Numerical control grinding and machining method of stepwise variable pressure angle involute gear

A technology of involute gears and variable pressure angles, which is applied to elements with teeth, belts/chains/gears, gear teeth, etc., which can solve problems such as low production efficiency, limited use range, and unguaranteed gear machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

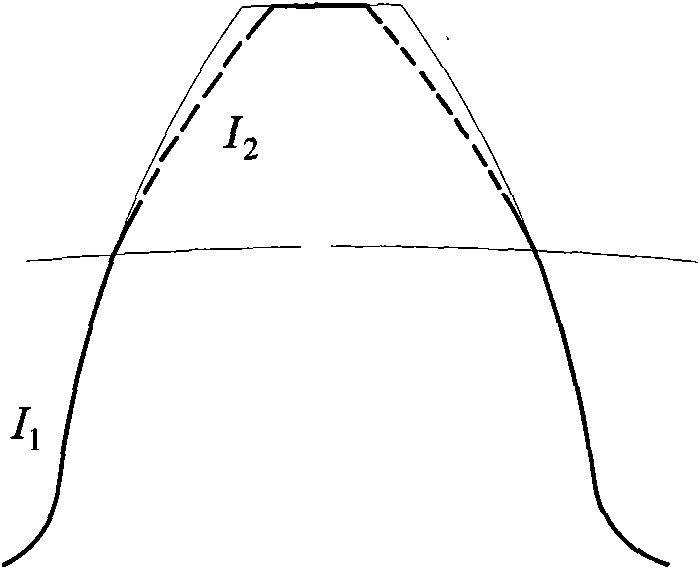

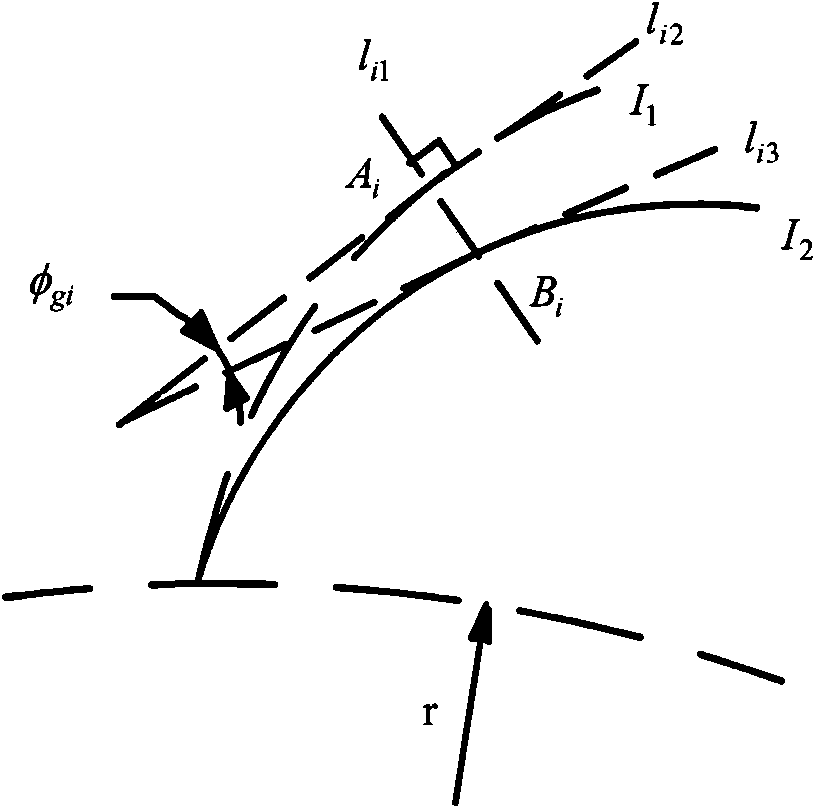

[0077] This embodiment is aimed at stepwise variable pressure angle involute gears, the tooth shape of which has a stepwise double involute structure, the entire tooth profile is divided by the index circle, and the part below the index circle is the index circle pressure angle is α 1 The standard involute I 1 , the part above the graduation circle is the graduation circle pressure angle is α 2 The stepped involute I 2 , α 1 = 20°, α 2 >20°, r is the radius of the indexing circle, the tooth shape of the involute gear with stepwise variable pressure angle is as follows figure 1 shown;

[0078] Standard Involute I 1 The parametric equation for :

[0079]

[0080] Stepped Involute I 2 The parametric equation for is:

[0081] x ( 2 ) y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com