Patents

Literature

42results about How to "Achieve fine grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

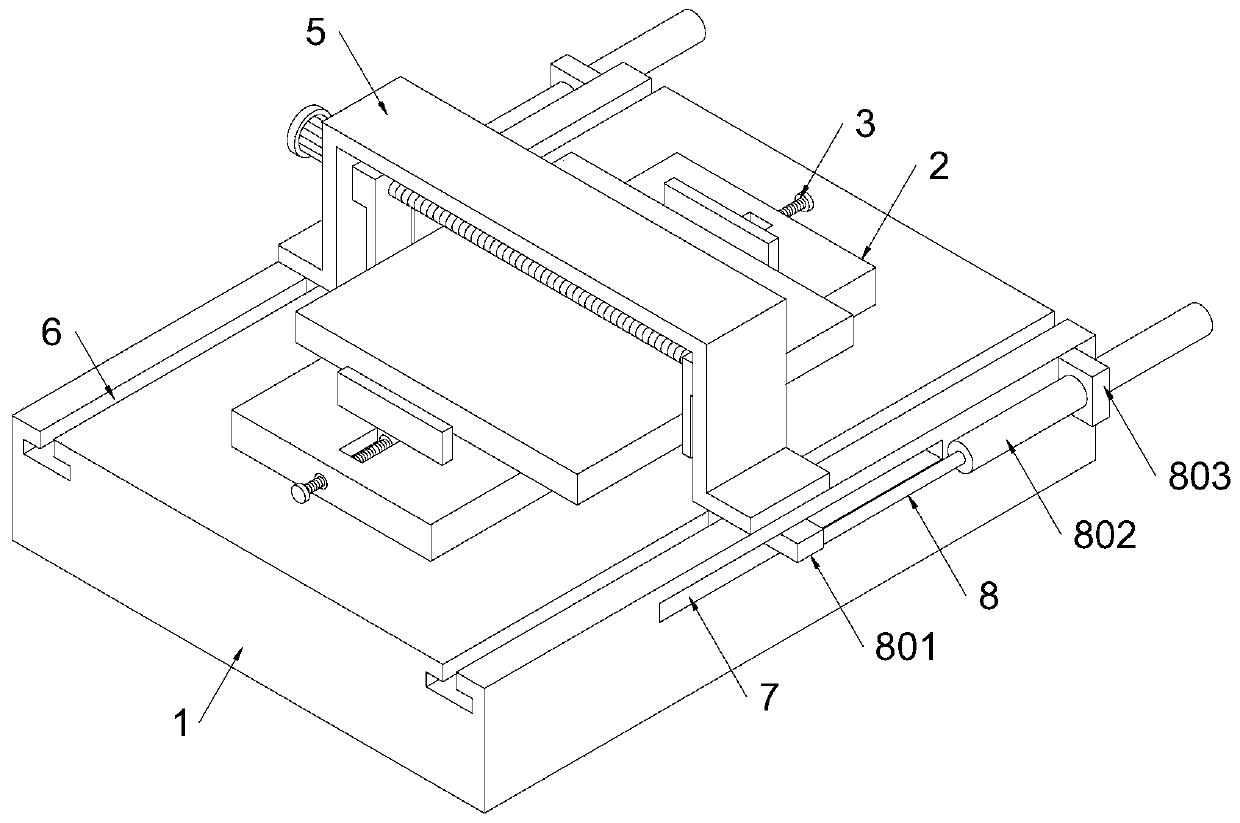

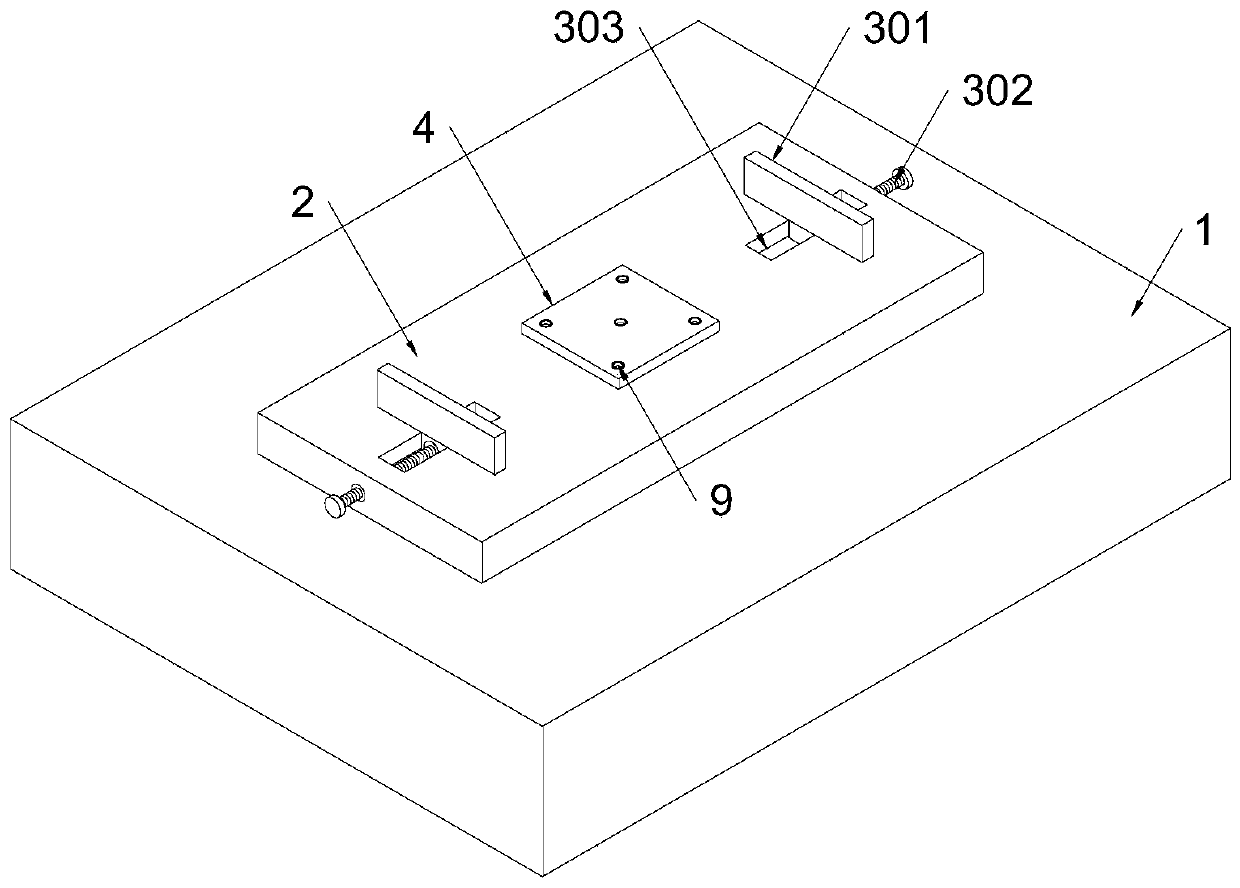

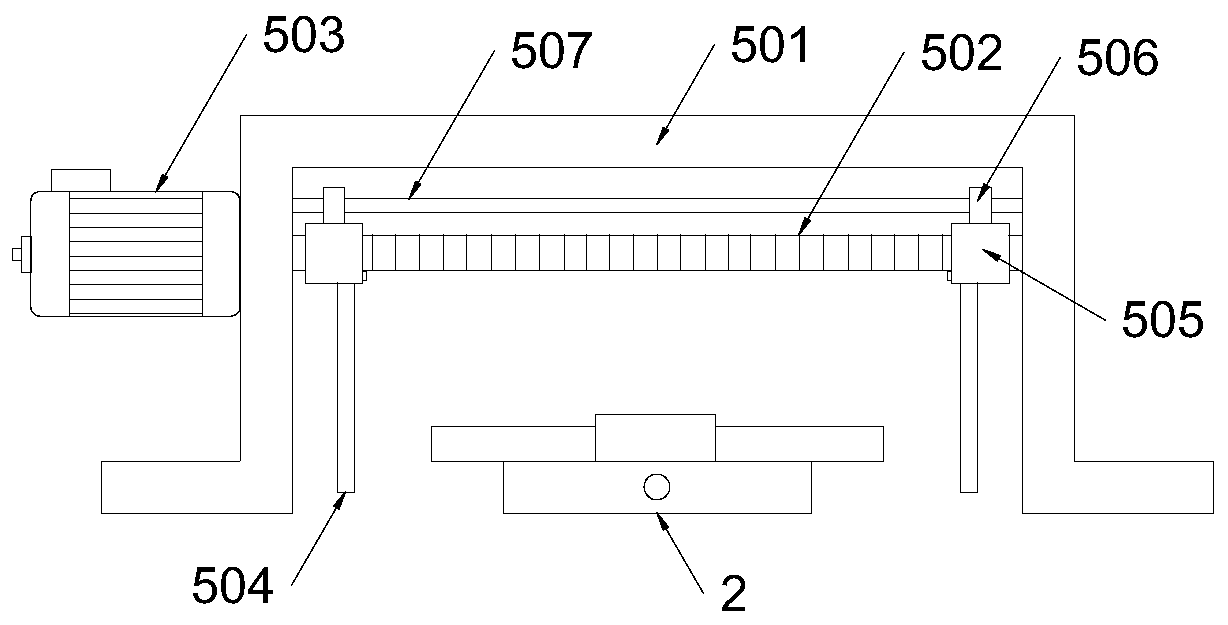

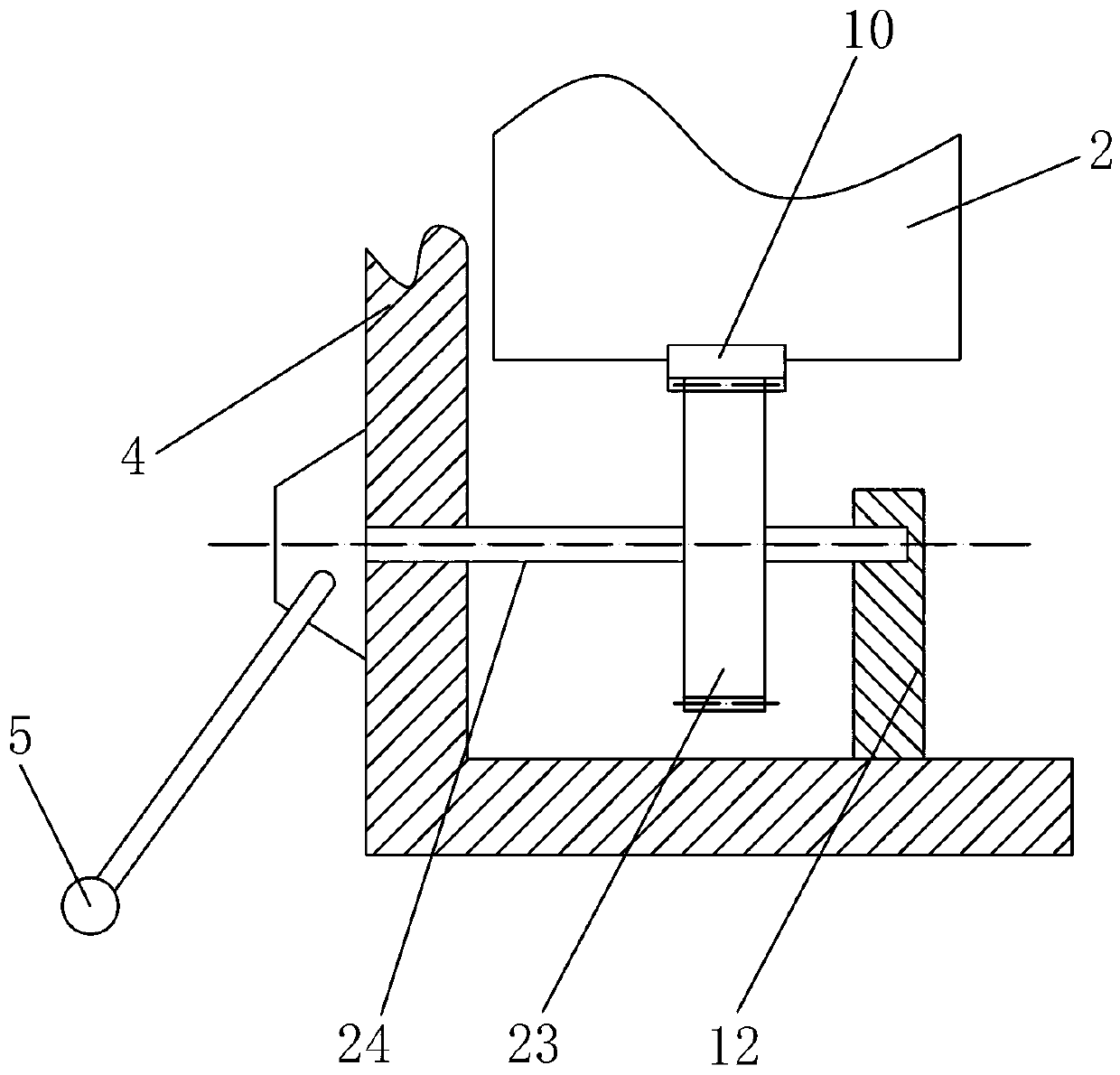

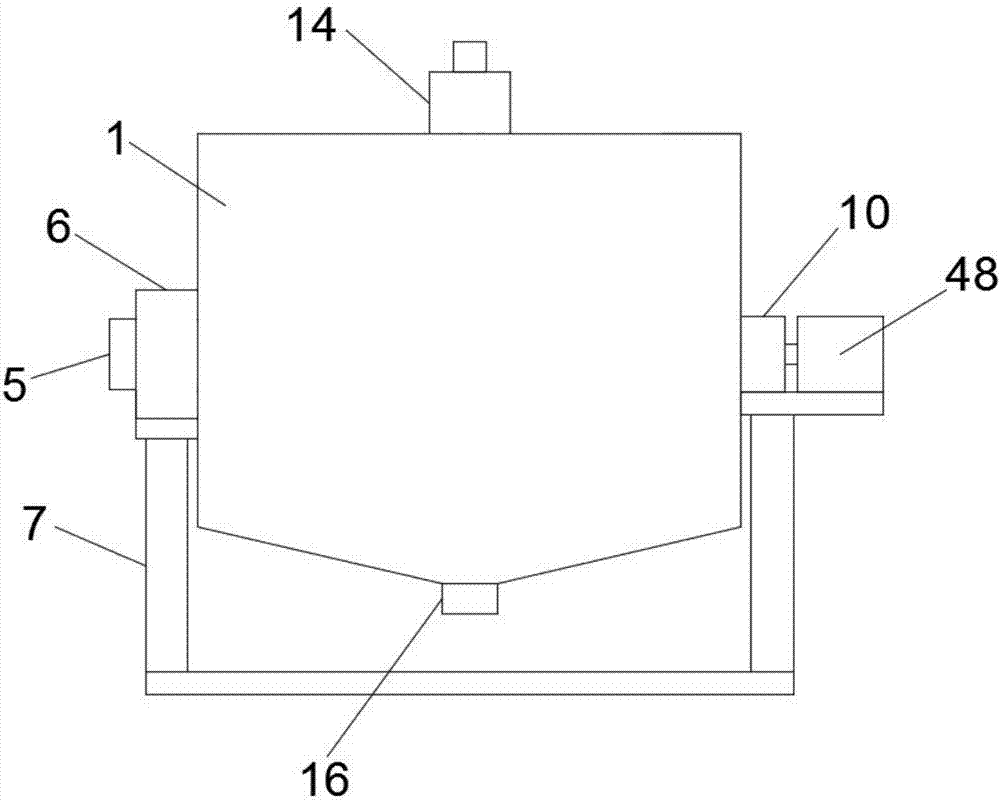

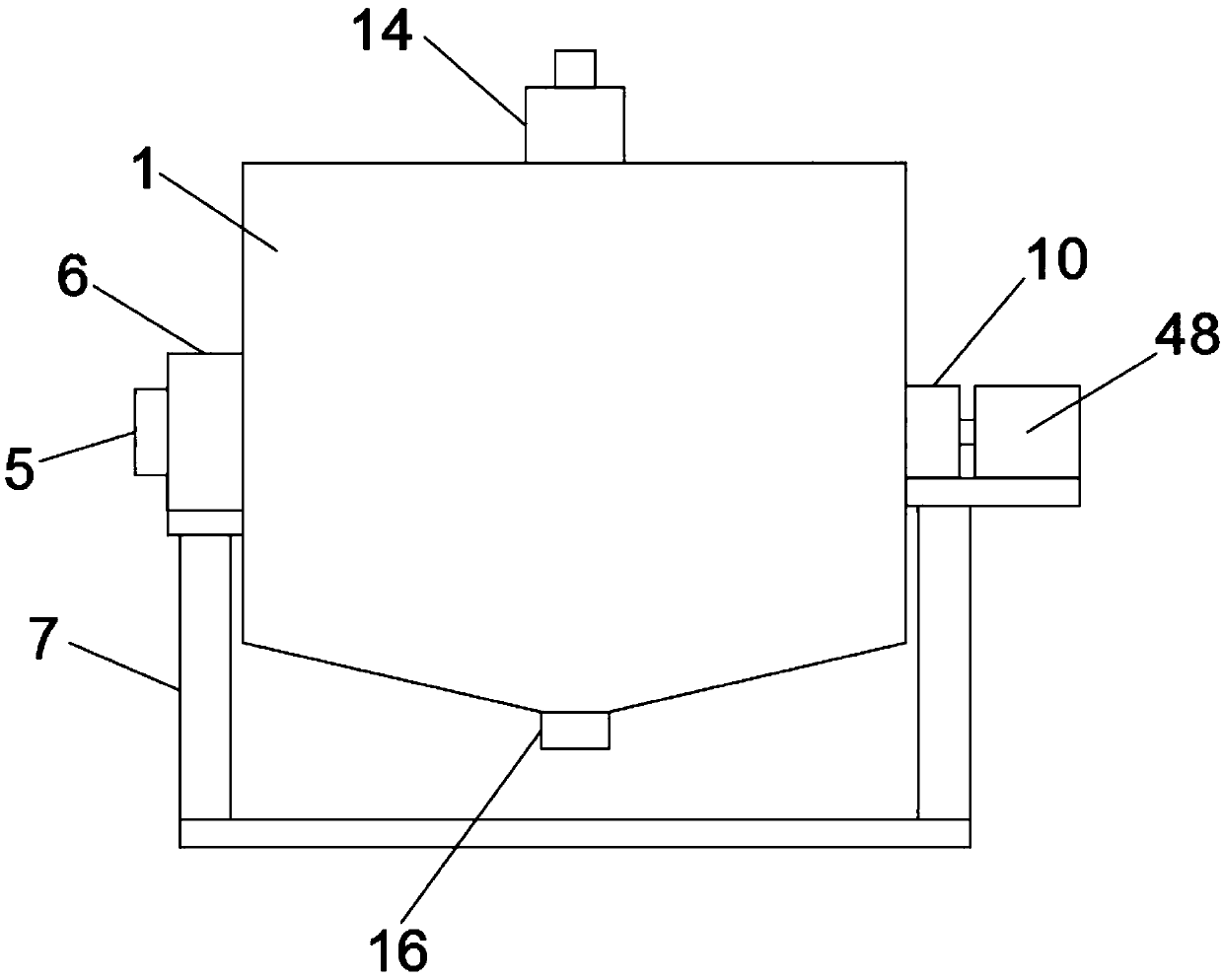

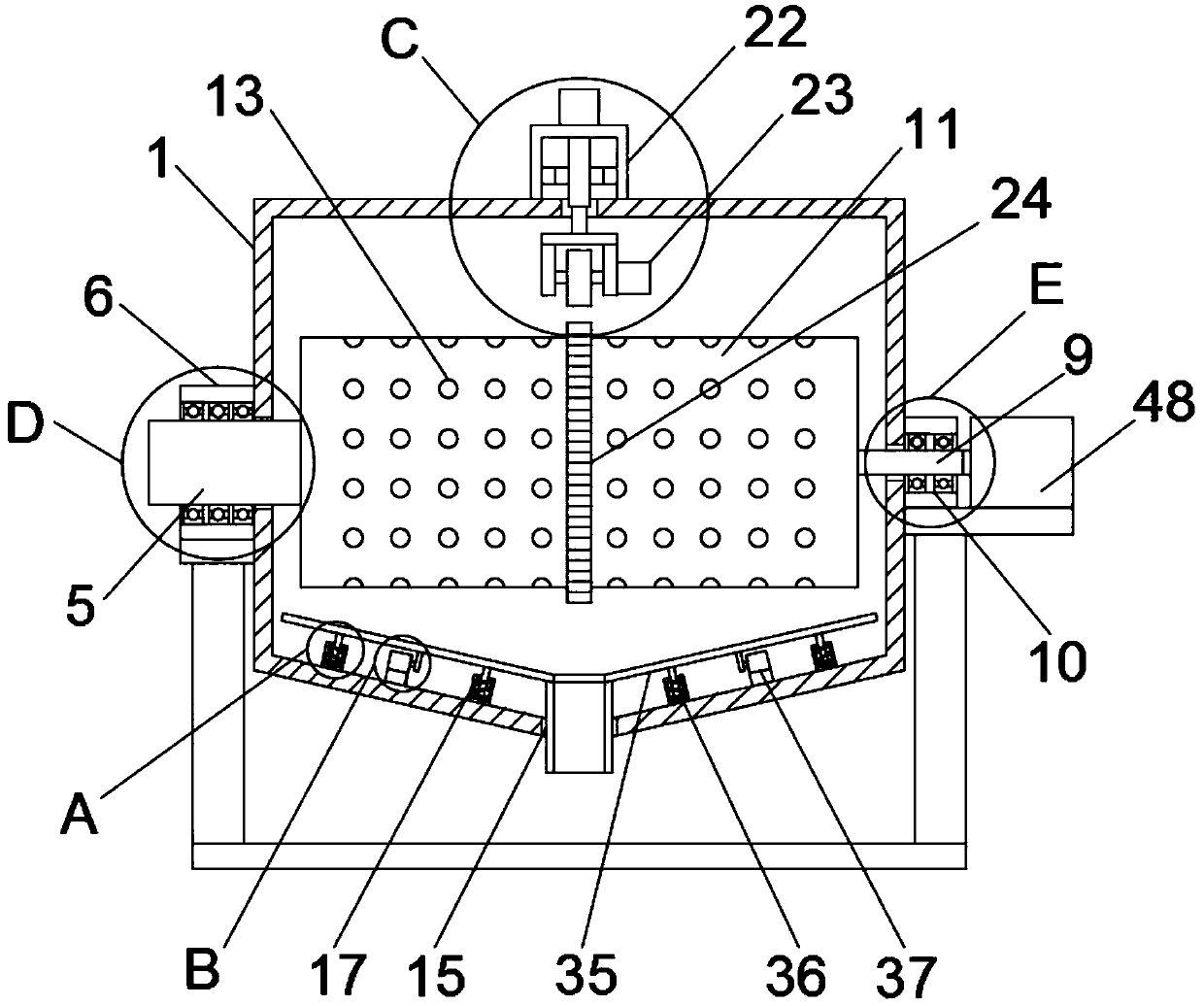

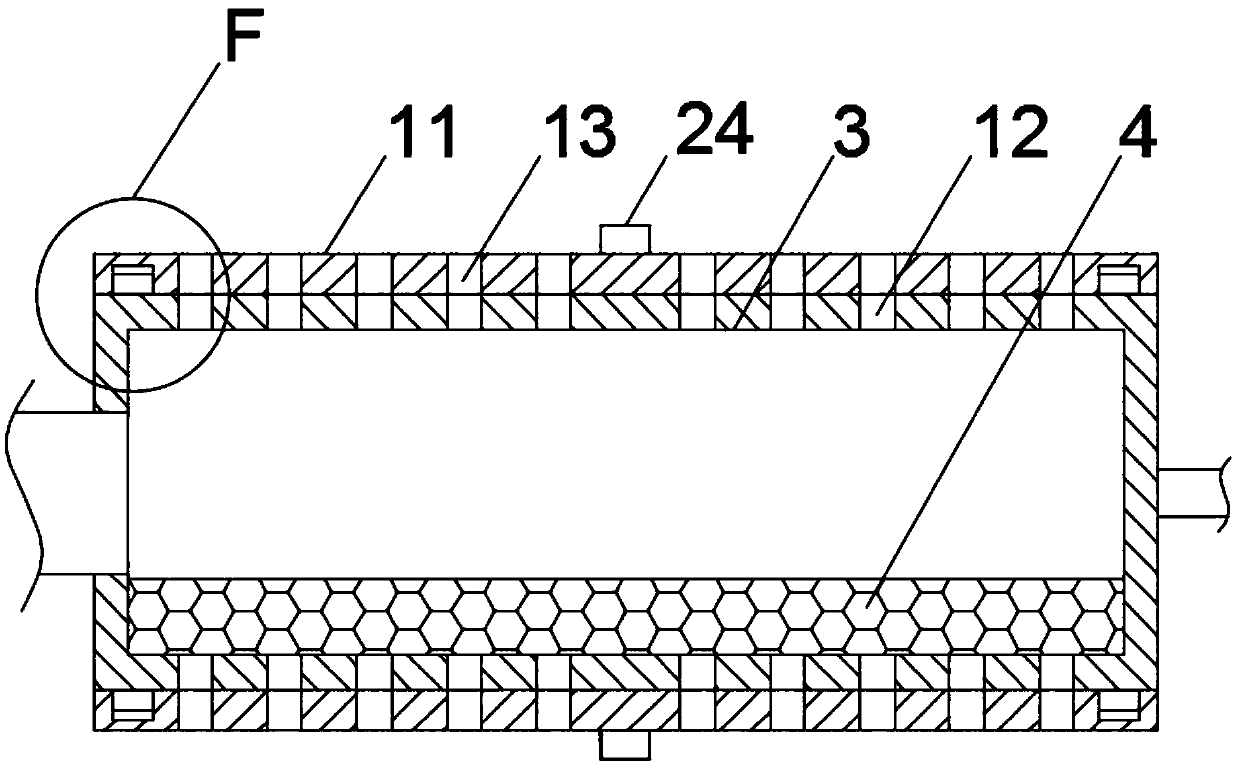

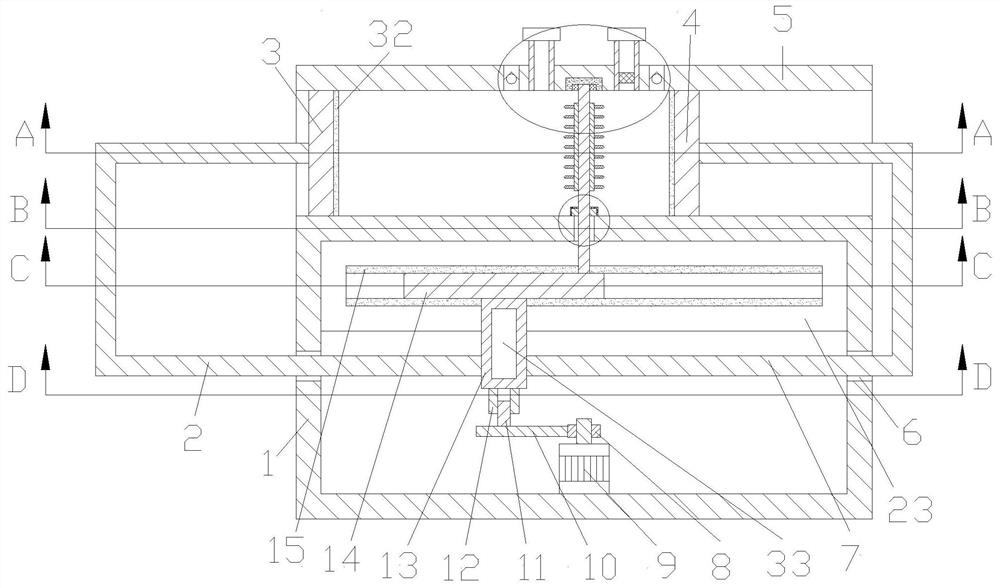

Finish grinding device of steel plate

PendingCN110405608AReduce shakingAchieve fine grindingEdge grinding machinesGrinding drivesSheet steelReciprocating motion

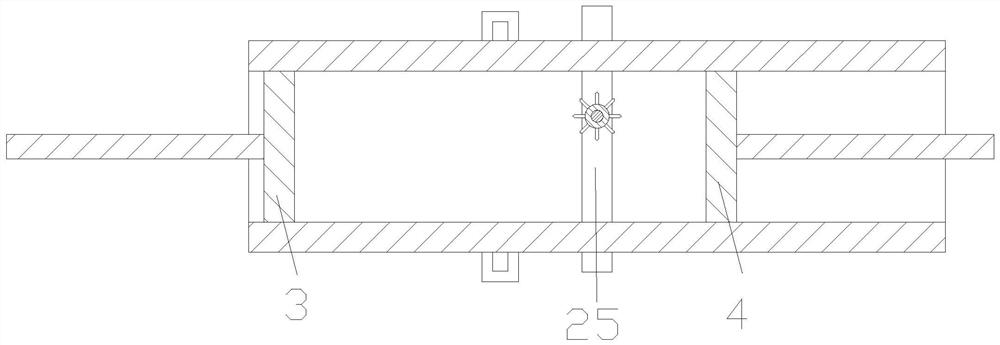

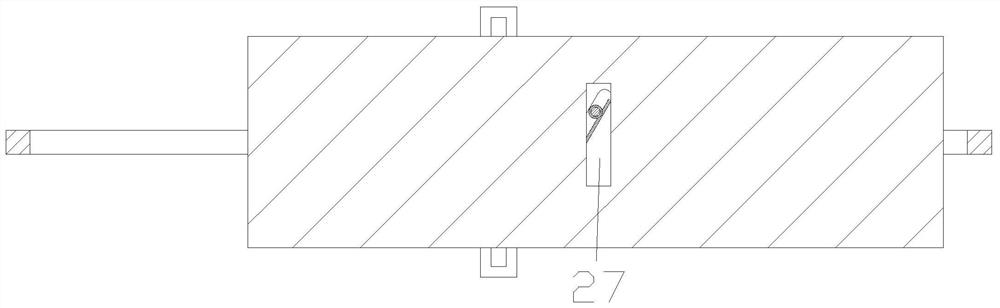

The invention discloses a finish grinding device of a steel plate. An operation table and a fixed plate fixedly arranged on the middle portion of the top end of the operation table are included; clamping mechanisms used for clamping the steel plate are symmetrically arranged on the two sides of the top end of the fixed plate; the middle portion of the top end of the fixed plate is movably providedwith a containing plate used for containing the steel plate; and the top of the fixed plate is provided with a grinding mechanism used for grinding the steel plate. According to the finish grinding device of the steel plate, due to the fact the two oppositely arranged clamping mechanisms are used for clamping the position of the steel plate, a servo motor works and drives a lead screw to rotate,the lead screw rotates on its own to drive two movable blocks in threaded connection with the lead screw to move oppositely along the lead screw; the movable blocks move and drive grinding pieces to move, the two grinding pieces are correspondingly moved to be in abut-against contact with the two sides of the square steel plate due to self rotation; at the moment, an electric push rod reciprocates, the movable plates are driven to move back and forth, then rusting on the side face of the square steel plate is removed due to back-and-forth friction of the grinding pieces, and time and labor aresaved.

Owner:张家港市众利机电制造有限公司

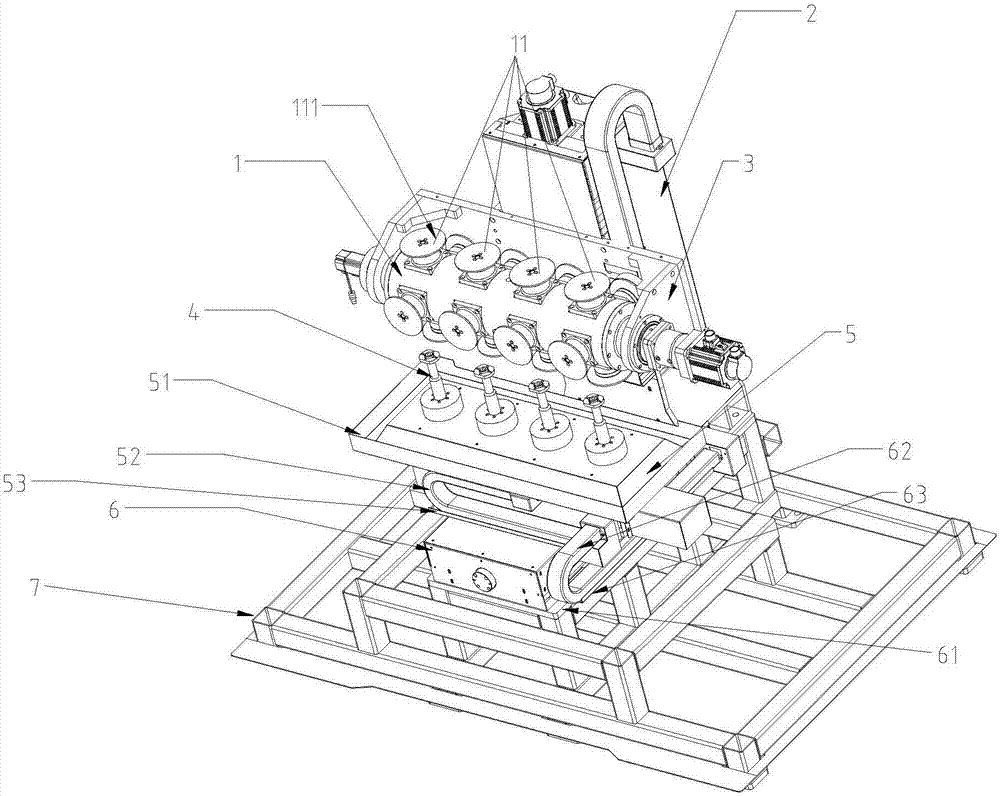

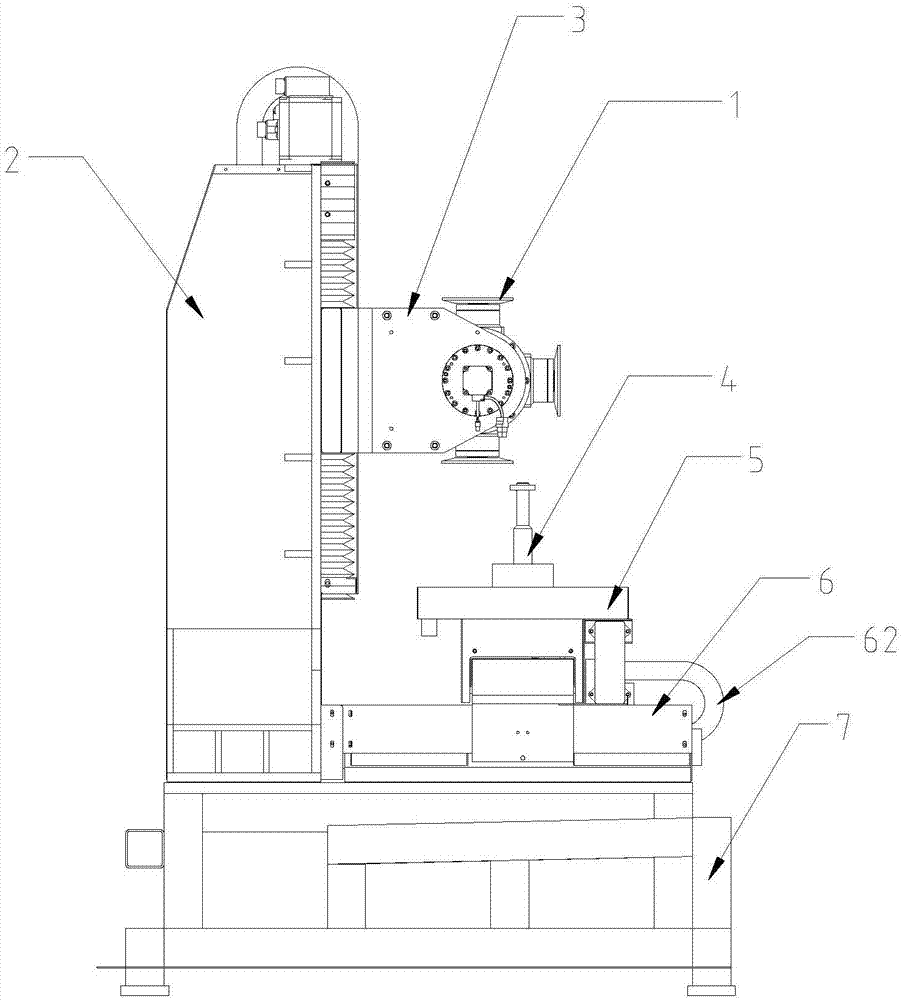

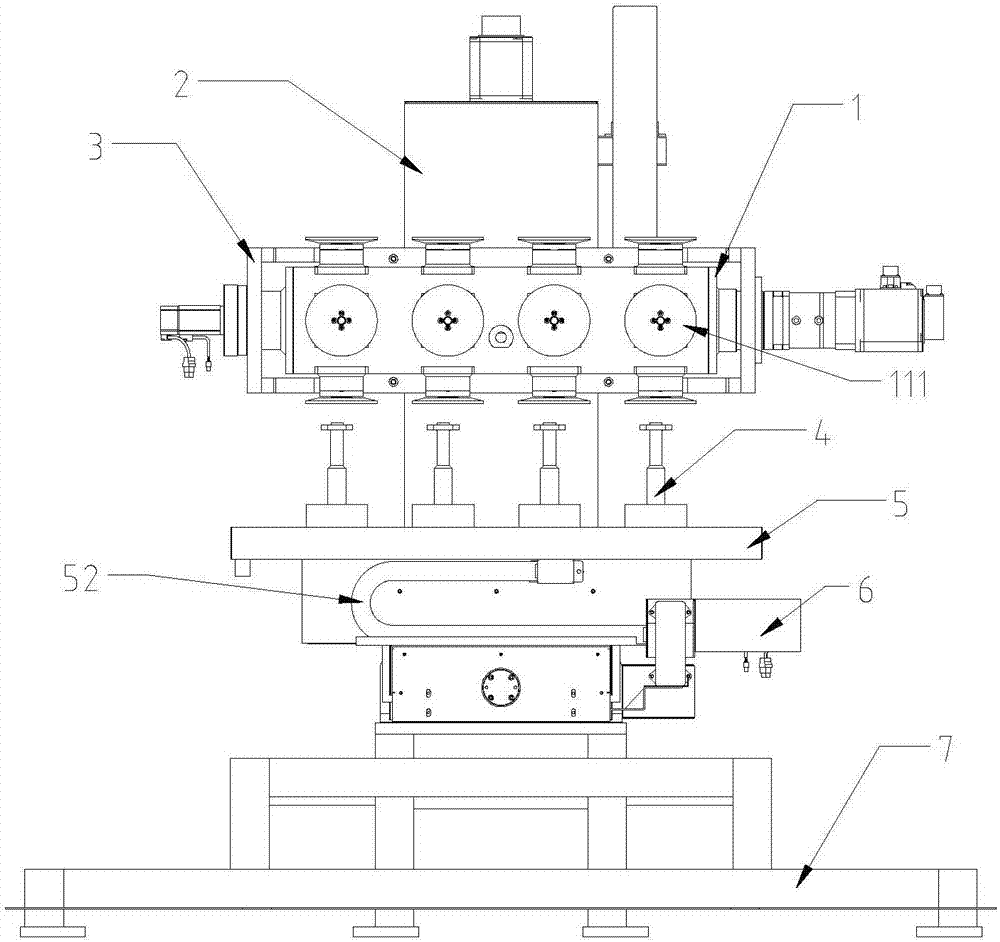

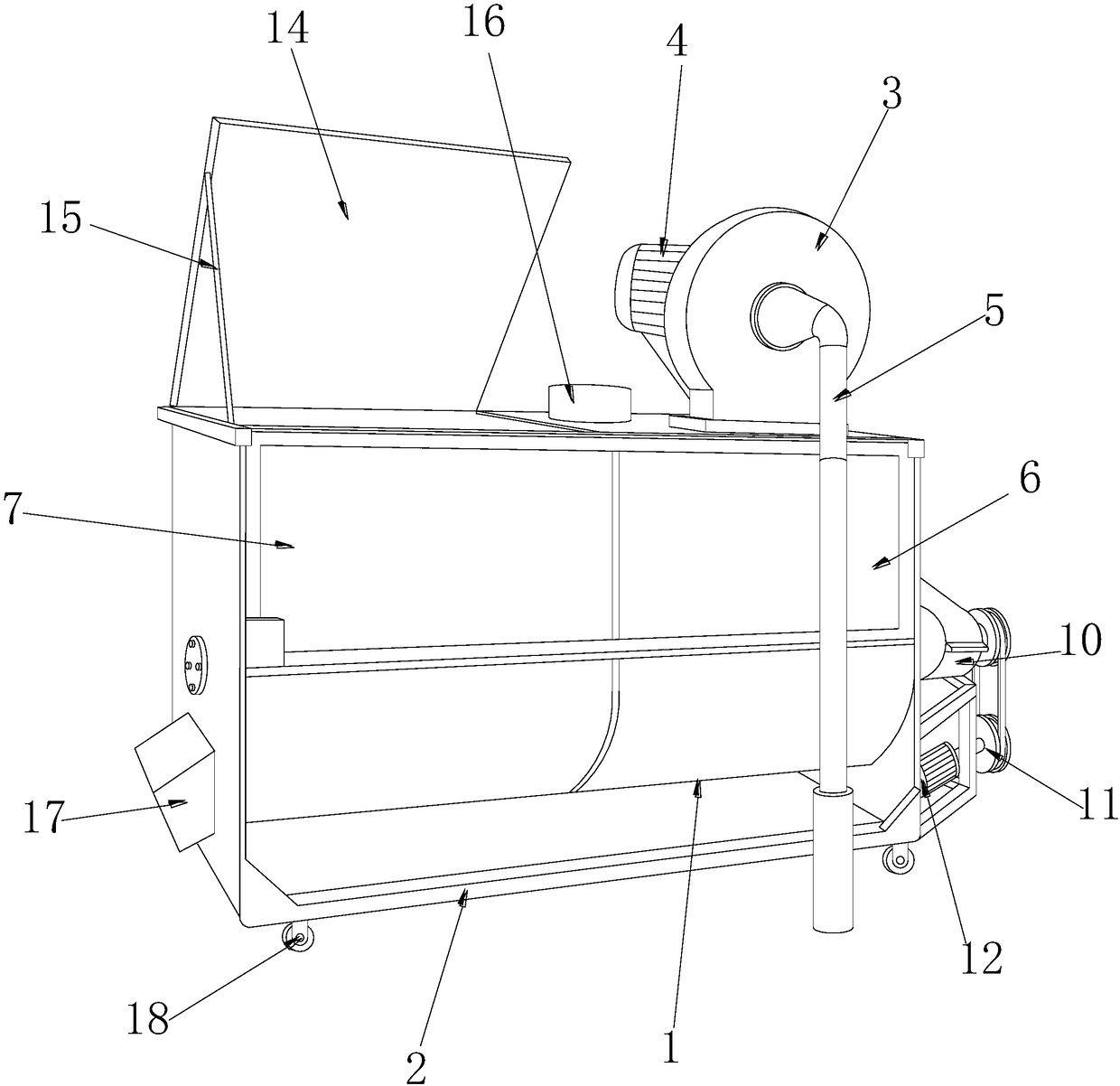

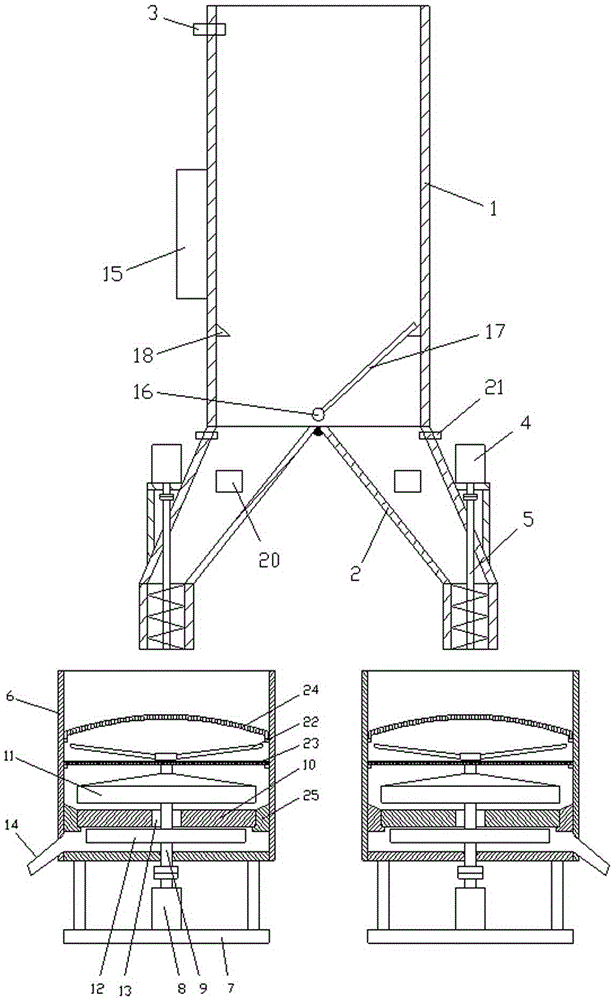

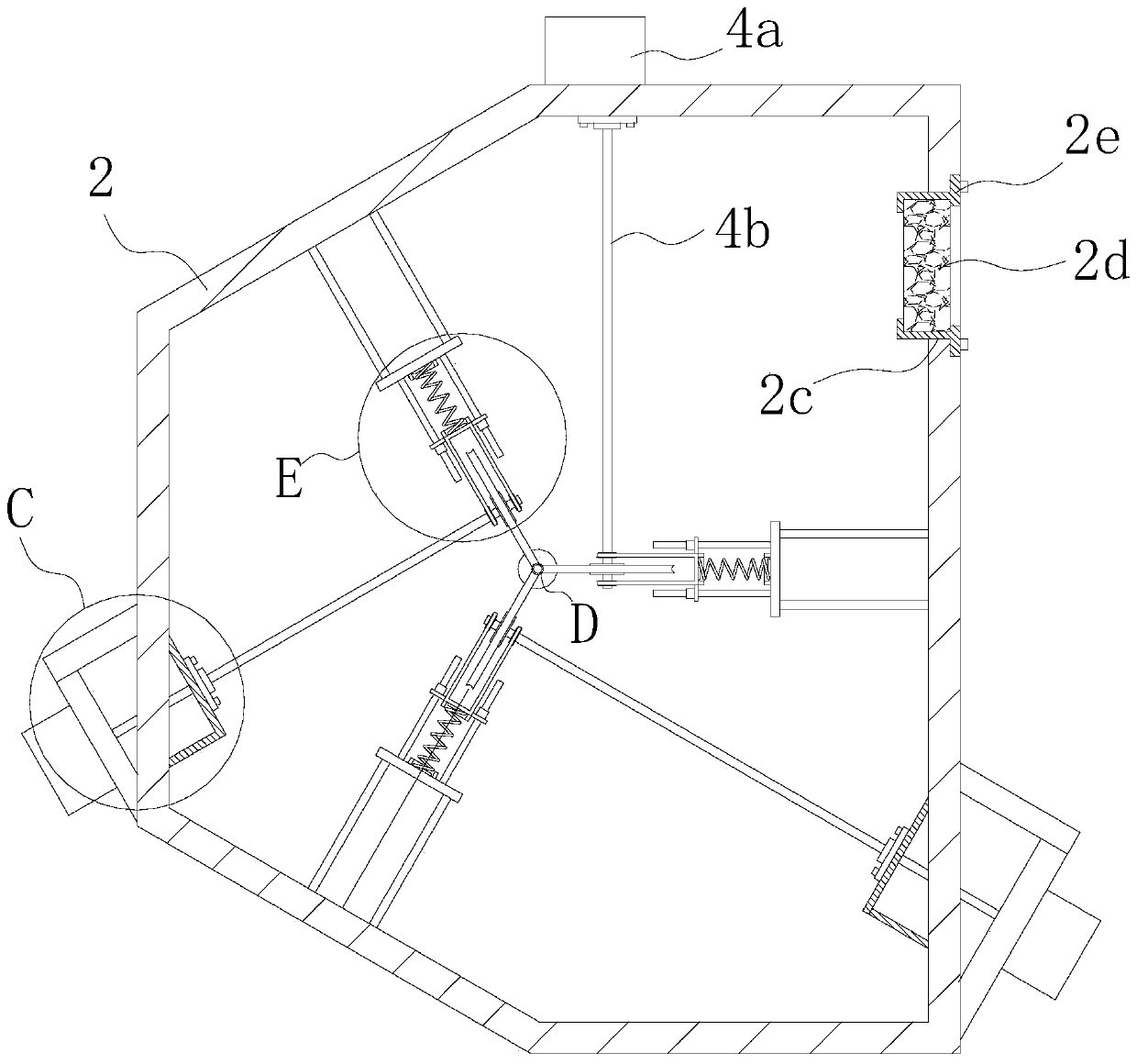

All-directional automatic polishing machine and polishing method

PendingCN107097131AAchieve rotationRealize simultaneous processingGrinding carriagesGrinding drivesMechanical engineering

The invention discloses an all-directional automatic polishing machine and a polishing method. The polishing machine comprises a polishing frame, a lifting mechanism, a grinding disc power mechanism, a tool mechanism and a translation mechanism; the tool mechanism is arranged on the translation mechanism; the translation mechanism is arranged on the polishing frame; the bottom of the lifting mechanism is connected to the polishing frame; the translation mechanism comprises an X-axle slide table mechanism and a Y-axle slide table mechanism; the grinding disc power mechanism is connected to the side surface of the lifting mechanism through a support frame; the grinding disc power mechanism comprises a grinding disc group, a grinding disc fixing module and a transmission module; the grinding disc group is assembled on a grinding disc bearing base; the grinding disc group consists of multiple grinding disc sets; and the grinding disc sets consist of multiple unit grinding discs. Multiple grinding disc sets with different specifications are provided; rotating angles of grinding disc fixed pipes are adjusted; the grinding disc sets are used for polishing bent surfaces of workpieces; and the all-directional polishing of the surfaces of the workpieces by multiple grades of precision through the grinding disc sets with different specifications is achieved.

Owner:广东遂联智能装备制造有限公司

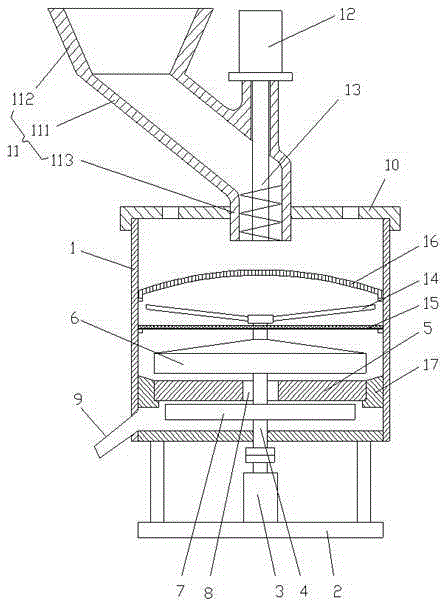

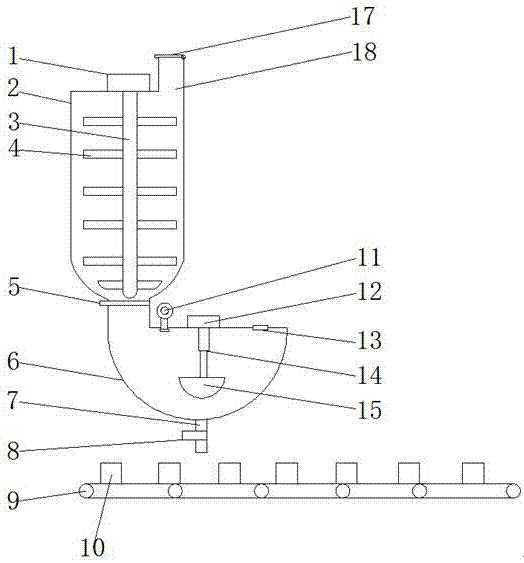

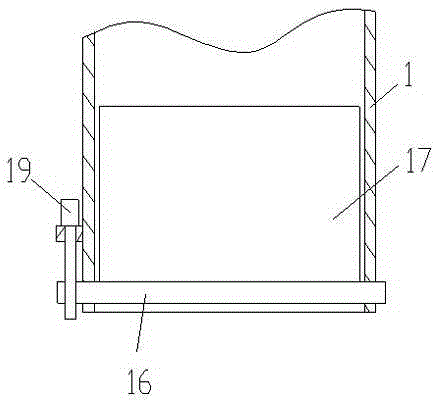

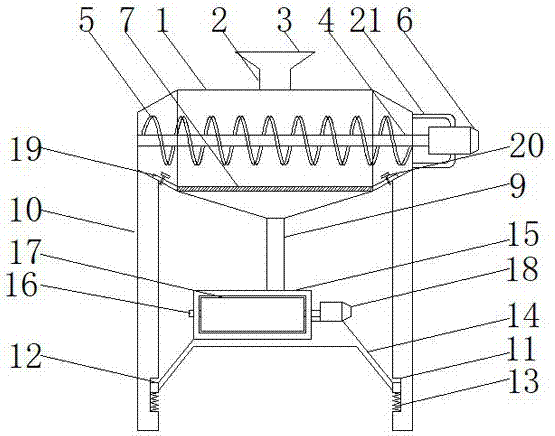

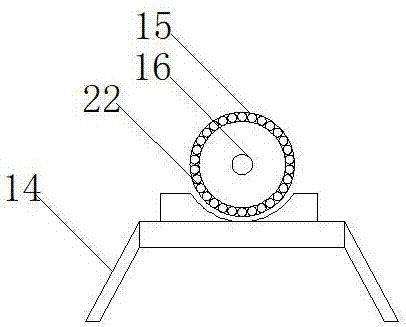

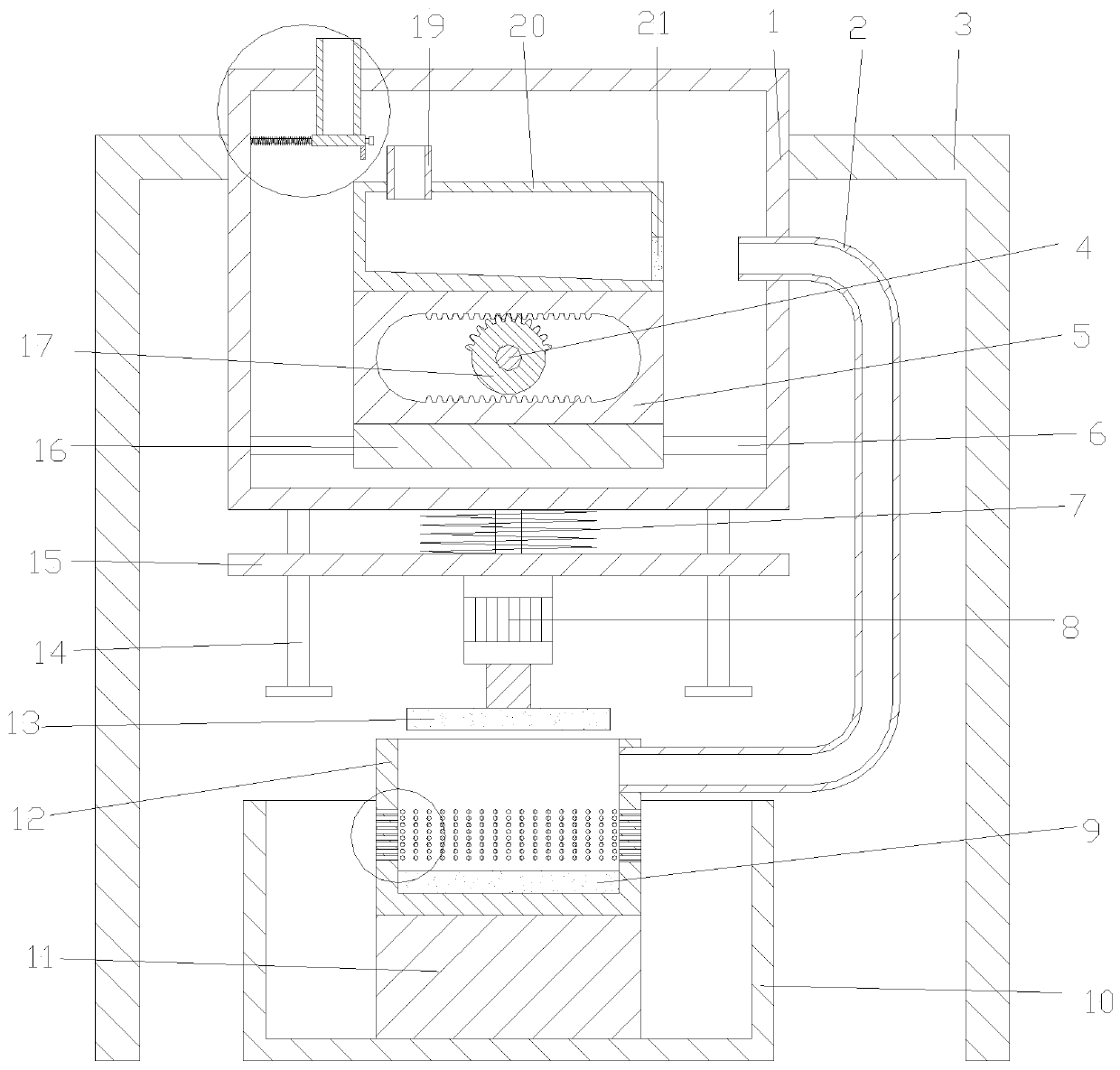

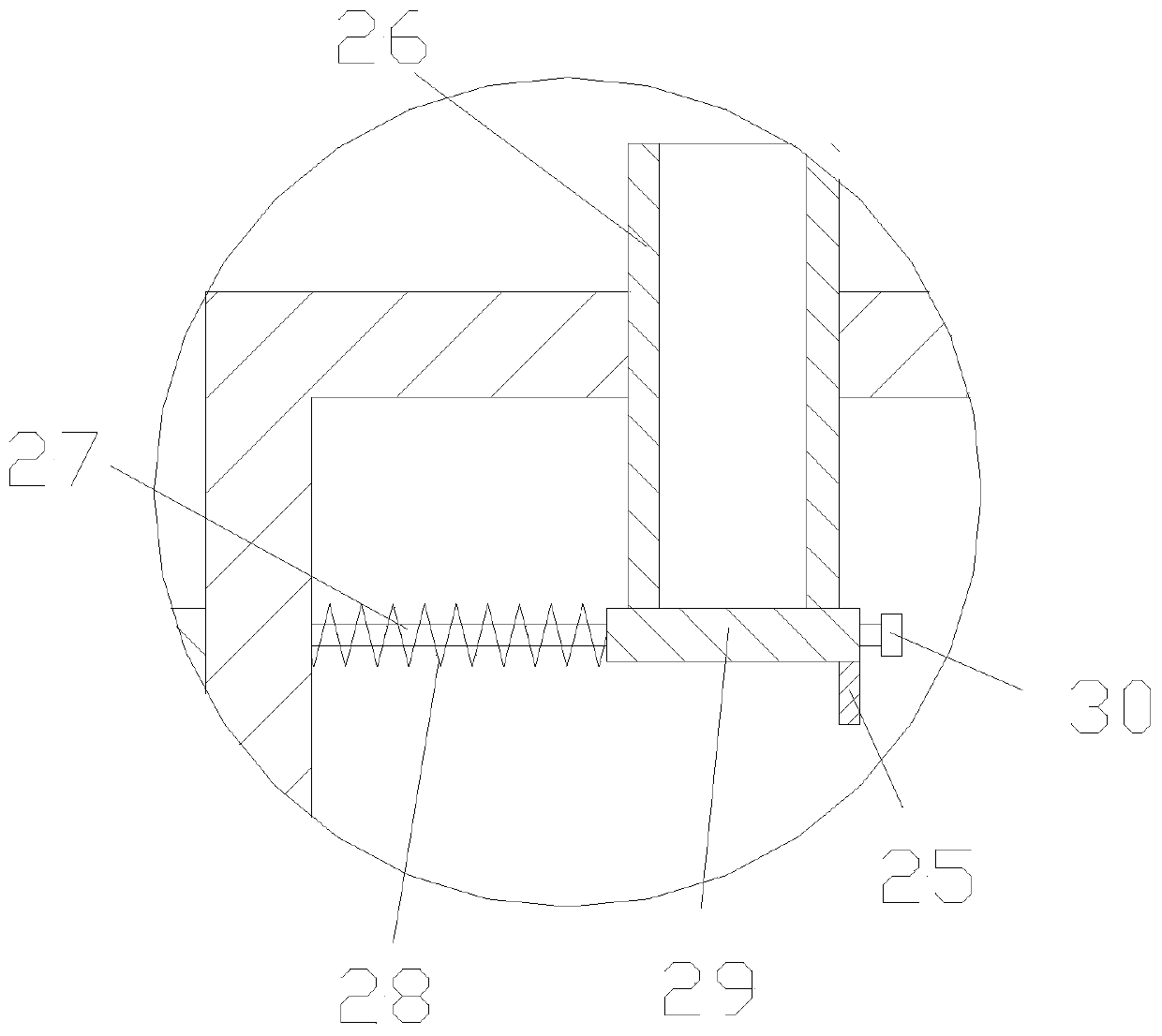

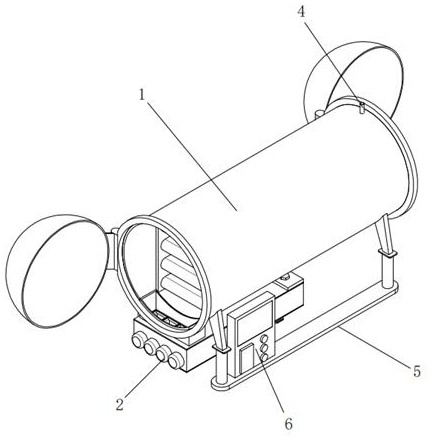

Anti-blocking soybean pulping device

InactiveCN105251566AAchieve coarse grindingAchieve fine grindingCocoaGrain treatmentsPulp and paper industrySmall footprint

The invention discloses an anti-blocking soybean pulping device. The anti-blocking soybean pulping device comprises a cylindrical machine case, a support, a motor, a fixed grinding disk, a rough-grinding movable grinding disk, a fine-grinding movable grinding disk and a uniform-speed feeding mechanism. The uniform-speed feeding mechanism comprises a feeding pipe, a feeding motor and a screw feeding shaft. According to the anti-blocking soybean pulping device, the rough-grinding movable grinding disk is matched with the upper end surface of the fixed grinding disk, the fine-grinding movable grinding disk is matched with the lower end surface of the fixed grinding disk, and therefore rough grinding and fine grinding on soybeans can be continuously carried out; the pulping effect achieved by connecting multiple pulping devices in series can be achieved through the pulping device; the size is small, the structure is compact, the occupied area is small, the production efficiency is high, and the production cost is low; the machine case is provided with the uniform-speed feeding mechanism, the uniform-speed feeding mechanism drives the screw feeding shaft to rotate at uniform speed through the feeding motor, the soybeans are uniformly fed into the machine case, the feed quantity can be regulated by controlling the rotation speed of the motor, and therefore overloading operation and blockage of the pulping device caused by non-uniform feeding and excessive feeding can be avoided.

Owner:CHONGQING YUPAI AGRI PROD DEV

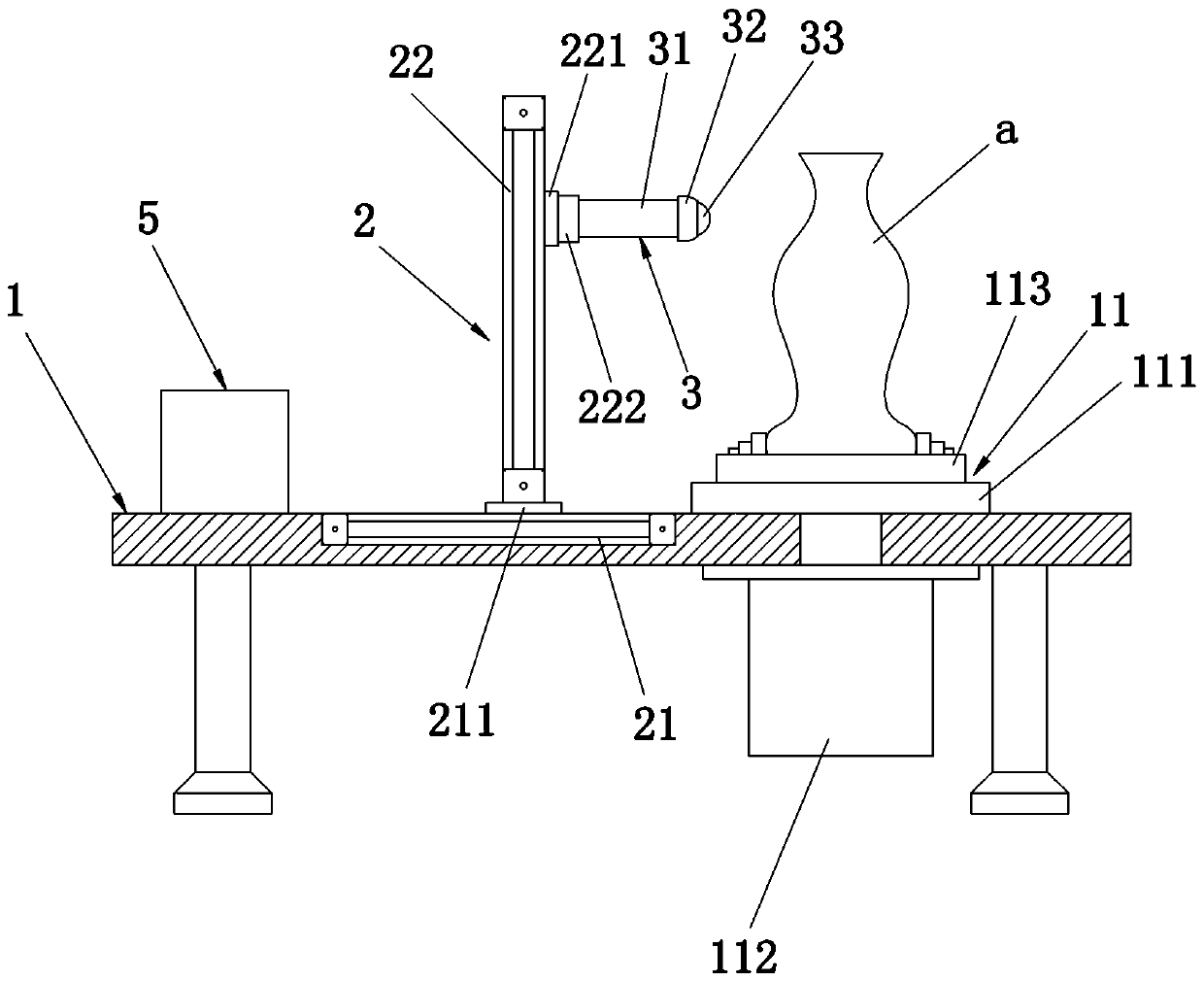

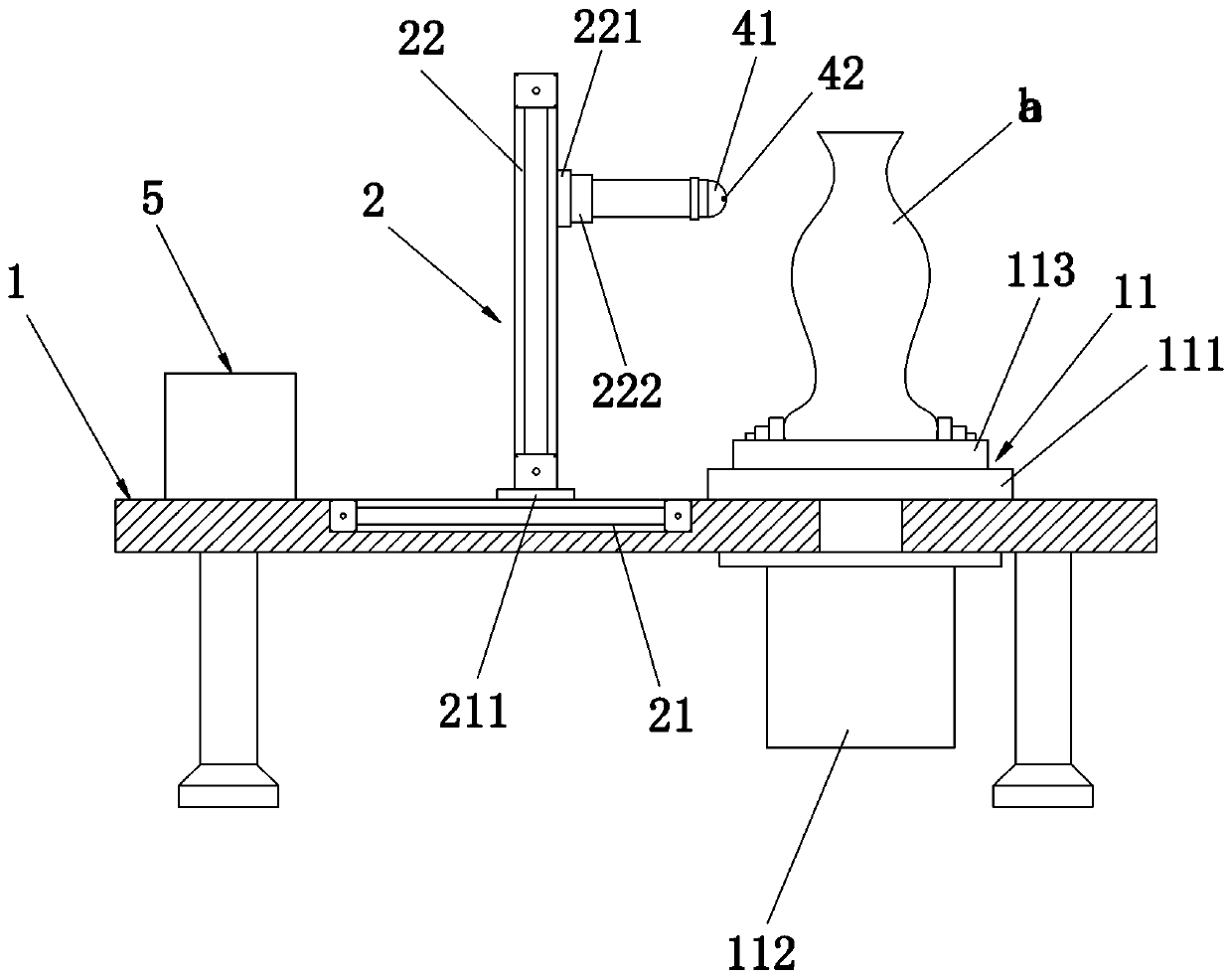

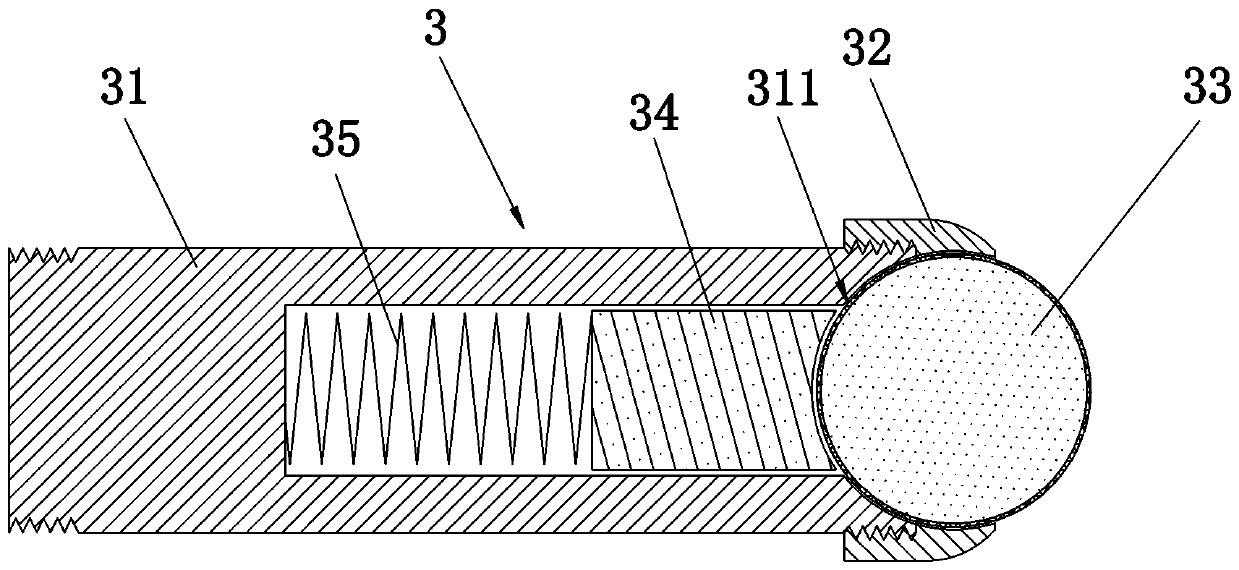

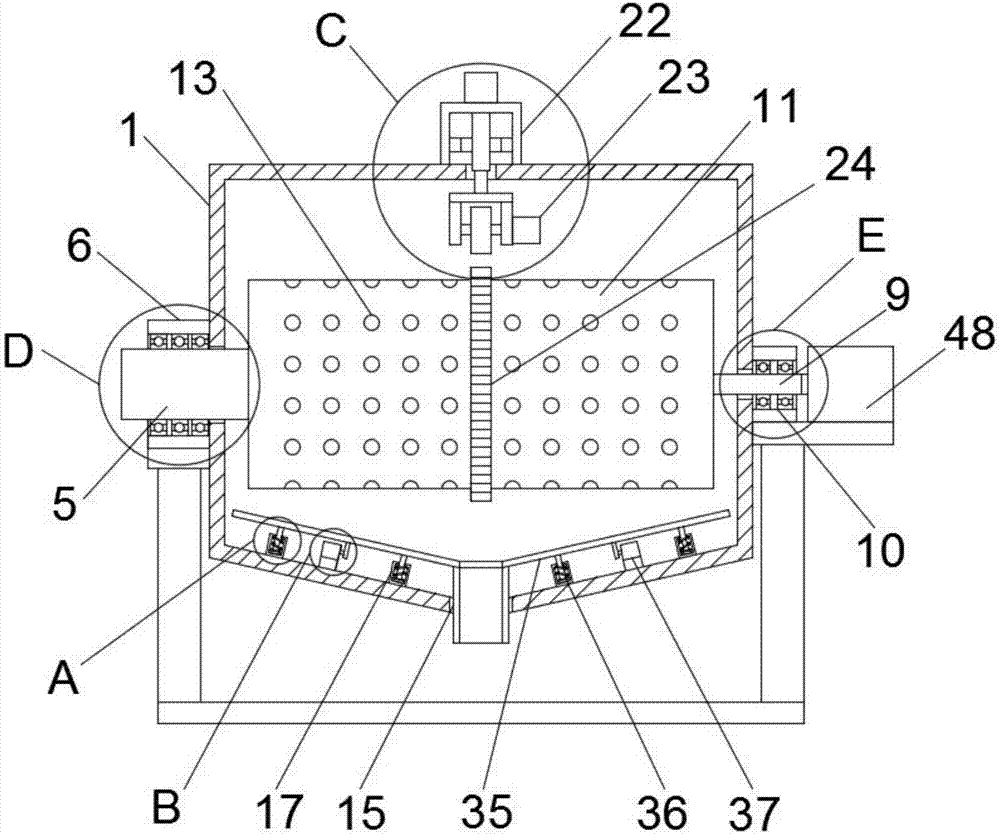

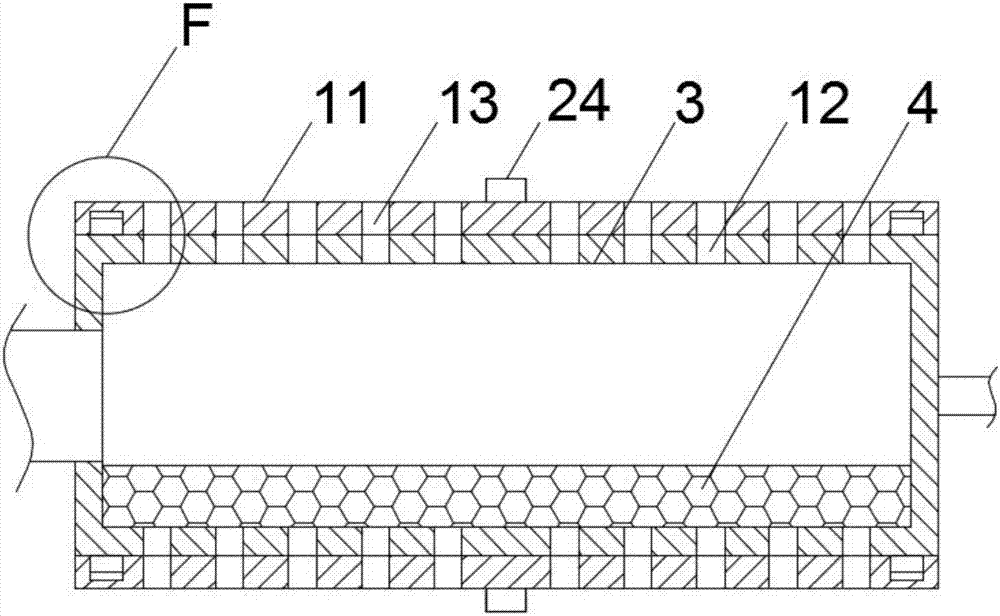

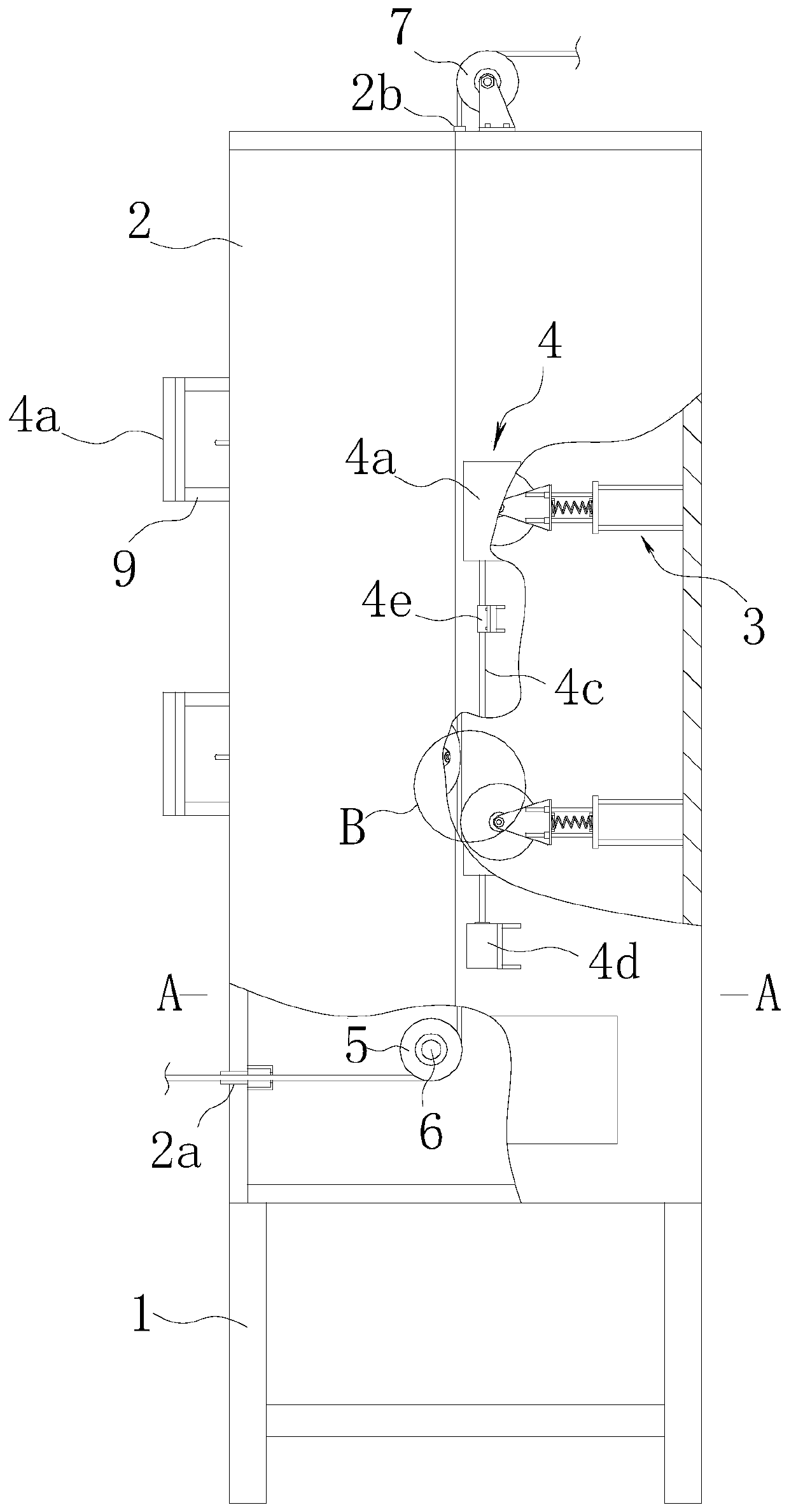

Ceramic blank automatic polishing machine

ActiveCN110860971ARealize automatic grinding processImprove sanding effectGrinding carriagesCeramic shaping apparatusPolishingWorkbench

The invention discloses a ceramic blank automatic polishing machine, and relates to the field of ceramic production equipment. The ceramic blank automatic polishing machine comprises a workbench, a sandbag polishing head and a driving device; the workbench is rotatably provided with a fixing seat where a ceramic blank can be placed; the sandbag polishing head is arranged on the upper portion of the workbench and driven to move up and down on the outer surface of the ceramic blank under action of the driving device, and polishing of the ceramic blank can be achieved. The ceramic blank automaticpolishing machine can achieve automatic polishing of the ceramic blank, the polishing effect and the polishing efficiency of the ceramic blank are improved advantageously, and the problems that the traditional ceramic polishing procedure relies on the manpower mode, the production efficiency is low, and the product quality is variable are solved. In addition, it is a large breakthrough to adopt the sandbag polishing head to polish the ceramic blank, the shape of the sandbag polishing head can be automatically changed along with changing of the outline of the ceramic blank in the polishing process, thus, unnecessary abrasion to the ceramic blank can be avoided, and in addition, precision polishing of the ceramic blank can be achieved.

Owner:FUJIAN JIAMEI GRP

Traditional Chinese medicine powder preparing packaging machine

InactiveCN107161436APrevent floatingAvoid wastingSolid materialGrain treatmentsHydraulic cylinderMotor drive

The invention discloses a preparation and packaging machine for traditional Chinese medicine powder, which includes a No. 1 motor, a crushing cylinder, a connecting rod, a crushing blade, a plug plate, a grinder, a discharge pipe, a solenoid valve, a conveyor belt, a packaging tank, a hot air blower, and a No. 2 motor , nano-microporous composite material layer, hydraulic cylinder, grinding workpiece, blast hood, sealing cover and feeding pipe, the No. 1 motor drives the crushing blade on the connecting rod to rotate, and crushes the herbs inside the crushing cylinder, pull out the plug Plate, pour the herbal medicine inside the crushing cylinder into the grinder, the hot air will dry the medicine in the grinder first, and the water vapor will pass through the nano-microporous composite material layer and go to the outside of the grinder to ensure that the crushed medicine will be dried before grinding. Keep dry for easy grinding. The blast hood can expand the blowing surface of the hot air blower, and the No. 2 motor drives the hydraulic cylinder to rotate, and the grinding workpiece can be lifted up and down through the hydraulic cylinder, thereby realizing the effect of fine grinding.

Owner:王山友

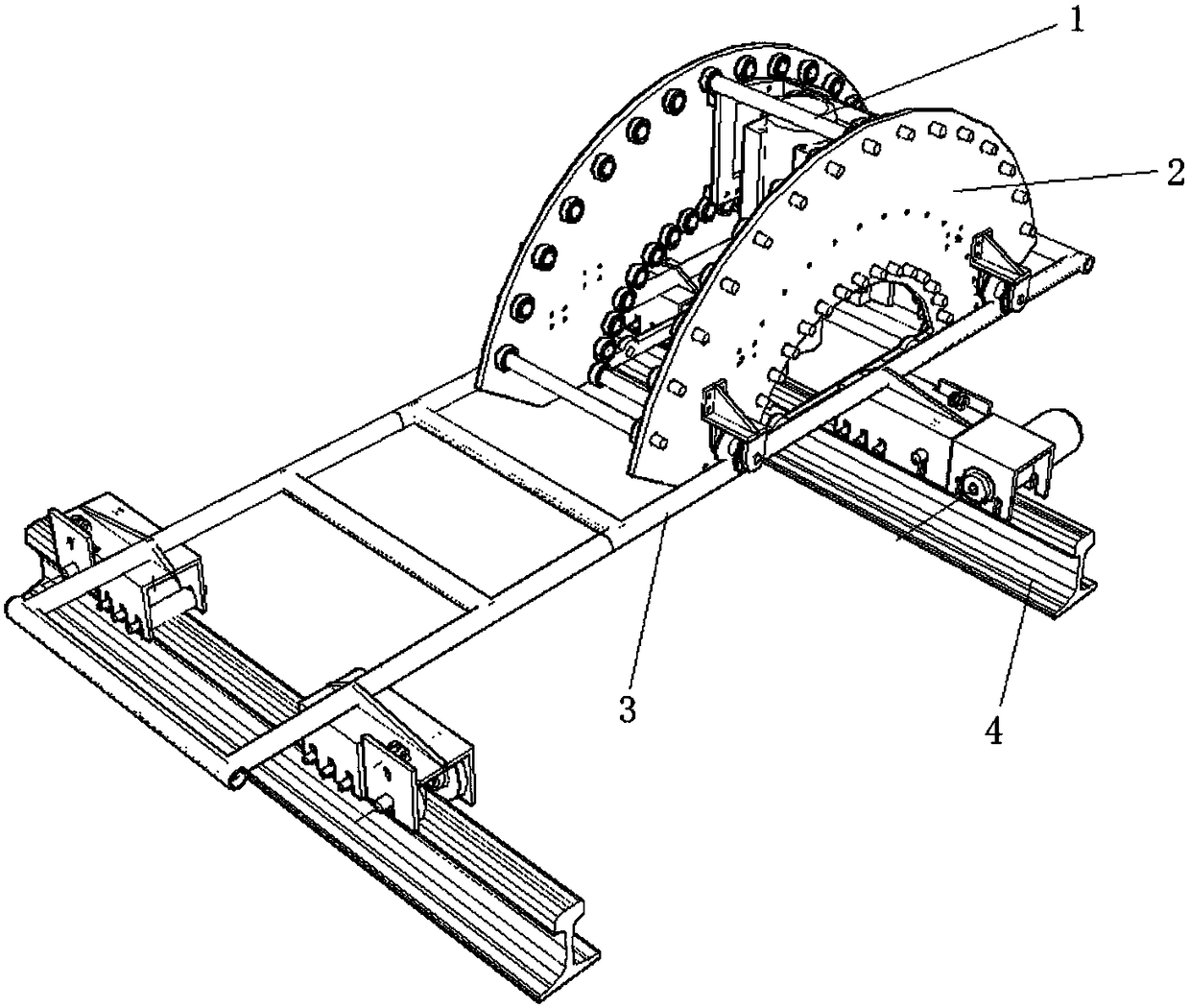

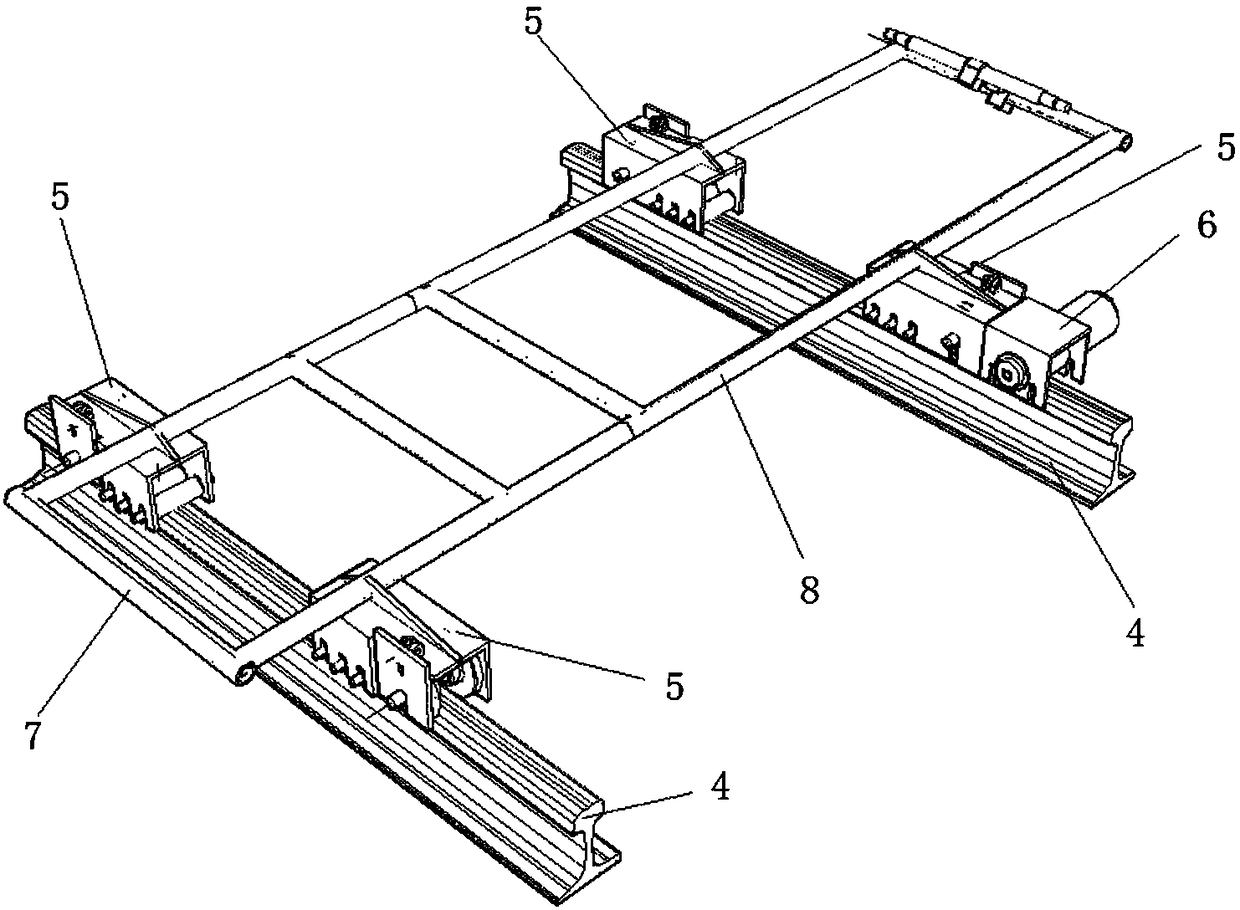

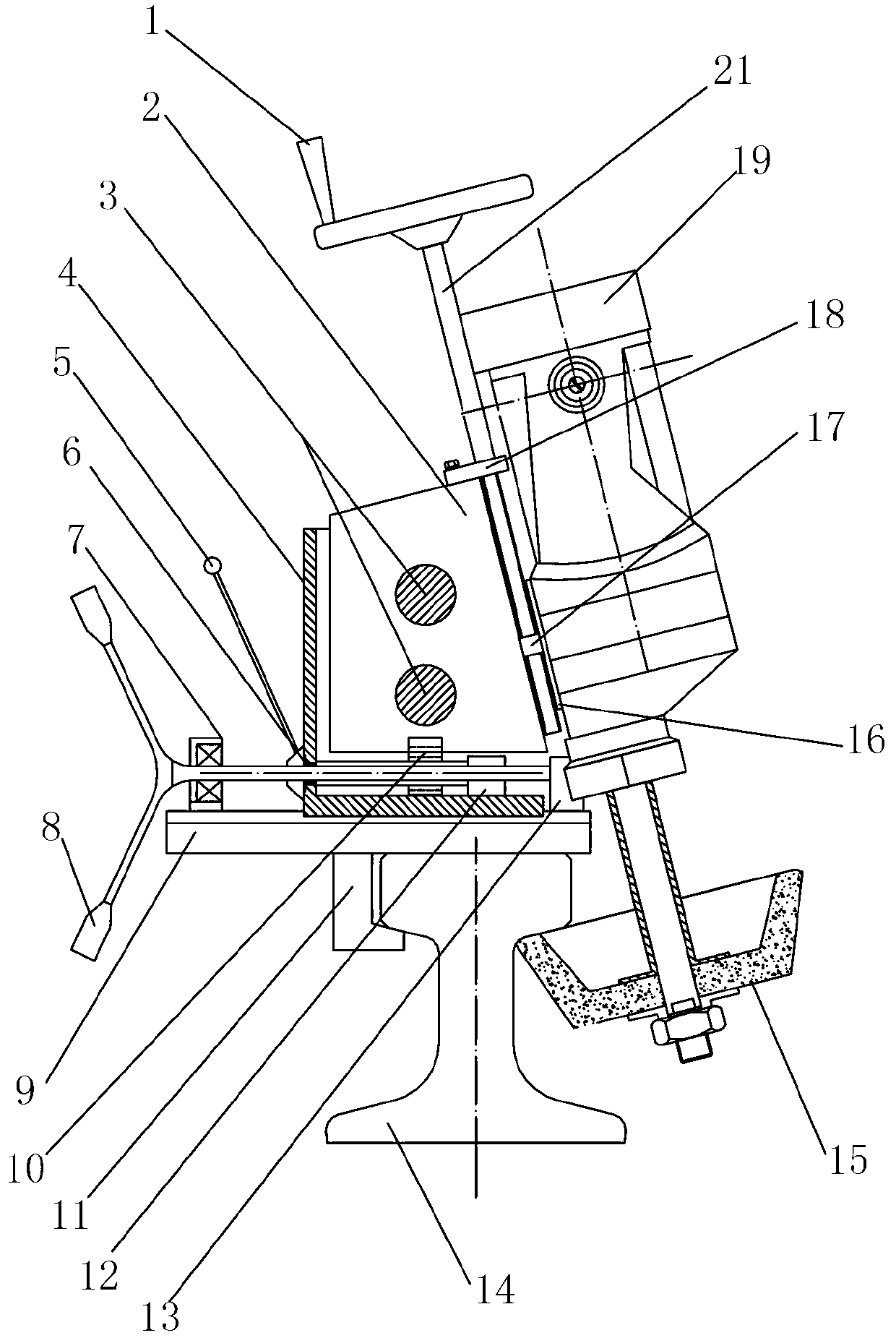

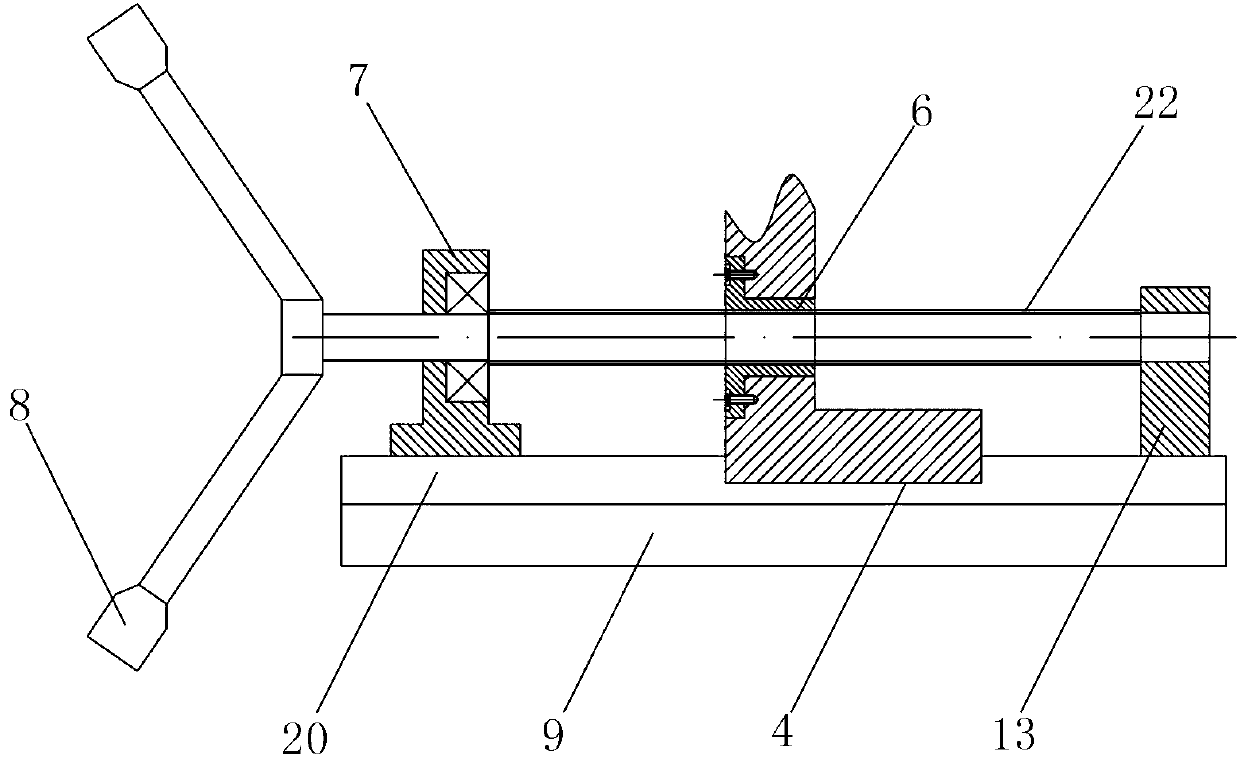

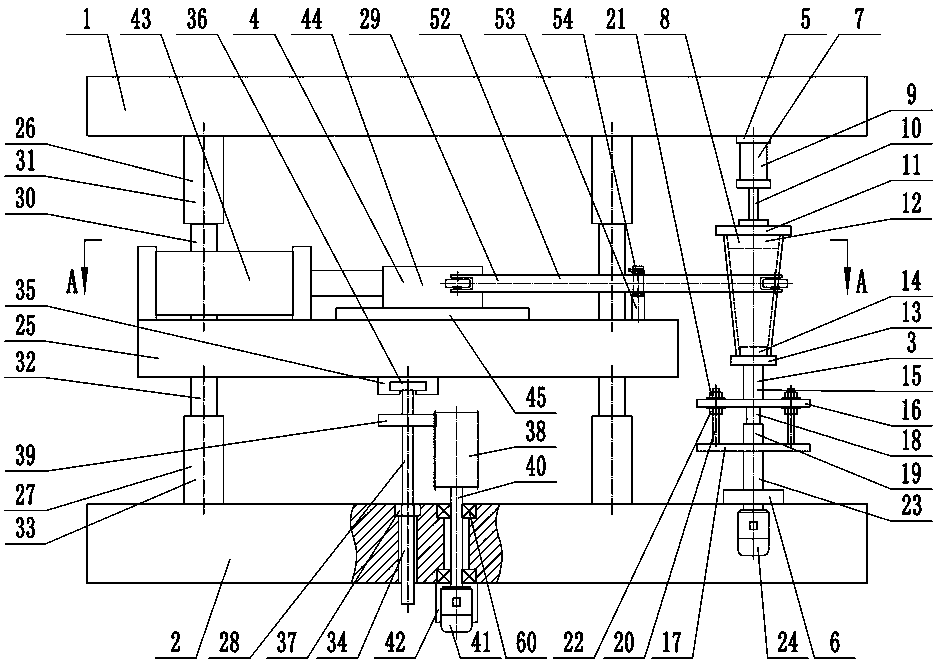

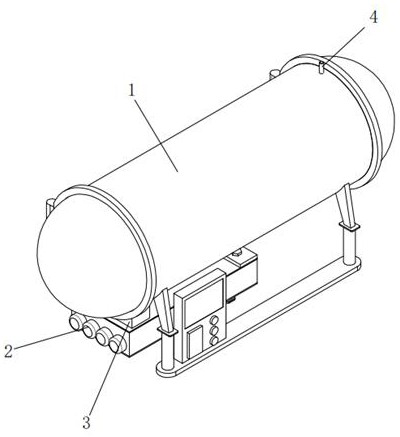

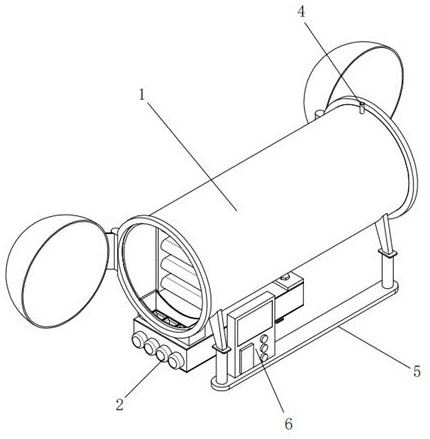

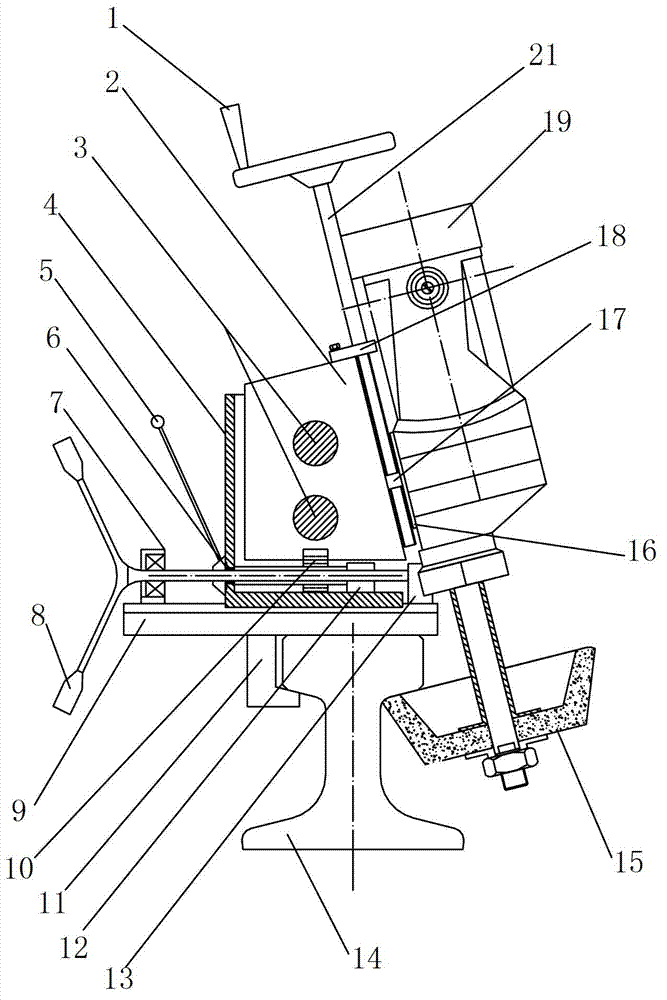

Numerical control fine grinding machine for rail contours and rail lines

InactiveCN108166341AAchieve fine grindingEasy to operateRailway track constructionNumerical controlDrive wheel

The invention discloses a numerical control fine grinding machine for rail contours and rail lines. The numerical control fine grinding machine comprises walking and shape-keeping assemblies, a walking and shape-keeping device, a traversing device and a grinding device, wherein the plurality of walking and shape-keeping assemblies are separately arranged on the left and right sides of the walkingand shape-keeping device and used for moving along steel rails; the traversing device comprises a grinding support frame, driven connectors and driven wheels; and the grinding device comprises a sliding block assembly, a first motor, a first reducer, a first gear, a sliding groove assembly, a vertical rack, a second motor, a second reducer, a second gear, a main motor and a grinding wheel. The numerical control fine grinding machine for the rail contours and the rail lines allows the walking and shape-keeping assemblies and a self-powered walking and shape-keeping assembly to move along the steel rails by arranging connection support frames, the walking and shape-keeping assemblies and the self-powered walking and shape-keeping assembly at the walking and shape-keeping device, and drives the grinding wheel to move to the to-be-ground position of the steel rails for grinding by arranging the sliding block assembly and the driven wheels at the traversing device, so as to realize the finegrinding of any position of the rail contours of the steel rails and to facilitate the operation.

Owner:中国铁路北京局集团有限公司保定工务段

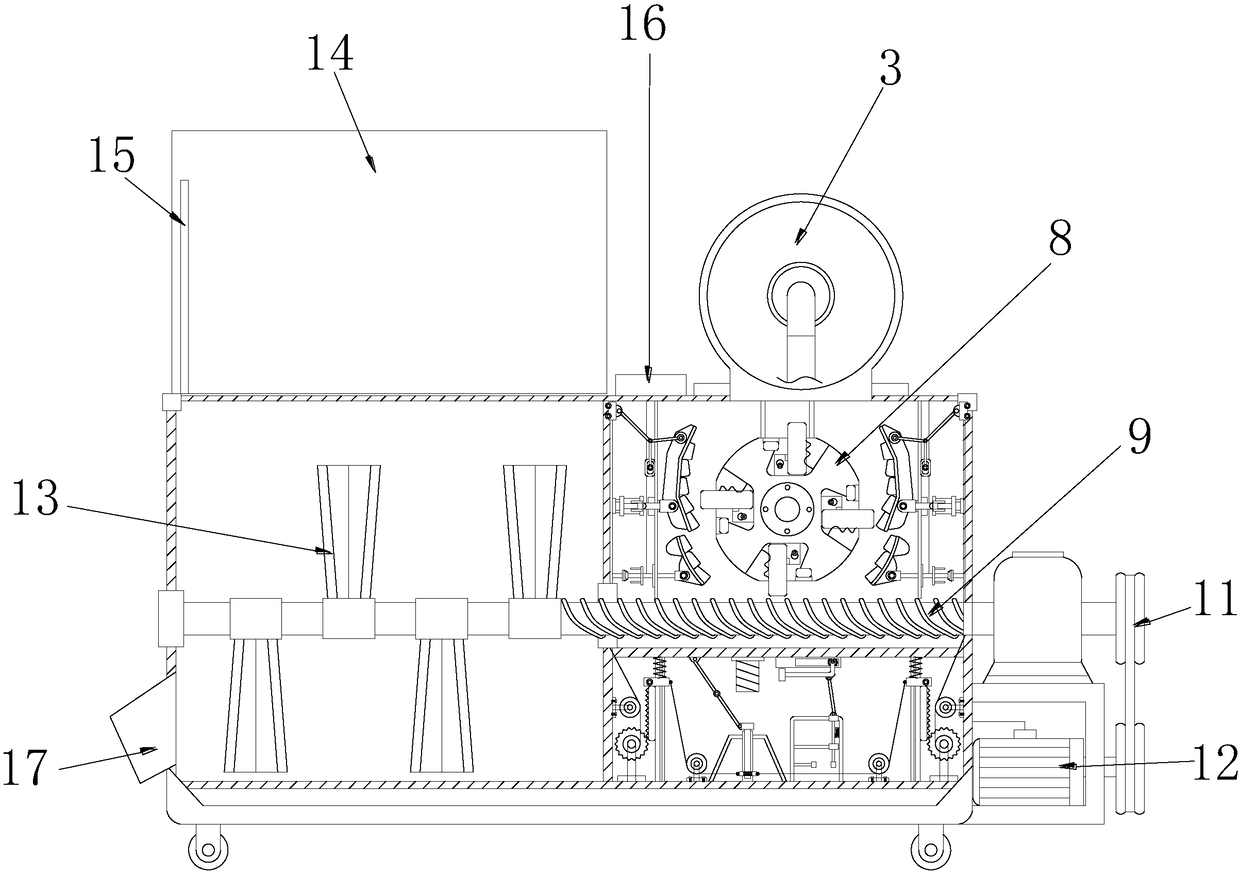

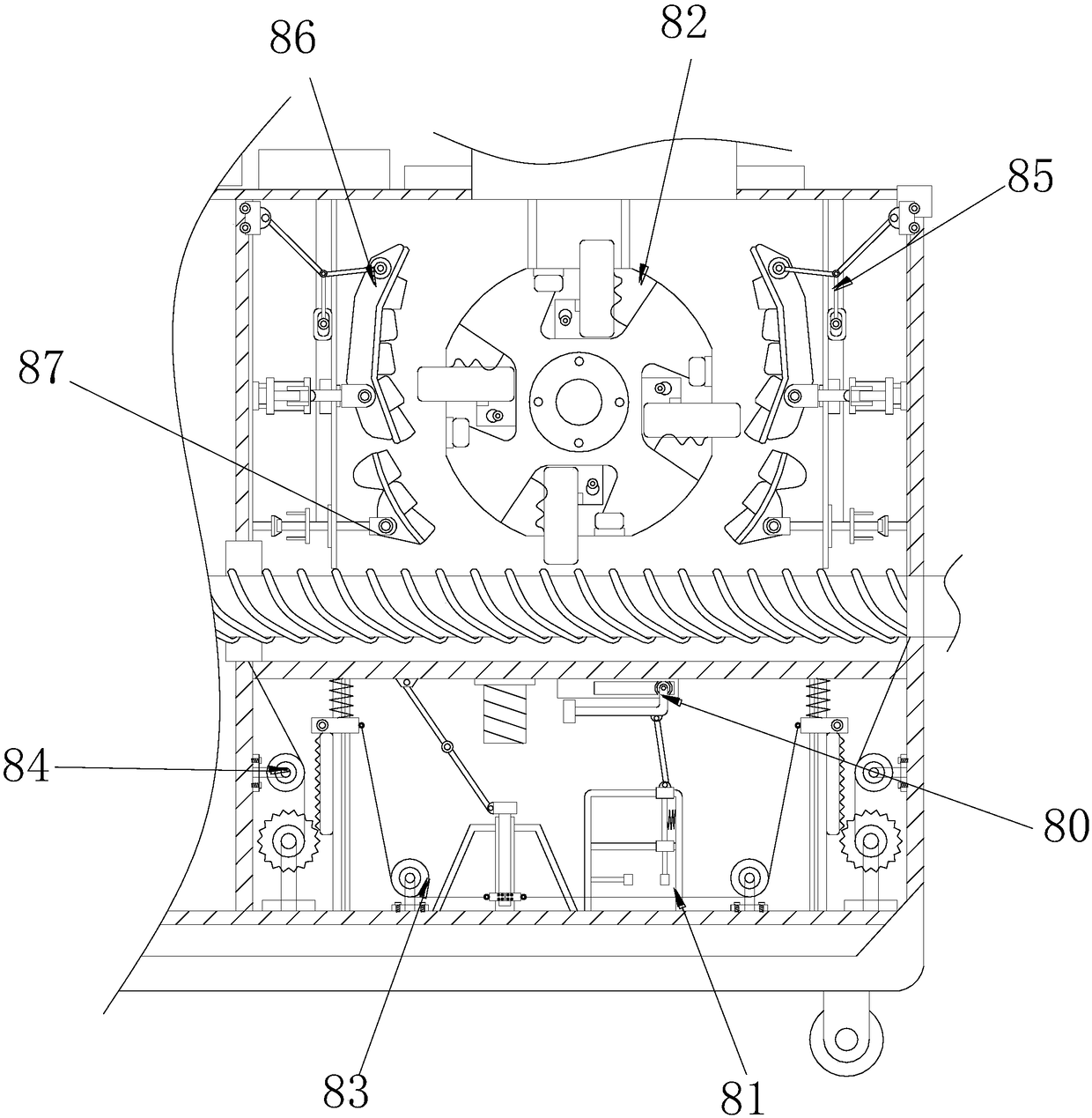

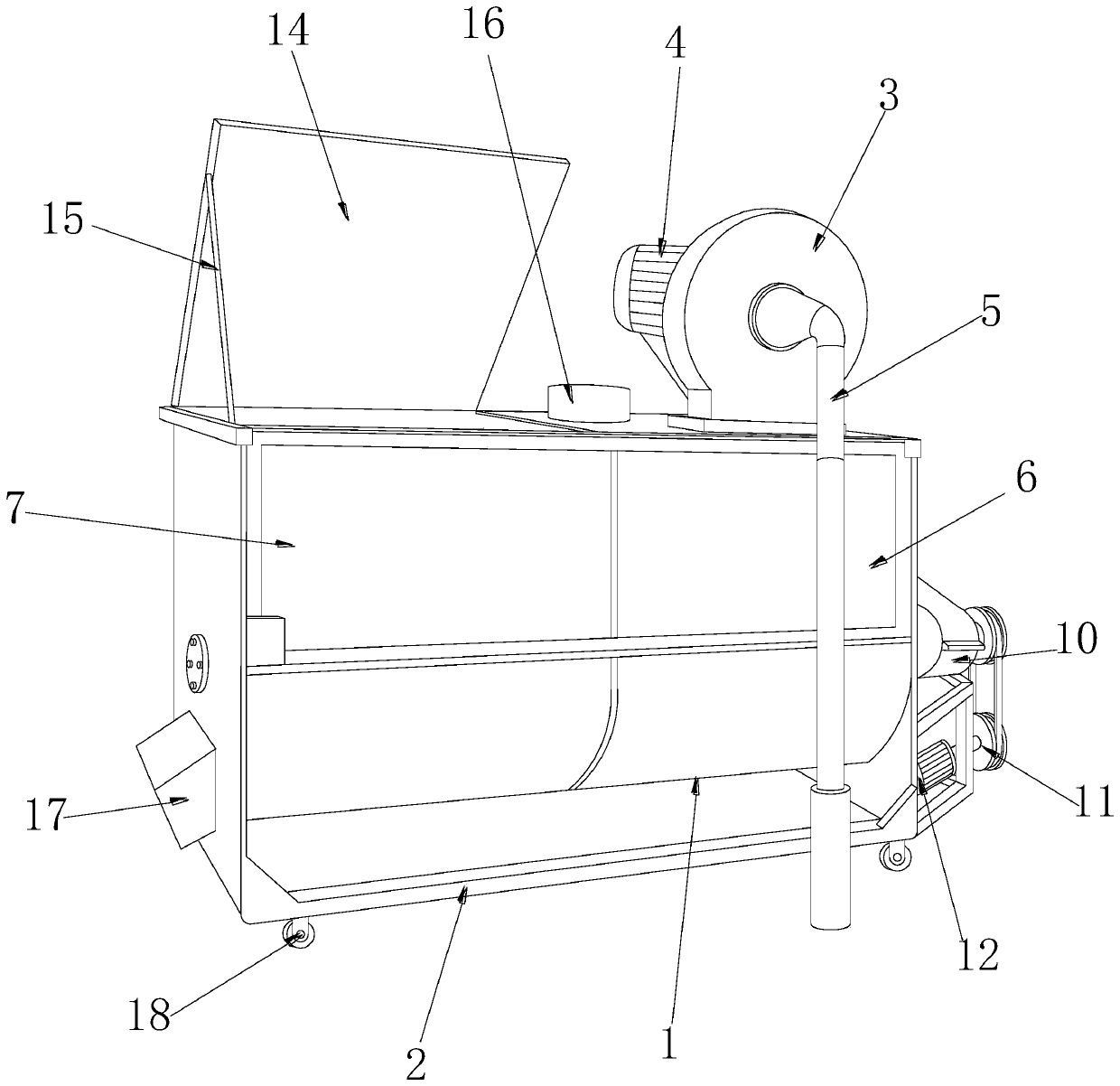

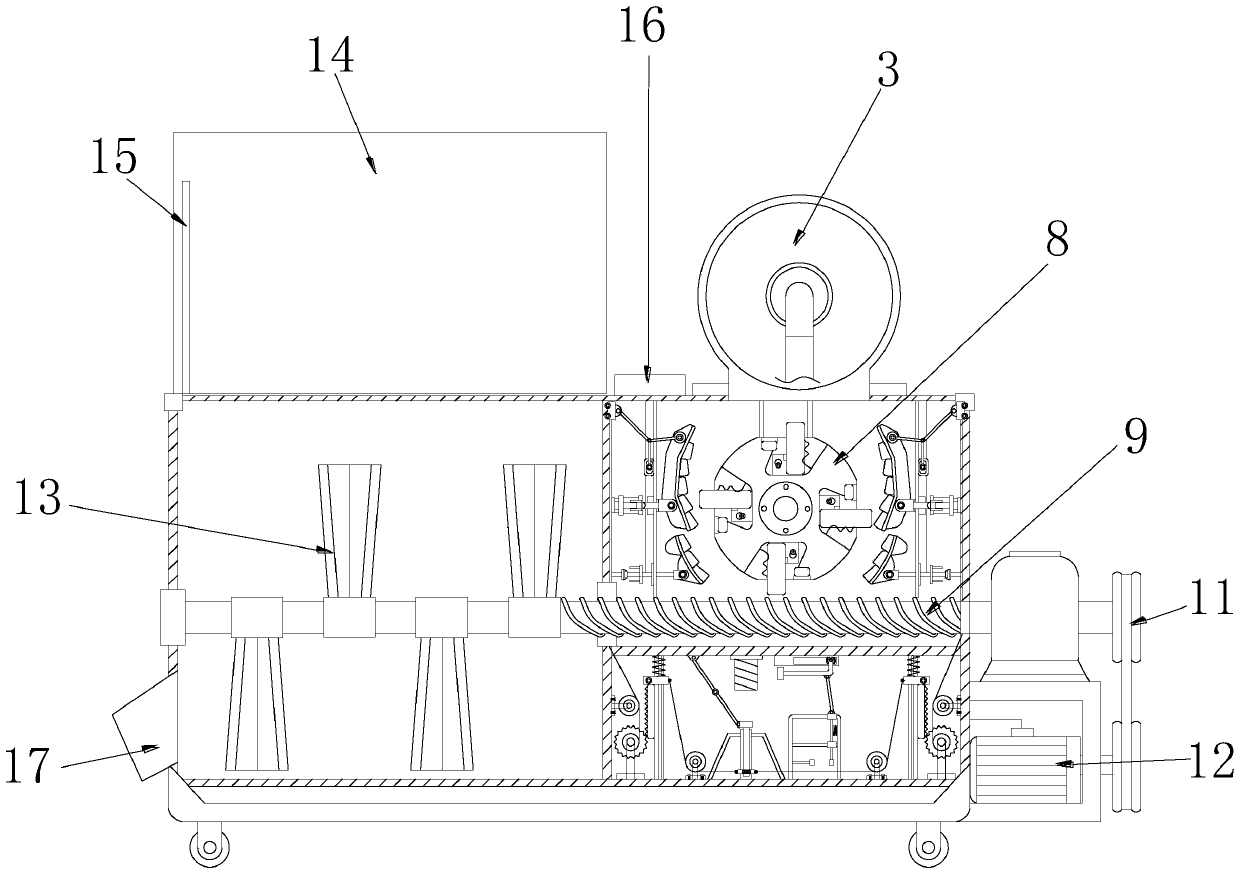

Self-sucking horizontal type feed smashing and stirring machine

ActiveCN108371989AImprove practicalityHigh degree of automationFeeding-stuffRotary stirring mixersEngineeringAutomation

The invention discloses a self-sucking horizontal type feed smashing and stirring machine. The structure of the self-sucking horizontal type feed smashing and stirring machine comprises a smashing andstirring machine body, a supporting rack, a wind driven material sucking machine, a material sucking smashing motor, a material sucking pipe, a smashing chamber, a stirring chamber, an efficient andautomatic smashing device, a material pushing screw rod, a speed reducer, a belt wheel set, a servo motor, stirring blades, a stirring chamber door, a door leaf support, a wind outlet, a discharging hopper and moving rollers; the smashing and stirring machine body is arranged in the upper portion of the supporting rack and is connected with the supporting rack through electric welding; the wind driven material sucking machine is arranged on the right upper portion of the smashing and stirring machine body and is connected with the smashing and stirring machine body in a penetrating manner through electric welding; and the material sucking smashing motor is arranged at the rear center of the wind driven material sucking machine and is connected with the wind driven material sucking machinethrough electric welding. According to the self-sucking horizontal type feed smashing and stirring machine, by arranging the efficient and automatic smashing device, fine grinding can be automaticallyperformed on feed after primary smashing is performed on the feed, efficient smashing is performed step by step, stirring can be performed more uniformly conveniently, the quality of the feed is improved, and the practical performance and the automation degree of the self-sucking horizontal type feed smashing and stirring machine are effectively enhanced.

Owner:安徽荣国环保智能科技有限公司

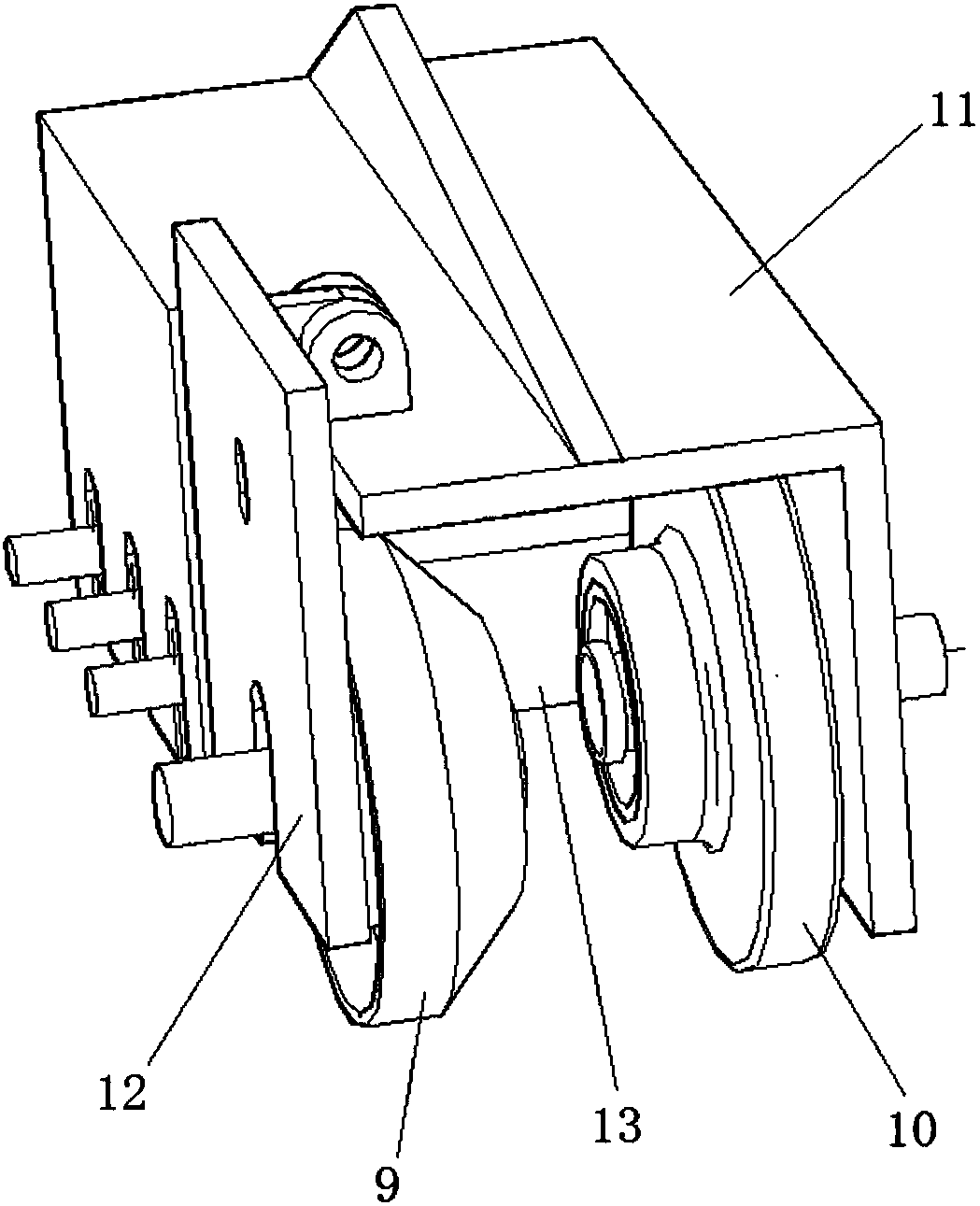

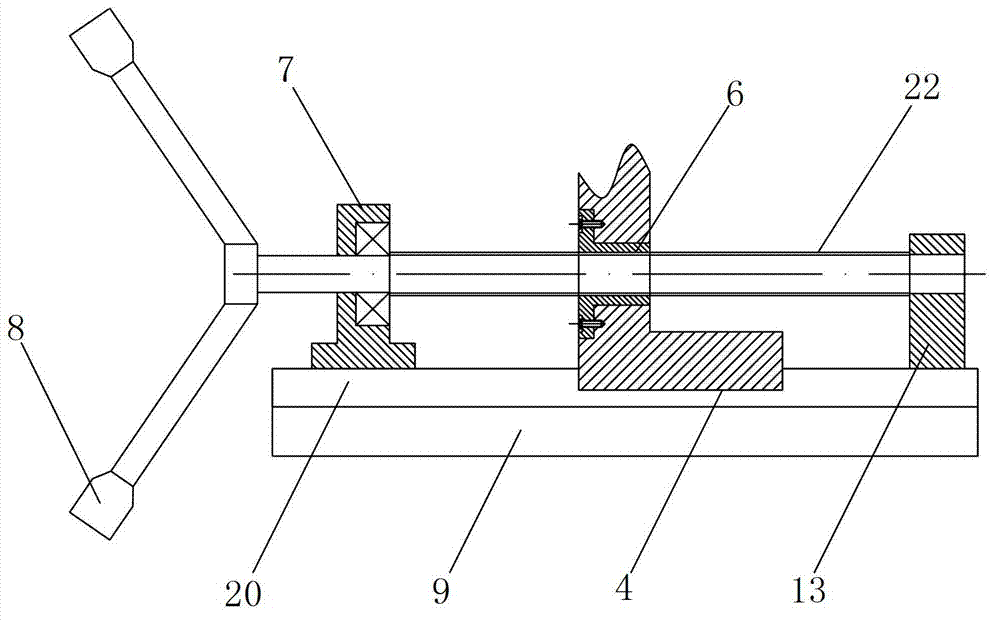

Rail jaw refiner of rocket sled sliding rail welding connector

ActiveCN103128616ASimple structureNovel and reasonable designPlane surface grinding machinesBench grinderRocket

The invention discloses a rail jaw refiner of a rocket sled sliding rail welding connector. The rail jaw refiner comprises a fixed base fixedly installed on the rocket sled sliding rail welding connector and a straight-direction grinding machine arranged on one side of a rocket sled sliding rail and used for grinding a rail jaw of the rocket sled sliding rail welding connector. The upper surface of a grinding wheel of the straight-direction grinding machine is bonded to the rail jaw of the rocket sled sliding rail welding connector, a transverse adjusting mechanism capable of moving transversely along the rocket sled sliding rail is installed on the fixed base and is connected with a vertical adjusting mechanism used for driving the straight-direction grinding machine to move vertically along the rocket sled sliding rail, and the vertical adjusting mechanism is connected with the straight-direction grinding machine through a height adjusting mechanism used for driving the straight-direction grinding machine to move vertically. The rail jaw refiner of the rocket sled sliding rail welding connector is high in automation degree, simple to process and convenient to use, saves cost and has wide popularization and application value in laying of rocket sled sliding rail jointless tracks.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

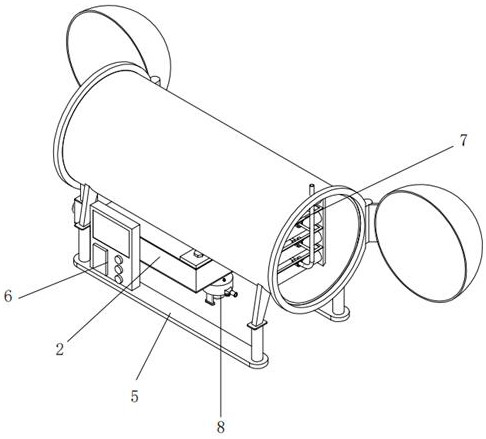

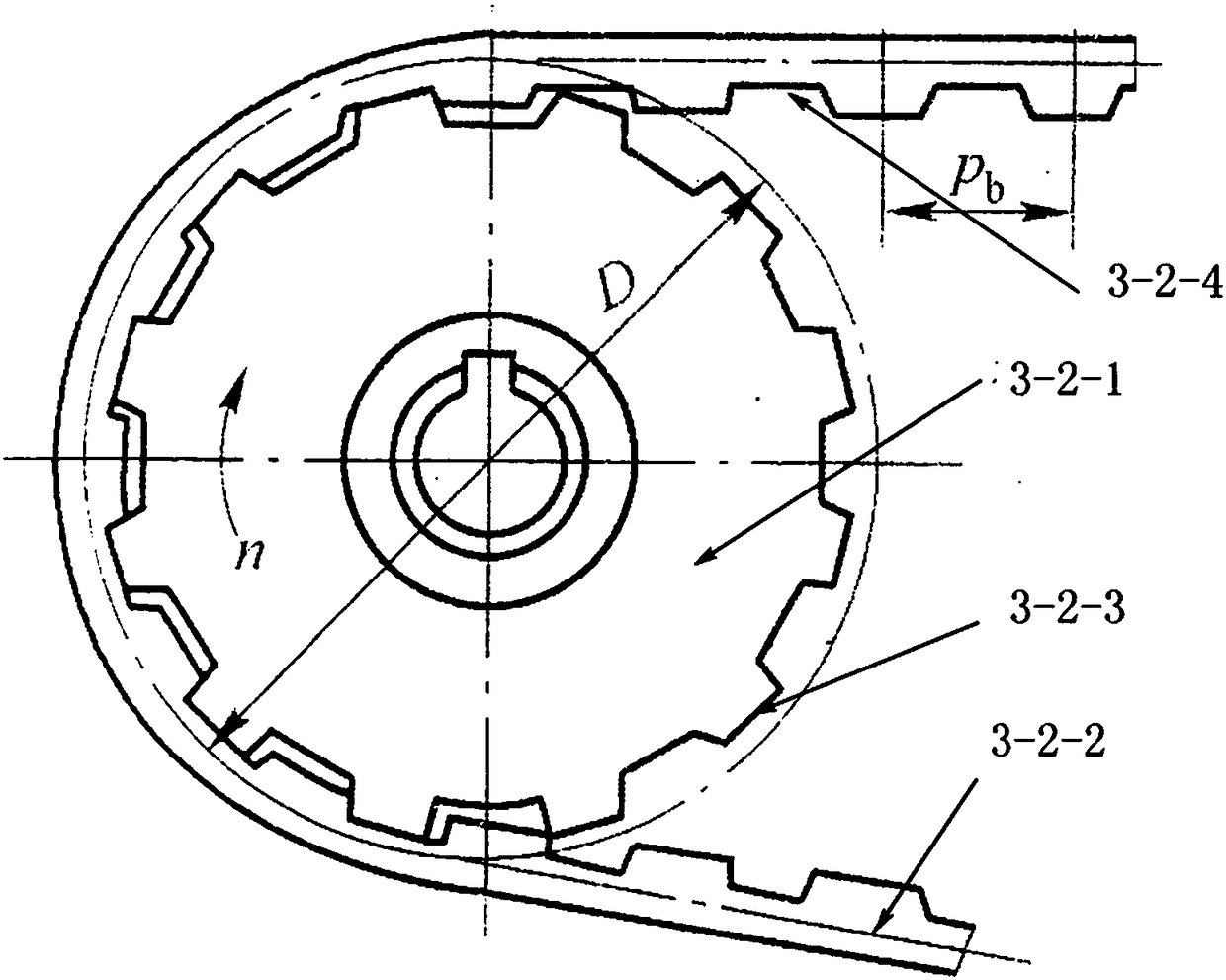

Parallel-type soybean pulping system

InactiveCN105233921AAvoid the problem of full warehouse leakageDischarge speed controllableCocoaGrain treatmentsLevel sensorPulp and paper industry

The invention discloses a parallel-type soybean pulping system which comprises a transit bin and pulping devices, wherein the transit bin comprises a bin body, discharging pipes, a bin level sensor and uniform-speed discharging mechanisms; and each pulping device comprises a housing, a supporting seat, a pulping motor, a fixed millstone, a rough-milling movable millstone and a fine-milling movable millstone. According to the parallel-type soybean pulping system, the bin level sensor arranged on the bin body is used for detecting a bin level, and a controller is used for controlling a feeding device for feeding soybeans to the transit bin, so as to avoid outleakage caused by excessive soybeans in the transit bin; the discharging speed of the transit bin is enabled to be controllable and uniform through the uniform-speed discharging mechanisms, so as to avoid the problems of blockage in a pulping machine and poor pulping quality; meanwhile, the rough-milling movable millstone and the fine-milling movable millstone are respectively matched with the upper and lower end surfaces of the fixed millstone, so that one pulping machine can achieve the pulping effect of a plurality of pulping machines connected in series; and the pulping machine is small in size, compact in structure, small in occupied area, high in production efficiency, and low in production cost.

Owner:CHONGQING YUPAI AGRI PROD DEV

Centering accurate-grinding device for metal bobbin

ActiveCN108637810AAchieve compactionContinuous and fast rotationGrinding carriagesRevolution surface grinding machinesBobbinEngineering

The invention provides a centering accurate-grinding device for a metal bobbin, belonging to the technical field of textile machinery. The centering accurate-grinding device comprises a centering clamping rotary mechanism and an accurate grinding mechanism. The lower end of an upper clamping piston rod of an upper clamping component of the centering clamping rotary mechanism is connected with an upper clamping centering block, and a lower centering cylinder block of a lower clamping component is concreted above a lower pressing plate. A lifting lead screw of a lifting component of the accurategrinding mechanism is in threaded connection with a lifting lead screw nut, and a first curved surface and a second curved surface are symmetrically arranged at the two ends of an accurate grinding sliding block of an accurate grinding component. A third accurate grinding wheel is rotationally arranged at the other end of a carrier rod. A first transfer roller is rotationally arranged at one endof a first swing arm, and a first accurate grinding wheel is rotationally arranged at the other end of the first swing arm. A second transfer roller is rotationally arranged at one end of a second swing arm, and a second accurate grinding wheel is rotationally arranged at the other end of the second swing arm. The centering accurate-grinding device can realize accurate grinding for a taper-pipe-shaped metal bobbin and has strong applicability to the metal bobbin.

Owner:嘉兴市恒泰化工科技有限公司

Raw material crushing equipment for production of Longquan celadon and using method thereof

ActiveCN107999211AAchieve separationImprove grinding efficiencyGrain treatmentsEngineeringMechanical engineering

The invention discloses raw material crushing equipment for production of Longquan celadon and a using method thereof. The raw material crushing equipment comprises a shell, a grinding cylinder, a supporting base, a base, a fixing base, a releasing cylinder, a driving device, a discharging cylinder, a grinding motor and a centralizing device, wherein a first opening is formed in one side of the shell, the grinding cylinder is located in the shell, and grinding beads are arranged in the grinding cylinder. One side of the grinding cylinder is fixedly provided with a feeding cylinder, the end, away from the grinding cylinder, of the feeding cylinder is rotationally connected with the supporting base, the bottom of the supporting base is fixed to the base, a second opening is formed in the side, far away from the first opening, of the shell, the end, far away from the feeding cylinder, of the grinding cylinder is fixedly provided with a rotating shaft, and the rotating shaft penetrates through the second opening and is rotationally connected with the fixing base. According to the raw material crushing equipment for production of the Longquan celadon and the using method thereof, a partof ground raw materials can be output from the discharging cylinder, so that the separation of the ground raw materials from the raw materials which are not subjected to grinding is realized, and thegrinding efficiency of the raw materials is improved.

Owner:龙泉市尚唐瓷艺发展有限公司

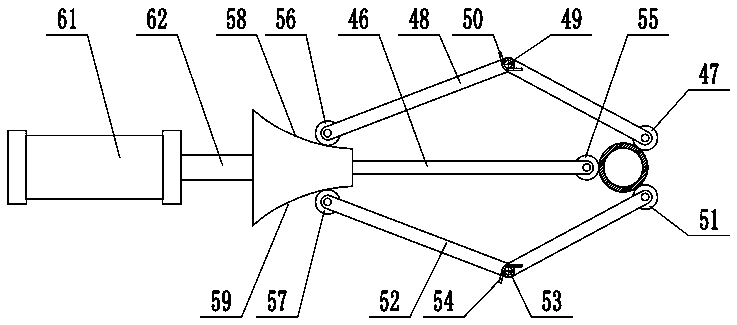

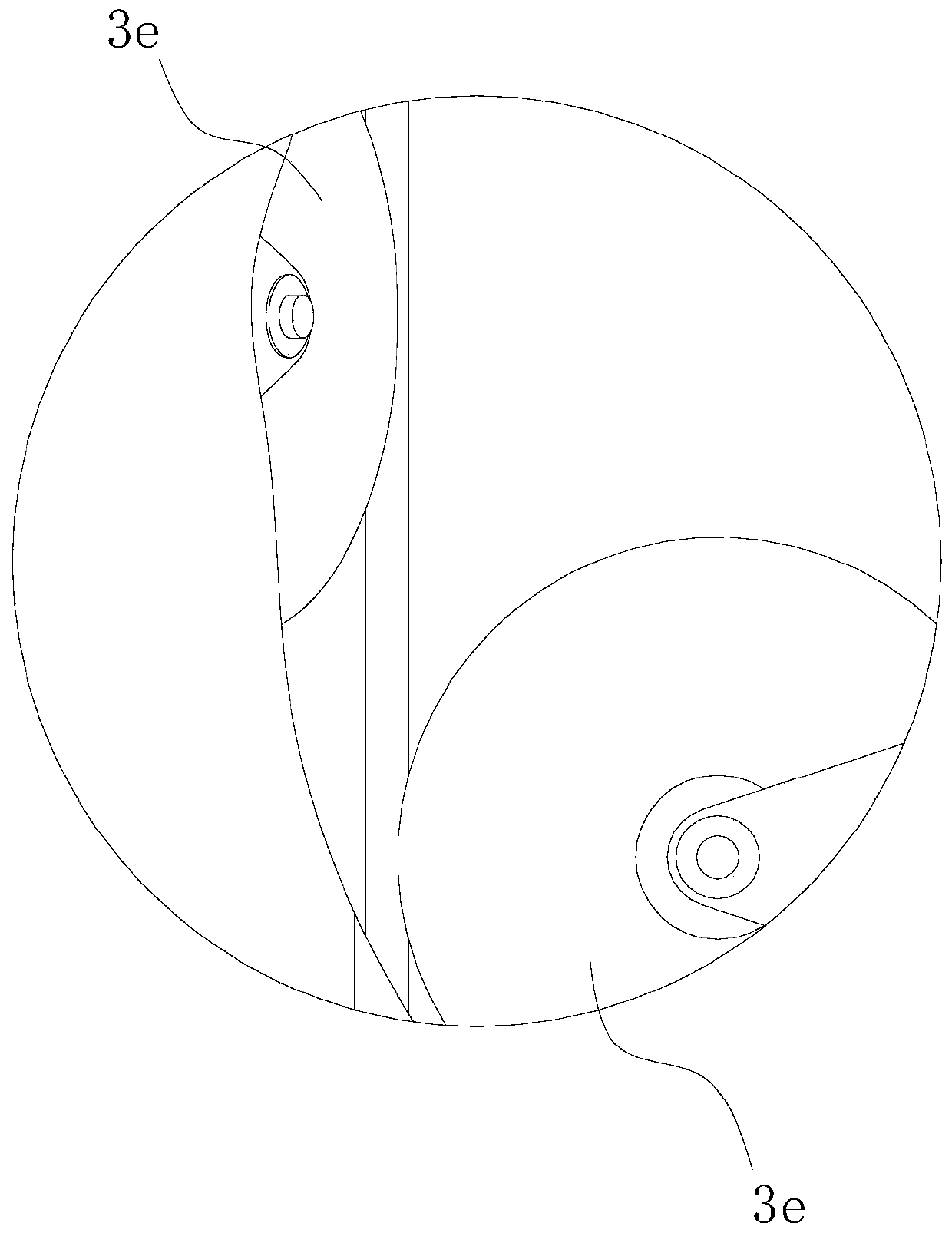

Polishing device special for up-drawing of oxygen-free copper rod

InactiveCN109746801AReduce the number of replacementsAchieve fine grindingGrinding machine componentsGrinding machinesGrinding wheelOxygen-free copper

The invention discloses a polishing device special for up-drawing of an oxygen-free copper rod, and belongs to the technical field of auxiliary polishing for varnished wire production. According to the technical key points, the polishing device comprises a bracket, a copper powder recovery box is arranged on the bracket in the vertical direction, a plurality of sets polishing units are arranged inthe copper powder recovery box at intervals in the height direction, and the to-be-polished copper rod passes through all the polishing units in the vertical direction; each polishing unit is composed of three or more grinding wheel polishing mechanisms which are evenly distributed at intervals in the circumferential direction of the to-be-polished copper rod and arranged in a staggered mode in the axial direction of the to-be-polished copper rod, and the grinding wheel polishing mechanisms comprise grinding wheels; the grinding wheels are arranged in the vertical direction, and the polishingend faces of the grinding wheels are each in an arc shape; and the total length of arc lines formed by contact between all the grinding wheels located on the same polishing unit and the to-be-polished copper rod is larger than the perimeter of the to-be-polished copper rod. The polishing device special for up-drawing of the oxygen-free copper rod is reasonable in structure, good in polishing effect and convenient to use, and is used for polishing of the oxygen-free copper rod.

Owner:广东金雁电工科技股份有限公司

Sectional type feed grinding device for animal husbandry and using method

ActiveCN110270405ASimple structureSimple and efficient operationFeeding-stuffCocoaMechanical engineeringLower half

The invention provides a sectional type feed grinding device for animal husbandry. The feed grinding device comprises a base, wherein a lower cylinder body 35 is movably connected to the center of the top of the base, a groove communicating with the outside is formed in the top of the lower cylinder body 35, a grinding plate I is slidably connected between the inner walls of the groove, a partition plate is fixedly arranged between the inner walls of the middle of the lower cylinder body 35, and the bottom of the grinding plate I is provided with a sliding rod with the bottom sequentially penetrating through the center of the bottom of the inner wall of the groove and the center of the partition plate to reach the lower half part of the inner part of the lower cylinder body 35. The sectional type feed grinding device for the animal husbandry has the beneficial effects that the structure is simple, the operation is simple and convenient, and large-grained feed can be subjected to grinding treatment; the feeding amount each time is very uniform, and the problem that feed grinding particles are too large due to the fact that the feeding amount is too much during manual operation is solved; and ground feed is automatically collected, so that four requirements of fine grinding, uniform grinding, quantitative grinding and automatic grinding of the feed are realized, and the device is simple, efficient, convenient and rapid.

Owner:董建芬

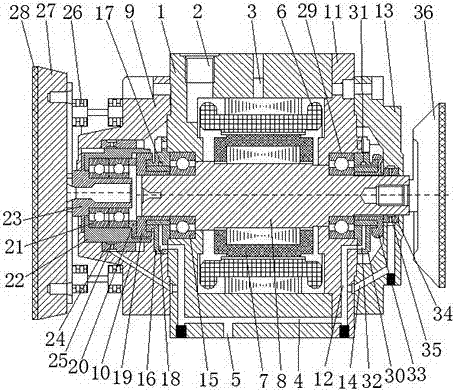

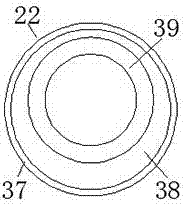

Efficient polishing and grinding composite spindle

PendingCN107498461AAchieve polishAchieve fine grindingMechanical energy handlingSupports/enclosures/casingsInterference fitPolishing

The invention relates to an efficient polishing and grinding composite spindle comprising a machine body, a stator and a rotor. The stator and the rotor are arranged in the machine body. A front end cover is installed at the front end of the machine body. A bearing seat and a rear end cover are installed at the rear end of the machine body. A spindle core is installed in the middle of the rotor in an interference fit mode. A grinding assembly and a front bearing assembly are connected to the front portion of the spindle core. A polishing assembly and a rear bearing assembly are connected to the rear portion of the spindle core. The efficient polishing and grinding composite spindle has the beneficial effects that the grinding assembly is connected to the front portion of the spindle core, the polishing assembly is connected to the rear portion of the spindle core, and polishing and fine grinding of a workpiece and artware are completed on the same spindle.

Owner:广州市锐恒科技有限公司

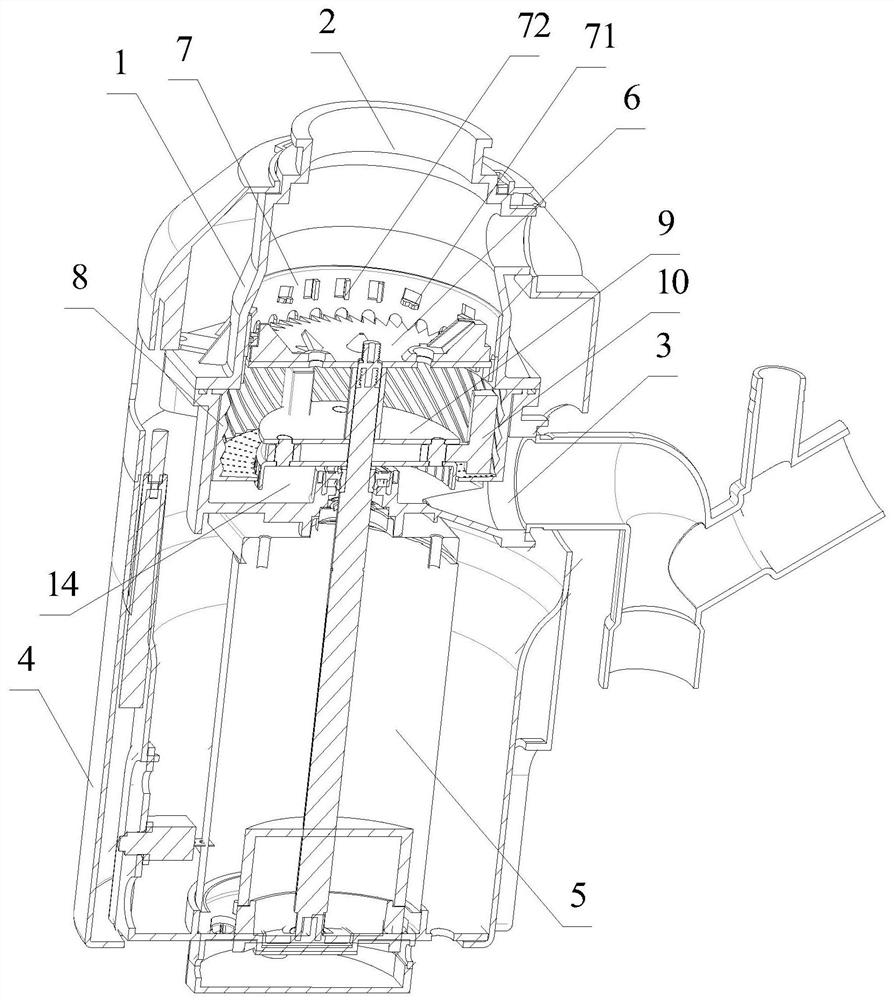

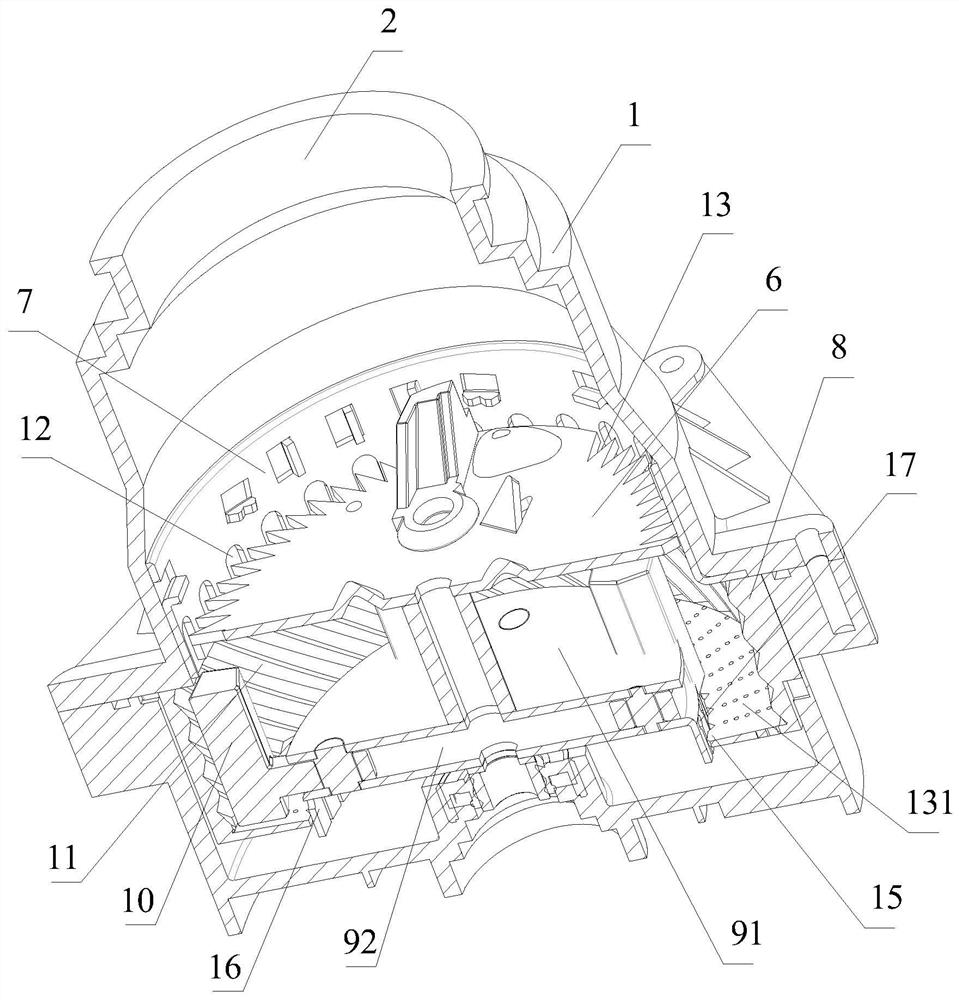

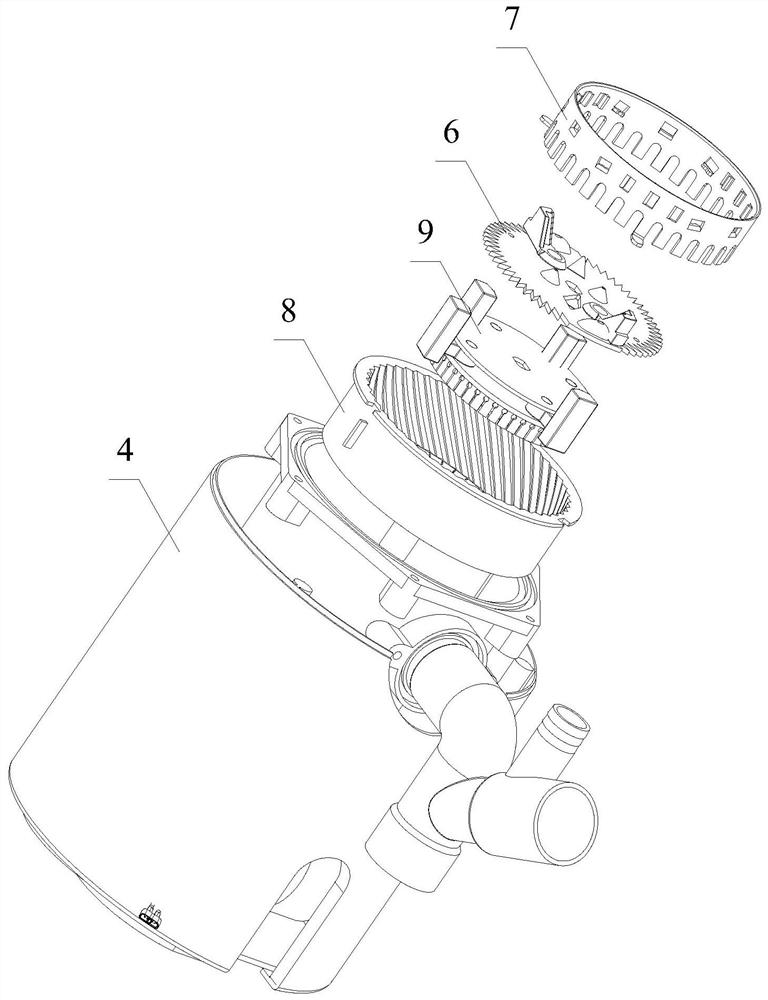

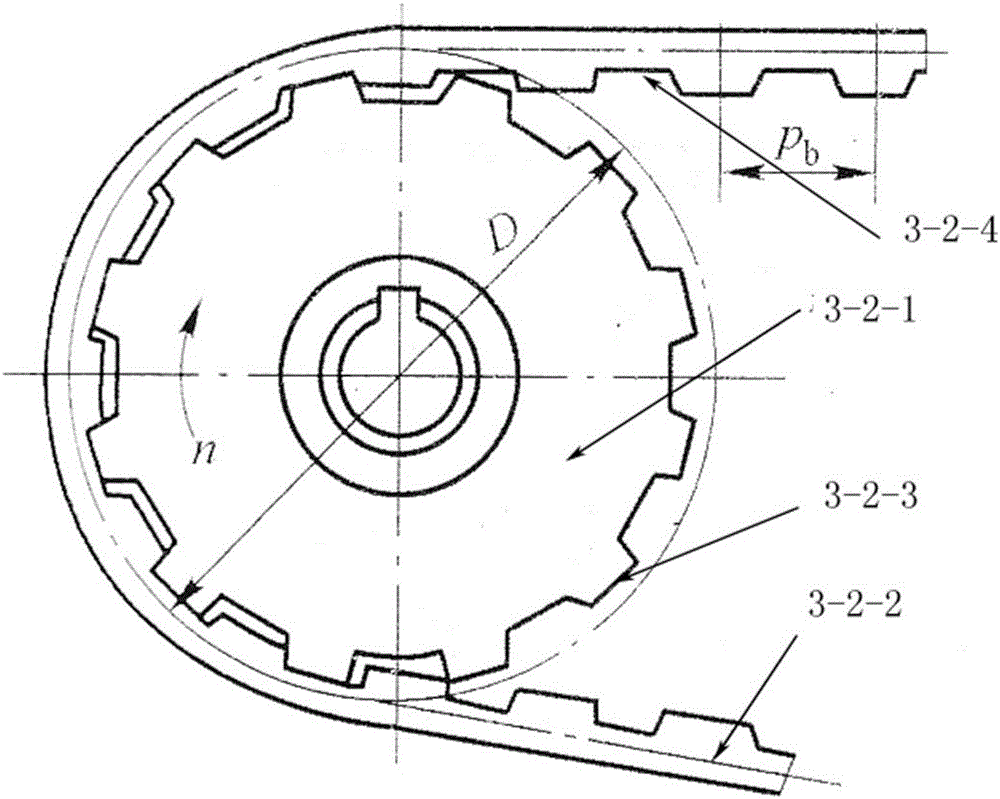

Household kitchen garbage disposer

InactiveCN113136928AAchieve fine grindingSolve the blockageDomestic plumbingElectric machineryProcess engineering

The invention discloses a household kitchen garbage disposer, and relates to the technical field of kitchen garbage disposal devices. The household kitchen garbage disposer comprises a crushing shell, a smashing chamber and a grinding chamber, wherein a grinding mechanism for grinding materials is arranged in the grinding chamber; the grinding mechanism comprises a grinding gear ring lined on the inner wall of the grinding chamber and a grinding disc located in the center of the grinding gear ring; the grinding disc is driven by a motor and synchronously rotates with a smashing disc; and the grinding disc is provided with a grinding throwing block which is close to the grinding end face in the grinding gear ring and rotates relative to the grinding end face in the grinding gear ring. Compared with the prior art, according to the household kitchen garbage disposer provided by the invention, the grinding chamber is additionally arranged under the smashing chamber, fibers and hard substances in the kitchen garbage are primarily cut and beaten by a cutting ring and the smashing disc in the smashing chamber and then enter the grinding chamber, and the grinding disc drives the grinding throwing block to be matched with the grinding gear ring, so that the hard garbage is finely ground, and the particle size of the hard garbage is greatly reduced; and the hard garbage is mixed with sewage to form slurry fluid, so that the slurry fluid can be conveniently discharged into a sewer, and the problem of blockage caused by garbage particles is effectively solved.

Owner:浙江博特电子科技有限公司

Environment design model grinding device

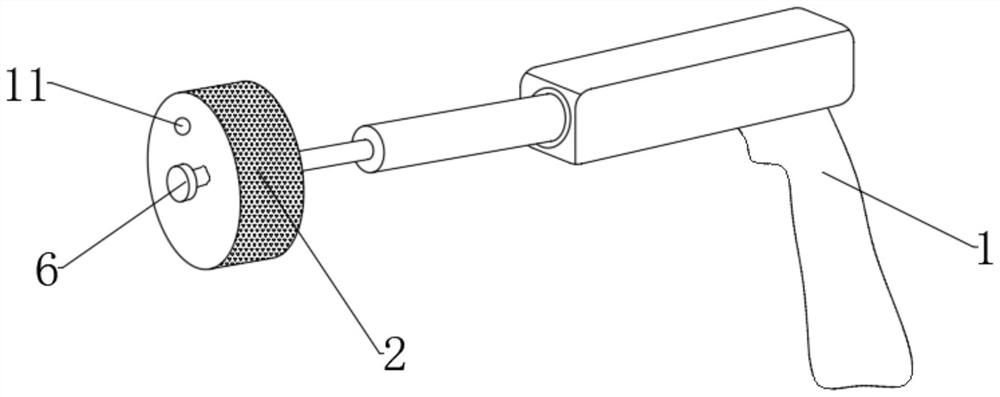

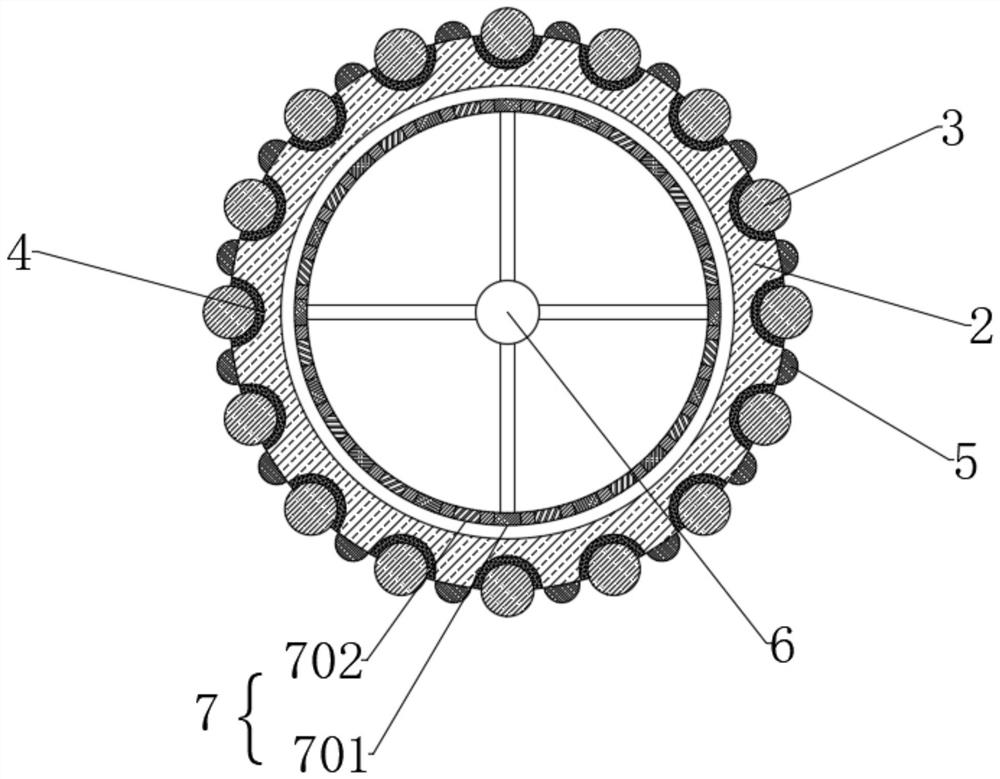

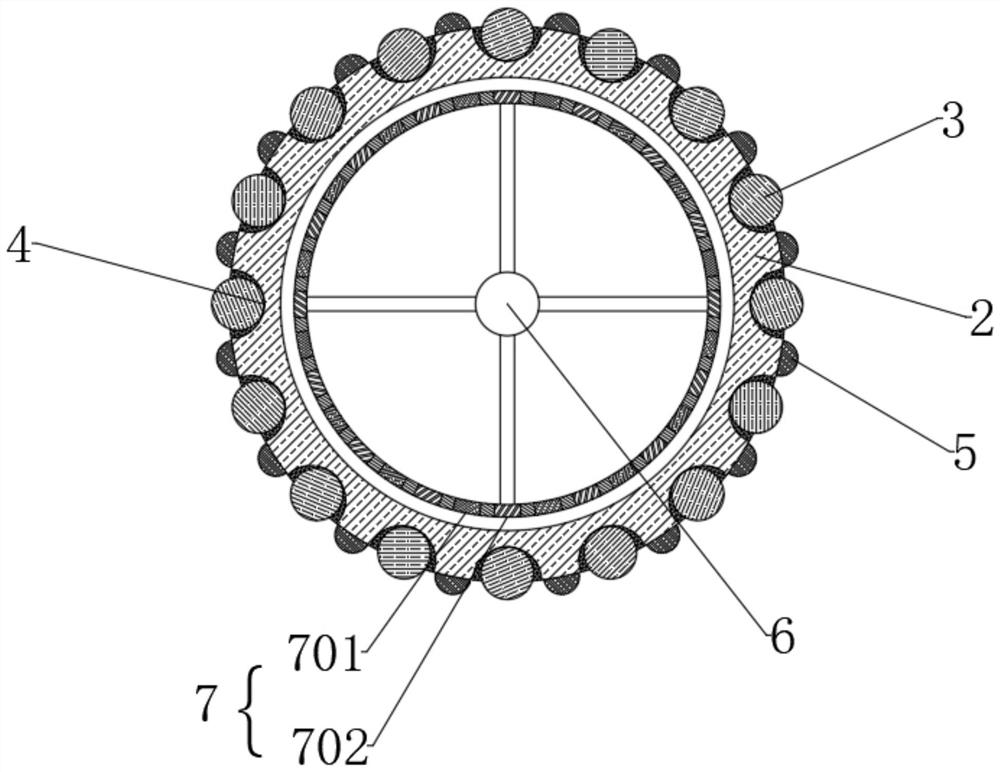

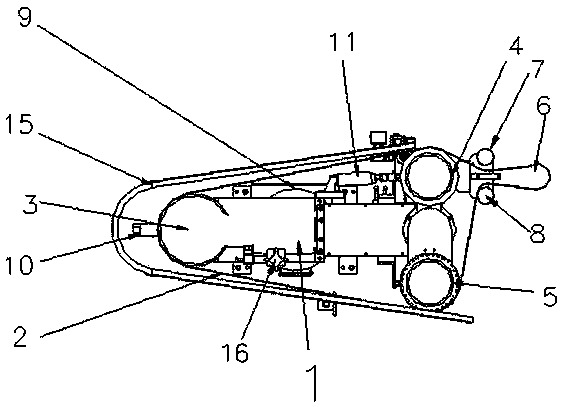

ActiveCN113798961AReduce wearReduce generationBonded abrasive wheelsGrinding machinesCentrifugal forceGrinding

The invention discloses an environment design model grinding device, and belongs to the field of grinding. The environment design model grinding device comprises a handheld grinding machine body, wherein an output shaft of the handheld grinding machine body is connected to a grinding disc, and the grinding disc is of a hollow structure. According to the scheme, rough grinding particles and fine grinding particles are arranged to achieve the two grinding effects of rough grinding and fine grinding; the rough grinding particles are recessed and protruded through the attraction force and the repulsive force of a magnetic adjusting part on the rough grinding particles, and the protruded rough grinding particles conduct rough grinding on a model; the concave rough grinding particles and the fine grinding particles jointly conduct fine grinding on a model, so that the grinding effect is effectively improved, abrasion of the coarse grinding particles and the fine grinding particles is delayed, and the grinding device is more durable; water is added into the grinding disc, and the centrifugal force during rotation and the absorption effect of capillary water tubes are used for achieving grinding and watering at the same time, so that raised dust generated during grinding is effectively reduced, the health of people is protected, and the air environment is also protected.

Owner:王宏

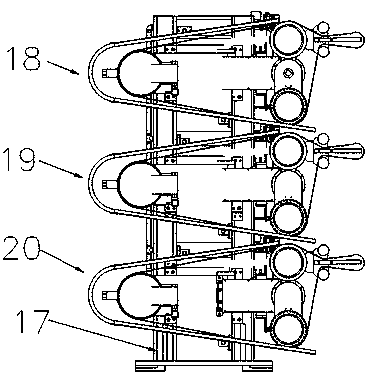

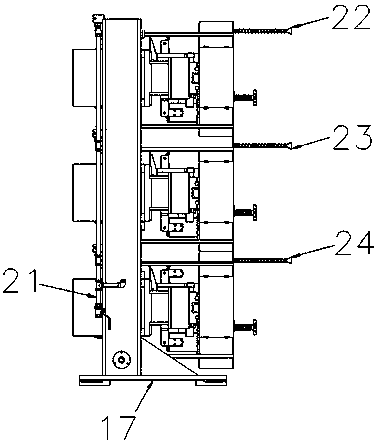

Stable belt sander

PendingCN109955134AAchieve coarse grindingRealize medium grindingBelt grinding machinesSanderLiquid storage

The invention discloses a stable belt sander. The stable belt sander comprises a rack, an elaborate polishing belt set, a moderate polishing belt set and a rough polishing belt set are mounted on therack from top to bottom. A main pipeline is mounted on one side of the rack, and one end of the main pipeline communicates with a cutting liquid storage box. The main pipeline is connected with a branch pipe, and a first spray head, a second spray head and a third spray head are mounted at the end of the branch pipe. The first spray head is arranged above the elaborate polishing belt set, the second spray head is arranged above the moderate polishing belt set, and the third spray head is arranged above the rough polishing belt set. The stable belt sander is novel in structural design, a workpiece can be fast polished, rough polishing, moderate polishing and elaborate polishing of the workpiece are achieved, the polishing uniformity is good, and the workpiece quality is improved.

Owner:JIANGSU ZUNSION AUTOMOBILE TECH CO LTD

Efficient grinding device

PendingCN107442203ATo achieve the purpose of crushing and filteringSolve the problem of low product qualityGrain treatmentsEngineeringPhysics

The invention discloses an efficient grinding device. The efficient grinding device comprises a crushing chamber, wherein a feeding pipe is fixedly connected with the top of the crushing chamber, a feeding funnel is fixedly connected with the top of the feeding pipe, the right side of the crushing chamber is penetratingly connected with a crushing roller, the outside of the crushing roller is connected with a crushing blade in a sleeved mode, a filtering plate is fixedly connected with the bottom of the inside of the crushing chamber, the top of the filtering plate is equidistantly provided with filtering holes, the bottom of the crushing chamber is fixedly connected with a discharge pipe, a grinding chamber is fixedly connected with the left side of the top of a supporting frame, a rotating shaft is connected with the right side of the grinding chamber in a penetrating mode, and the outside of the rotating shaft is connected with a grinding rod in a sleeved mode. The efficient grinding device solves a problem of low product quality in industrial production through the use of the crushing chamber, the crushing roller, the crushing blade, the filtering plate, the filtering holes and the discharge pipe, and solves a problem of reduced productivity in production process through using of a sliding block, a damping spring, the grinding chamber, the grinding rod and a second motor.

Owner:郑州博尔德磨料磨具有限公司

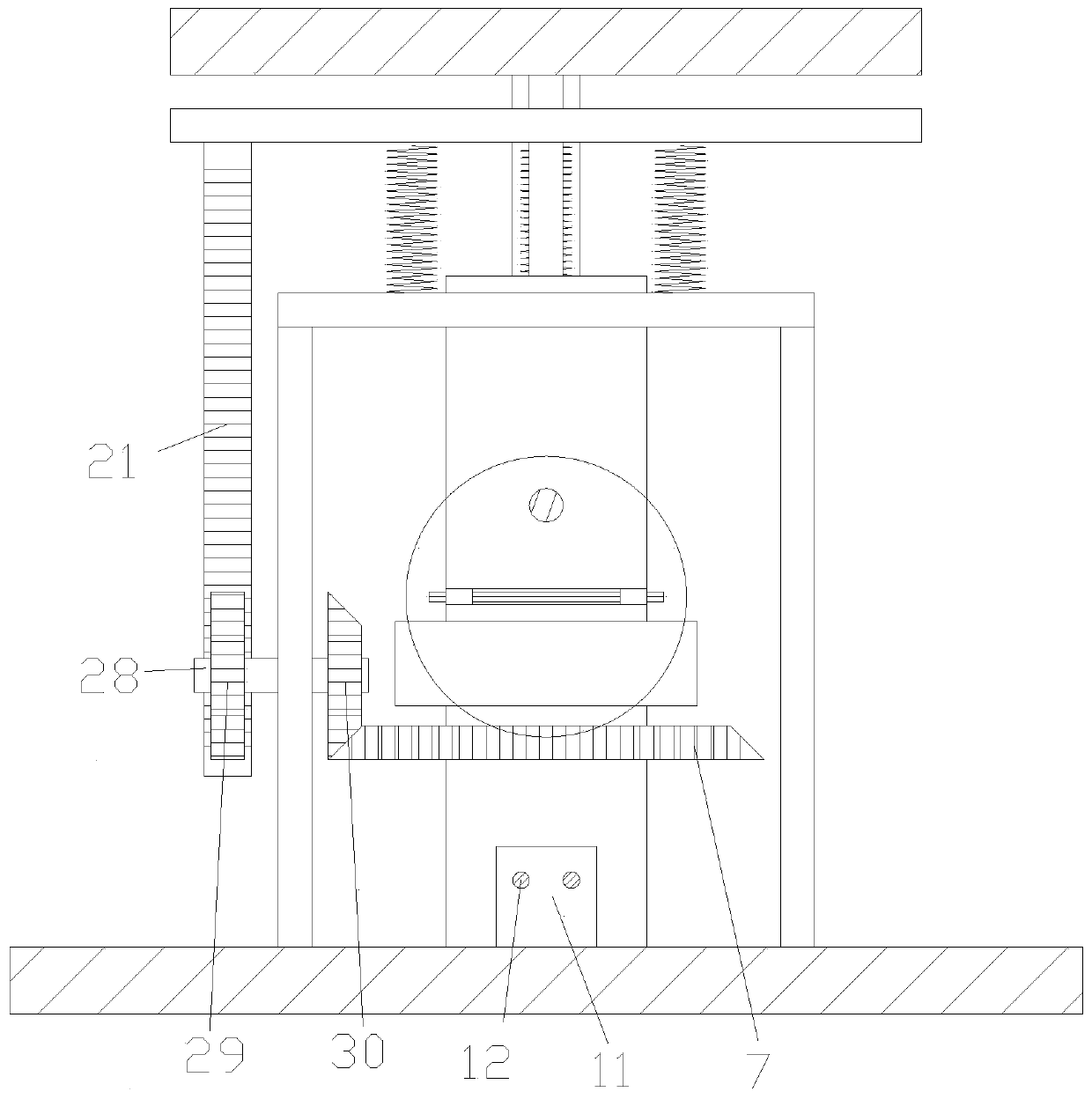

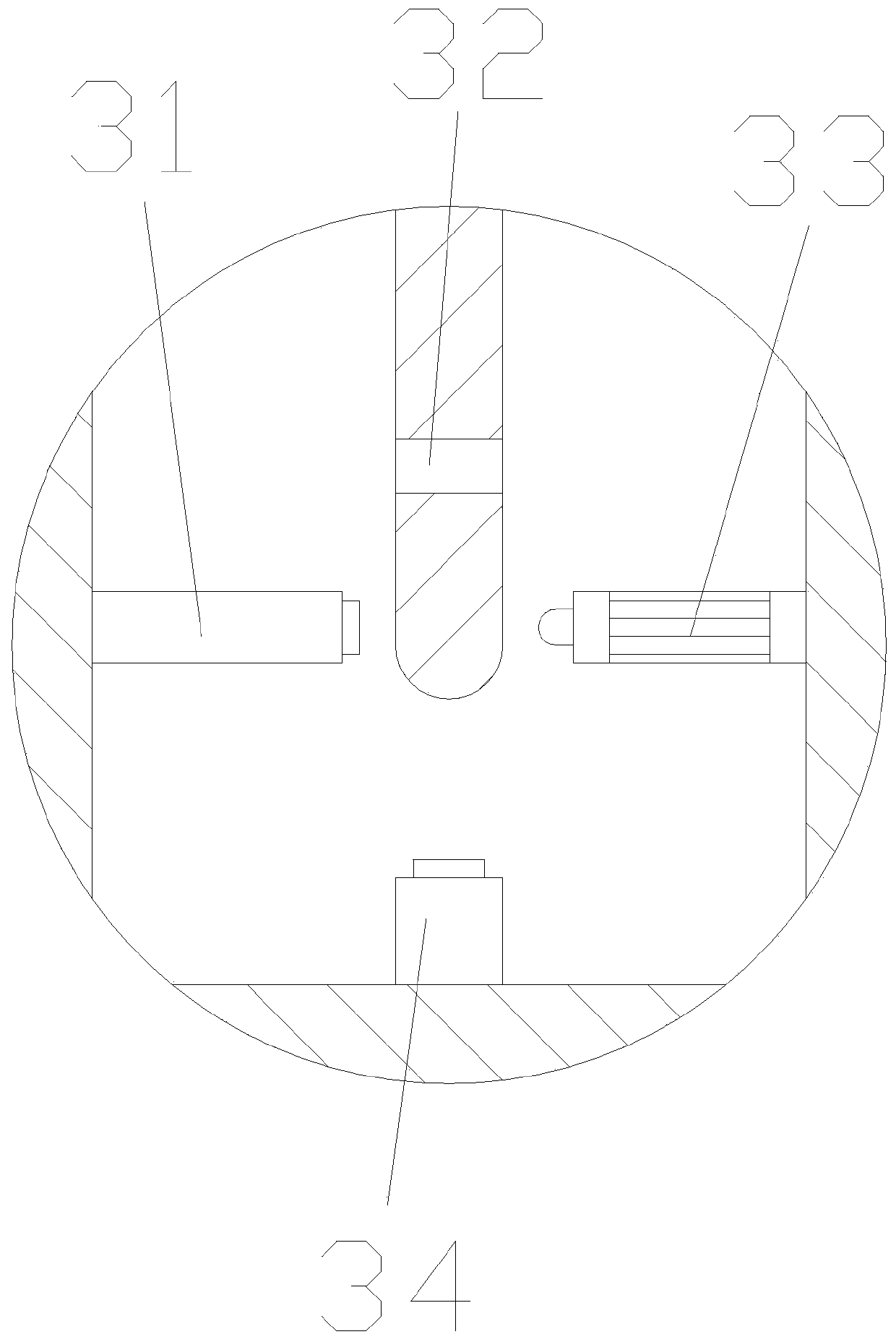

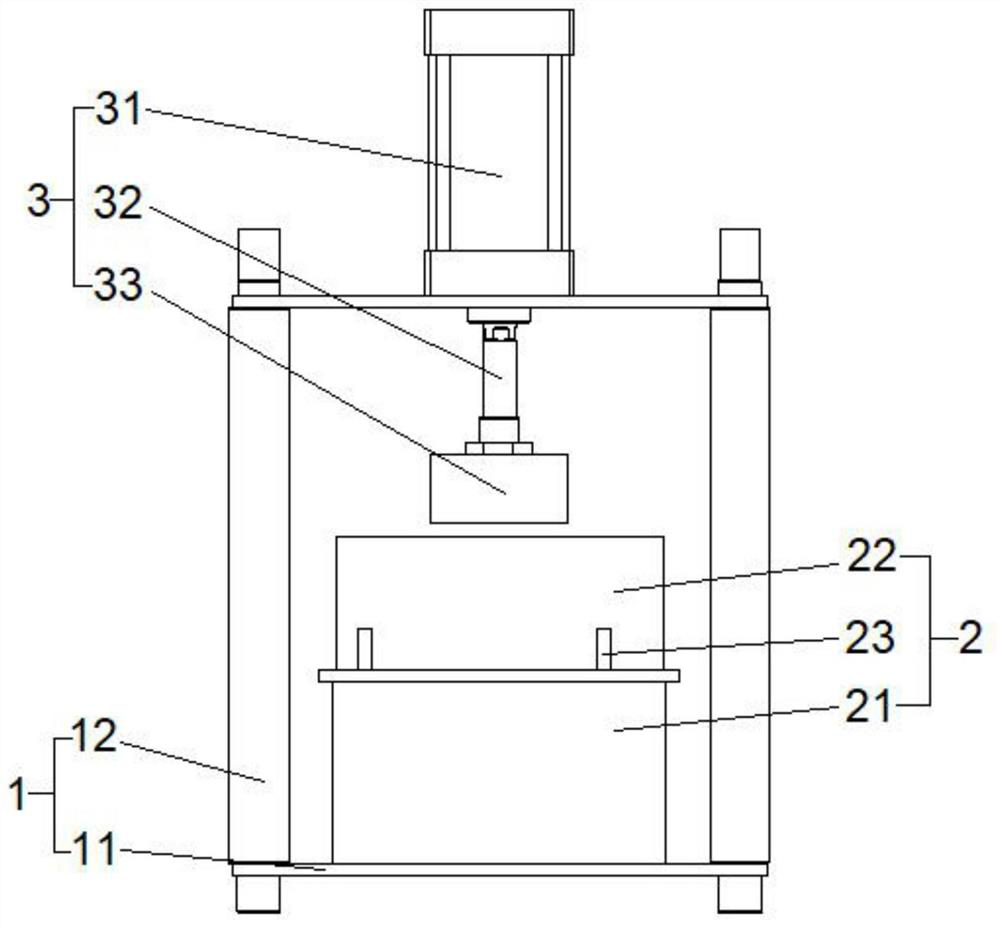

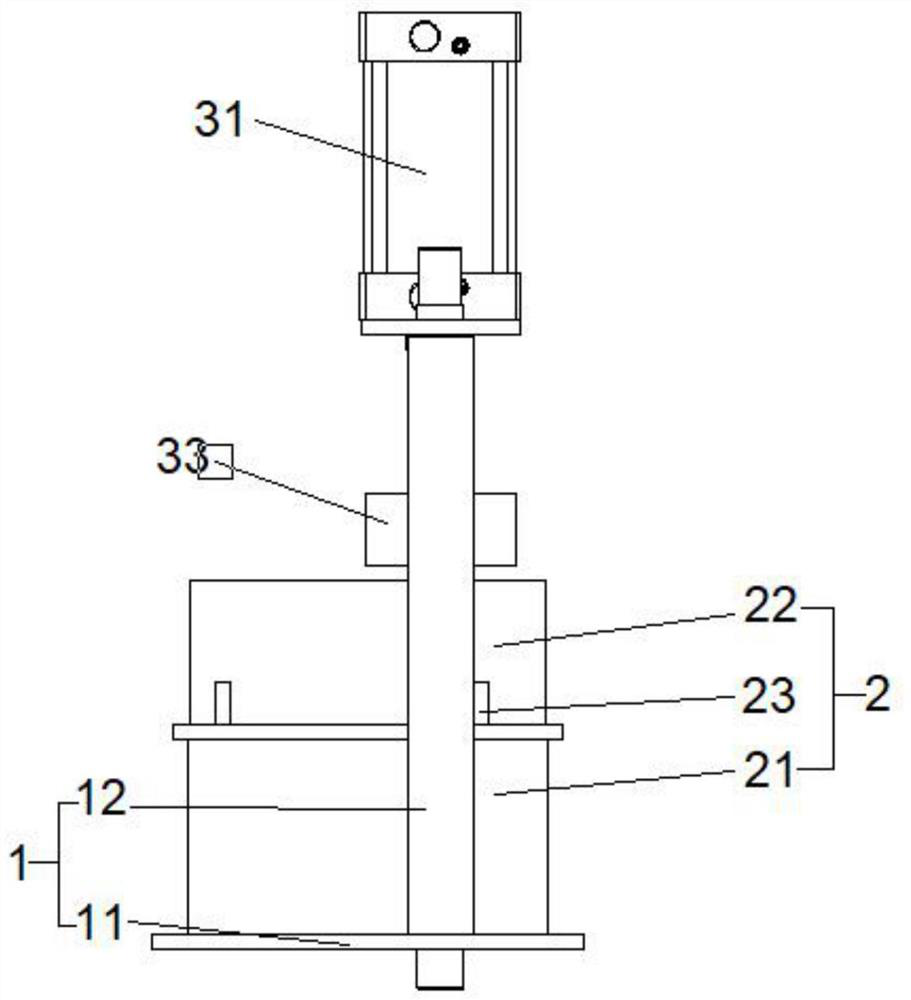

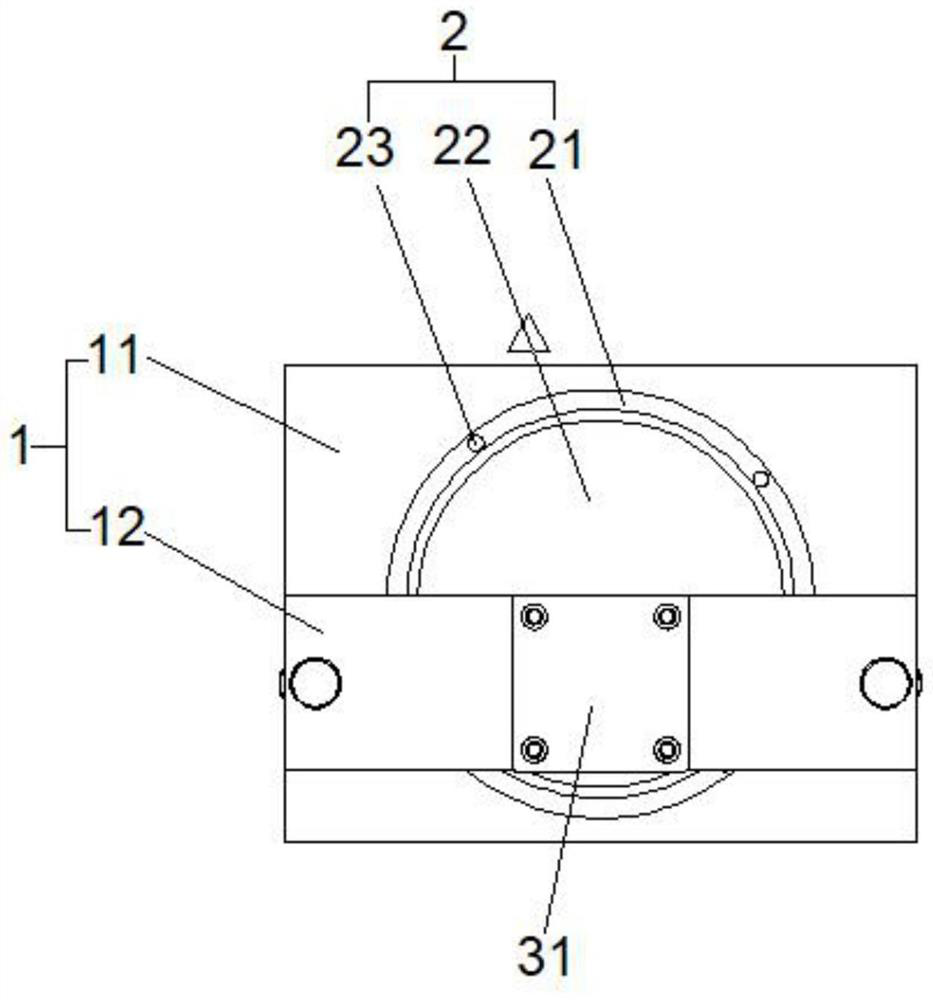

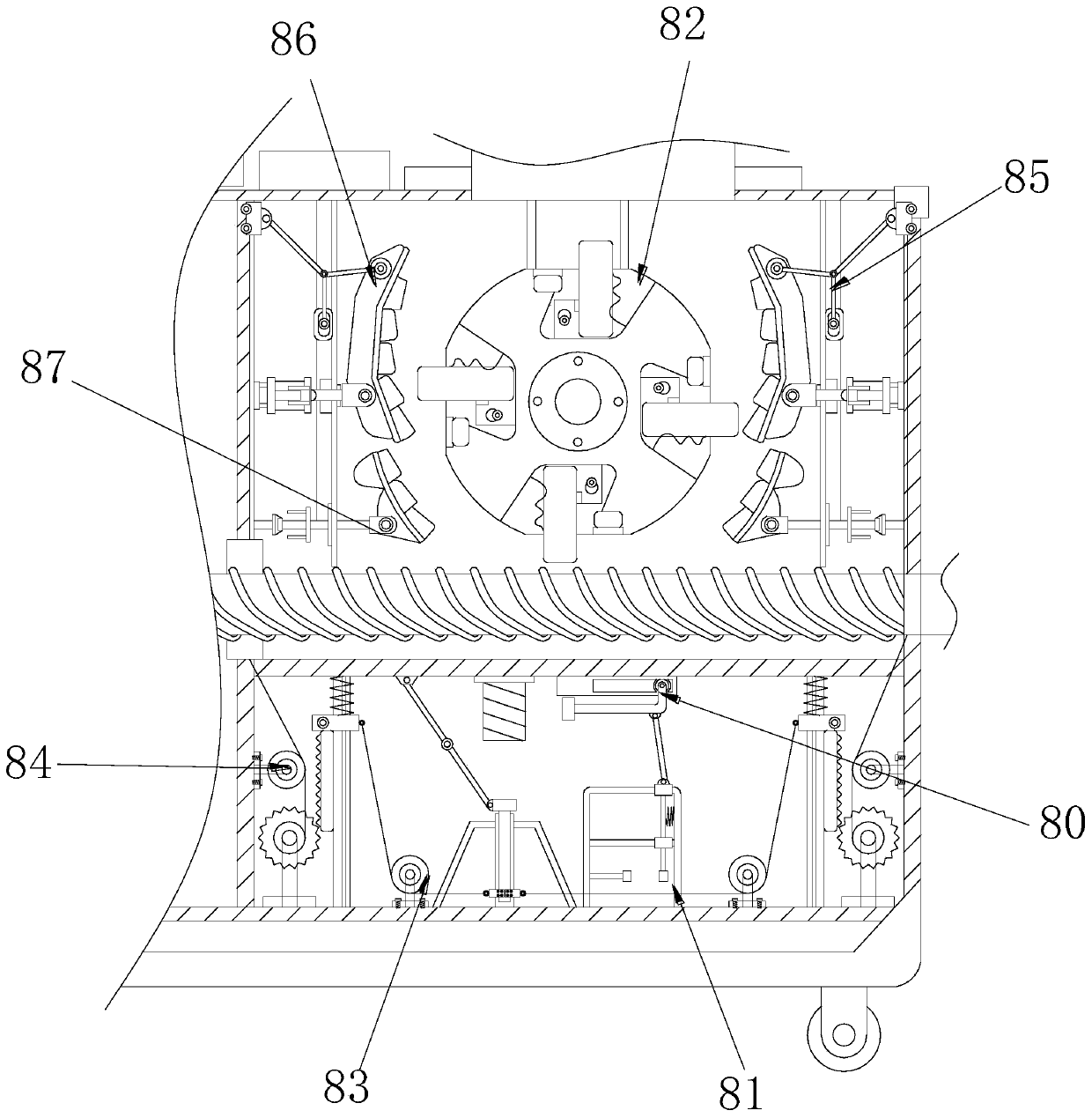

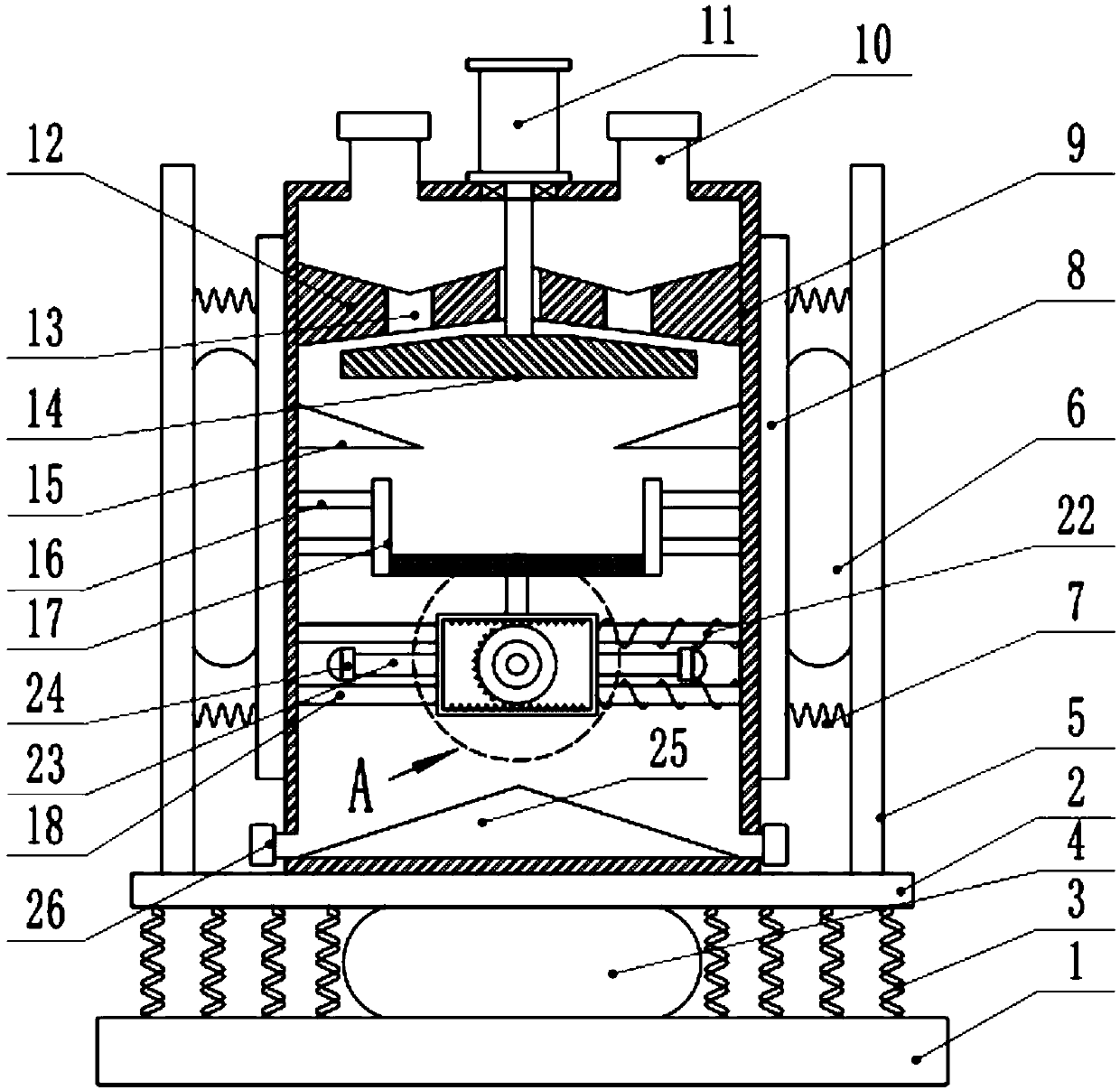

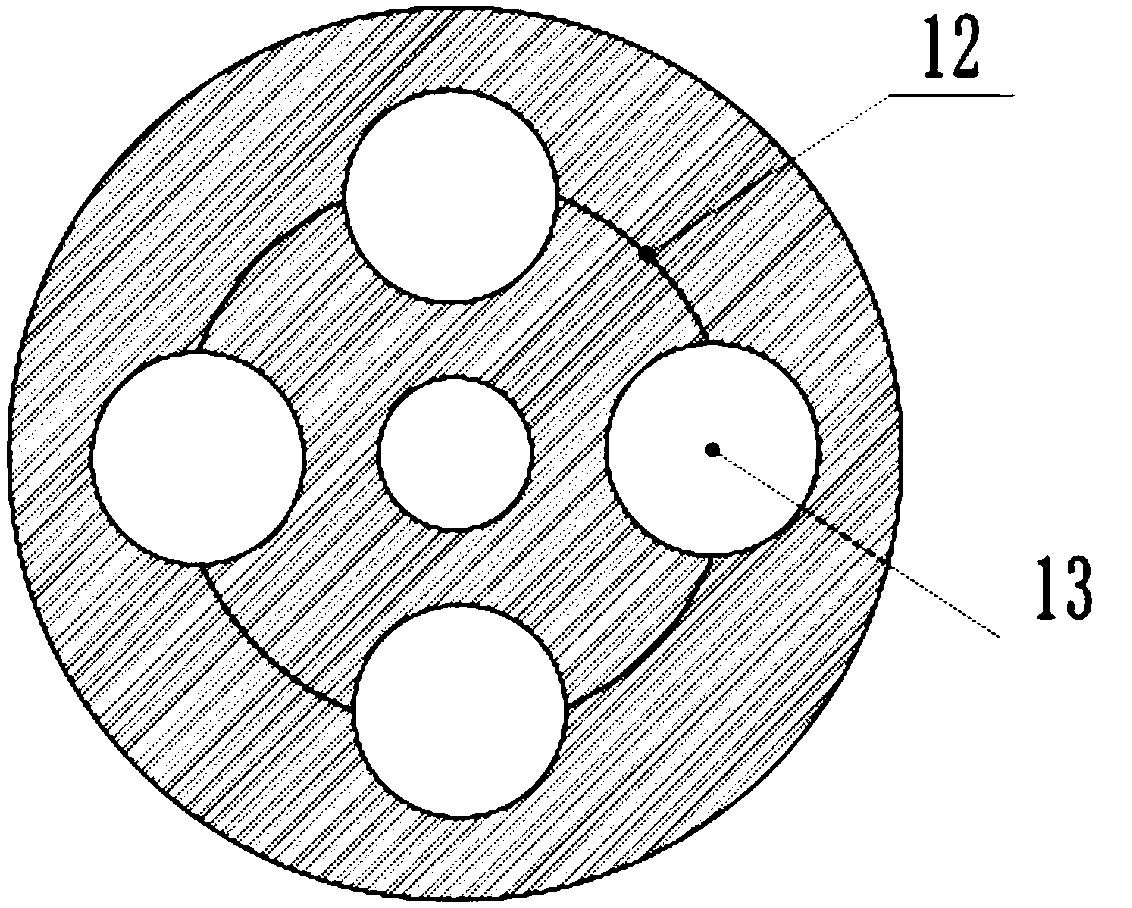

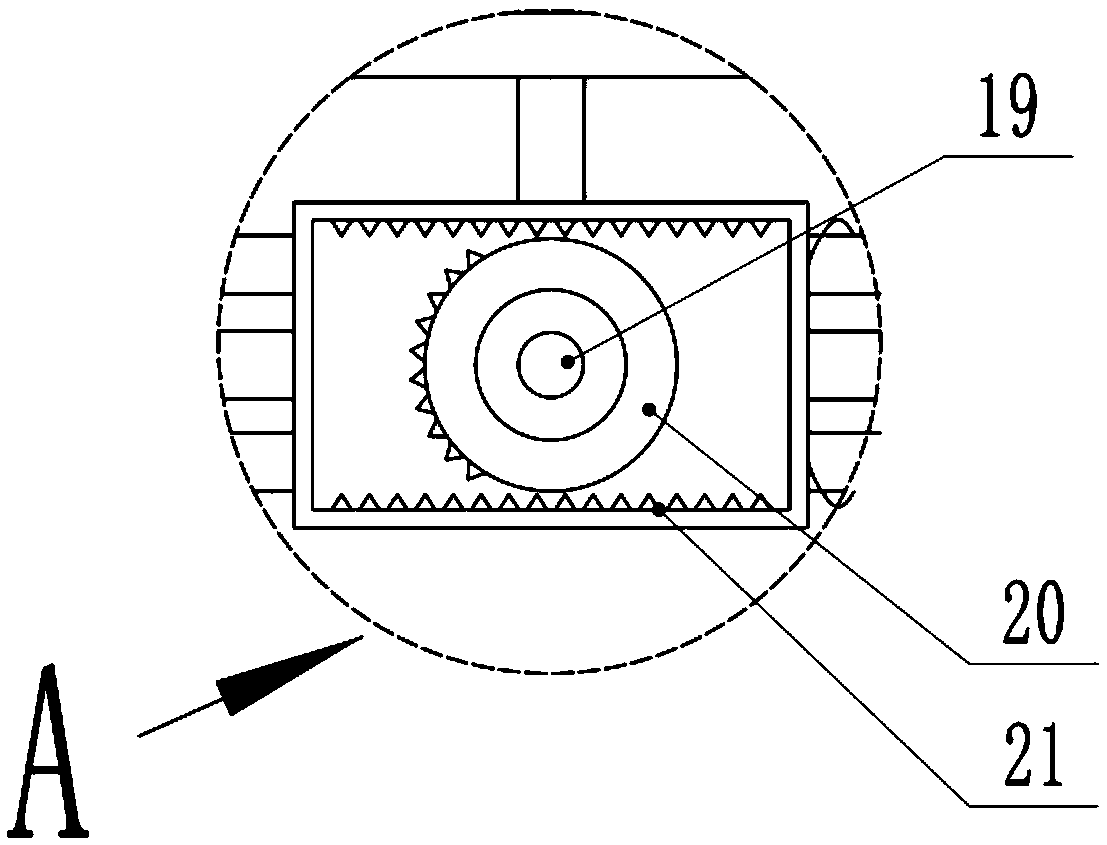

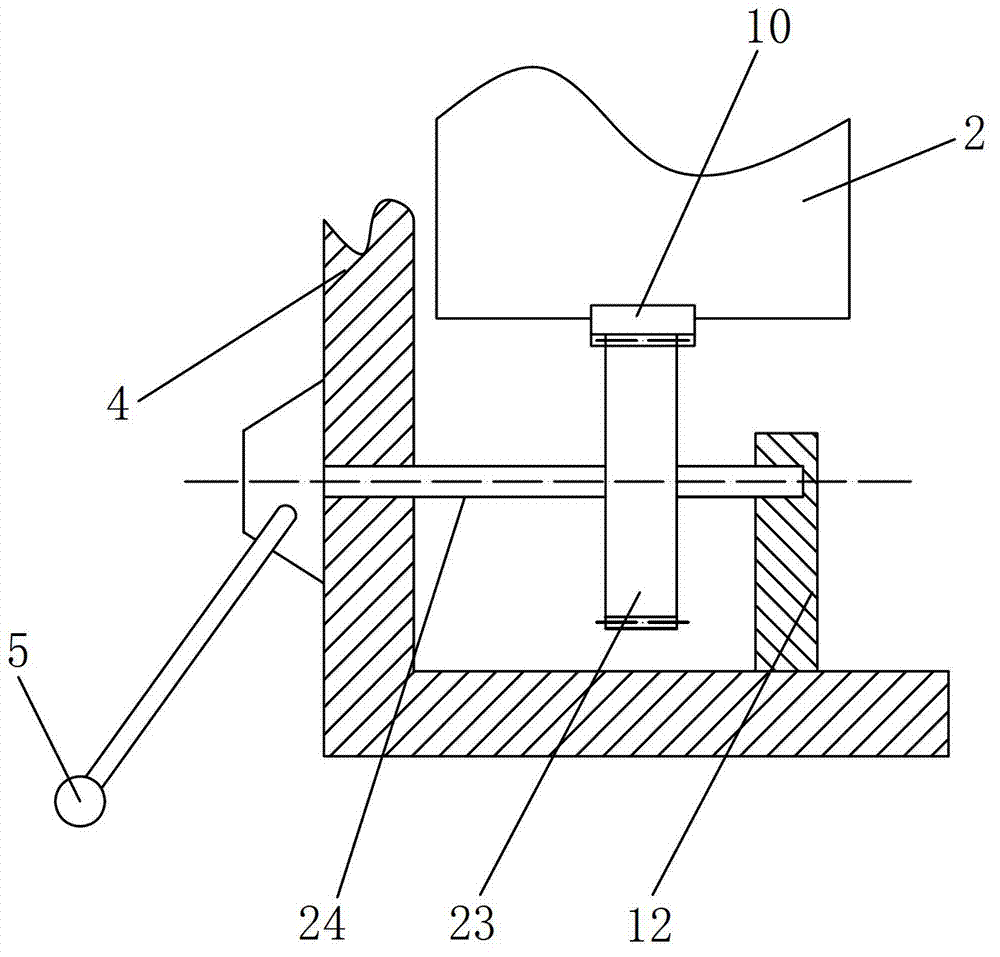

Impact rolling two-stage treatment soil grinding machine

PendingCN113368938AAchieve fine grindingMeet the process requirementsPreparing sample for investigationEarth material testingAgricultural engineeringElectric machinery

The invention discloses an impact rolling two-stage treatment soil grinding machine. The impact rolling two-stage treatment soil grinding machine comprises a rack and a grinding device mounted on the rack, the rack comprises a rack base and a mounting frame mounted on the rack base, and the grinding device comprises a grinding seat and a grinding working part erected above the grinding seat. The grinding seat comprises a supporting table mounted on the rack base and a bearing bin coaxially connected to the supporting table in a switched mode, the grinding working part comprises a grinding motor mounted on the upper end face of the mounting frame and a lifting pressing rod mounted on the lower end face of the mounting frame and connected to the power end of the grinding motor, and a cylindrical pressing block is mounted at the bottom end of the lifting pressing rod. The impact rolling two-stage treatment soil grinding machine has the beneficial effects that two-stage operation treatment including impact crushing and rotary rolling can be carried out on soil samples in a bearing bin, and fine grinding of the soil samples can be achieved so as to meet the follow-up treatment requirements.

Owner:江苏聚源实验科技有限公司

A raw material crushing equipment for Longquan celadon production and its use method

ActiveCN107999211BAchieve separationImprove grinding efficiencyGrain treatmentsElectric machineryEngineering

The invention discloses raw material crushing equipment for production of Longquan celadon and a using method thereof. The raw material crushing equipment comprises a shell, a grinding cylinder, a supporting base, a base, a fixing base, a releasing cylinder, a driving device, a discharging cylinder, a grinding motor and a centralizing device, wherein a first opening is formed in one side of the shell, the grinding cylinder is located in the shell, and grinding beads are arranged in the grinding cylinder. One side of the grinding cylinder is fixedly provided with a feeding cylinder, the end, away from the grinding cylinder, of the feeding cylinder is rotationally connected with the supporting base, the bottom of the supporting base is fixed to the base, a second opening is formed in the side, far away from the first opening, of the shell, the end, far away from the feeding cylinder, of the grinding cylinder is fixedly provided with a rotating shaft, and the rotating shaft penetrates through the second opening and is rotationally connected with the fixing base. According to the raw material crushing equipment for production of the Longquan celadon and the using method thereof, a partof ground raw materials can be output from the discharging cylinder, so that the separation of the ground raw materials from the raw materials which are not subjected to grinding is realized, and thegrinding efficiency of the raw materials is improved.

Owner:龙泉市尚唐瓷艺发展有限公司

An automatic and repeated crushing device for animal feed and its use method

ActiveCN110420728BEvenly groundPrevent the problem of oversized grinding particlesFeeding-stuffGrain treatmentsCrop livestockEngineering

An automatic repeated crushing device for livestock feed, comprising a box body 1, the front and rear ends of the box body 1 communicate with the outside world, and the top of the box body 1 is sealed and connected with a box body 2 whose left and right ends communicate with the outside world. The upper half of the front and rear ends of the body are sealed and connected with baffles, and the opposite ends of the baffles are respectively provided with chute, and the inside of the chute is slidably connected with a sliding plate. The beneficial effect of the present invention is that the structure of the present invention is simple, It is easy to operate and can grind large-grained feed, and the amount of feeding is very uniform each time, which prevents the problem of excessive grinding of feed particles caused by too much single-feeding during manual operation, and has a great impact on grinding. The final feed is automatically collected, which realizes the four requirements of fine grinding, uniform grinding, quantitative grinding and automatic grinding of feed, which is simple, efficient, convenient and fast.

Owner:陈惠英

A self-priming horizontal feed grinding mixer

ActiveCN108371989BReduce distanceAchieve fine grindingFeeding-stuffTransportation and packagingAgricultural engineeringReducer

The invention discloses a self-priming horizontal feed pulverizer, which comprises a pulverizer body, a support frame, a wind suction machine, a suction pulverization motor, a suction pipe, a pulverization chamber, a mixing chamber, a high-efficiency automatic pulverization device, Pushing screw, reducer, pulley set, servo motor, stirring plate, mixing chamber door, door leaf bracket, air outlet, hopper, moving roller, the pulverizing mixer body is located inside the supporting frame and connected by electric welding, and the wind suction The feeder is located on the upper right side of the crushing mixer body and connected through electric welding, and the suction crushing motor is located in the center of the rear of the wind suction machine and connected by electric welding. The invention is equipped with a high-efficiency automatic crushing device, which can automatically finely grind the feed after preliminary crushing, realizes step-by-step high-efficiency crushing, facilitates more uniform stirring, improves the quality of the feed, and effectively enhances the self-priming horizontal feed The practical performance and degree of automation of the crushing mixer.

Owner:安徽荣国环保智能科技有限公司

Full-automatic feed grinding device for livestock raising and using method

The invention provides a full-automatic feed grinding device for livestock raising. The grinding device comprises a case body, wherein a material fixing case is arranged at the upper half part in thecase body, and a feeding pipe which communicates with the outside is fixedly arranged at the left half part of the inner wall of the top of the material fixing case; and the inner wall of the bottom of the fixed material case is a slope from high to low from the left to the right. The full-automatic feed grinding device has the beneficial effects that the structure is simple, and the operation iseasy and convenient to achieve; large-particle feed can be subjected to grinding treatment, and the amount of feeding at each time is very uniform; the problem that the feed grinding particles are toolarge due to the fact that the single feeding amount is too much during manual operation is solved, so that the four requirements of fine grinding, uniform grinding, quantitative grinding and automatic grinding on the feed are realized; and the method is simple, efficient, convenient and rapid.

Owner:黎星满

A high-efficiency catalyst fine grinding device for chemical experiments

ActiveCN107715990BAchieve fine grindingAchieve left and right movementNon-rotating vibration suppressionCocoaCompound (substance)Drive motor

The invention discloses an efficient catalyst fine grinding device for a chemical experiment. The efficient catalyst fine grinding device comprises a damping plate, a damping spring A, a grinding box,a fixed abrasive disk, a rotary abrasive disk, a screening box, a movable sliding frame and impacting heads. The damping spring A is further connected between the damping plate and a base. An elasticgasbag A is further arranged between the damping plate and the base. The fixed abrasive disk is further arranged in the grinding box. An extending shaft of a first driving motor penetrates through ashaft hole in the center of the fixed abrasive disk, and the rotary abrasive disk is connected to the lower portion of the fixed abrasive disk. Jacking rods are welded to both the left side and the right side of the movable sliding frame. The impacting heads are further in threaded connection with the other ends of the jacking rods. In the efficient catalyst fine grinding device, left and right moving of the movable sliding frame is achieved, thus on the one hand, left and right moving of the screening box can be achieved, so that catalyst screening efficiency is improved greatly; and on the other hand, the impacting heads on the left side and the right side can be driven to impact on the inner wall of the grinding box, adhesion of catalyst powder on the inner wall of the grinding box is avoided effectively, and simple and effective effects are achieved.

Owner:鹤山市新力翘粉末有限公司

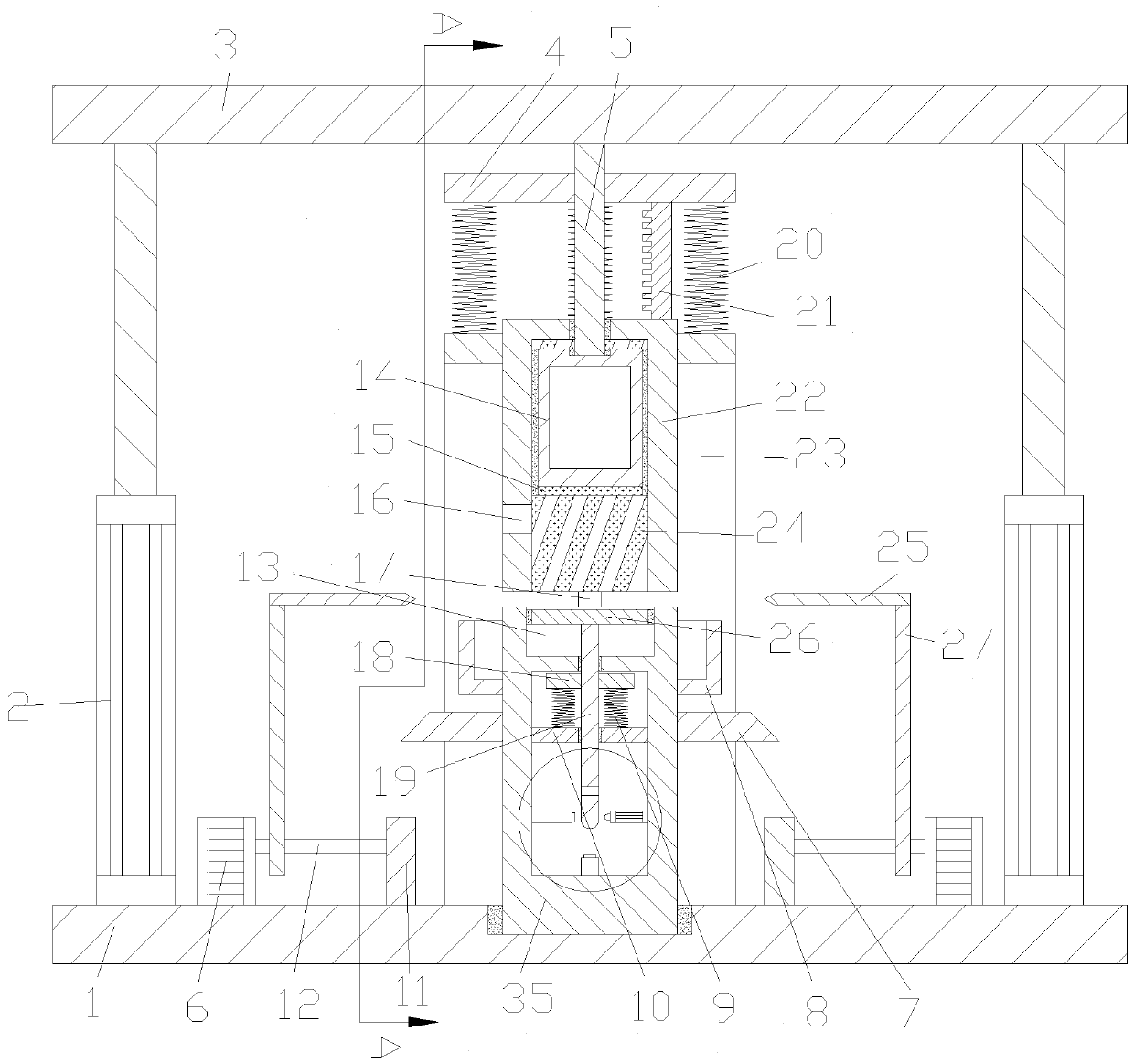

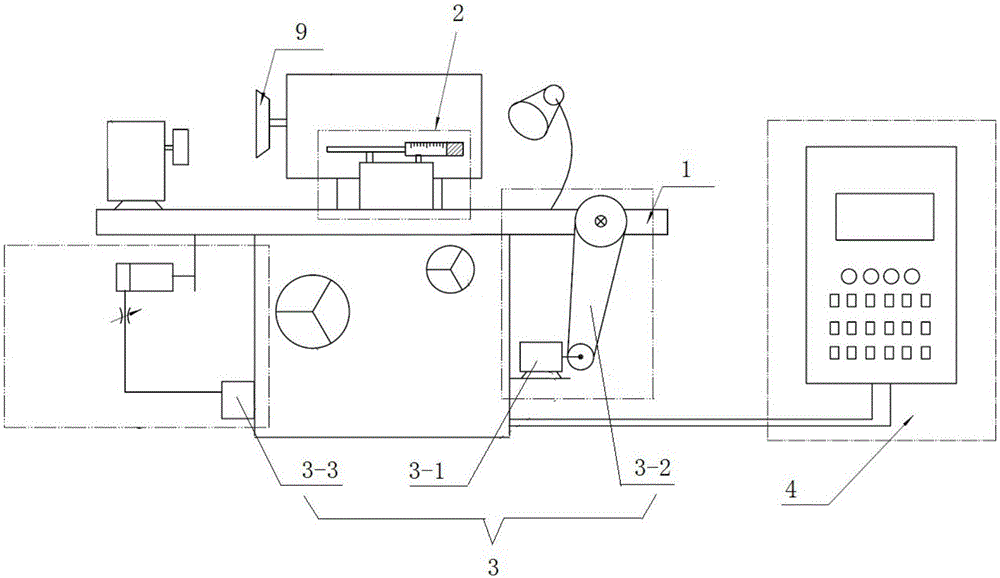

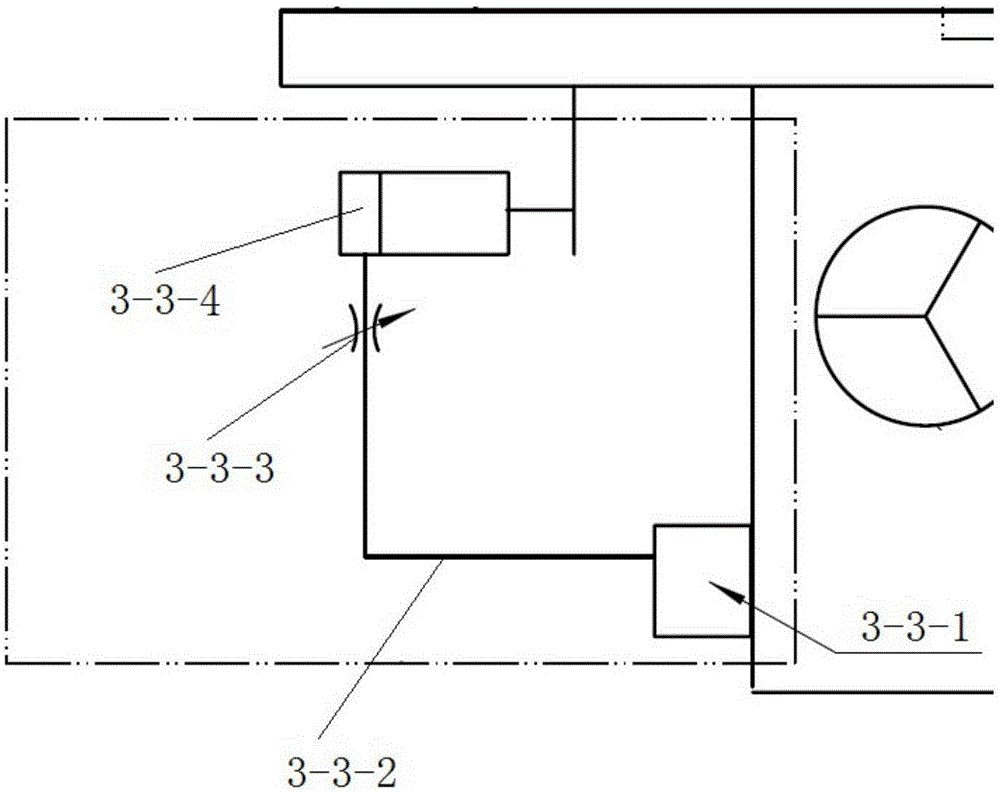

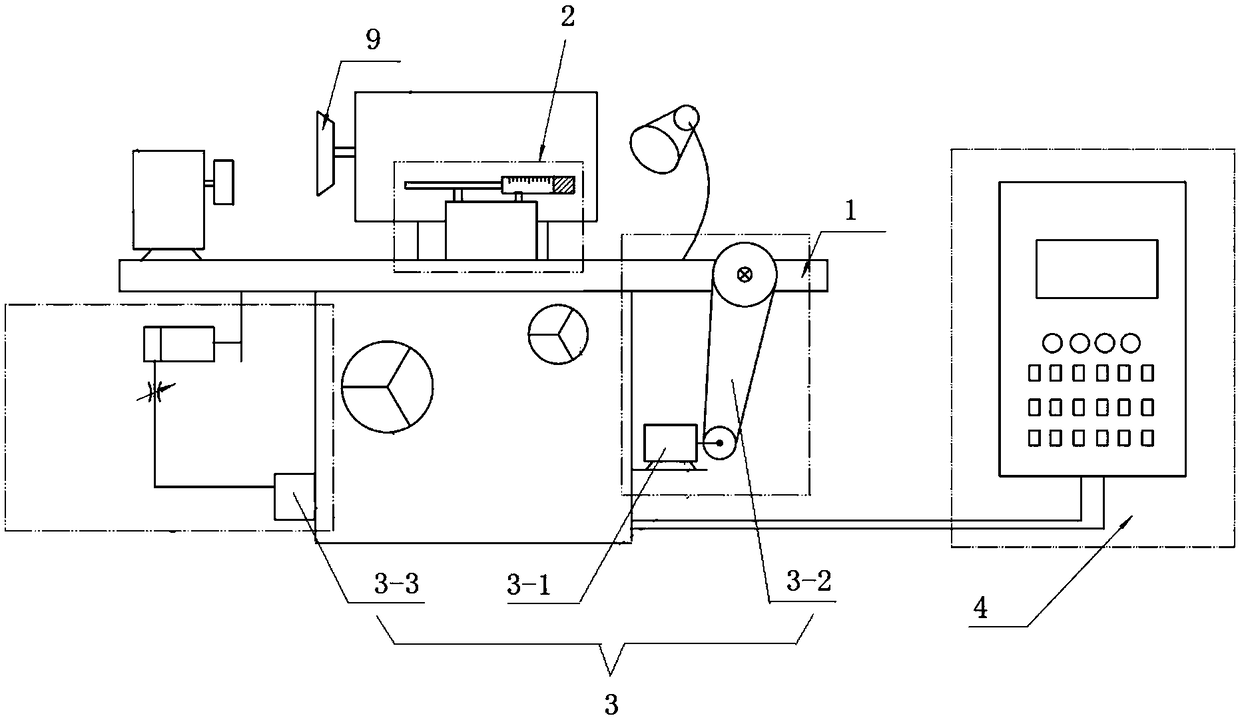

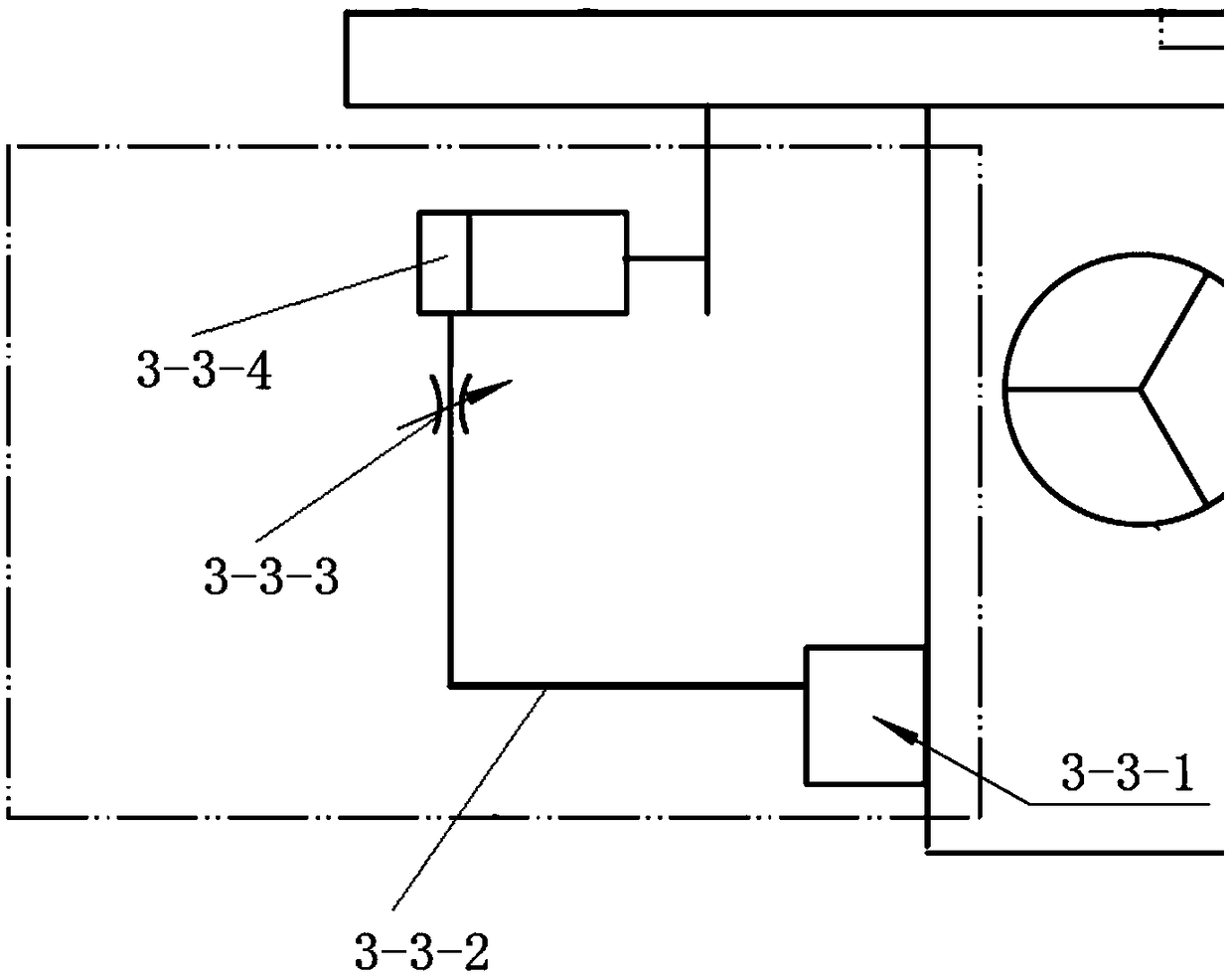

Constant-force grinding system integrating detection with grinding

ActiveCN106078515AExpand the grinding rangeGood processing qualityGrinding drivesGrinding feed controlThrough transmissionConstant torque

The invention discloses a constant-force grinding system integrating detection with grinding. The constant-force grinding system is characterized by comprising a working table, as well as an on-line detecting system, a constant-force grinding system and a controller mounted on the working table; the controller controls operation of the constant-force grinding system according to the information fed back by the on-line detecting system; the constant-force grinding system comprises a servo motor, a synchronous transmission mechanism and a working table return device; the servo motor serves as a constant-torque servo motor; the constant-torque servo motor is converted into the constant feed force of the working table through transmission of the synchronous transmission mechanism; and the working table return device is used for realizing returning of horizontal operation of the working table. Aiming at a machine tool transmission chain deformation phenomenon caused by unstable grinding feed force during ground finish and the constant-displacement forceful feeding mode adopted in numerically controlled grinder design, the design concept of constant-force grinding is adopted, and the grinding feed force is set into a constant quantity from an unstable variable, so that deformation of a machine tool transmission chain is in a stale state.

Owner:FOSHAN POLYTECHNIC

ASA high rubber powder drying process conveying equipment

The invention discloses ASA high rubber powder drying process conveying equipment, and relates to the technical field of high rubber powder conveying equipment. The ASA high rubber powder drying process conveying equipment comprises a belt type vacuum dryer, a discharging square pipe is fixedly connected to the bottom of the outer wall of the discharging end of the belt type vacuum dryer, a finished product conveying mechanism is installed at the bottom of the discharging square pipe, and a raw material pipe is fixedly connected to the top of the outer wall of the feeding end of the belt type vacuum dryer in a penetrating manner; and the end, located in the belt type vacuum dryer, of the raw material pipe is fixedly connected with a plurality of raw material tiling mechanisms. According to the ASA high rubber powder drying process conveying equipment, the belt type vacuum dryer more suitable for slurry drying is used, and the raw material tiling mechanisms on a vacuum conveying belt in the belt type vacuum dryer is matched, so that a traditional rocker arm circulating spreading mode is avoided, and uniform tiling of the materials is realized; and a material pump which works in a static state is adopted to replace swing arm type tiling mechanisms, movement of the mechanisms is reduced, the probability of equipment damage is reduced, a more reasonable tiling mode is provided, and drying and later processing of the materials are better facilitated.

Owner:山东颐工材料科技股份有限公司

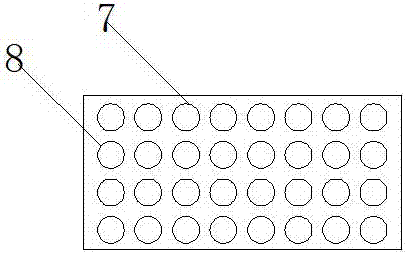

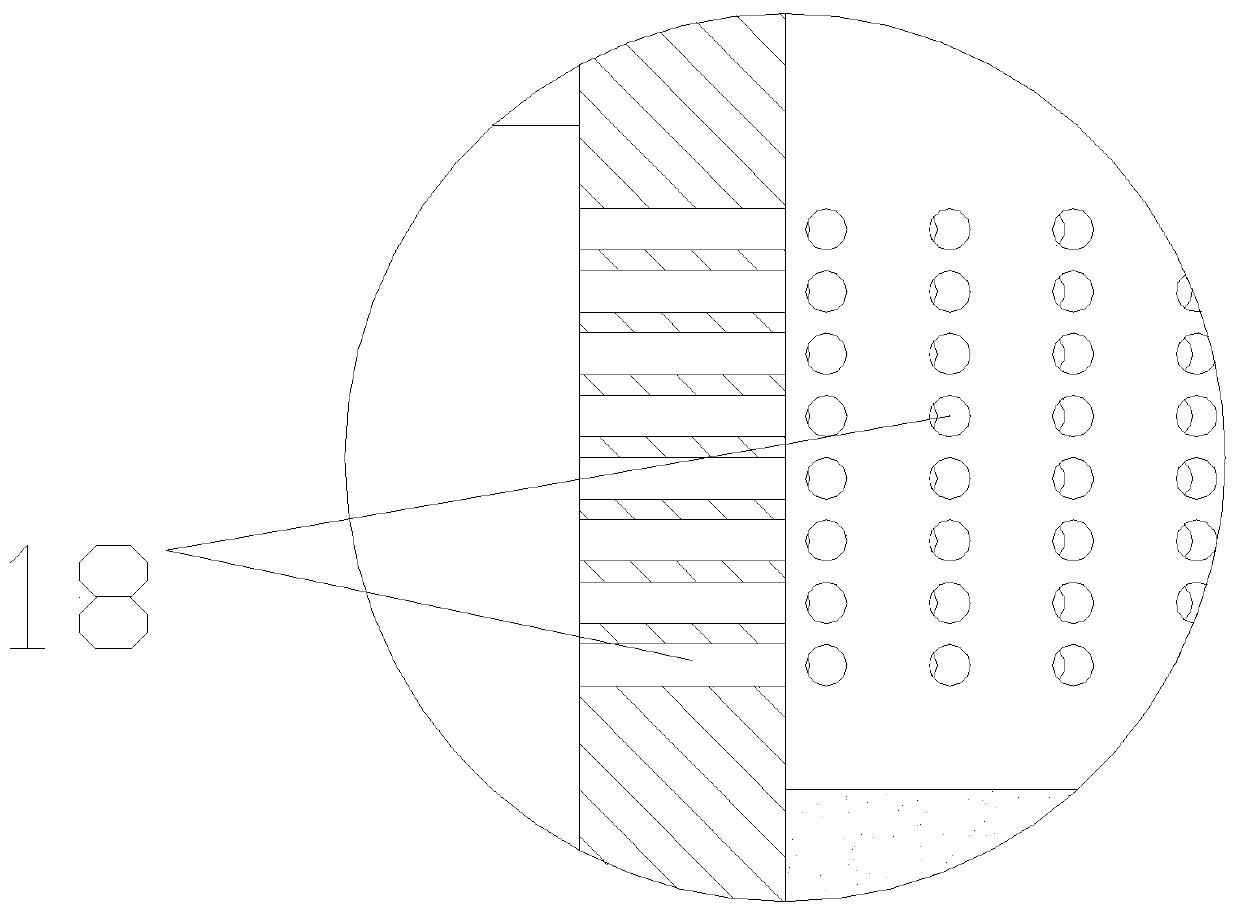

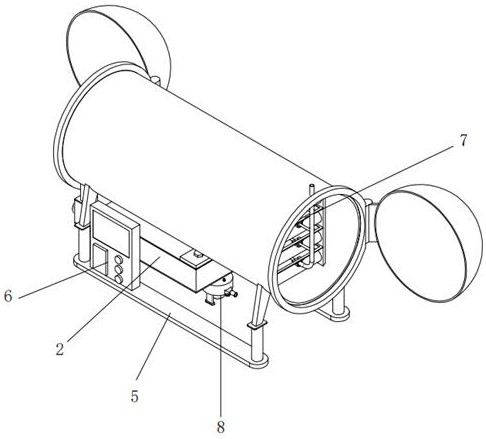

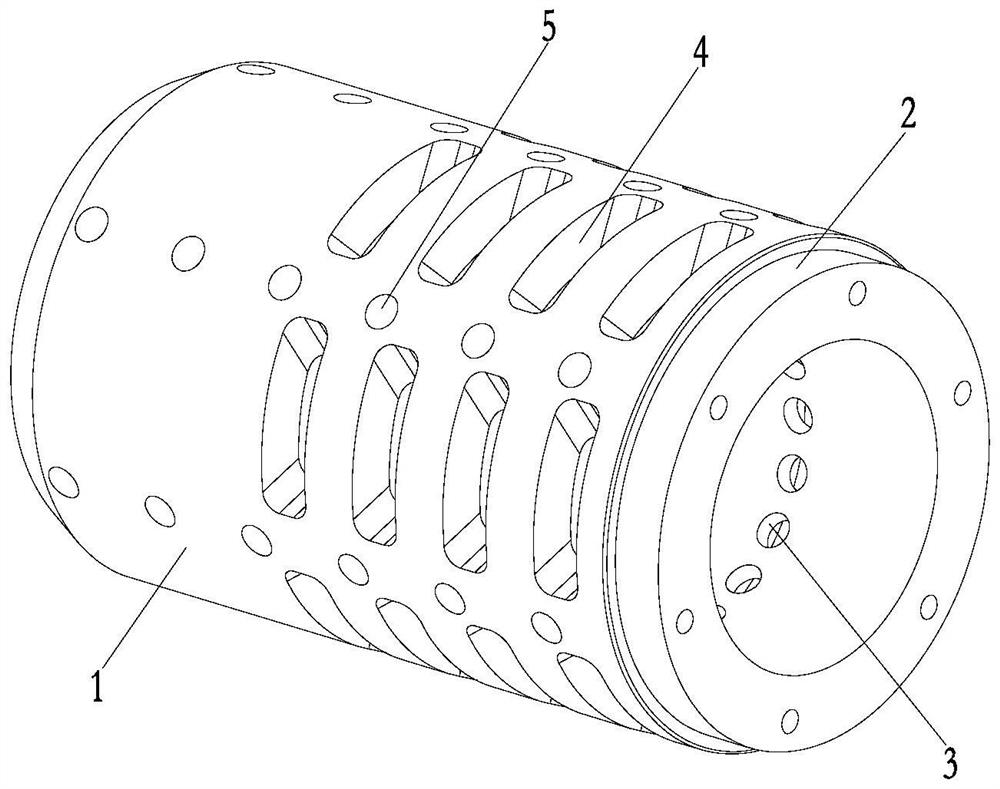

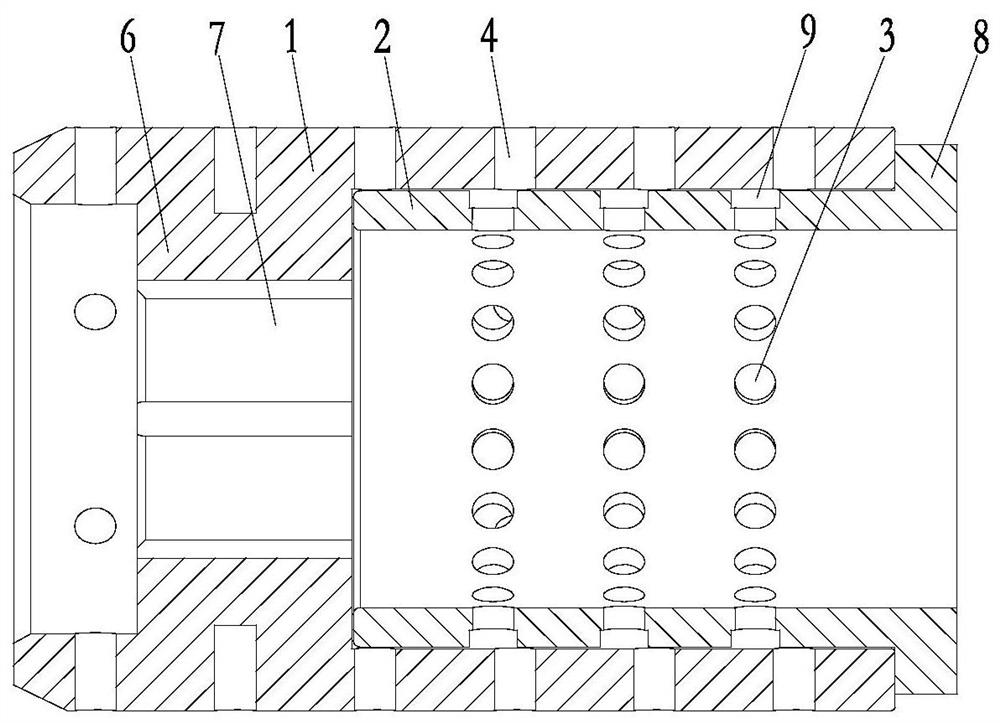

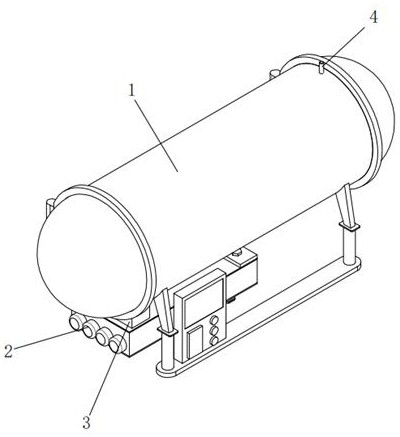

Movable and static ring for integrated sand mill

PendingCN112337589AImprove the situation of poor particle size distributionAchieve fine grindingGrain treatmentsEngineeringParticle-size distribution

The invention relates to a movable and static ring for an integrated sand mill. The movable and static ring comprises a movable ring and a fixed ring, and the movable ring is provided with an inner cavity with an opening in one end; the fixed ring extends into the inner cavity of the movable ring, and is in clearance fit with the wall of the inner cavity of the movable ring; a plurality of rows ofthrough hole sets arranged at intervals are formed in the peripheral wall of the fixed ring in the axis direction of the fixed ring; a plurality of rows of elongated slot sets arranged at intervals are formed in the peripheral wall of the movable ring in the axis direction of the movable ring, and are provided with elongated slots evenly distributed in the circumferential direction; and the through hole sets and the elongated slot sets are arranged in a staggered mode, and communicate with each other through rotation of the movable ring. According to the movable and static ring, through arrangement of the movable ring and the fixed ring which are moved relatively, and by using the shearing effect between the through holes and the elongated slots which are formed in a staggered mode, finegrinding of materials is achieved in cooperation with a grinding medium, so that the conditions of uneven distribution and poor particle size distribution of grinding media after grinding can be overcome properly, and the grinding quality is improved.

Owner:CHANGZHOU LONGXIN MACHINERY

A kind of asa high rubber powder drying process conveying equipment

The invention discloses a conveying device for the drying process of ASA high rubber powder, and relates to the technical field of high rubber powder conveying equipment. Including the belt vacuum dryer, the bottom of the outer wall of the discharge end of the belt vacuum dryer is fixedly connected with the discharge square tube, the bottom of the discharge square tube is equipped with a finished product transportation mechanism, and the top of the outer wall of the belt vacuum dryer feed end is fixedly connected in the form of a through-hole There are raw material pipes, and one end of the raw material pipes located inside the belt vacuum dryer is respectively fixedly connected with a plurality of raw material flattening mechanisms. The present invention uses a belt-type vacuum dryer that is more suitable for slurry drying, and cooperates with a raw material laying machine on the vacuum conveyor belt inside the belt-type vacuum dryer, avoiding the traditional way of rocker arm circulation material spreading, and realizing Uniform paving of materials, using a static working material pump instead of a swing arm type paving mechanism reduces the movement of the mechanism and thus reduces the probability of equipment damage, and provides a more reasonable paving method that is more conducive to the drying and post-processing of materials.

Owner:山东颐工材料科技股份有限公司

Rail jaw refiner of rocket sled sliding rail welding connector

ActiveCN103128616BSimple structureNovel and reasonable designPlane surface grinding machinesBench grinderRocket

The invention discloses a rail jaw refiner of a rocket sled sliding rail welding connector. The rail jaw refiner comprises a fixed base fixedly installed on the rocket sled sliding rail welding connector and a straight-direction grinding machine arranged on one side of a rocket sled sliding rail and used for grinding a rail jaw of the rocket sled sliding rail welding connector. The upper surface of a grinding wheel of the straight-direction grinding machine is bonded to the rail jaw of the rocket sled sliding rail welding connector, a transverse adjusting mechanism capable of moving transversely along the rocket sled sliding rail is installed on the fixed base and is connected with a vertical adjusting mechanism used for driving the straight-direction grinding machine to move vertically along the rocket sled sliding rail, and the vertical adjusting mechanism is connected with the straight-direction grinding machine through a height adjusting mechanism used for driving the straight-direction grinding machine to move vertically. The rail jaw refiner of the rocket sled sliding rail welding connector is high in automation degree, simple to process and convenient to use, saves cost and has wide popularization and application value in laying of rocket sled sliding rail jointless tracks.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

A constant force grinding system integrating detection and grinding functions

ActiveCN106078515BAchieve coarse grindingAchieve fine grindingGrinding drivesGrinding feed controlFeeding forceConstant force

The invention discloses a constant-force grinding system integrating detection with grinding. The constant-force grinding system is characterized by comprising a working table, as well as an on-line detecting system, a constant-force grinding system and a controller mounted on the working table; the controller controls operation of the constant-force grinding system according to the information fed back by the on-line detecting system; the constant-force grinding system comprises a servo motor, a synchronous transmission mechanism and a working table return device; the servo motor serves as a constant-torque servo motor; the constant-torque servo motor is converted into the constant feed force of the working table through transmission of the synchronous transmission mechanism; and the working table return device is used for realizing returning of horizontal operation of the working table. Aiming at a machine tool transmission chain deformation phenomenon caused by unstable grinding feed force during ground finish and the constant-displacement forceful feeding mode adopted in numerically controlled grinder design, the design concept of constant-force grinding is adopted, and the grinding feed force is set into a constant quantity from an unstable variable, so that deformation of a machine tool transmission chain is in a stale state.

Owner:FOSHAN POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com