Workbench for groove machining of large-caliber hot bends

A technology of groove processing and hot-simmering pipe bending, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of occupation, low processing efficiency, high equipment occupation rate, etc., to reduce occupation and auxiliary work Time, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

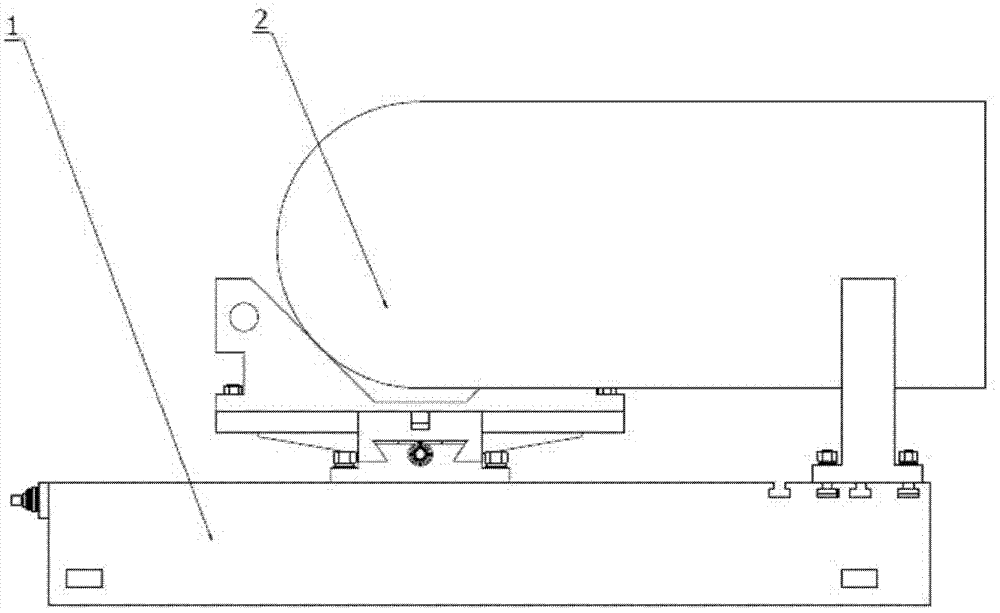

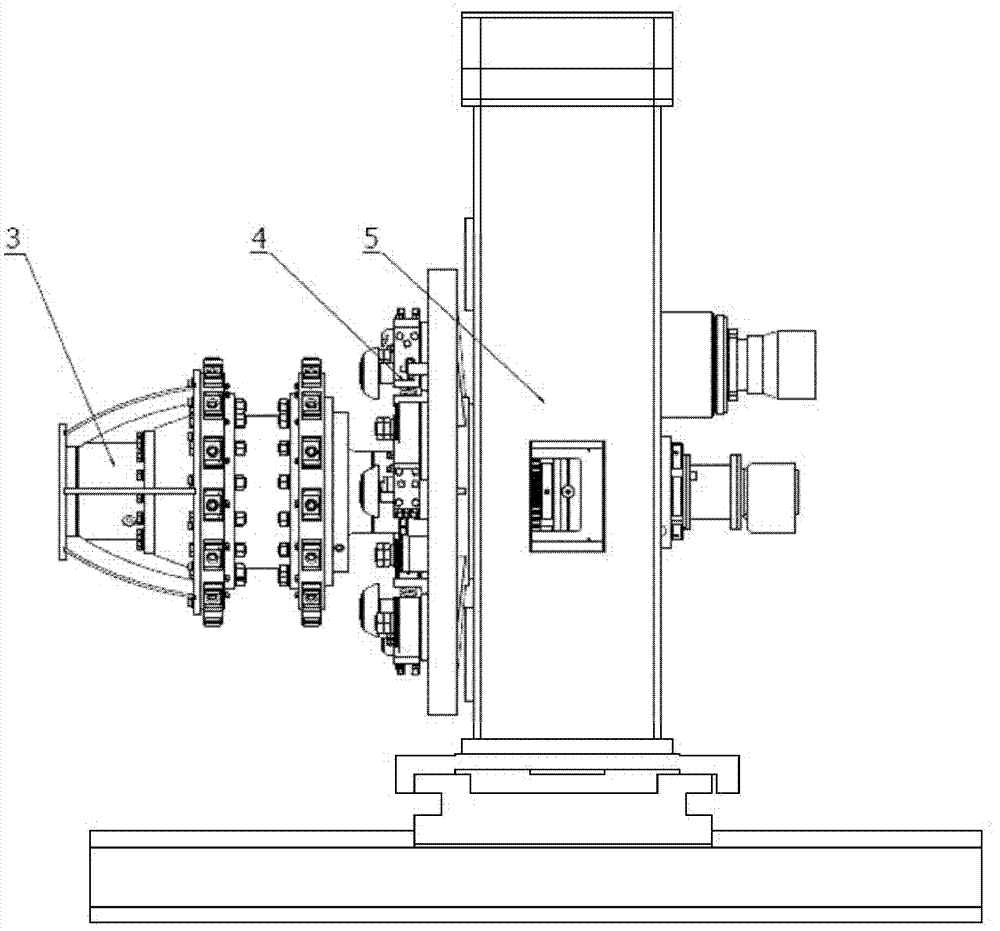

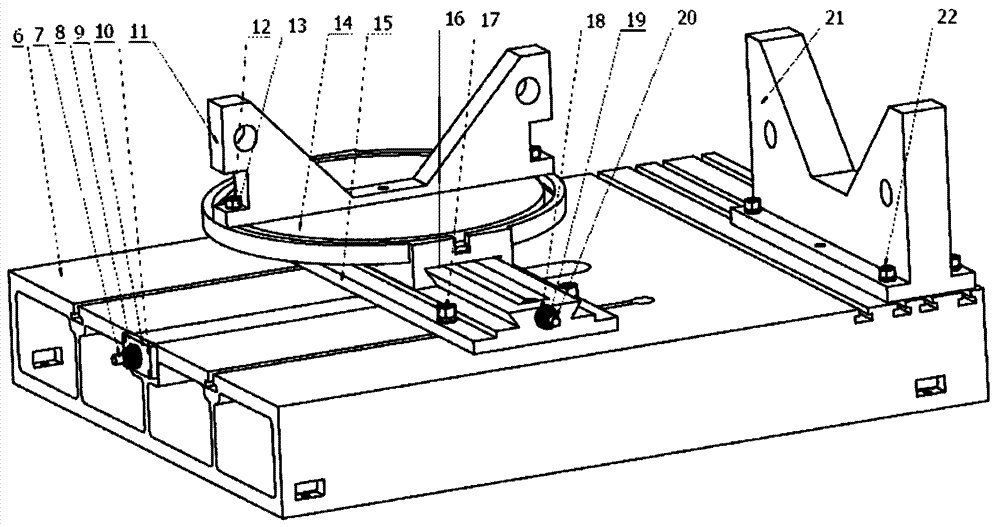

[0041] Example. Taking the processing of Φ1016 pipes with a bending angle of 90° as an example, the structure of the hot-simmering pipe beveling machine and its special processing table is as follows figure 1 , figure 2 shown. The fixed bottom plate 9 is fixed on the port leading to the middle groove of the platform base 6 by the inner hexagonal screws 10, two thrust ball bearings 8 are installed on the fixed bottom plate 9, and the thrust ball bearings 8 and the lower slider wire are connected by two round nuts. The bar 7 is fixed on the fixed base plate 9, the threaded end of the lower slider screw 7 is screwed into the threaded seat of the horizontal V-shaped slider 15, the nut 17 is loosened, and the lower slider screw 7 can drive the horizontal V-shaped slider 15 Move back and forth; the "V" groove at the lower part of the fixed turntable base 14 cooperates with the "V" bump that is integrated with the horizontal V-shaped slider 15 to form a sliding connection; the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com