Double-wing continuous coal mining technique for open-pit coal mine

A technology of open-pit coal mine and process method, which is applied in the mining of open-pit mine, earthwork drilling, special mining, etc., can solve the problems of long time consumption, waste of resources, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

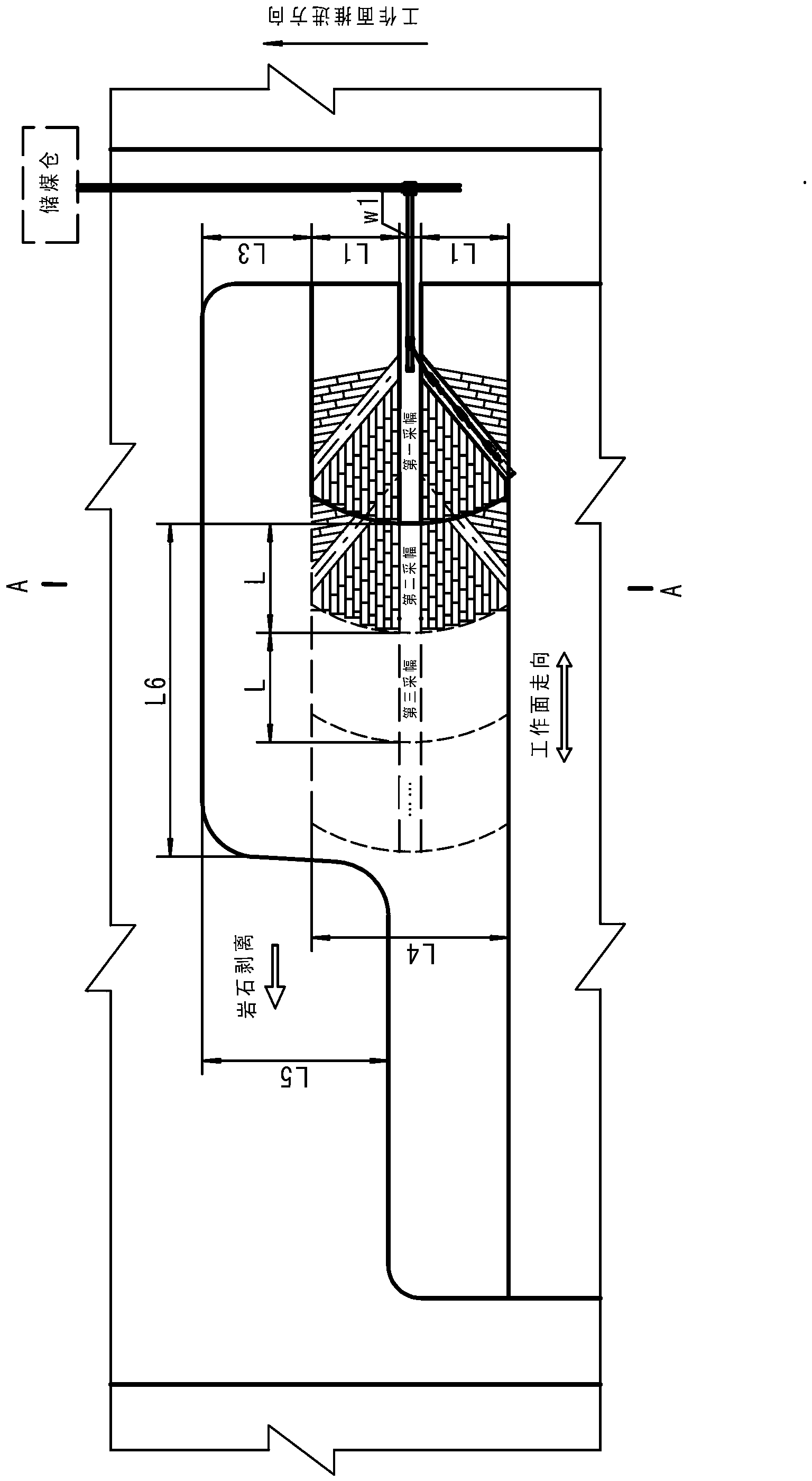

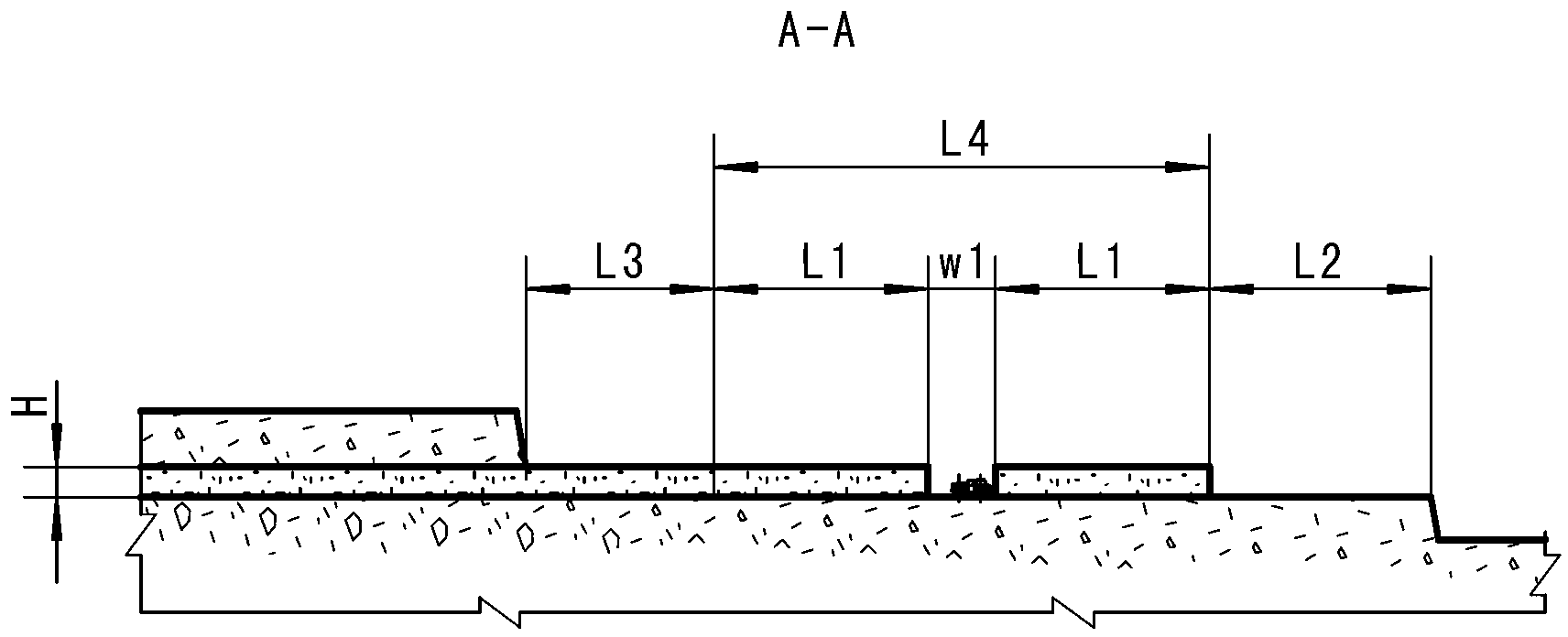

[0045] figure 1 As shown, it is the plane setting diagram of the double-wing mining area of the open-pit coal mine. The positions of each part must be correct, and the mining areas are arranged in an orderly manner. Laying and installation of roadway and right-wing roadway, the distance and height of each mining area are the same, the direction, length, width and height of coal cutting in each mining area are the same, and each mining area forms a standardized operation mode of mining, crushing, reloading, and transportation .

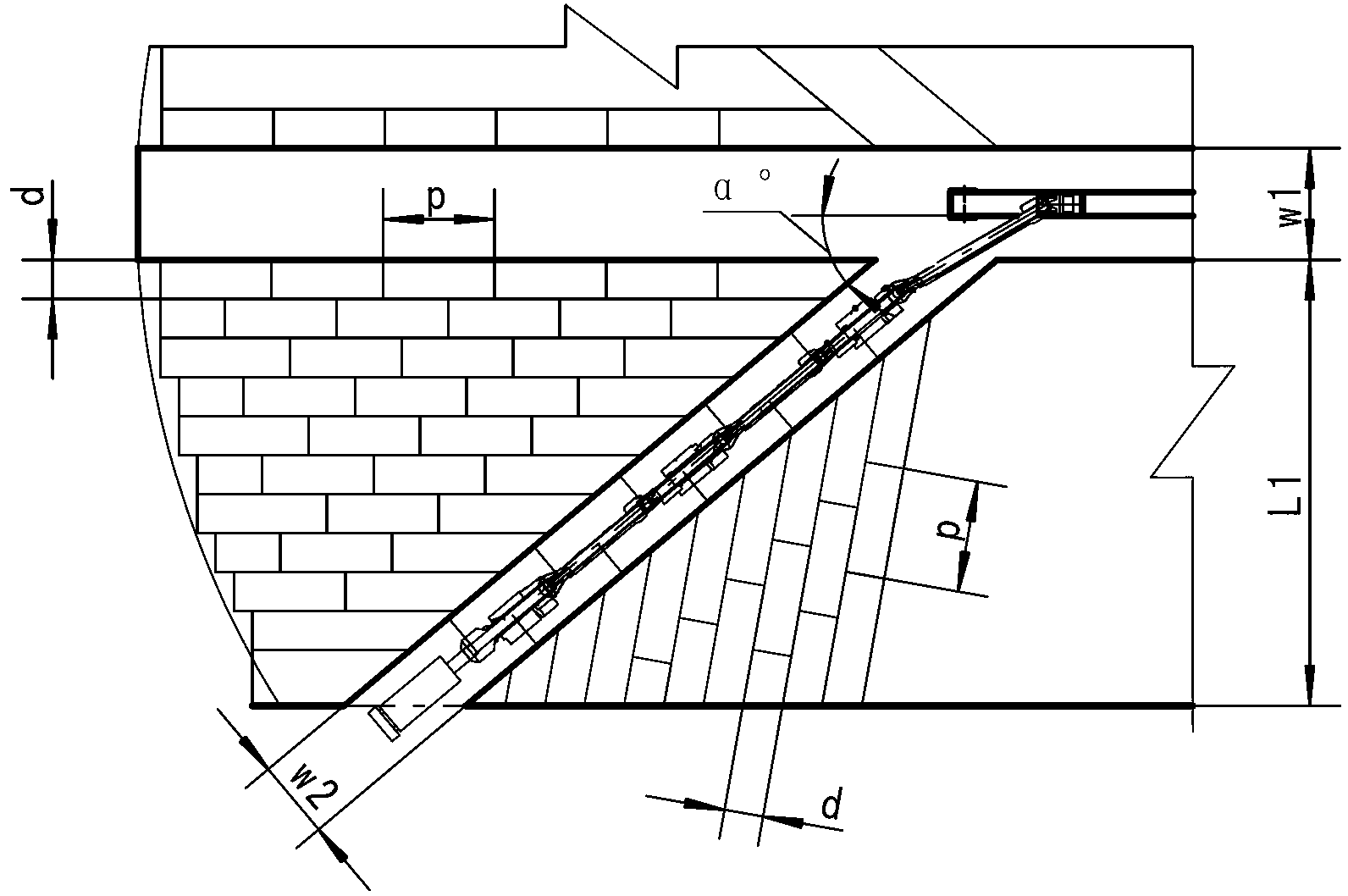

[0046] figure 2 As shown, it is the location state map of each part of the left and right wing mining areas, the middle is the main roadway, the side is the wing roadway, W1 is the main roadway excavation width, W2 is the wing roadway excavation width, the angle between the main roadway and the left and right wing roadway =30 o -45 o , P is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com