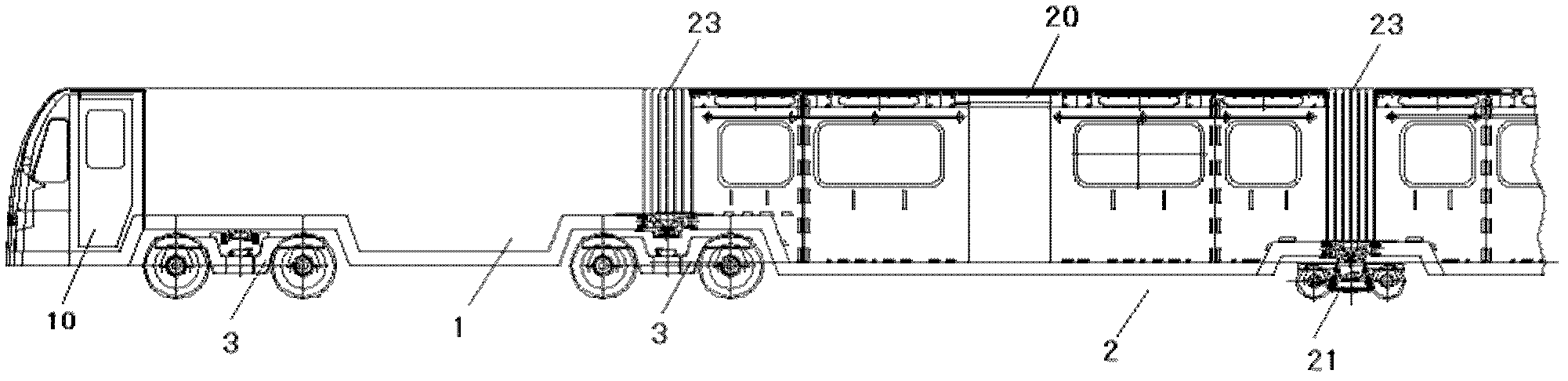

[0020] Such as figure 1 , figure 2 As shown, the present invention includes two front and rear motor cars 1, and a trailer 2 composed of several carriages is arranged between the front and rear motor cars 1.

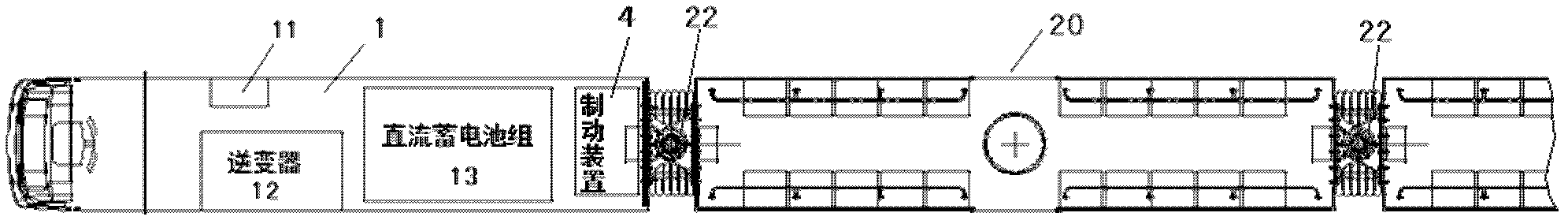

[0021] Similar to the prior art, the motor car 1 of the present invention includes a driver's cab 10, which is provided with a traction control handle, a brake control handle, a speed display meter, a wind pressure gauge, a driving power monitor, a cabin lighting control button, and a cabin. Door control buttons, emergency brake buttons, traction and braking status display devices, etc. The feature of the present invention is that an electric control system 11 and a driving power supply are also provided in the motor car 1. The driving power supply includes an inverter 12 and a DC battery pack 13 connected to it. The electrical control system 11 is connected to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com