Pretreatment finishing agent for opening filter material and application of pretreatment finishing agent

A pretreatment and finishing agent technology, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, fiber processing, etc., can solve the problem of fiber damage that increases the difficulty of pulling out, and it is difficult to prepare high value-added products and regenerated fibers. Large damage and other problems, to achieve the effect of facilitating subsequent carding, reducing friction coefficient, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

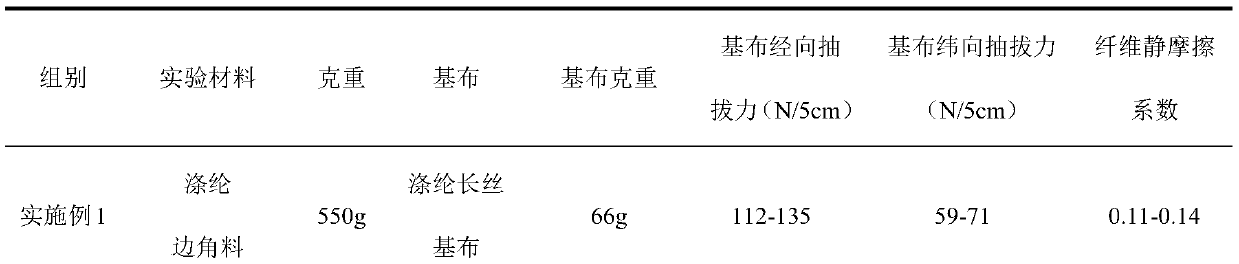

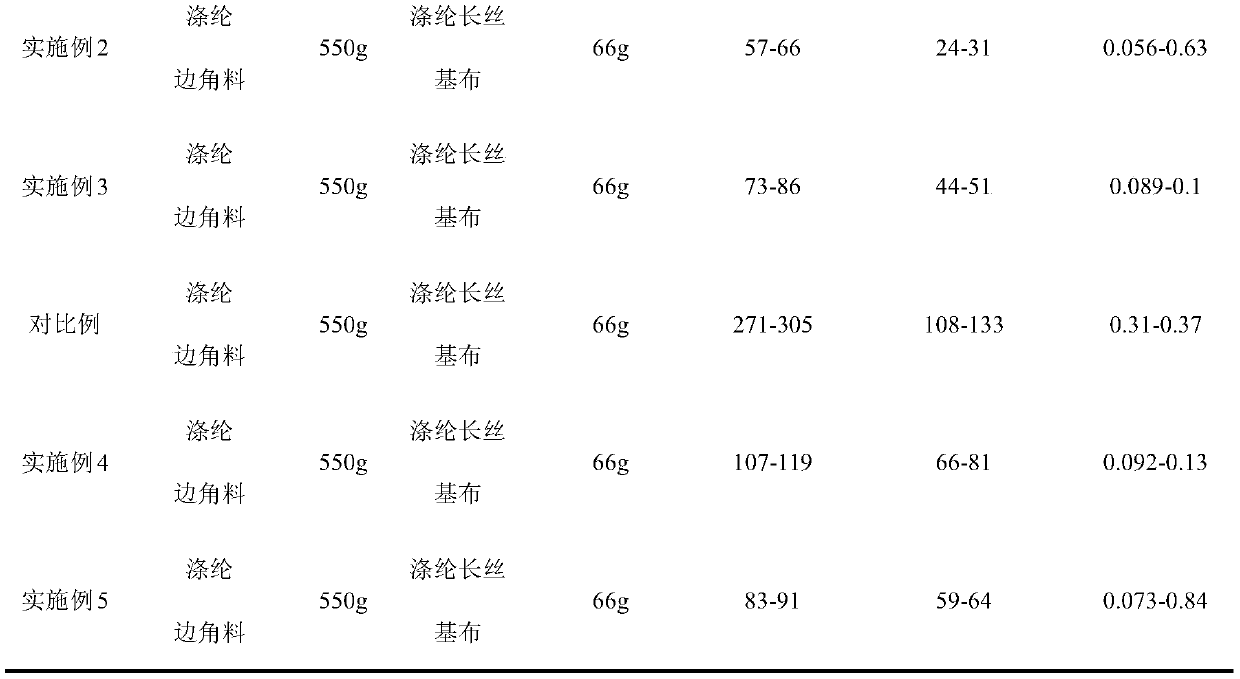

Embodiment 1

[0033] Preparation of pretreatment finishing agent for filter material opening:

[0034] (1) 40 parts by weight of polyethylene glycol (average molecular weight is 400), 15 parts by weight of polytetrafluoroethylene emulsion with a solid content of 60%, 12 parts by weight of simethicone emulsion, 5 parts by weight of dioctadecyl di Methyl quaternary ammonium salt, 0.5 parts by weight of potassium monododecyl phosphate, and 130 parts by weight of deionized water are mixed; the damage of carding machine clothing to fibers in the opening process is reduced by polyethylene glycol, and dimethyl silicone oil, Dioctadecyl dimethyl quaternary ammonium salt and potassium monododecyl phosphate make the filter material fluffy and soft;

[0035] (2) Stir at 60°C. Stirring method: first rotate forward, the speed of forward rotation is 150rpm, and the stirring time is 2h. 2h, continue to invert at 800rpm for 40min, and make a pretreatment finishing agent after stirring.

[0036] Apply the...

Embodiment 2

[0043] Preparation of pretreatment finishing agent for filter material opening:

[0044] (1) 60 parts by weight of polyethylene glycol (average molecular weight is 400), 25 parts by weight of polytetrafluoroethylene emulsion with a solid content of 60%, 20 parts by weight of simethicone emulsion, 8 parts by weight of dioctadecyl di Methyl quaternary ammonium salt, 1.5 parts by weight of potassium monododecyl phosphate, and 130 parts by weight of deionized water are mixed; reduce the damage of carding machine clothing to fibers in the opening process by polyethylene glycol, simethicone, Dioctadecyl dimethyl quaternary ammonium salt and potassium monododecyl phosphate make the filter material fluffy and soft;

[0045] (2) Stir at 60°C. Stirring method: first rotate forward, the speed of forward rotation is 150rpm, and the stirring time is 2h. 2h, continue to invert at 800rpm for 40min, and make a pretreatment finishing agent after stirring.

[0046] Apply the prepared pretreat...

Embodiment 3

[0053] Preparation of pretreatment finishing agent for filter material opening:

[0054] (1) 50 parts by weight of polyethylene glycol (average molecular weight is 400), 20 parts by weight of polytetrafluoroethylene emulsion with a solid content of 60%, 15 parts by weight of simethicone emulsion, 6 parts by weight of dioctadecyl di Methyl quaternary ammonium salt, 1 weight part of potassium monododecyl phosphate, and 130 parts by weight of deionized water are mixed; through polyethylene glycol (average molecular weight is 400) to reduce the damage of carding machine clothing to fibers in the opening process , Dimethicone oil, dioctadecyl dimethyl quaternary ammonium salt and potassium monododecyl phosphate make the filter material fluffy and soft;

[0055] (2) Stir at 80°C. Stirring method: first rotate forward, the speed of forward rotation is 150rpm, and the stirring time is 2h. 2h, continue to invert at 800rpm for 40min, and make a pretreatment finishing agent after stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com