Patents

Literature

35results about How to "Evenly ground" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

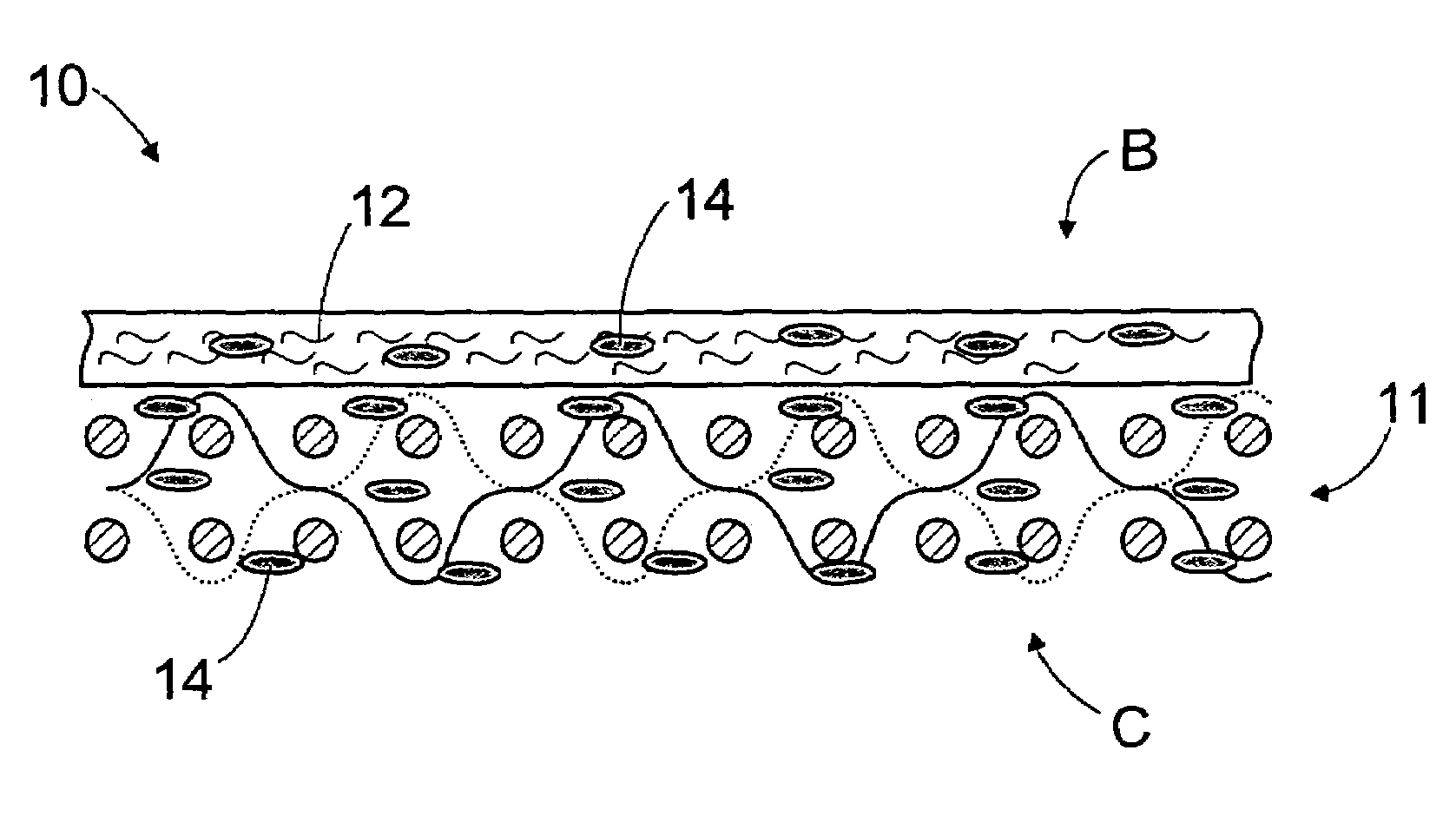

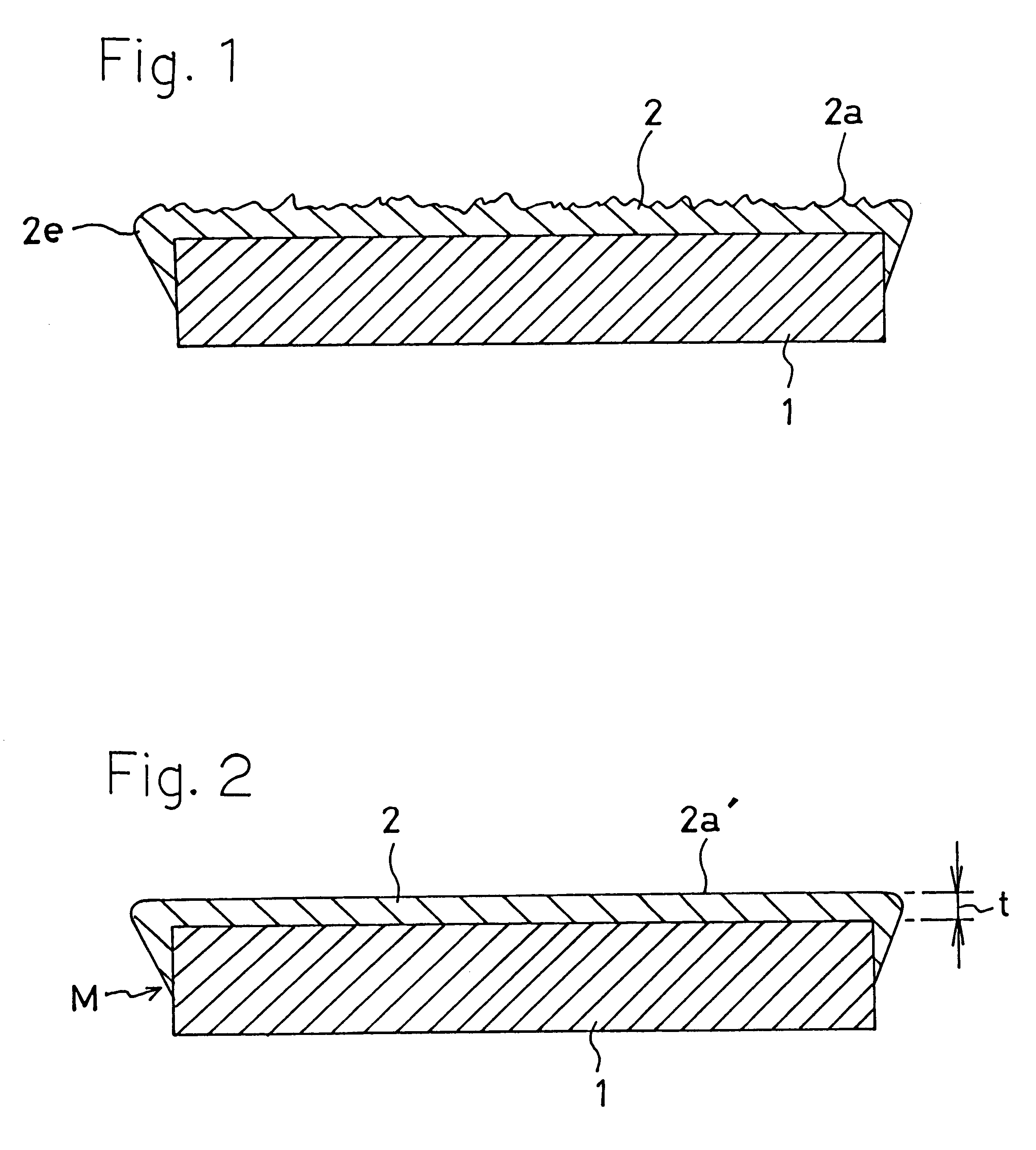

Press felt

InactiveUS20050124248A1Reduce basis weightImprove efficiencyLayered productsPaper/cardboardFiberEngineering

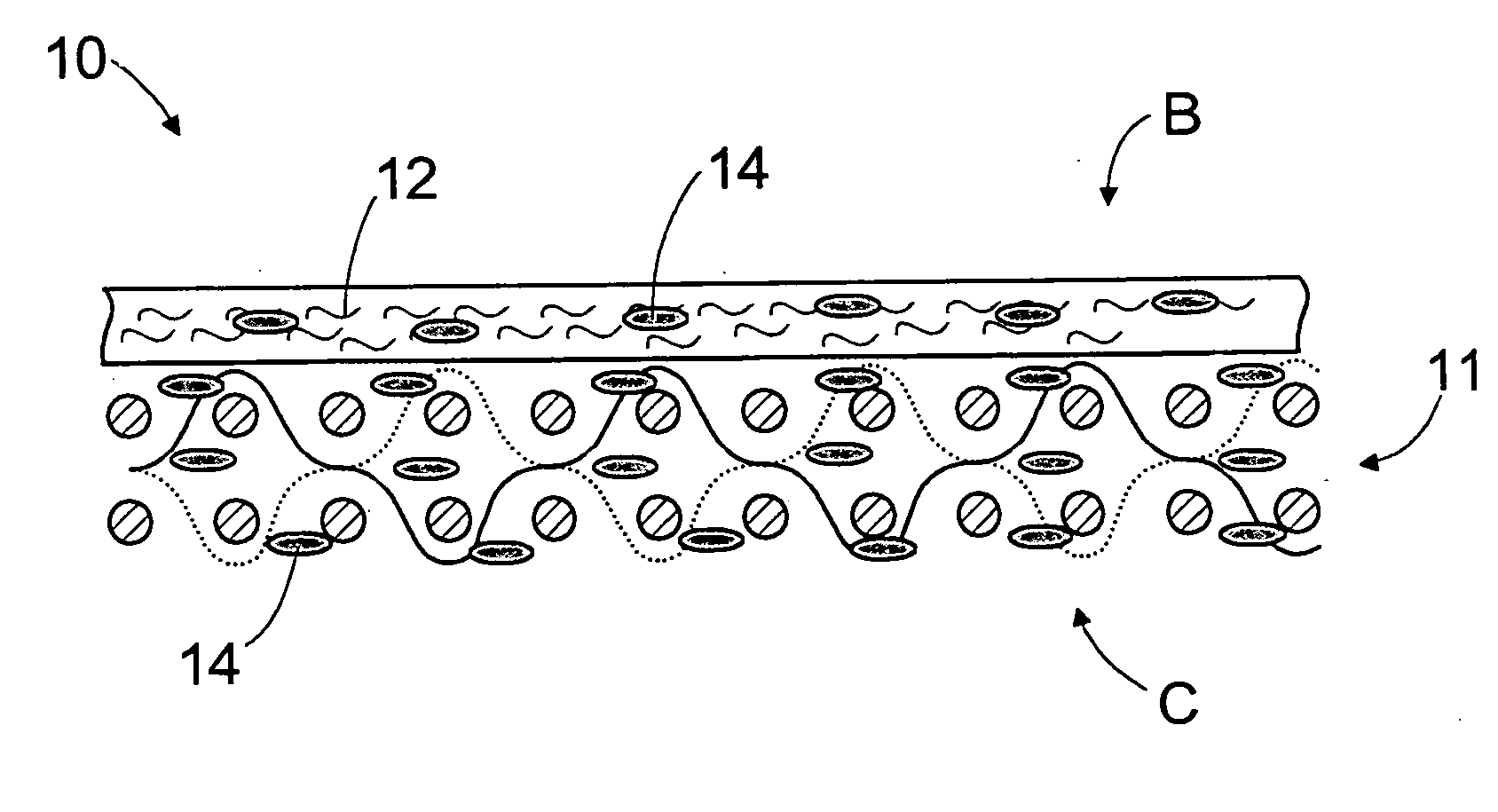

A method of manufacturing a press felt, a press section, and a press felt. The press felt comprises a base structure (11), a batt fibre layer (12) being attached to a first, web-side surface (B) of the base structure. Further, the structure of the press felt is compacted by treating it with a polymer material at least on the side of the first felt surface (B). After the polymer treatment, the surface of the felt is ground smooth.

Owner:TAMFELT PMC OY

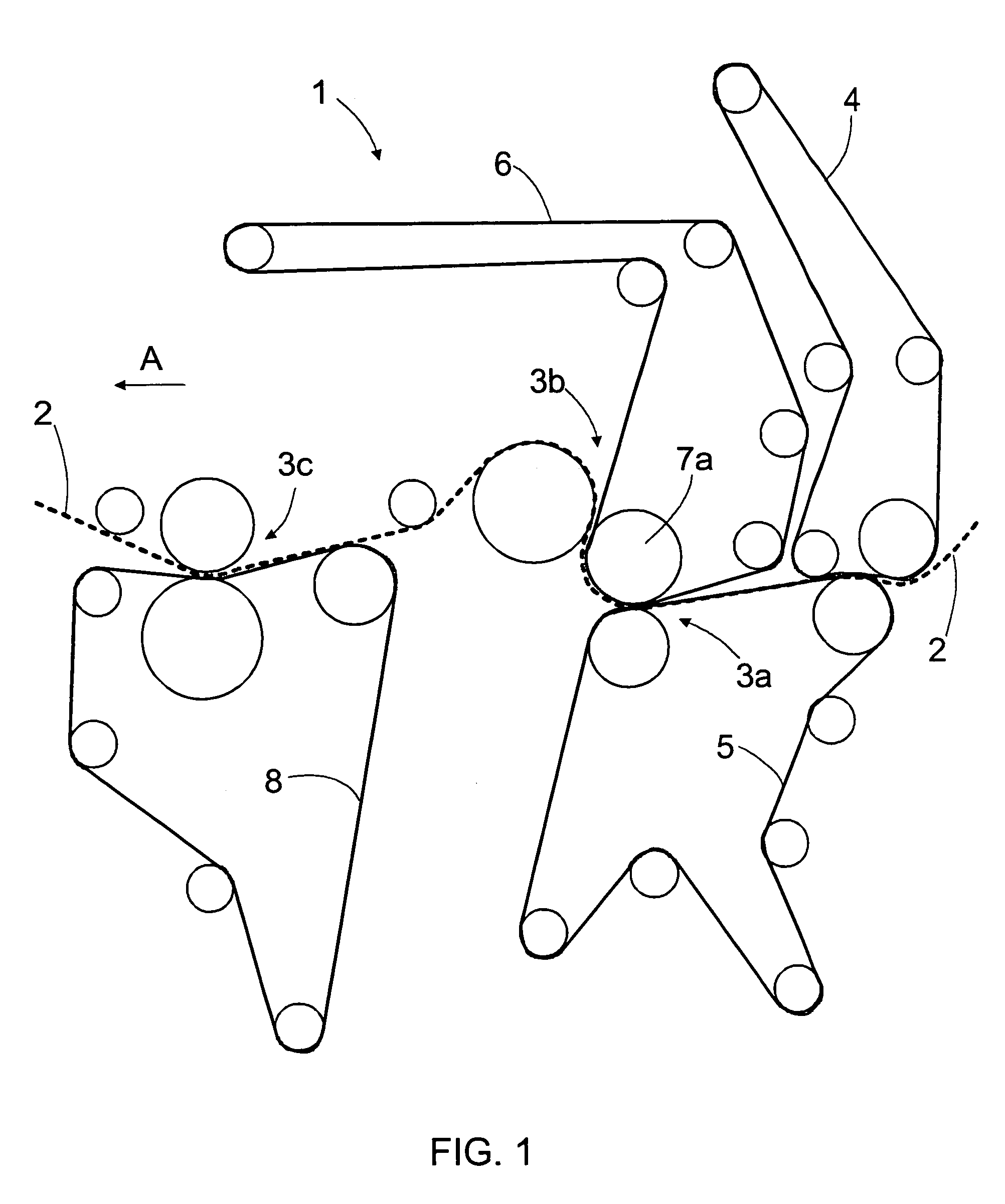

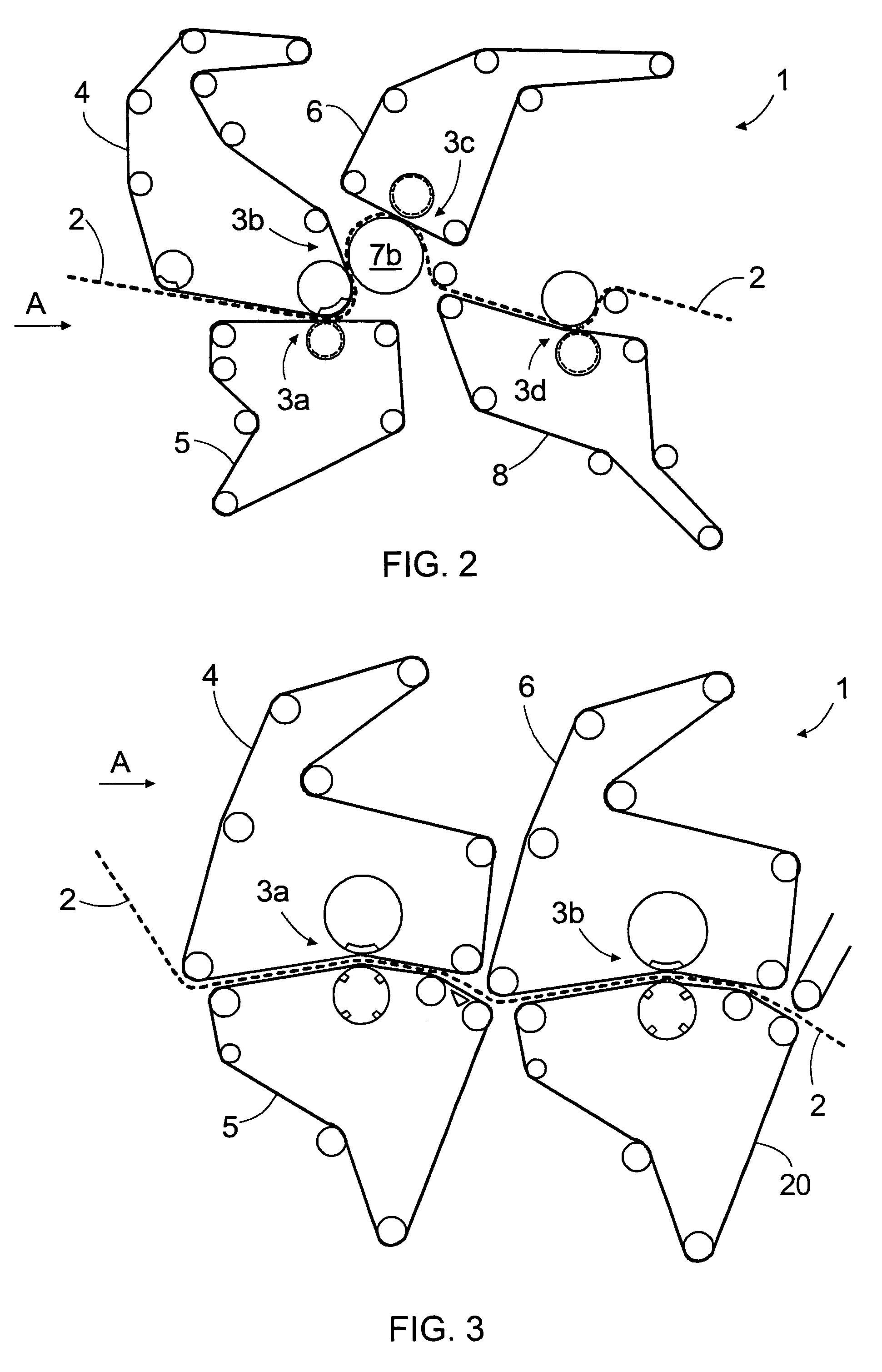

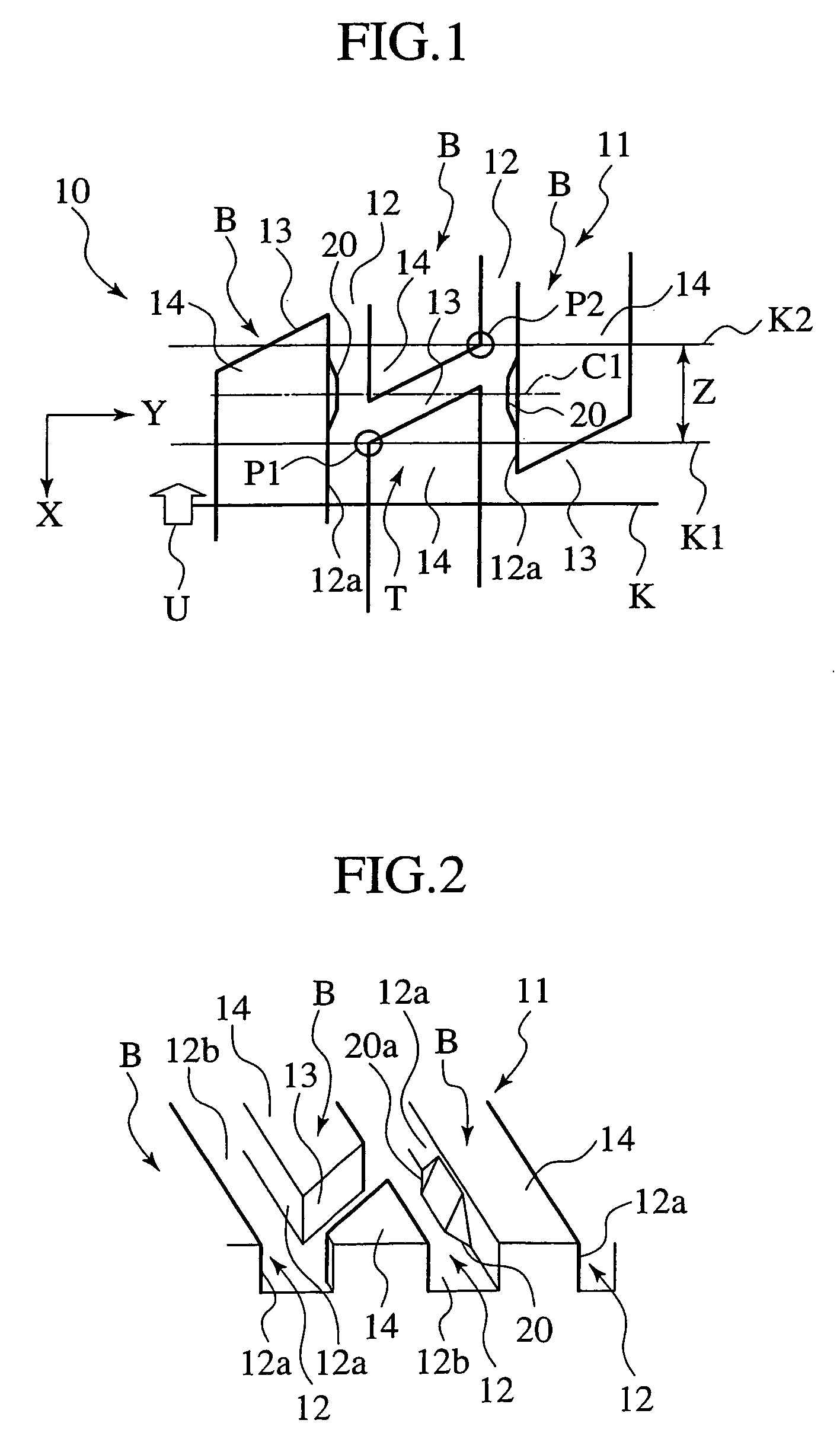

Pneumatic tire

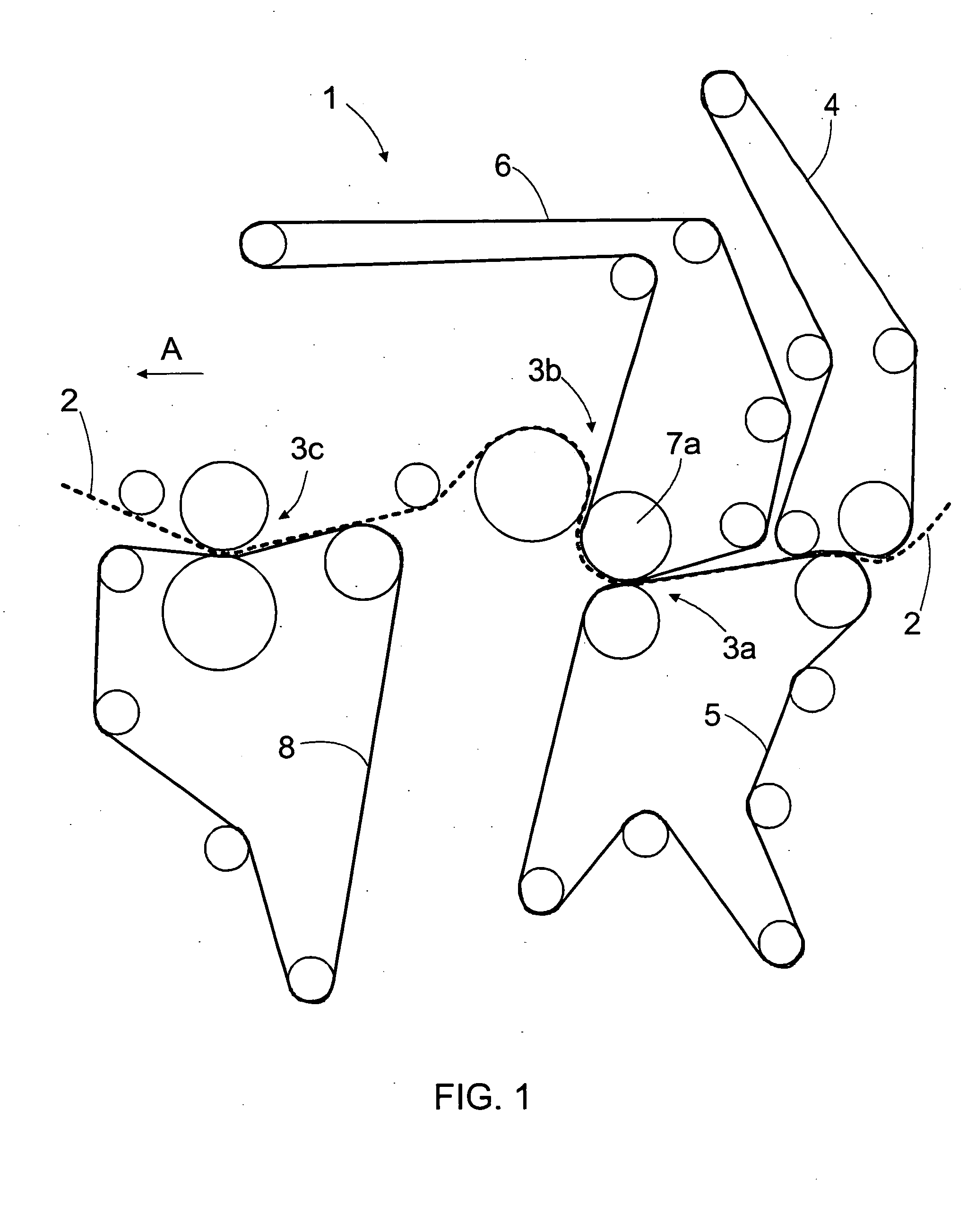

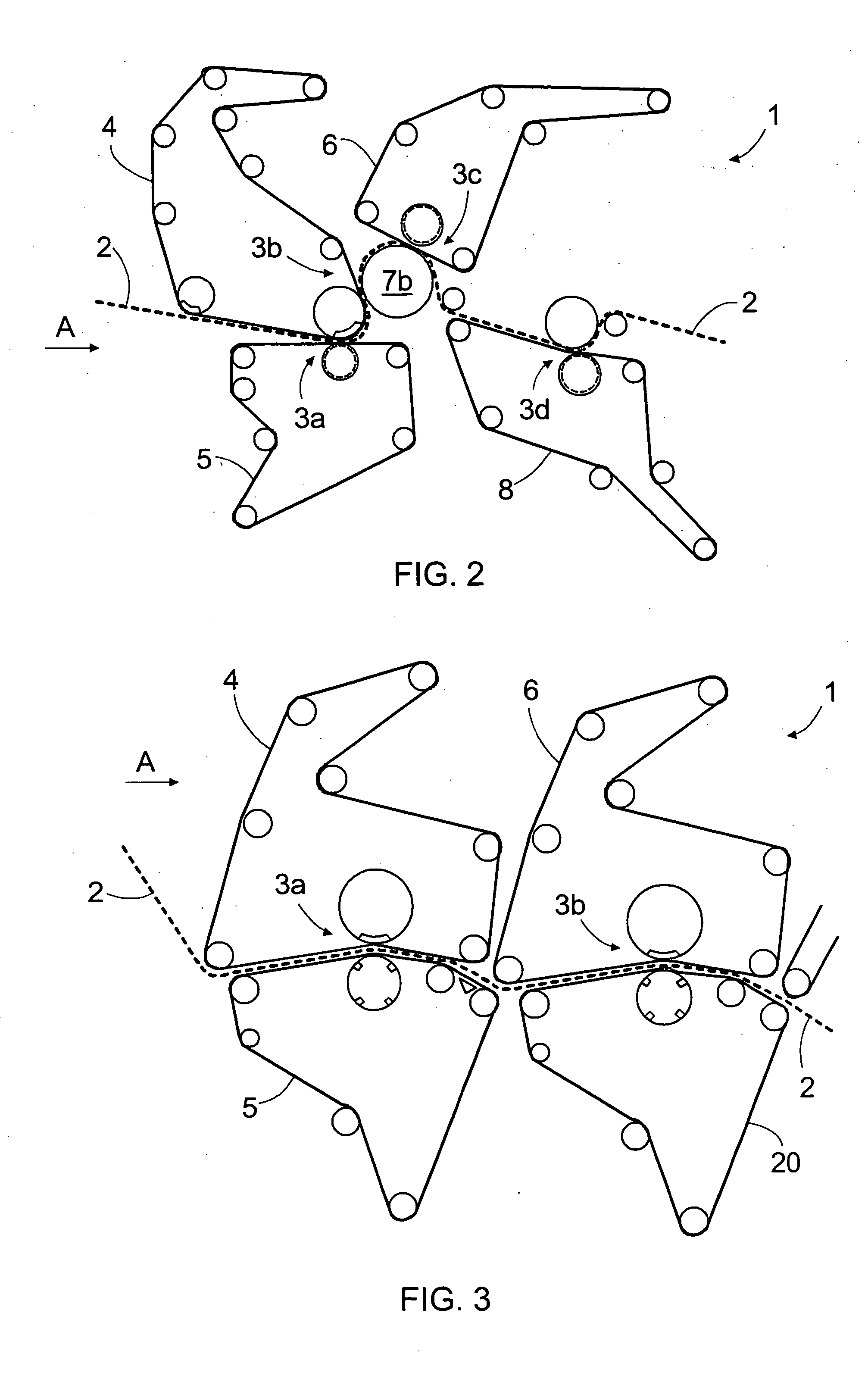

InactiveUS20050076986A1Reduce forceReduce pattern noiseTyre tread bands/patternsNon-skid devicesEngineeringTread

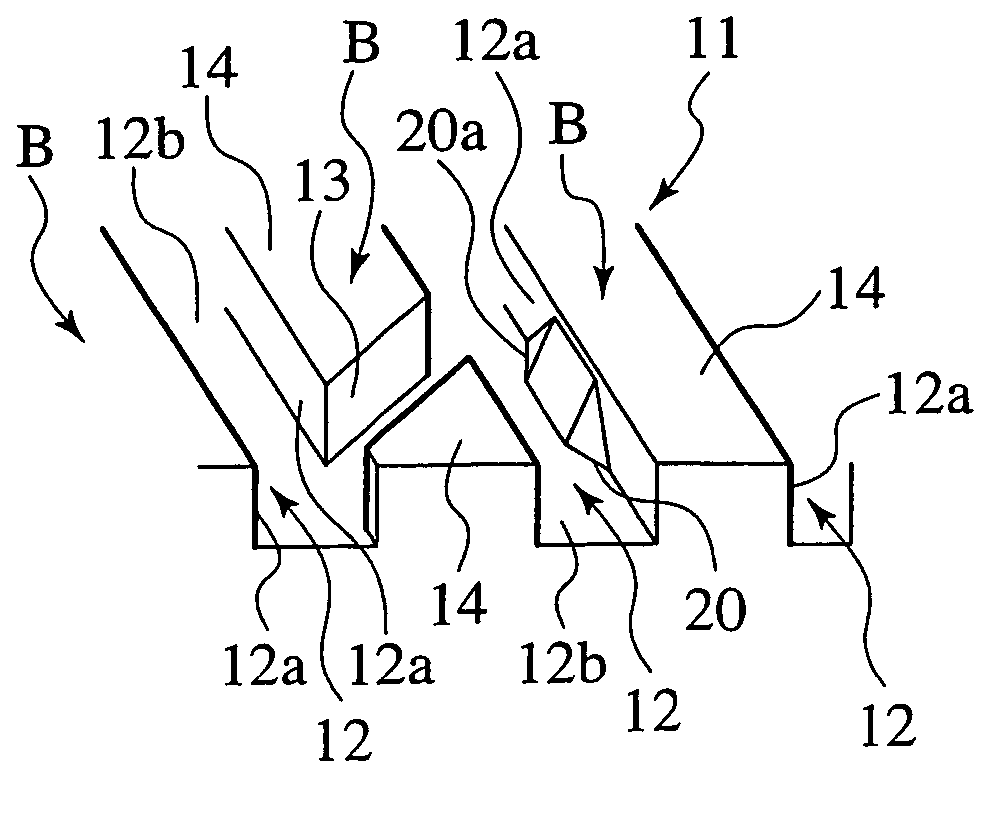

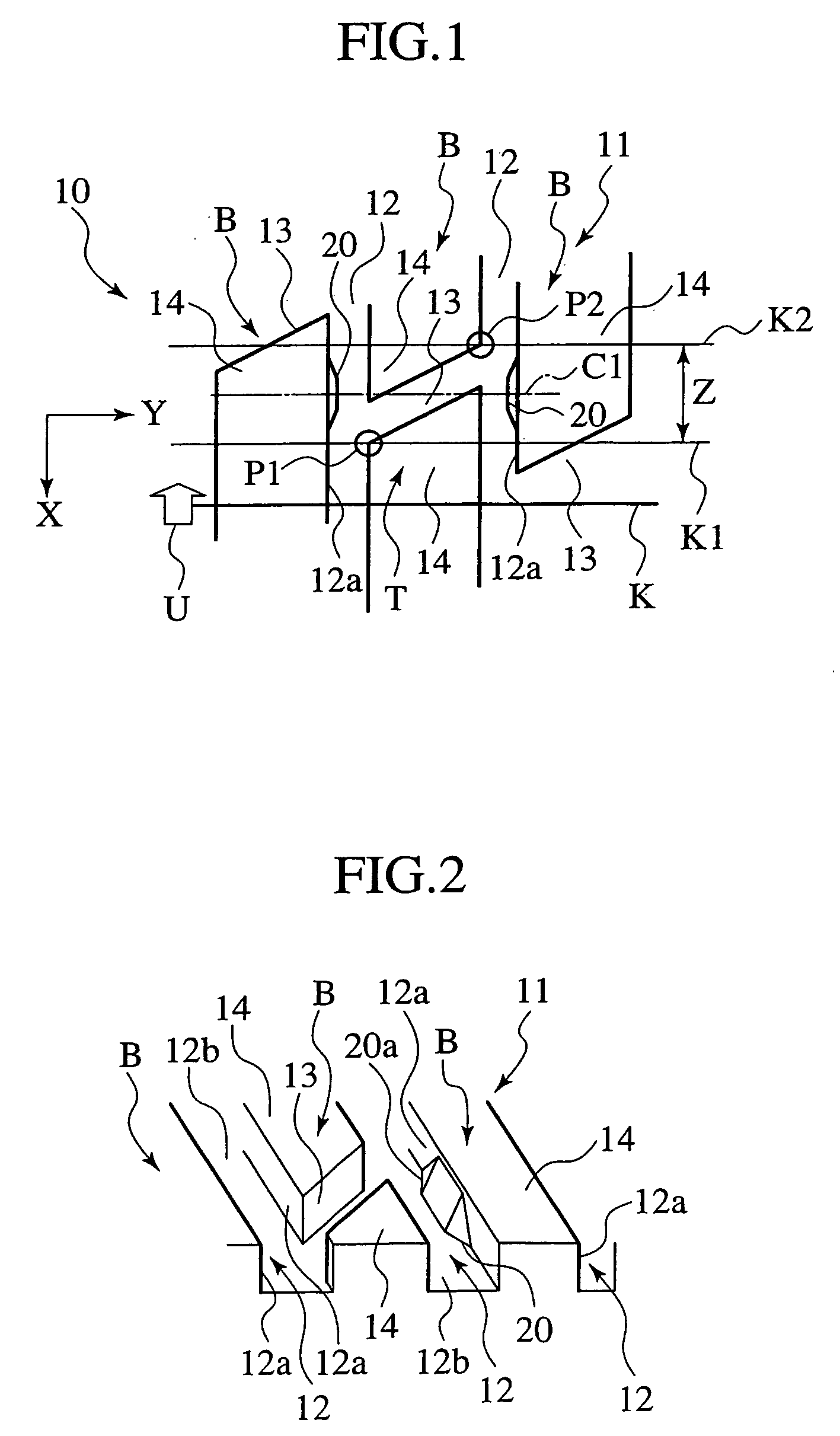

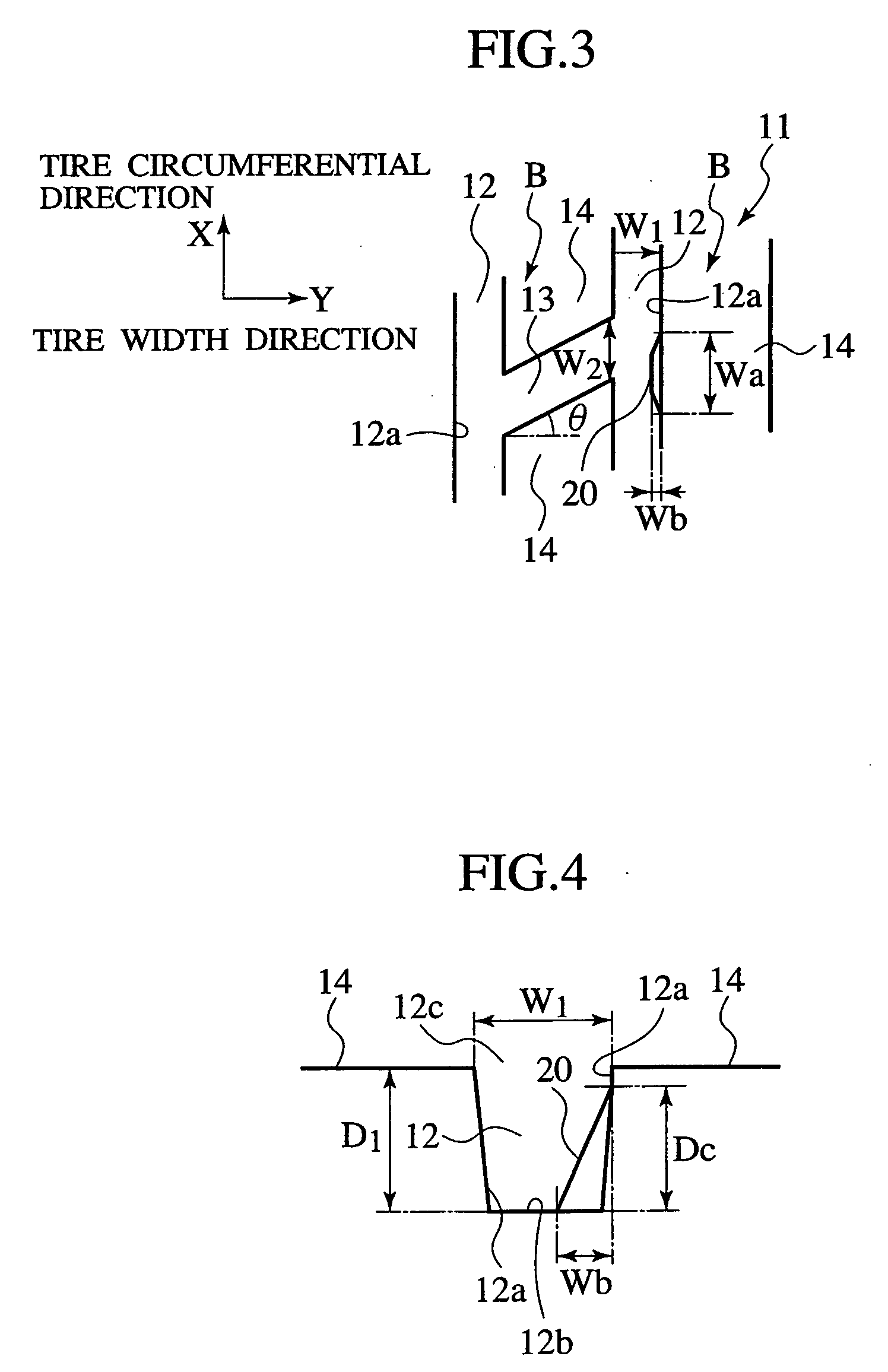

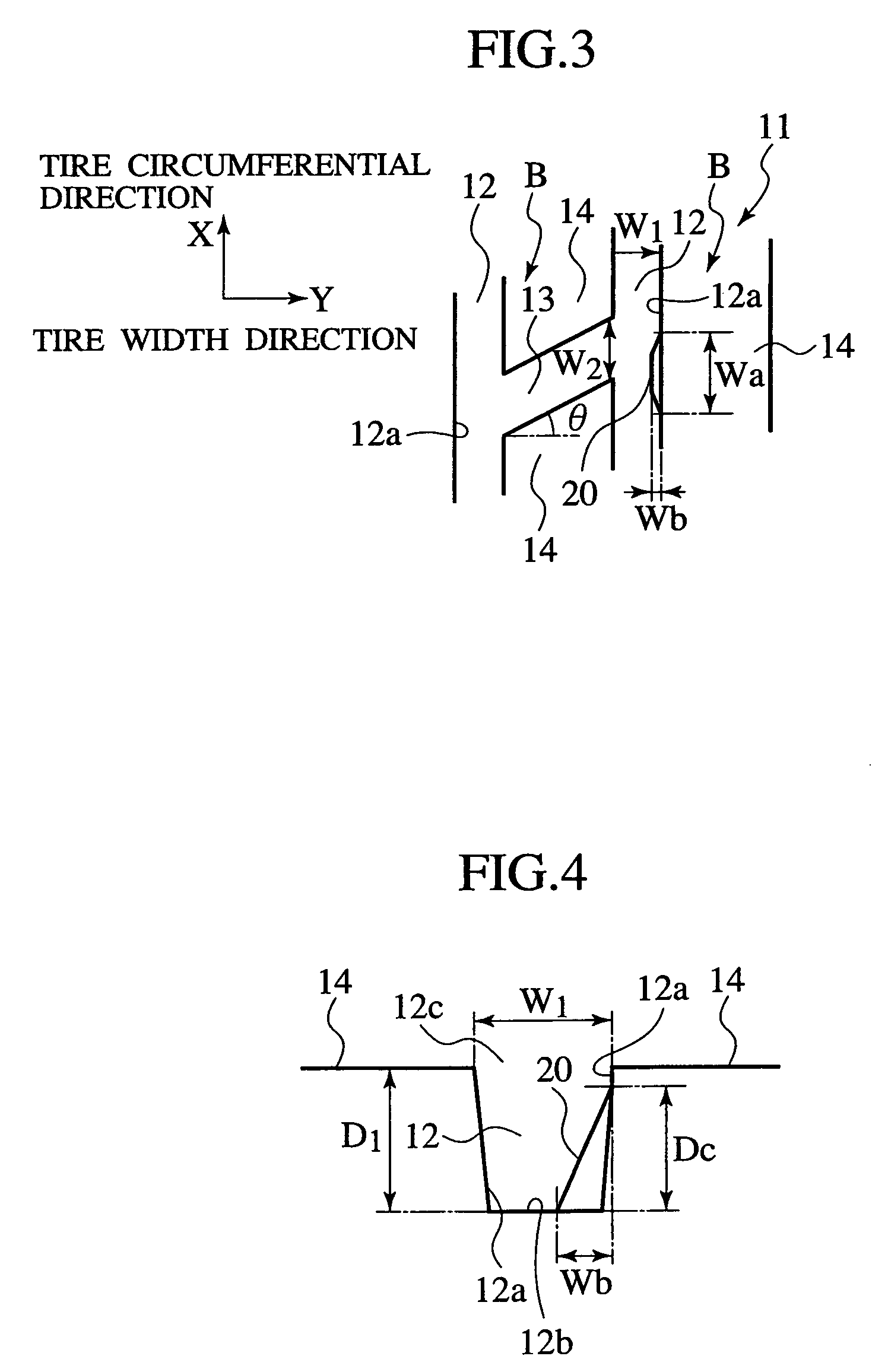

A pneumatic tire 10, in which at least one rib groove 12 extended in a tire circumferential direction is formed on a tread surface portion T of a tread portion 11, and portions 13 discontinuous in terms of rigidity are formed in a circumferential direction of rib lines B formed by the rib groove 12, the discontinuous portions 13 causing variations of tire axle force. Rigidity changing portions 20 which cancel the variations of the tire-axle force are provided in the rib groove 12, the variations being caused by the discontinuous portions 13. Thus, vibrational force to an axle is lowered, and pattern noise caused thereby is reduced effectively.

Owner:BRIDGESTONE CORP

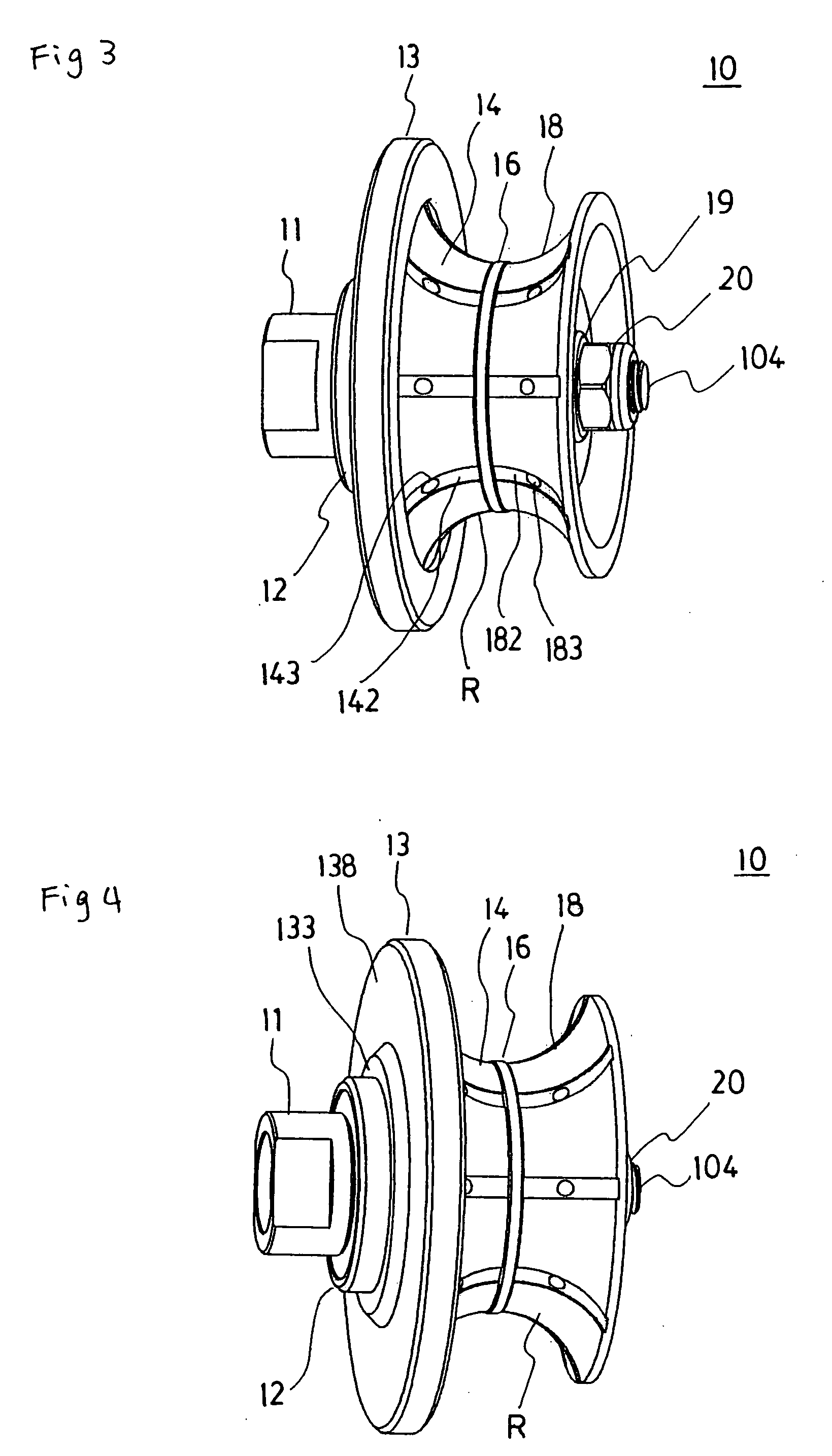

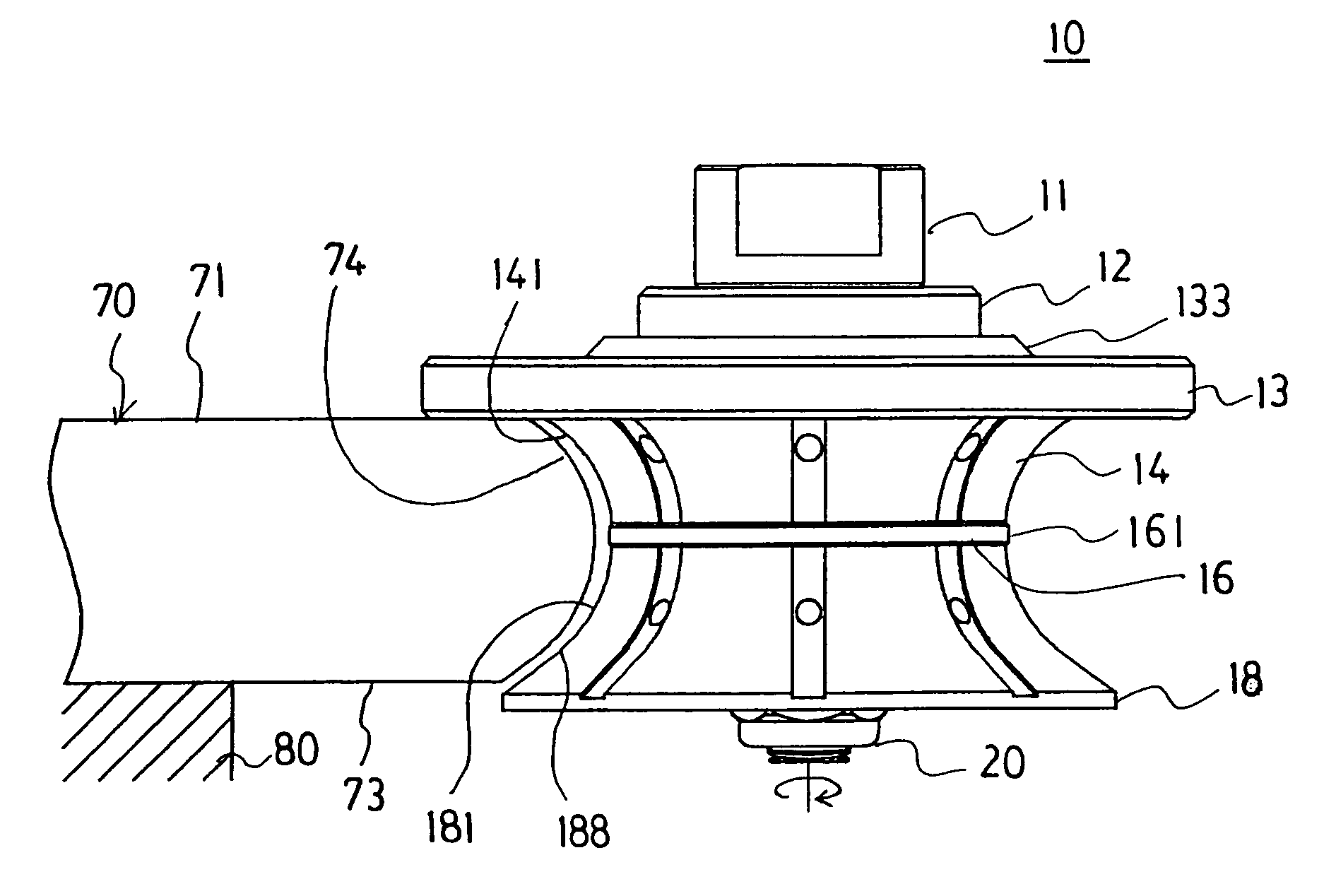

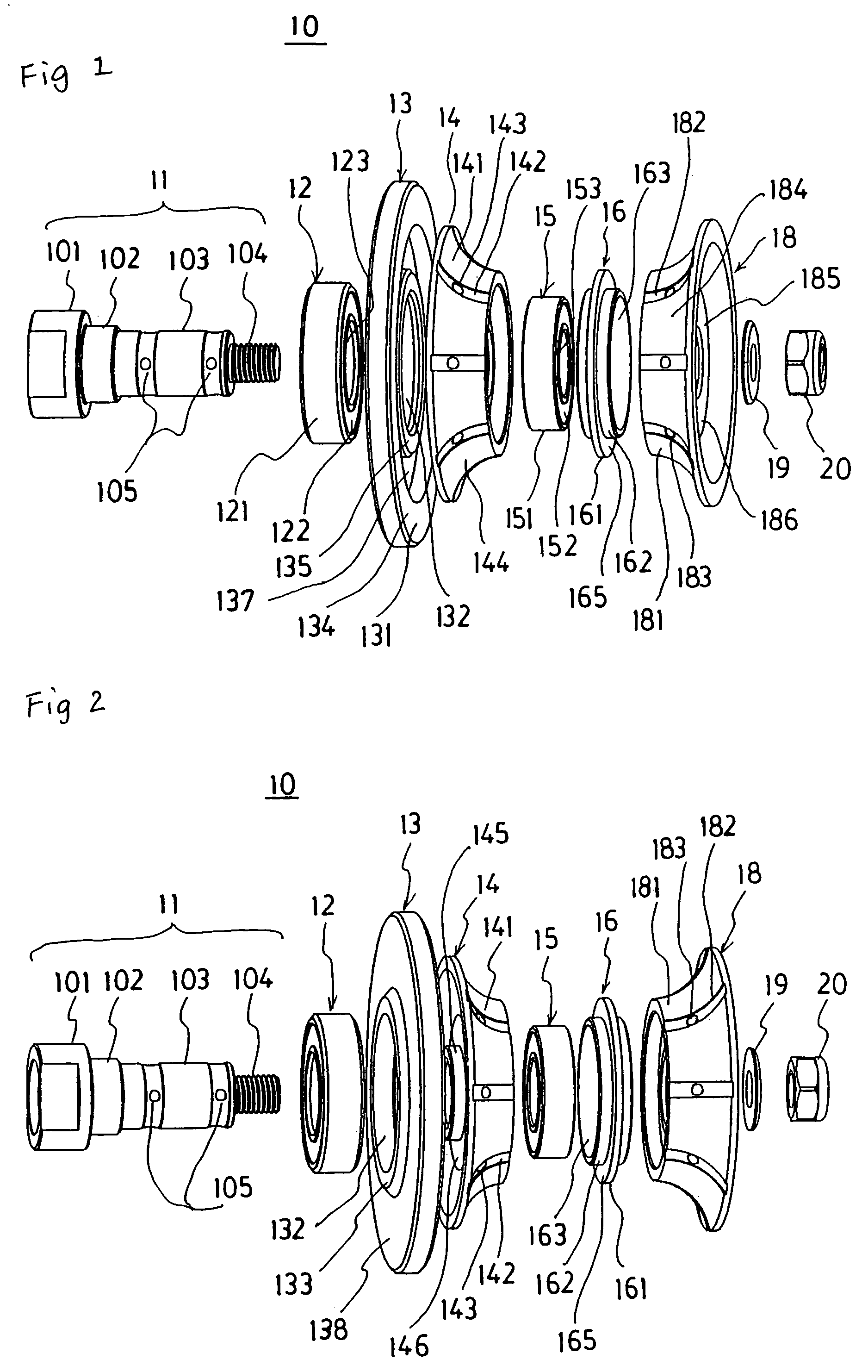

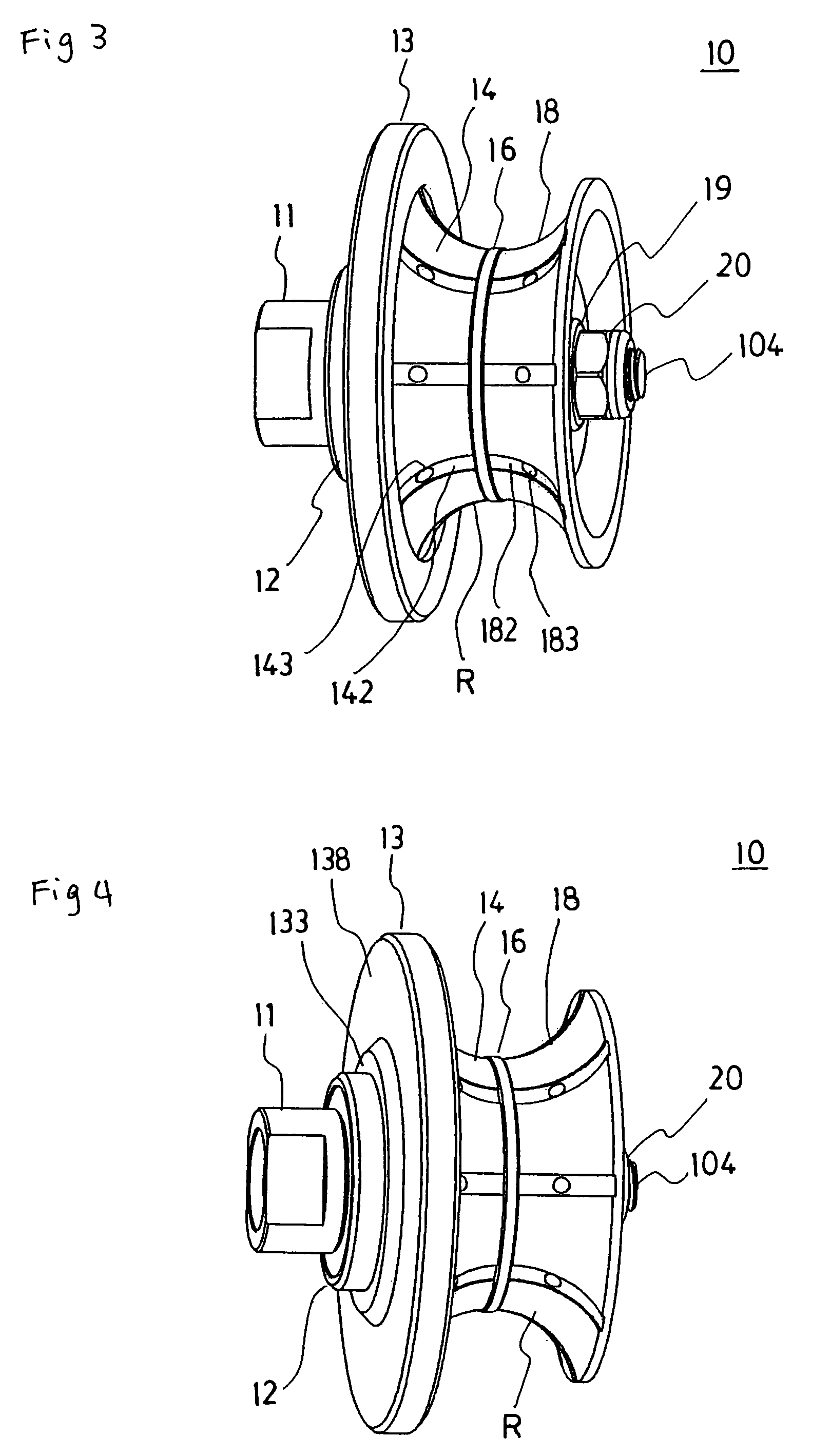

Grinding tool for edge circular processing

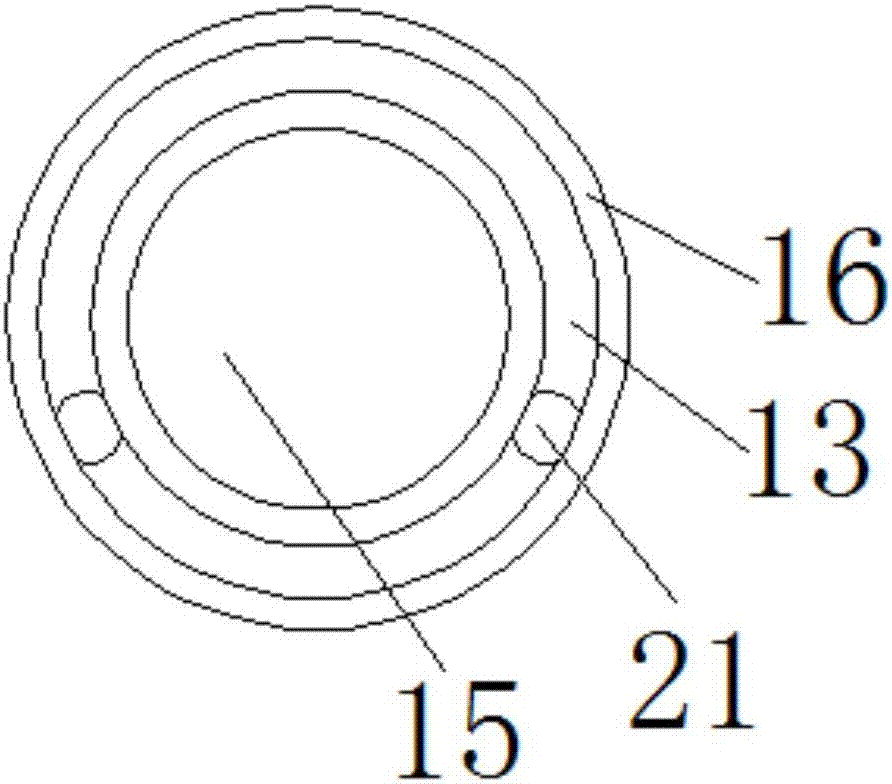

InactiveUS20050277377A1Easy to operate manuallyImplementation processEdge grinding machinesRevolution surface grinding machinesFree rotationCircular section

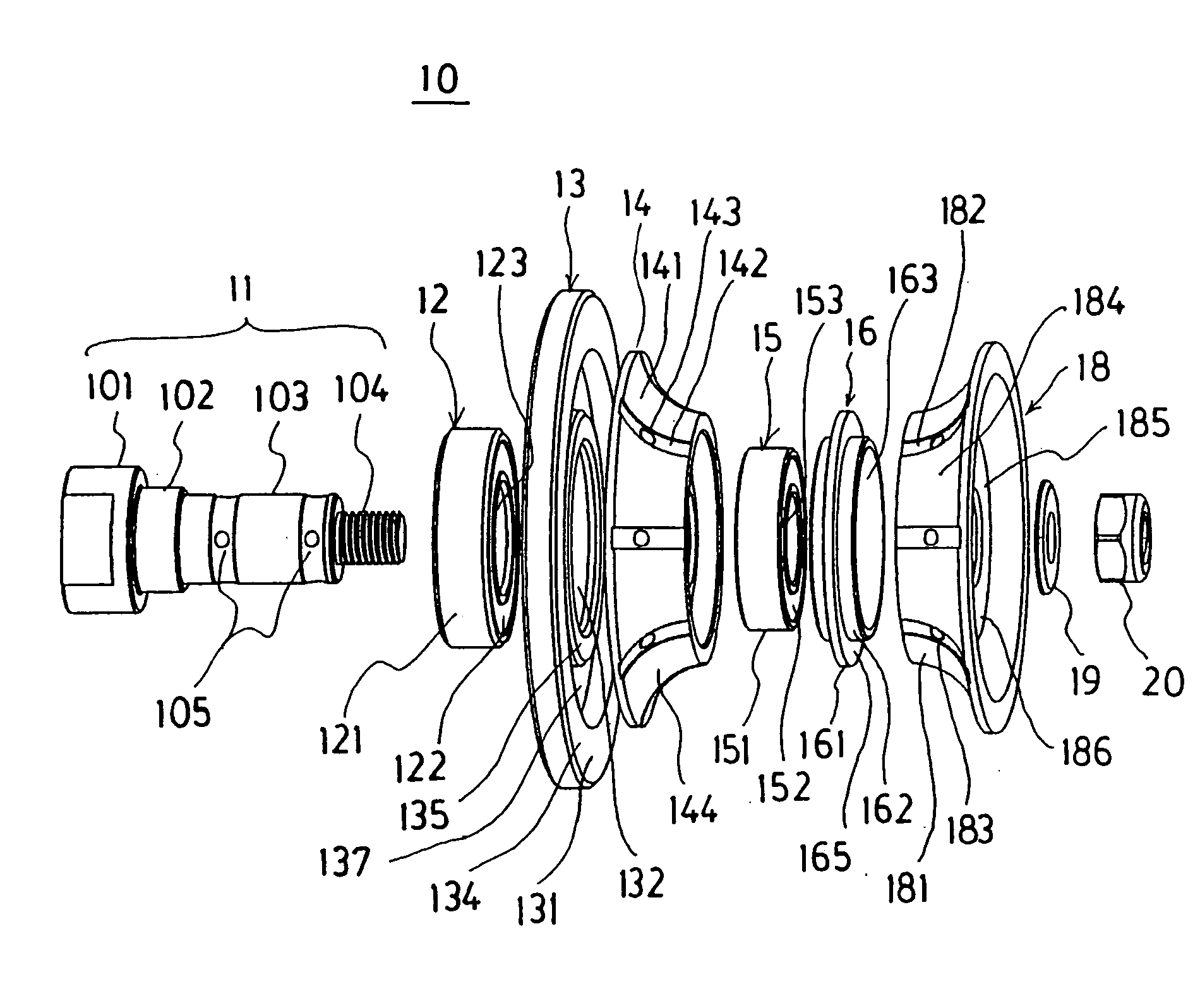

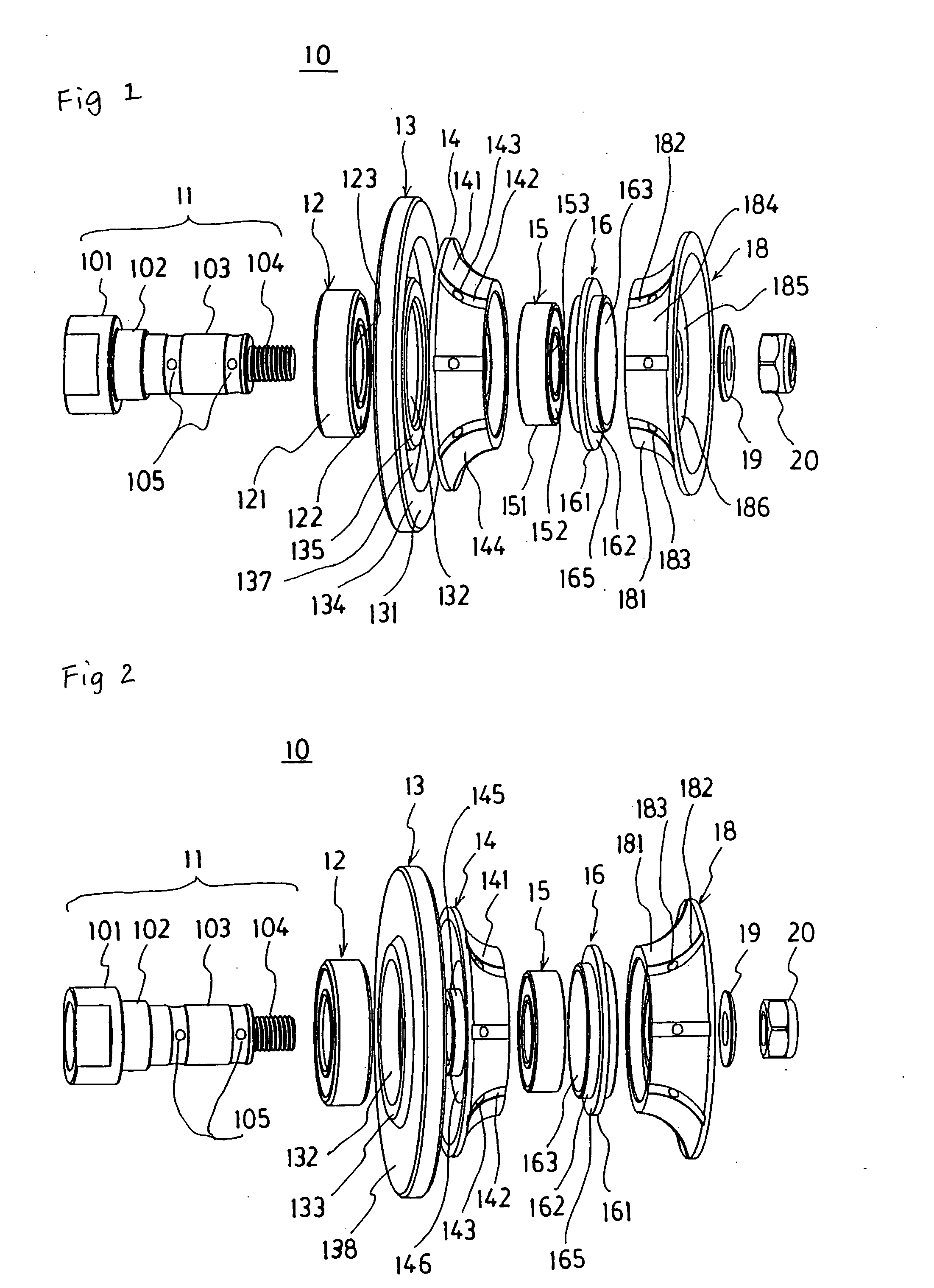

A pair of profile wheels 14, 18 in which concavely shaped grinding surfaces 141, 181 asymmetrical to each other are opposed to each other at right angle so as to form a concavely shaped grinding surface having a substantially semi-circular section, a guide plate 13 which is mounted on a spindle 11 of an electric or air tool side of the profile wheel 14 freely rotatably for guiding a grinding direction by bringing the edge of the circular shaped member into contact with a reference face of a grinding object material and a stopper ring 16 which is mounted to a spindle between the pair of the profile wheels 14 and 18 freely rotatably for controlling a grinding distance Y from the edge by bringing its outer peripheral end face 161 into contact with the edge of the grinding object material, are fixed to the spindle 11 with a lock nut such that they are set at right angle to the spindle.

Owner:SANKYO DIAMOND IND +1

Press felt

InactiveUS7306704B2Reduce basis weightImprove efficiencyLayered productsPaper/cardboardFiberEngineering

A method of manufacturing a press felt, a press section, and a press felt. The press felt comprises a base structure (11), a batt fibre layer (12) being attached to a first, web-side surface (B) of the base structure. Further, the structure of the press felt is compacted by treating it with a polymer material at least on the side of the first felt surface (B). After the polymer treatment, the surface of the felt is ground smooth.

Owner:TAMFELT PMC OY

Grinding tool for edge circular processing

InactiveUS7094136B2Easy to operate manuallyImplementation processEdge grinding machinesRevolution surface grinding machinesEngineeringMechanical engineering

A pair of profile wheels 14, 18 in which concavely shaped grinding surfaces 141, 181 asymmetrical to each other are opposed to each other at right angle so as to form a concavely shaped grinding surface having a substantially semi-circular section, a guide plate 13 which is mounted on a spindle 11 of an electric or air tool side of the profile wheel 14 freely rotatably for guiding a grinding direction by bringing the edge of the circular shaped member into contact with a reference face of a grinding object material and a stopper ring 16 which is mounted to a spindle between the pair of the profile wheels 14 and 18 freely rotatably for controlling a grinding distance Y from the edge by bringing its outer peripheral end face 161 into contact with the edge of the grinding object material, are fixed to the spindle 11 with a lock nut such that they are set at right angle to the spindle.

Owner:SANKYO DIAMOND IND +1

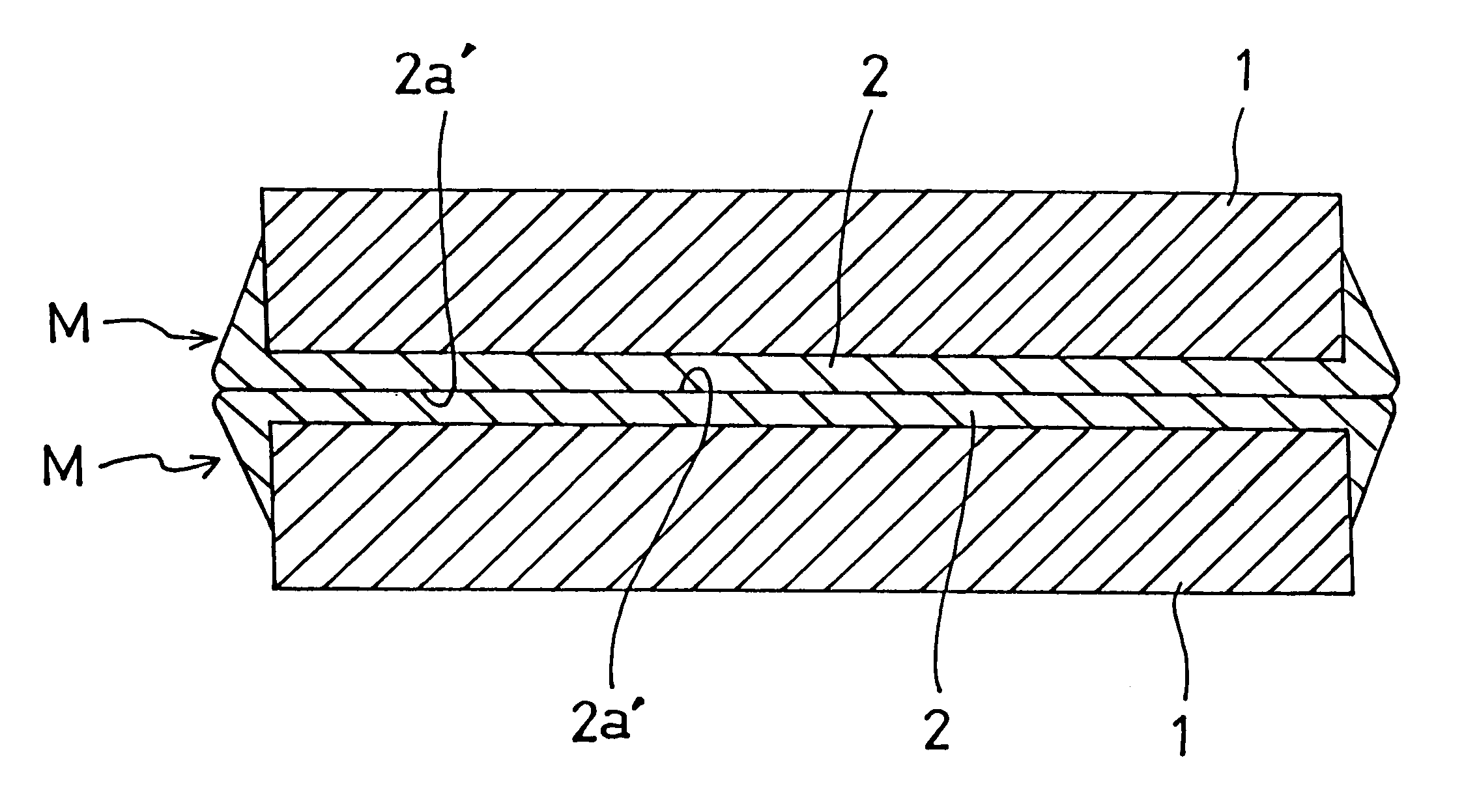

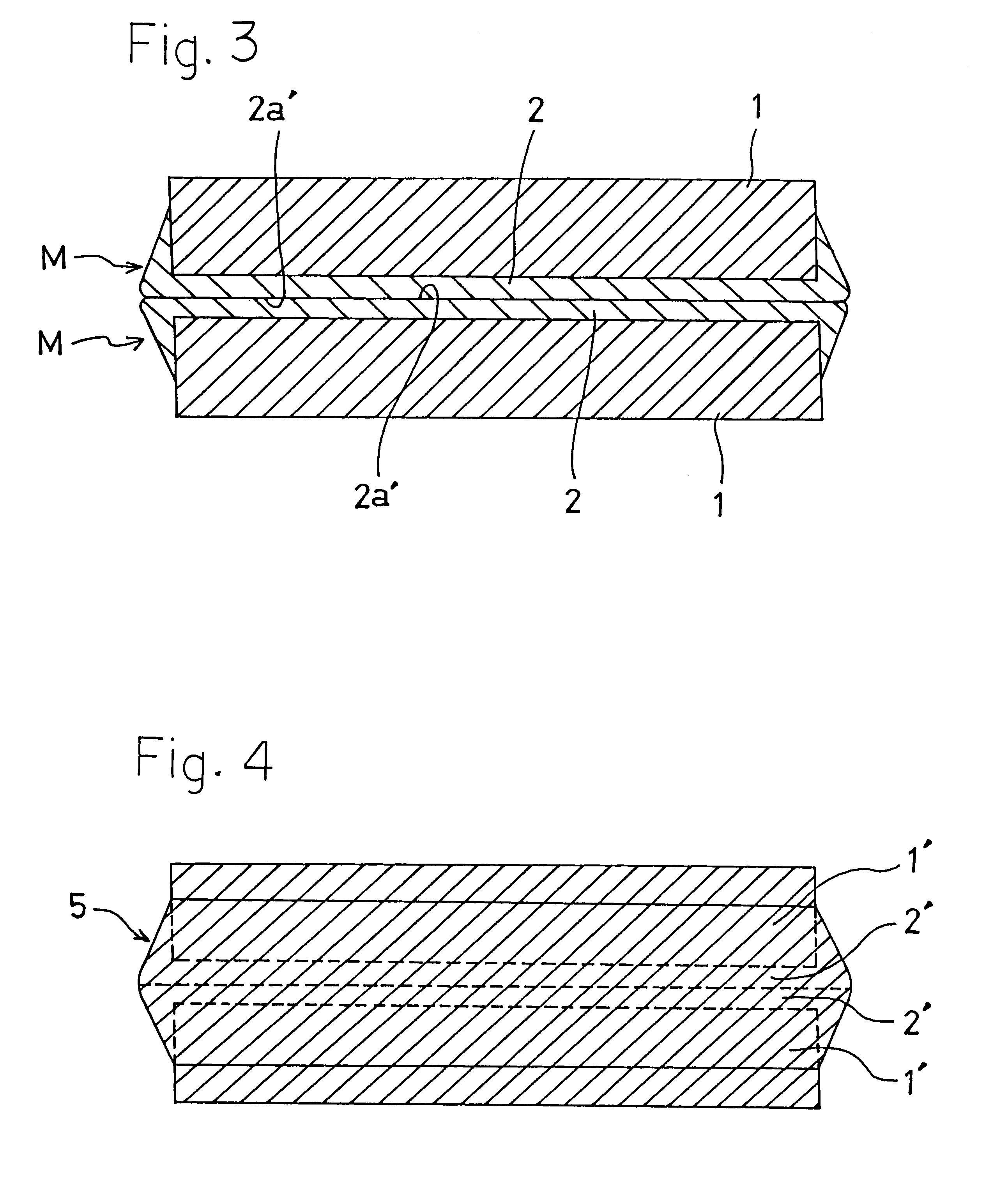

Single crystal SiC and a method of producing the same

InactiveUS6203772B1Quality improvementLarge capacityFrom gel statePolycrystalline material growthProduction rateSurface roughness

The single crystal SiC according to the present invention is produced in the following manner. Two complexes M in each of which a polycrystalline film 2 of beta-SiC (or alpha-SiC) is grown on the surface of a single crystal alpha-SiC substrate 1 by thermochemical deposition, and the surface 2a of the polycrystalline film 2 is ground so that the smoothness has a surface roughness of 200 angstroms RMS or smaller, preferably 100 to 50 angstroms RMS are subjected to a heat treatment under a state where the complexes are closely fixed to each other via their ground surfaces 2a', at a temperature of 2,000° C. or higher and in an atmosphere of a saturated SiC vapor pressure, whereby the polycrystalline films 2 of the complexes M are recrystallized to grow a single crystal which is integrated with the single crystal alpha-SiC substrates 1. Large-size single crystal SiC in which impurities, micropipe defects, and the like do not remain, and which has high quality can be produced with high productivity.

Owner:NISSIN ELECTRIC CO LTD

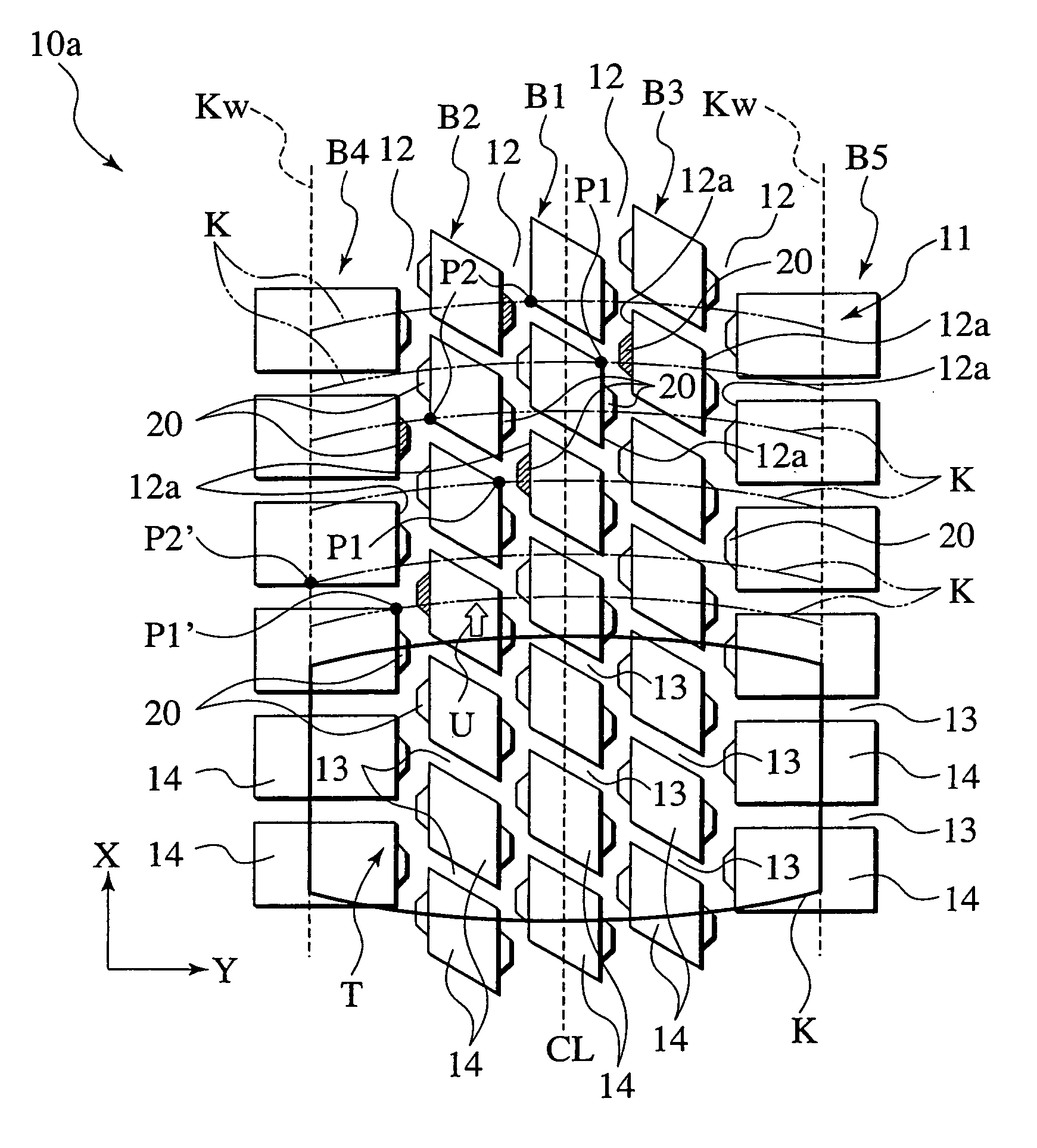

Pneumatic tire with tread including protruding portions on wall surface of groove

InactiveUS7182113B2Reduce forceReduce pattern noiseTyre tread bands/patternsNon-skid devicesEngineeringTread

A pneumatic tire 10, in which at least one rib groove 12 extended in a tire circumferential direction is formed on a tread surface portion T of a tread portion 11, and portions 13 discontinuous in terms of rigidity are formed in a circumferential direction of rib lines B formed by the rib groove 12, the discontinuous portions 13 causing variations of tire axle force. Rigidity changing portions 20 which cancel the variations of the tire axle force are provided in the rib groove 12, the variations being caused by the discontinuous portions 13. Thus, vibrational force to an axle is lowered, and pattern noise caused thereby is reduced effectively.

Owner:BRIDGESTONE CORP

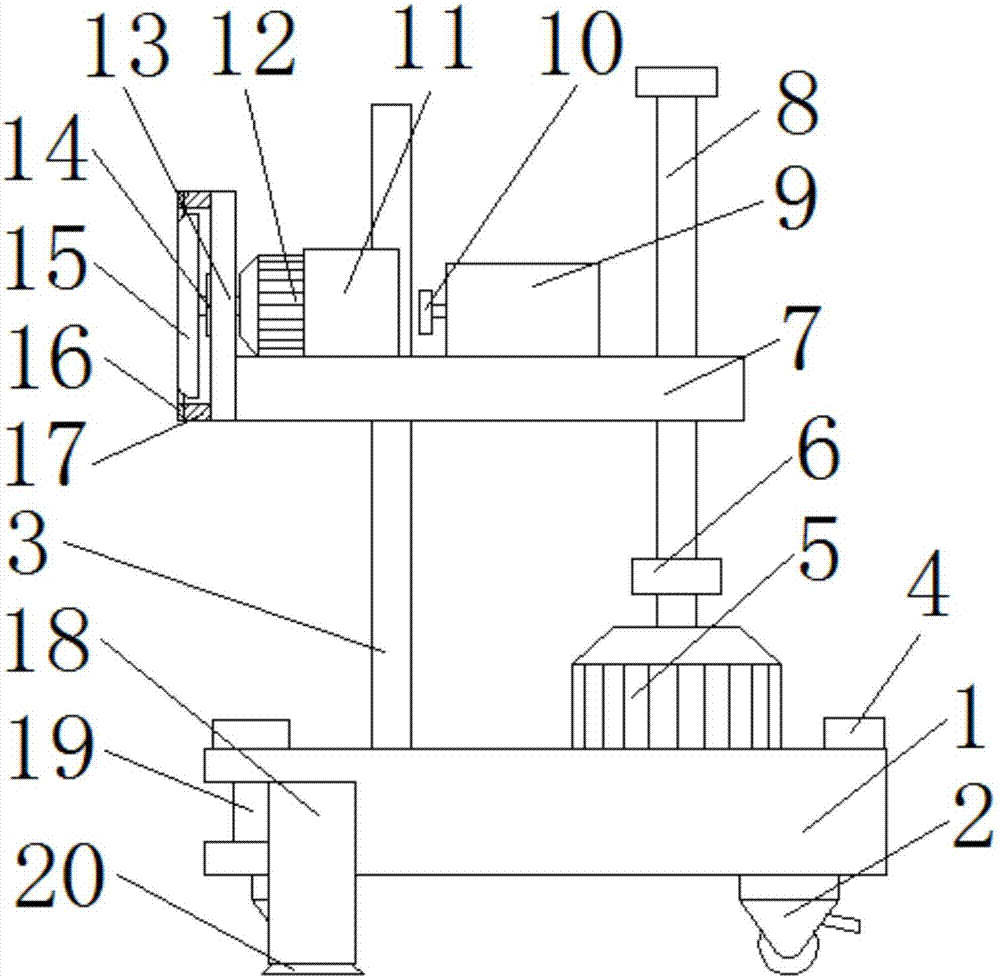

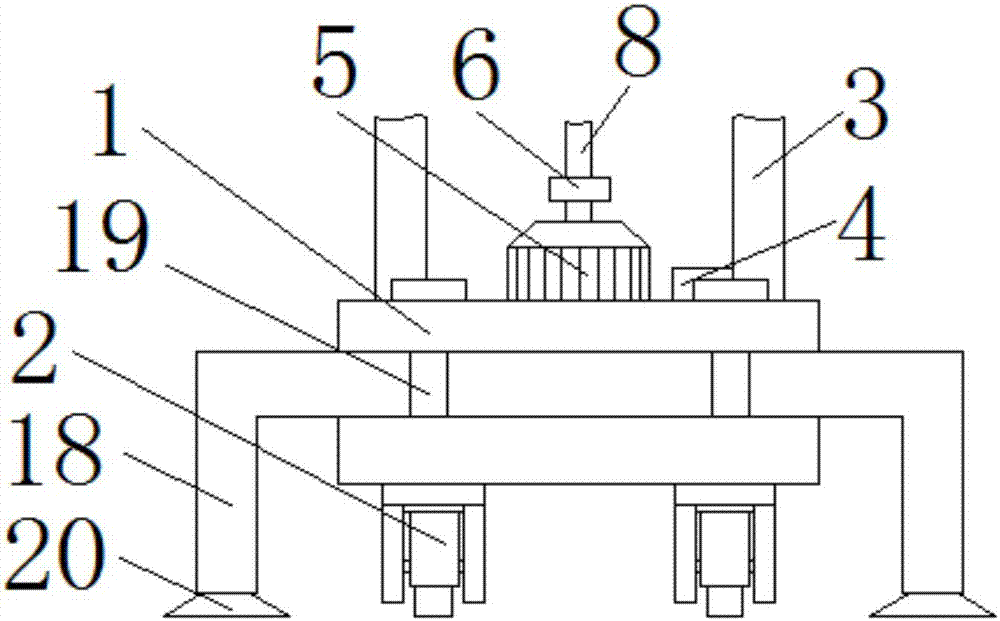

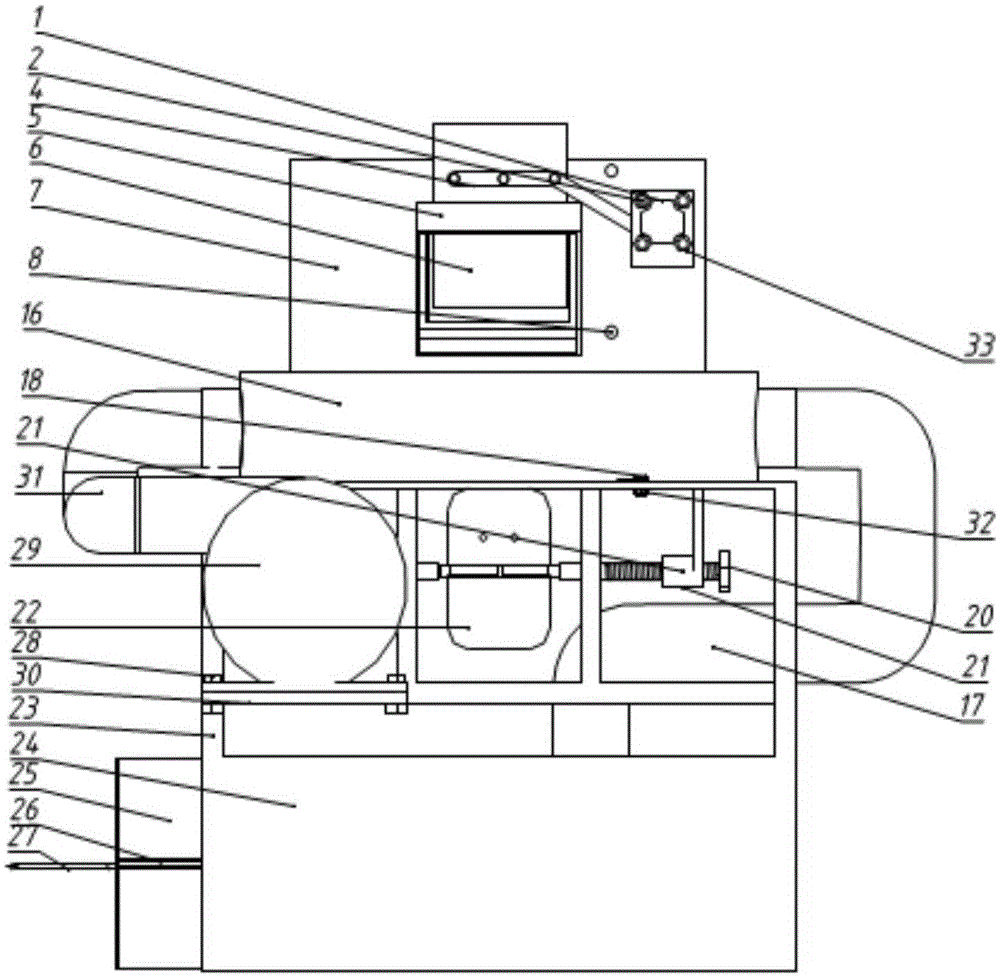

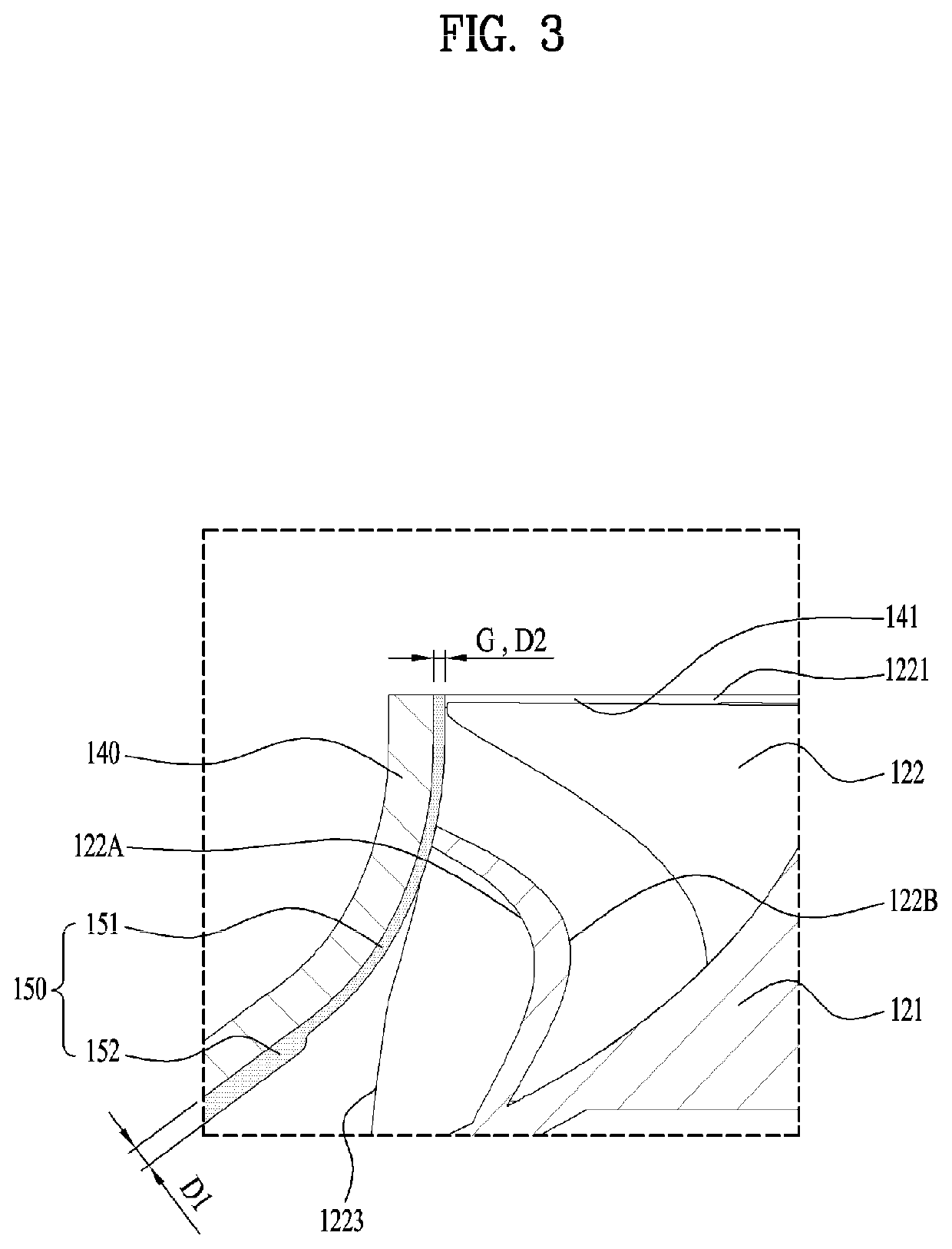

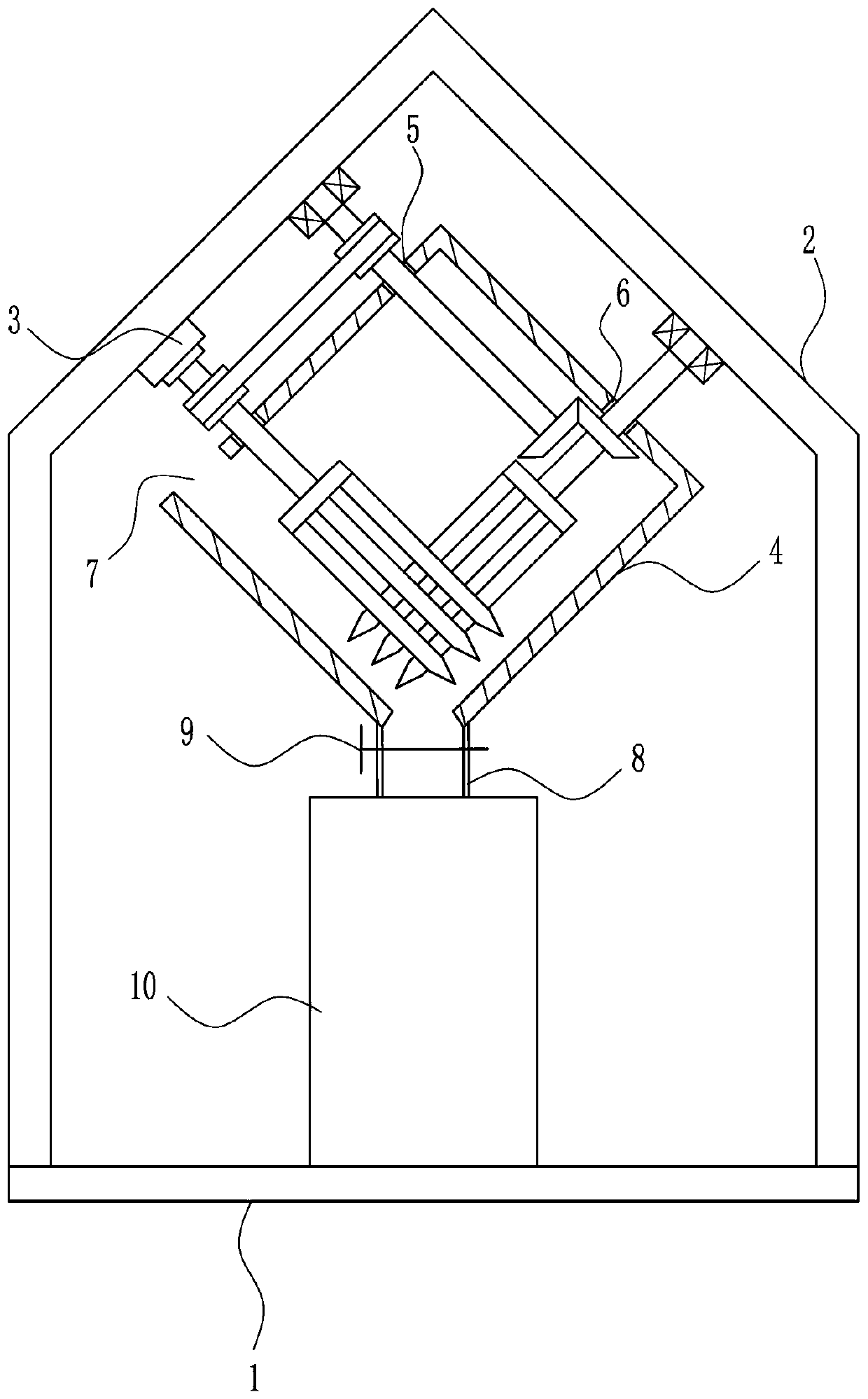

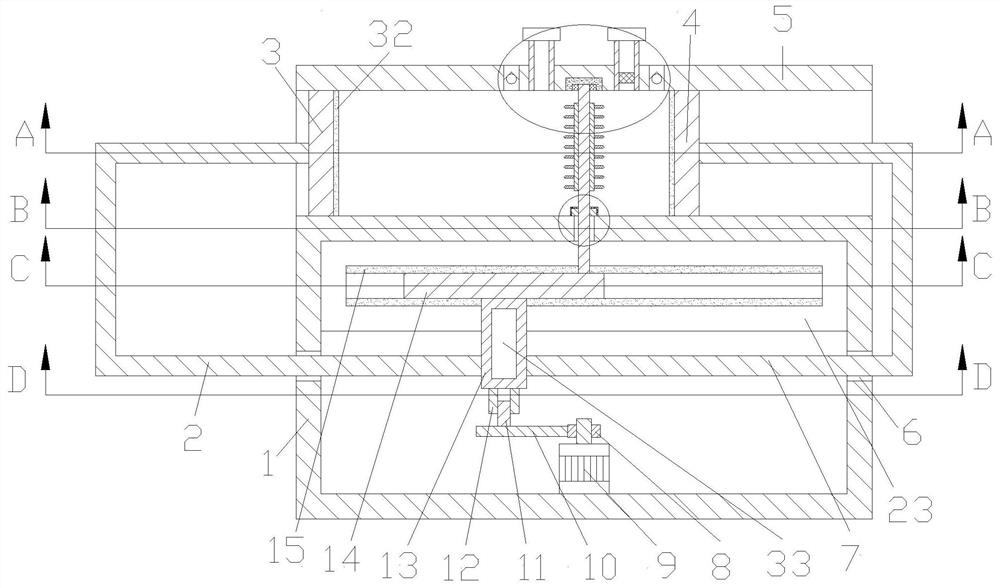

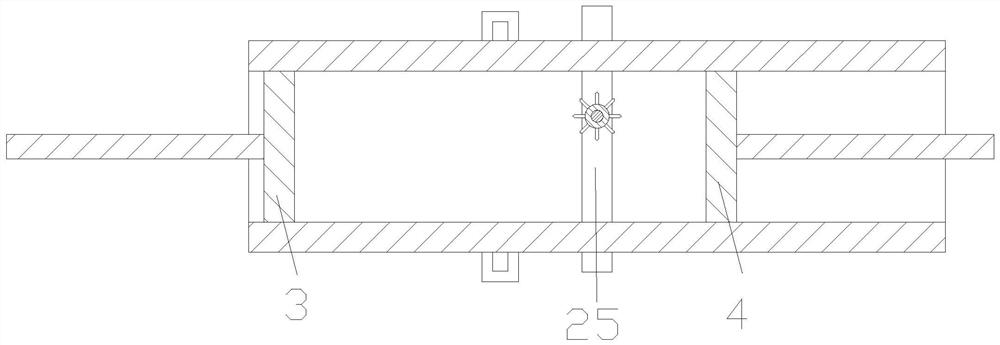

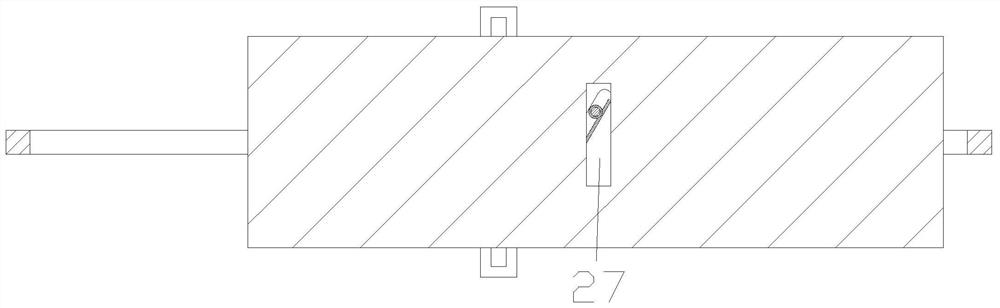

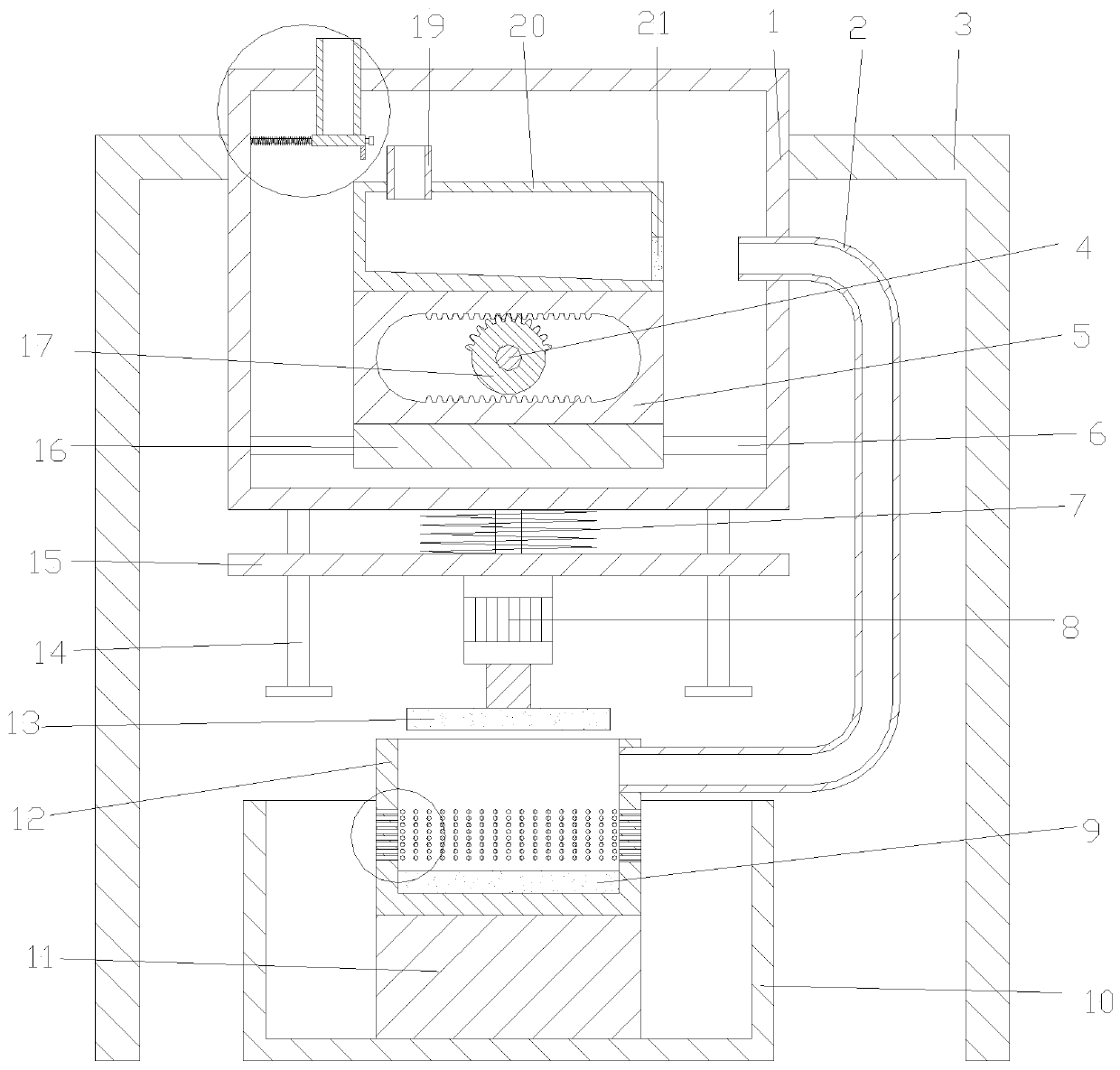

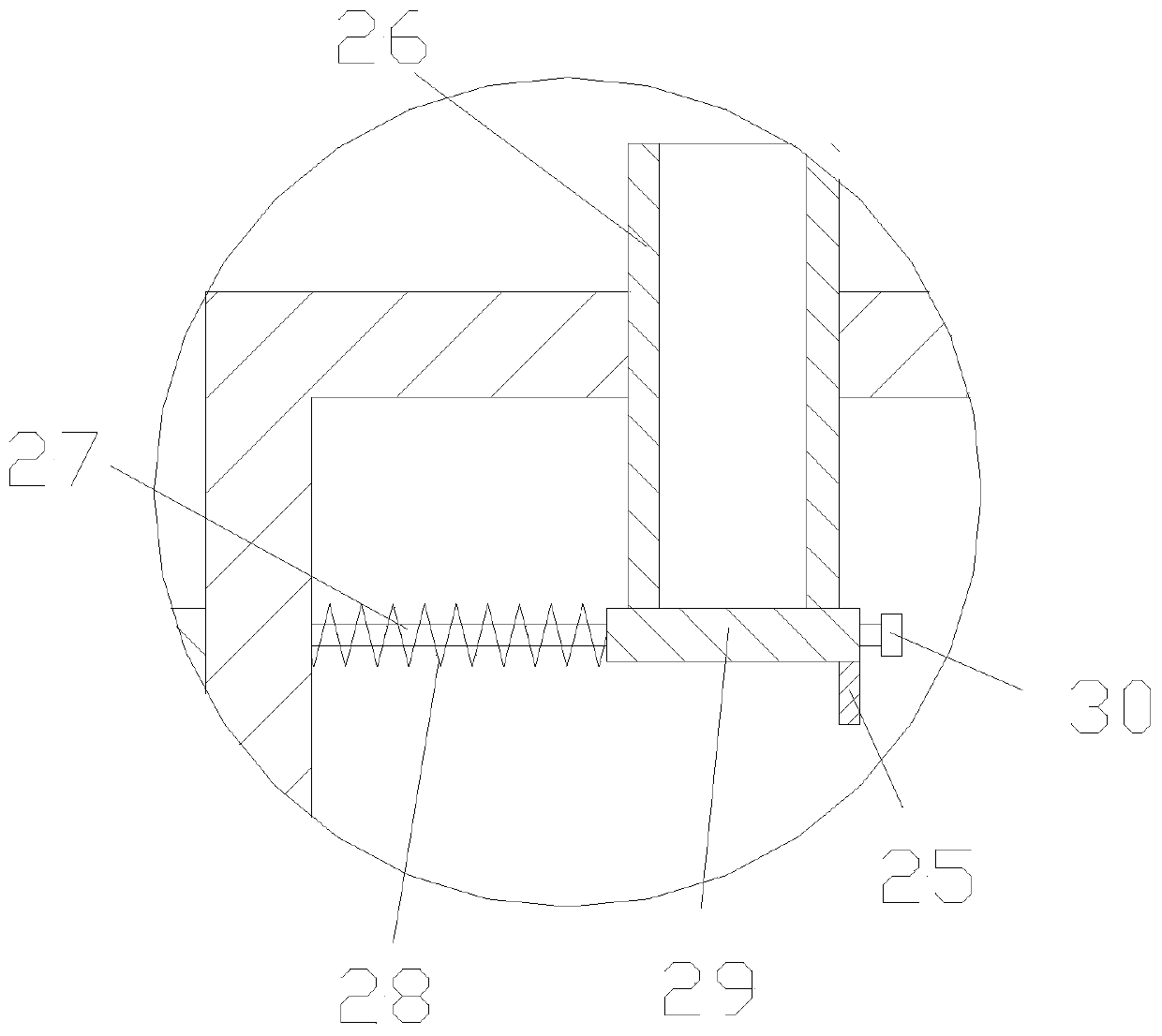

Wall face smoothing device used for indoor decoration

The invention discloses a wall smoother for indoor decoration, which comprises a base, the lower surface of the base is provided with universal wheels, and the right end of the upper surface of the base is provided with a controller, the controller is electrically connected with an external power supply, There is a first motor in the installation groove in the middle part of the right end of the upper surface of the base. The first motor is connected with the bottom end of the stud through a coupling. The middle part of the side of the stud is threaded with the screw hole at the right end of the mounting plate. The middle part is equipped with a dust-absorbing device, the through holes at the front and rear ends on the left side of the mounting plate are interspersed with uprights, the bottom of the uprights is set on the upper surface of the base, and the left end of the upper surface of the mounting plate is fixed with a second motor through a fixture. The wall smoother for interior decoration, the whole device is movable, can automatically lift and smooth the wall surface, improve the smoothing efficiency, reduce the waste of manpower and the harm of dust to the human body, and at the same time, the device can move on the same horizontal line, which can Smooth the surface evenly.

Owner:湖南鸣腾智能科技有限公司

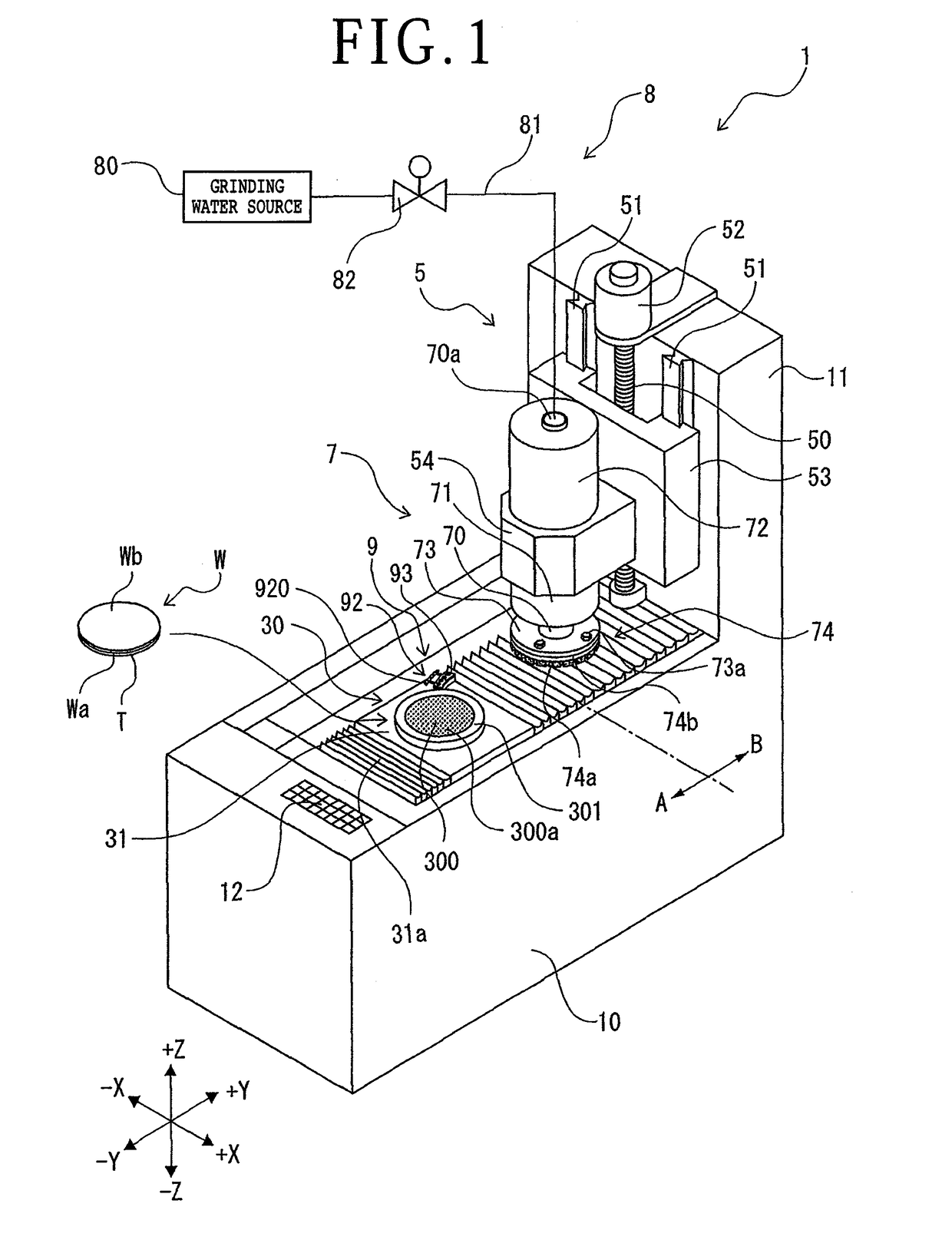

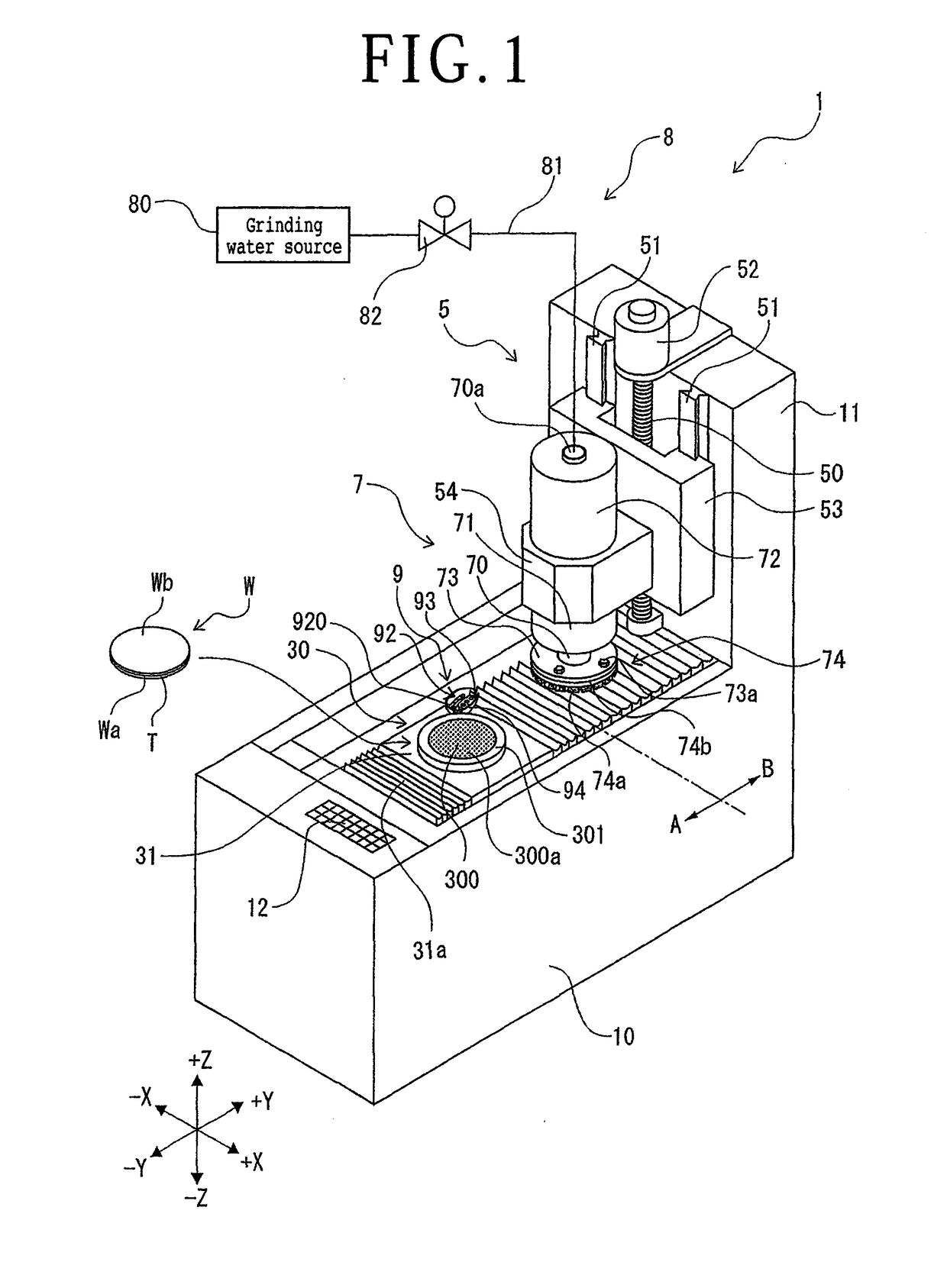

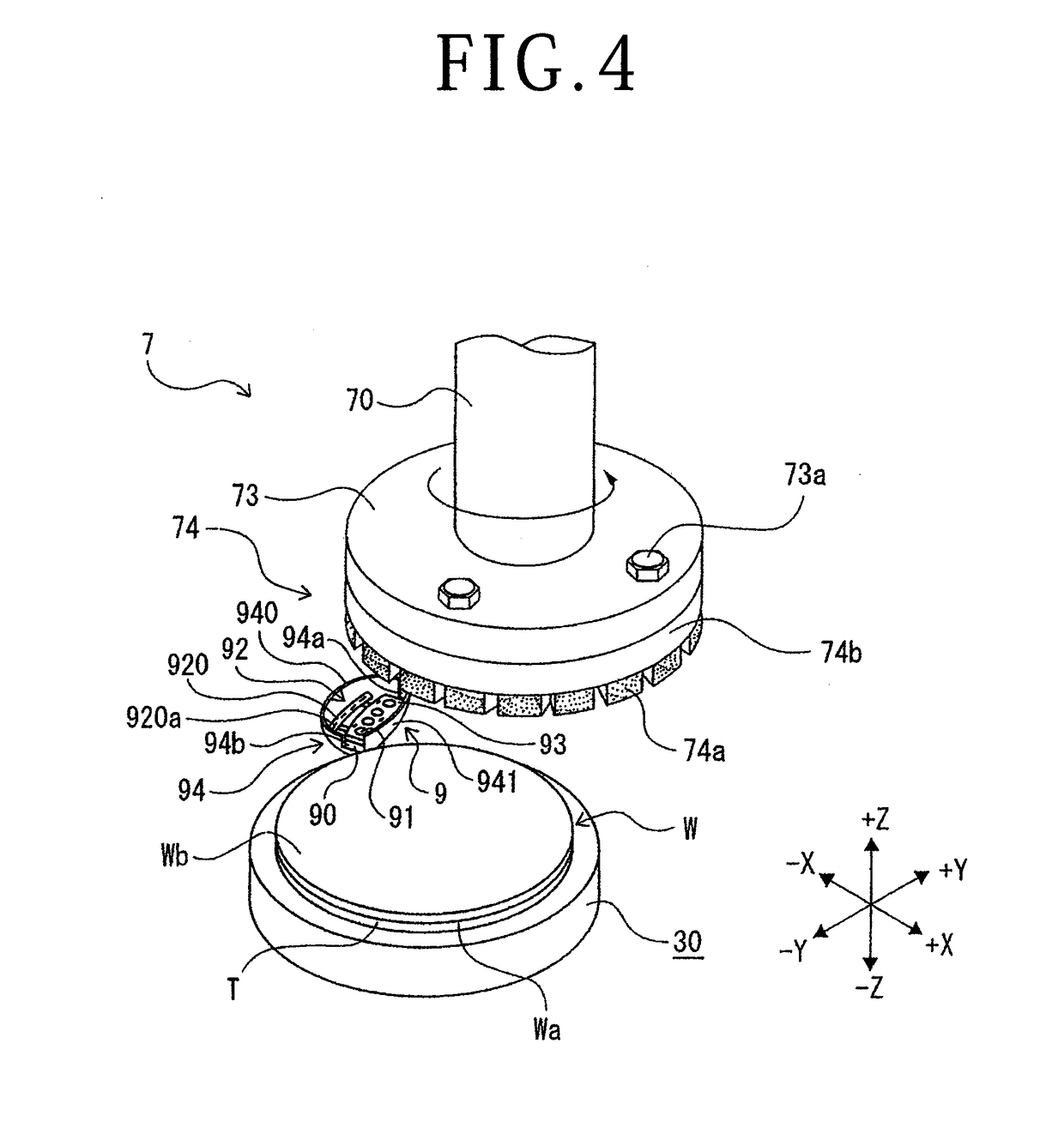

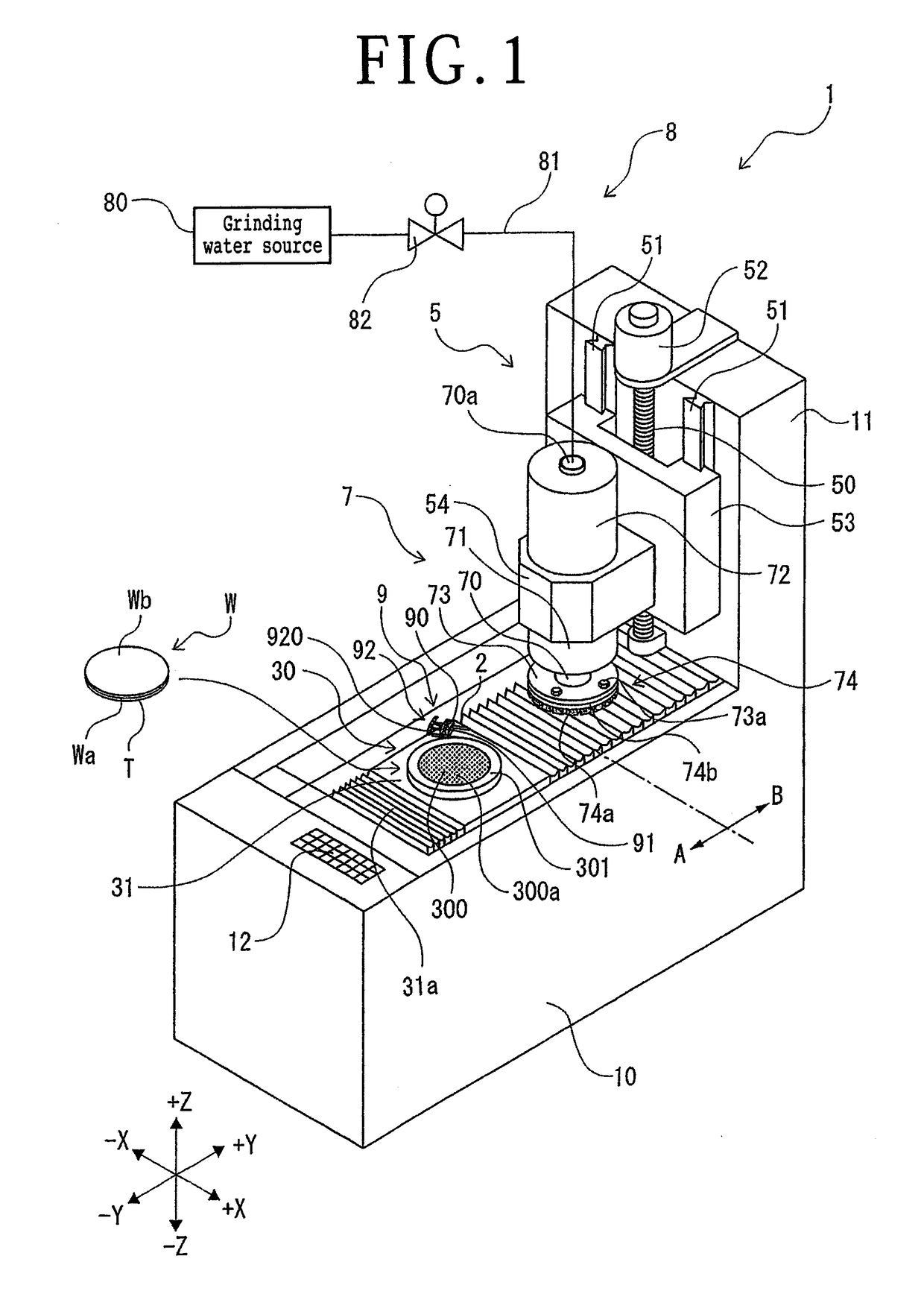

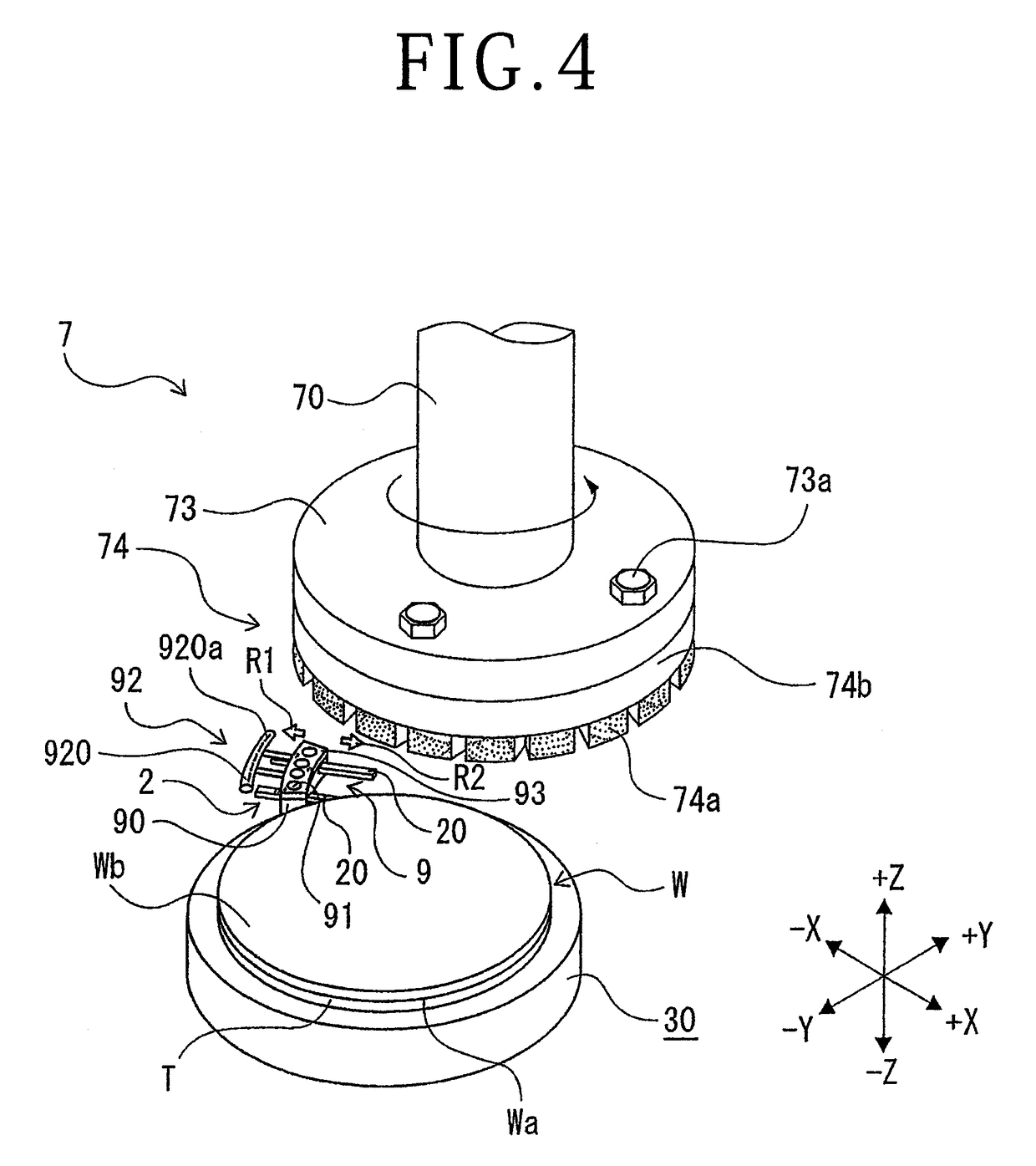

Grinding apparatus

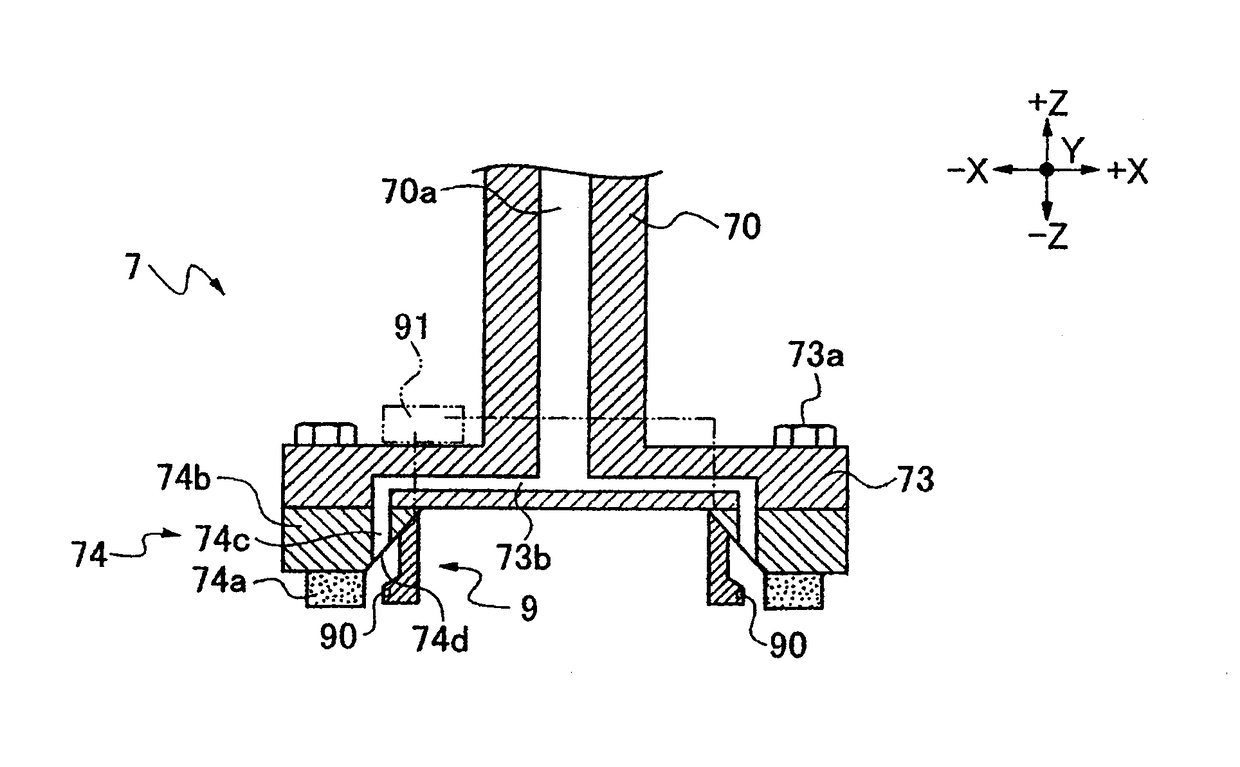

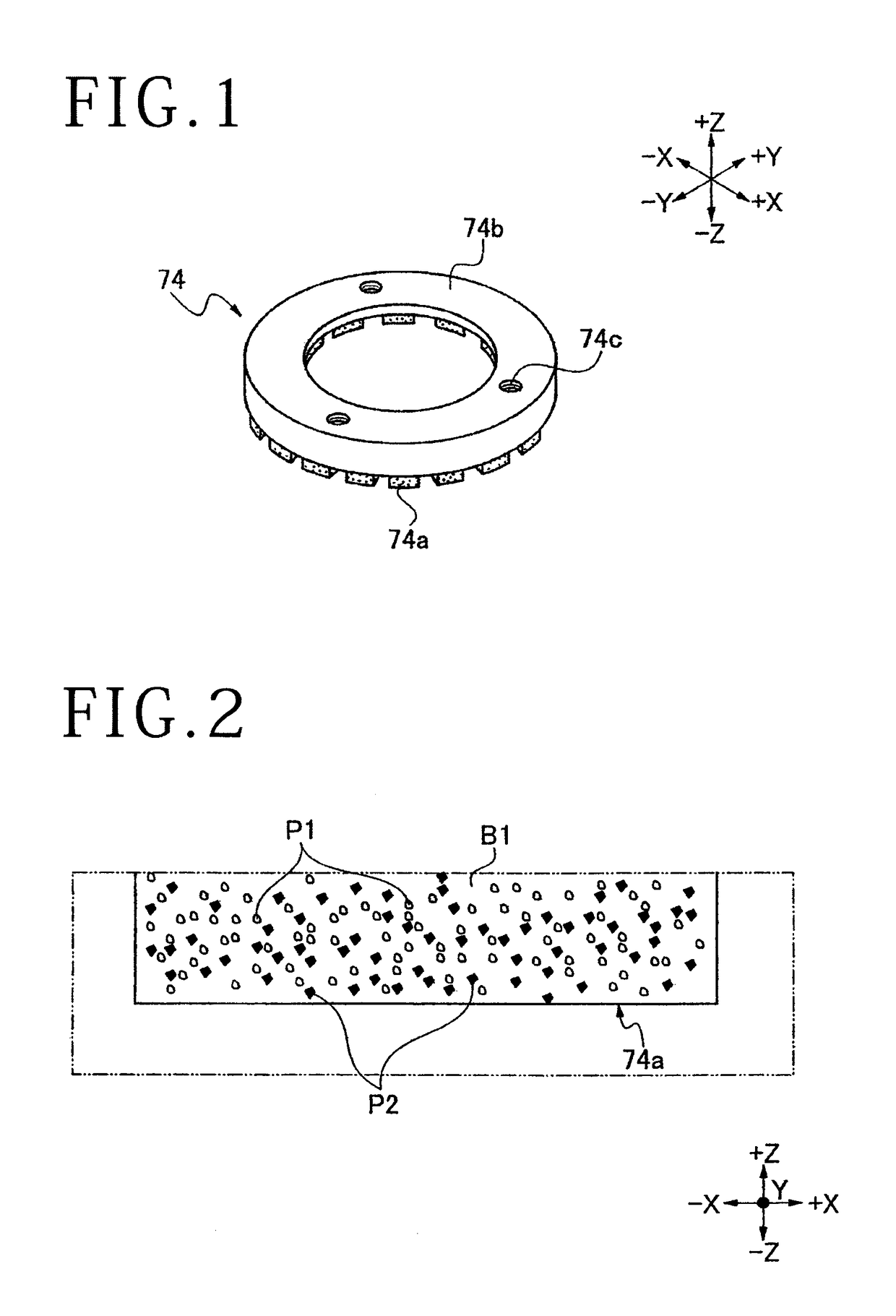

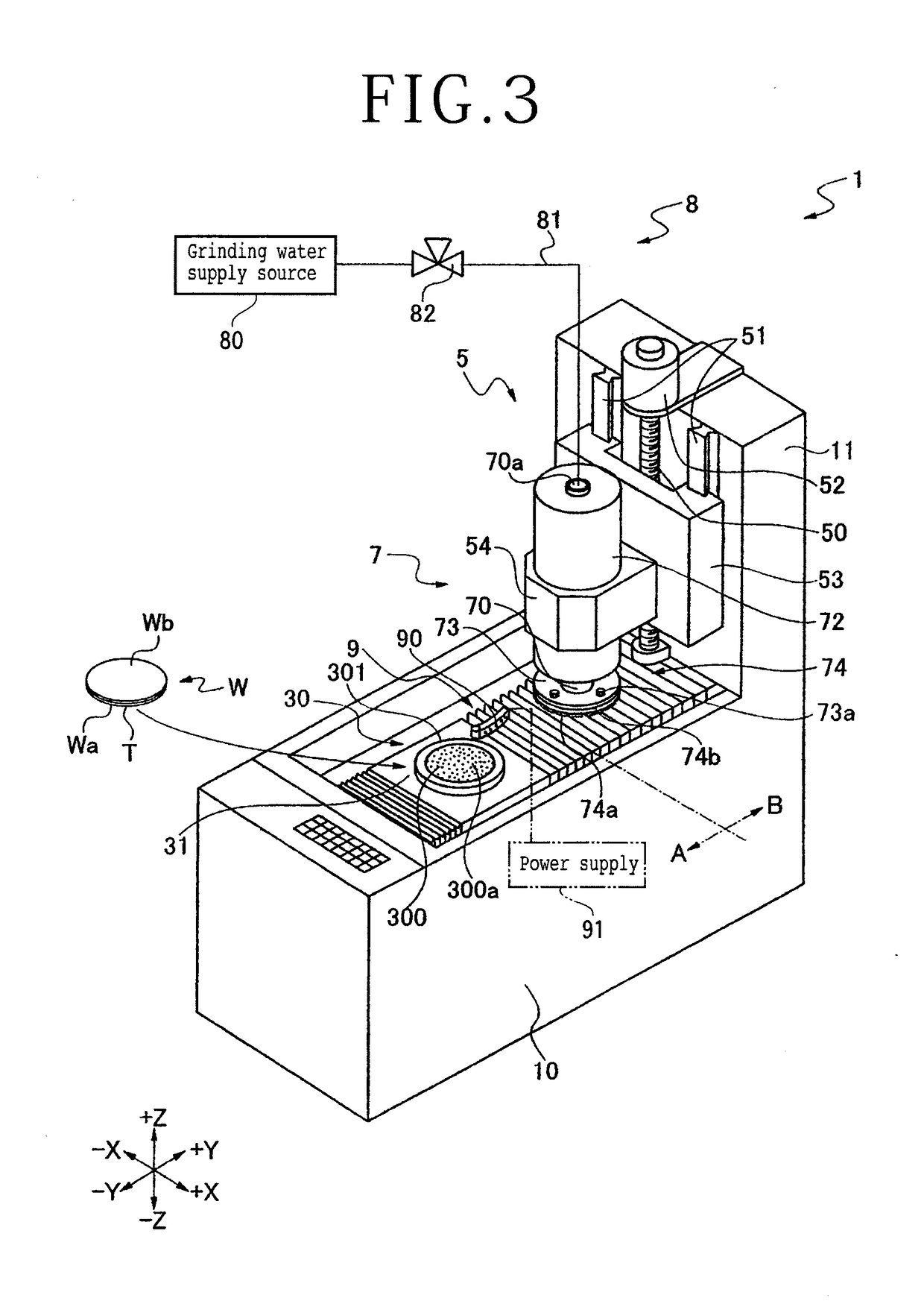

ActiveUS20180369990A1Increase costInhibit wearLapping machinesBonded abrasive wheelsGrinding wheelMechanical engineering

A grinding apparatus includes: a holding table for holding a workpiece thereon; a grinding unit including a grinding wheel for grinding the workpiece held on the holding table, the grinding wheel including a grinding stone made of abrasive grains and grains of photocatalyst bonded by a vitrified bonding material; a grinding water supply unit configured to supply grinding water to the grinding stone when the workpiece held on the holding table is ground by the grinding unit; and a light applying unit disposed adjacent to the holding table and configured to apply light to a grinding surface of the grinding stone while the workpiece held on the holding table being ground.

Owner:DISCO CORP

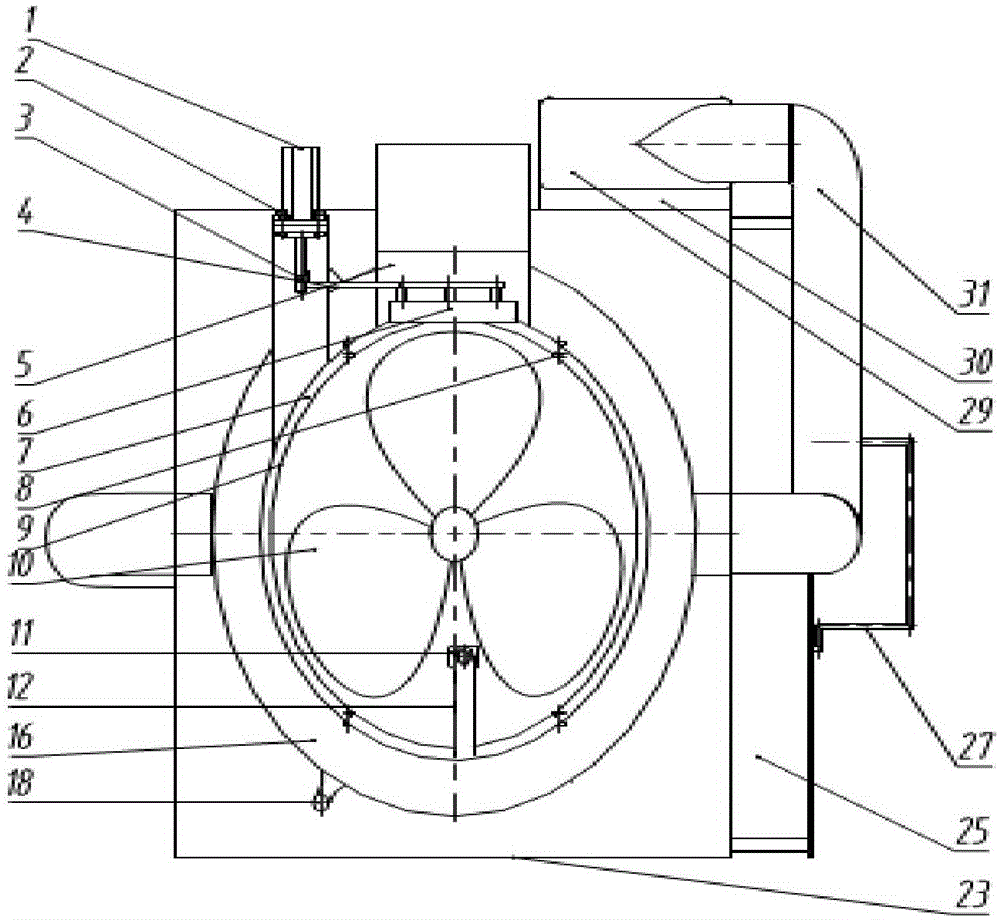

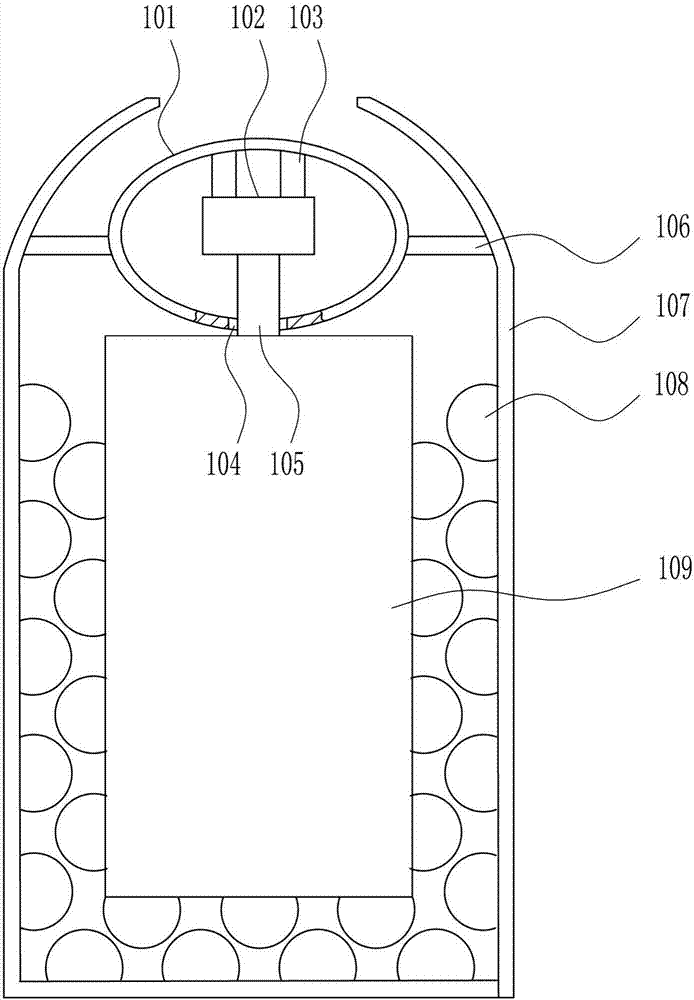

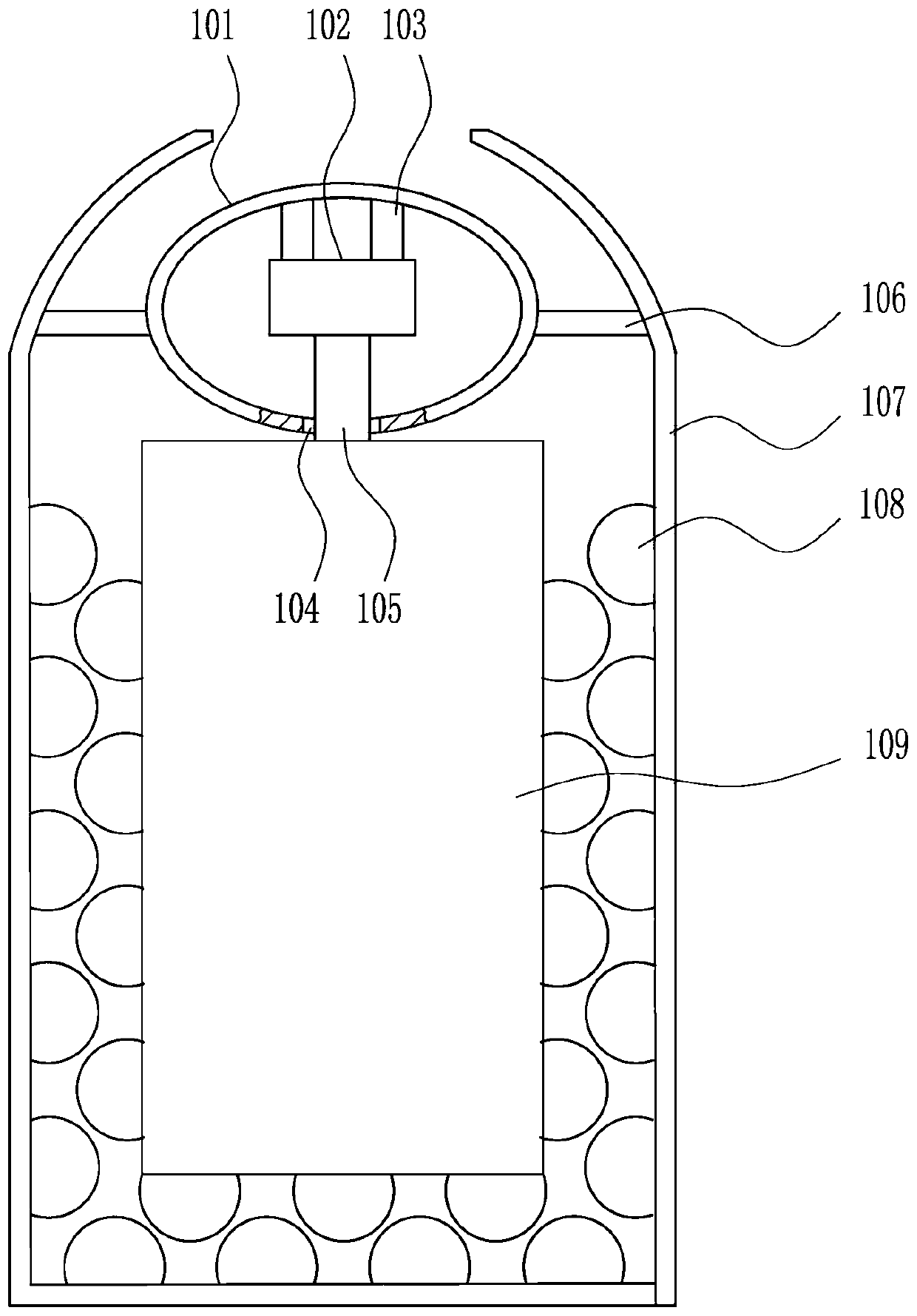

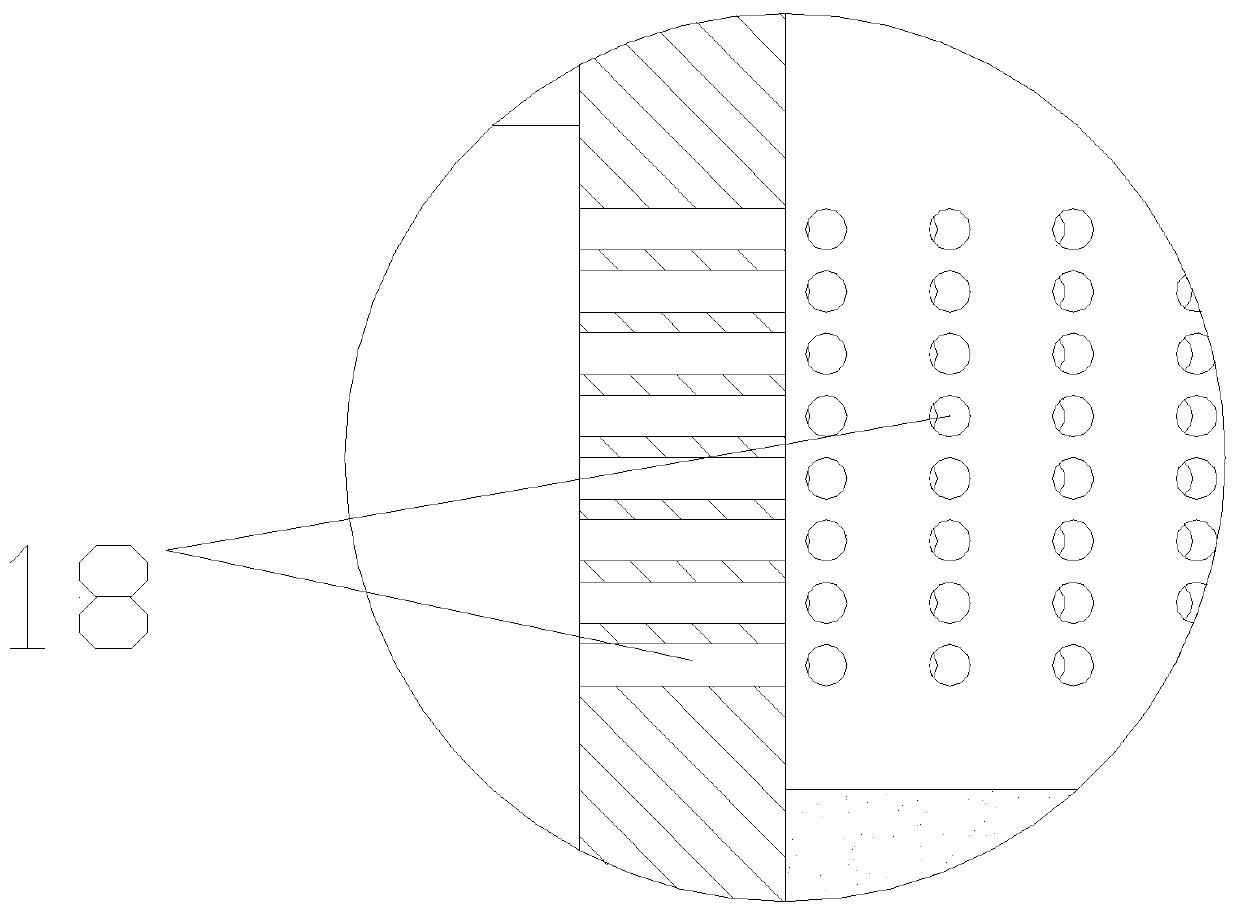

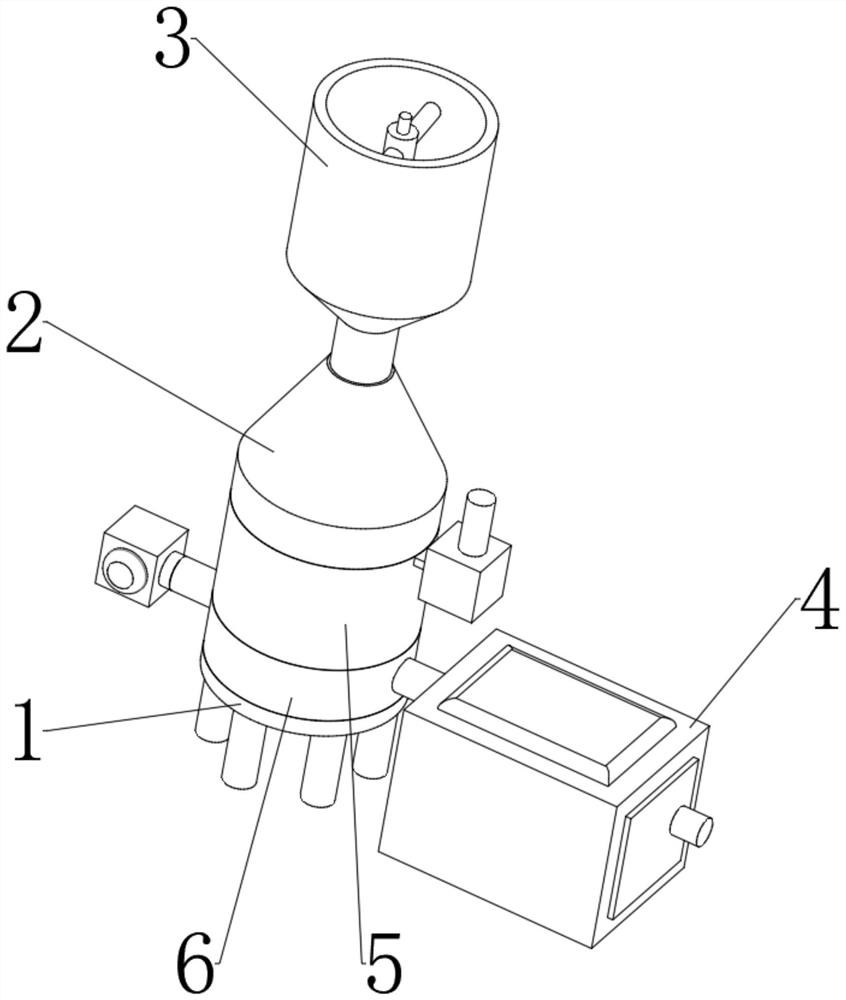

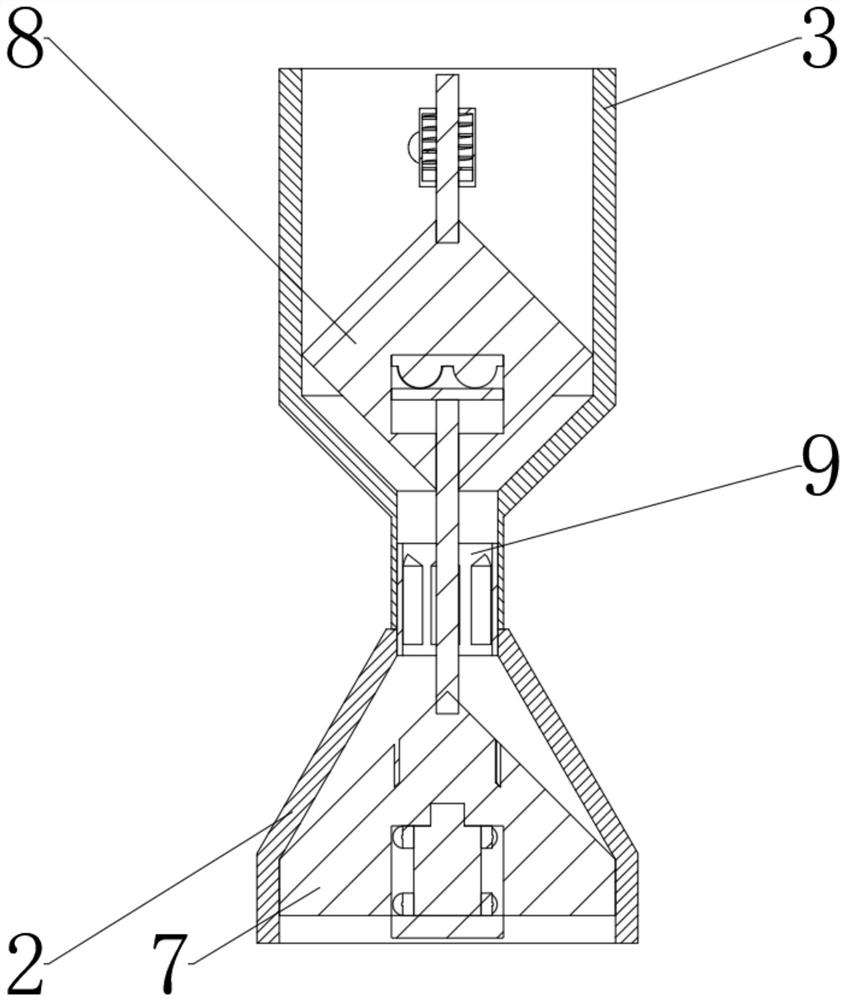

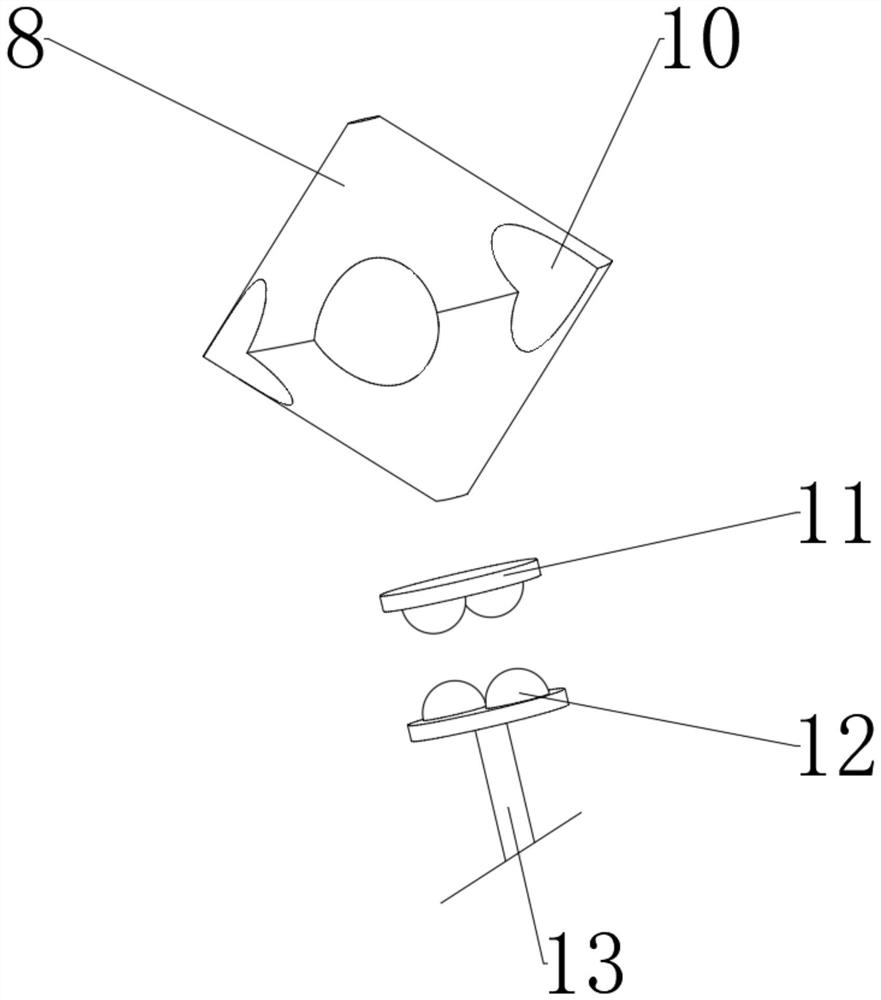

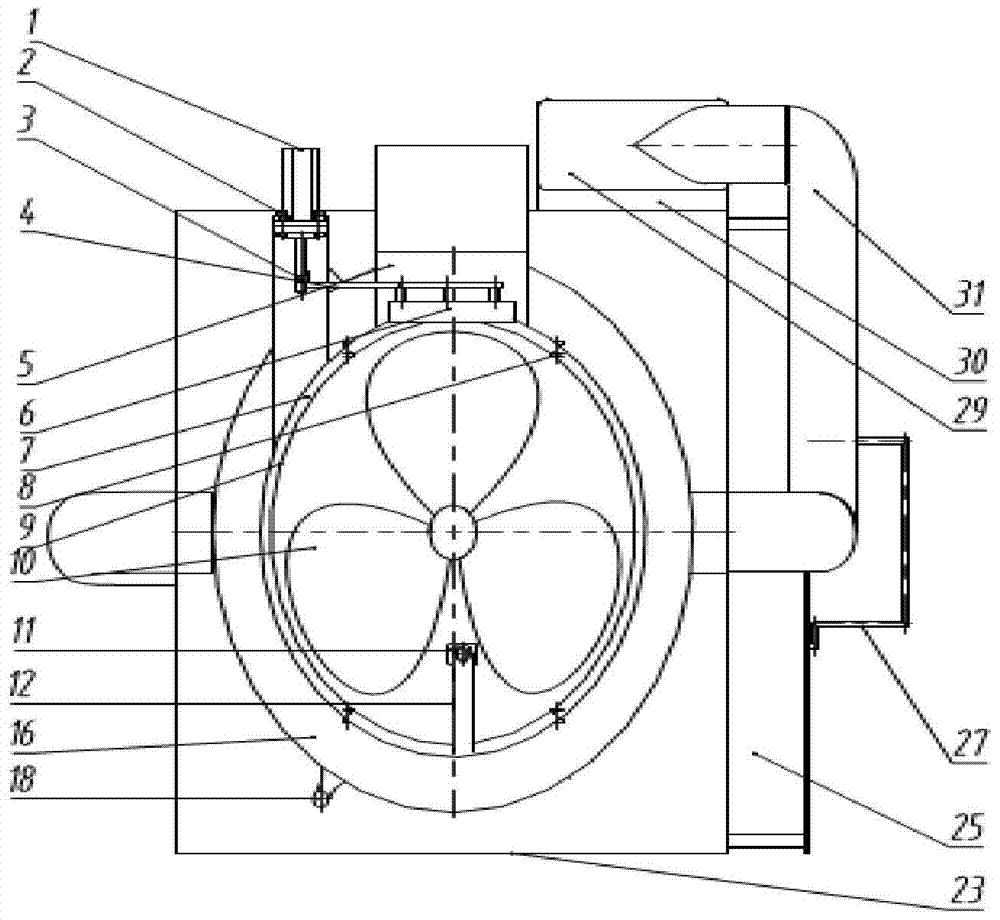

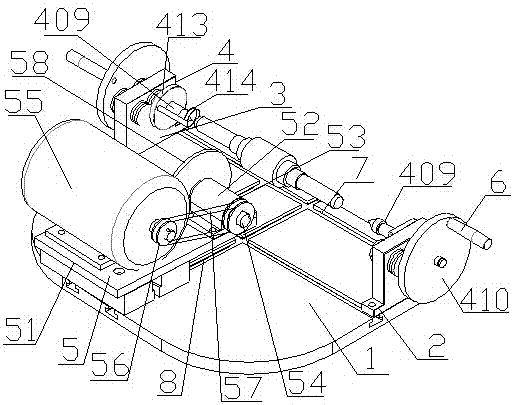

Intelligent lotus seed white grinding device

ActiveCN105054259AEvenly groundRealize quantitative exportFood treatmentSurface mountingAgricultural engineering

The present invention relates to an intelligent lotus seed white grinding device which includes a white grinding system, a lotus seed shell collecting device, and a lotus seed discharging device. A weight sensor is arranged at the lower surface of a grinding wheel in the white grinding system. The lotus seed shell collecting device is arranged at the lower end of the white grinding system and the lotus seed exporting device is mounted on the side wall of the white grinding system. The weight sensor is connected with the lotus seed exporting device, and when the lotus seed reduction amount in a sandpaper barrel reaches the set value, the lotus seed exporting device is turned off. Flip blades with a dull polish texture and having a different rotation speed compared to that of the grinding wheel device are added on the basis of the original white grinding system, thereby achieving all-dimensional and uniform white grinding. The weight sensor added at the bottom of the grinding wheel can realize lotus seed quantitative discharging after the process of white grinding and can facilitate quantitative packaging. A color sensor is added in the white grinding device, and during the white grinding process and during the process of turning lotus seeds from brown into white, the color sensor senses the color change and accurately controls the white grinding degree during the white grinding process.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

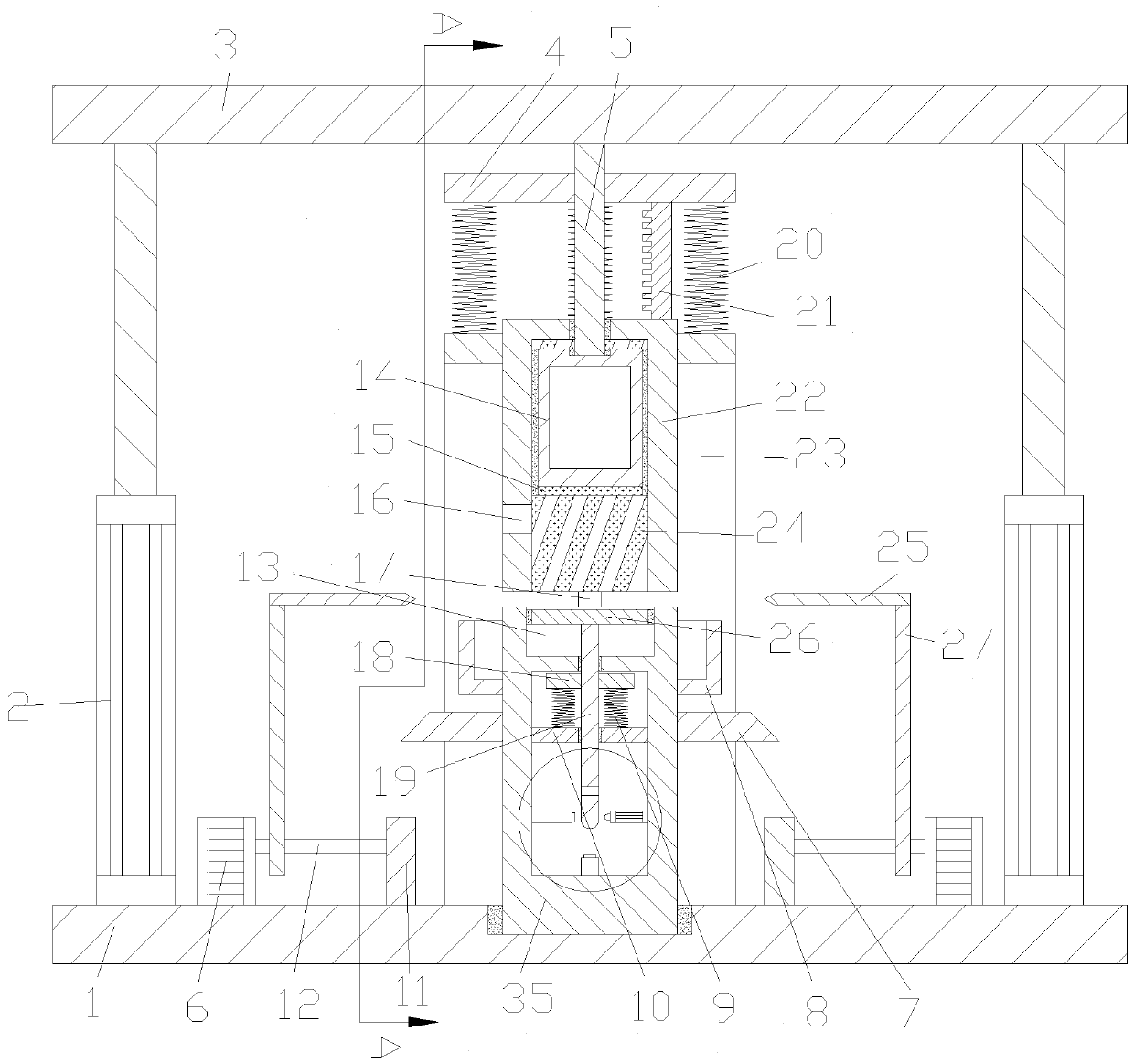

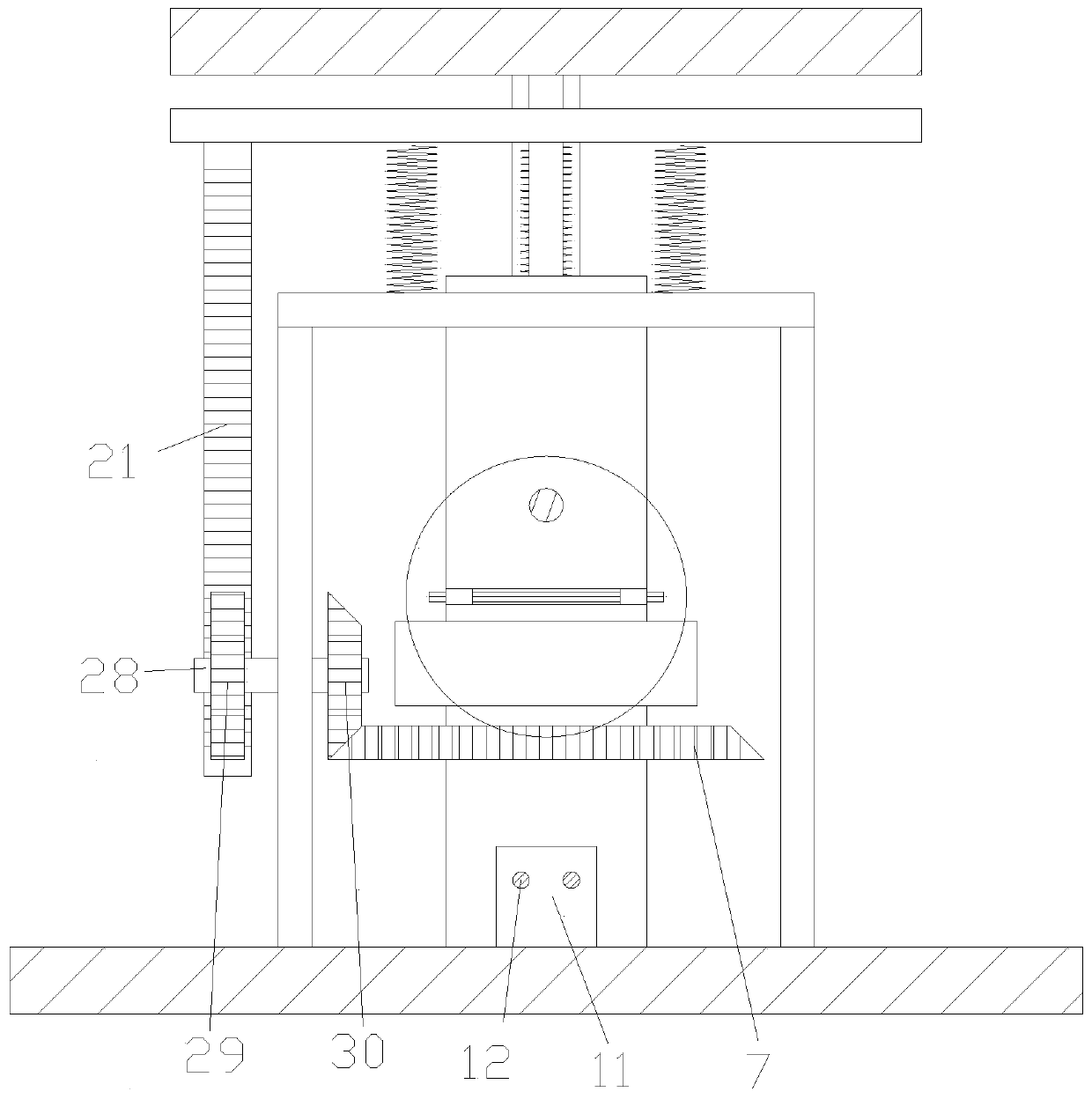

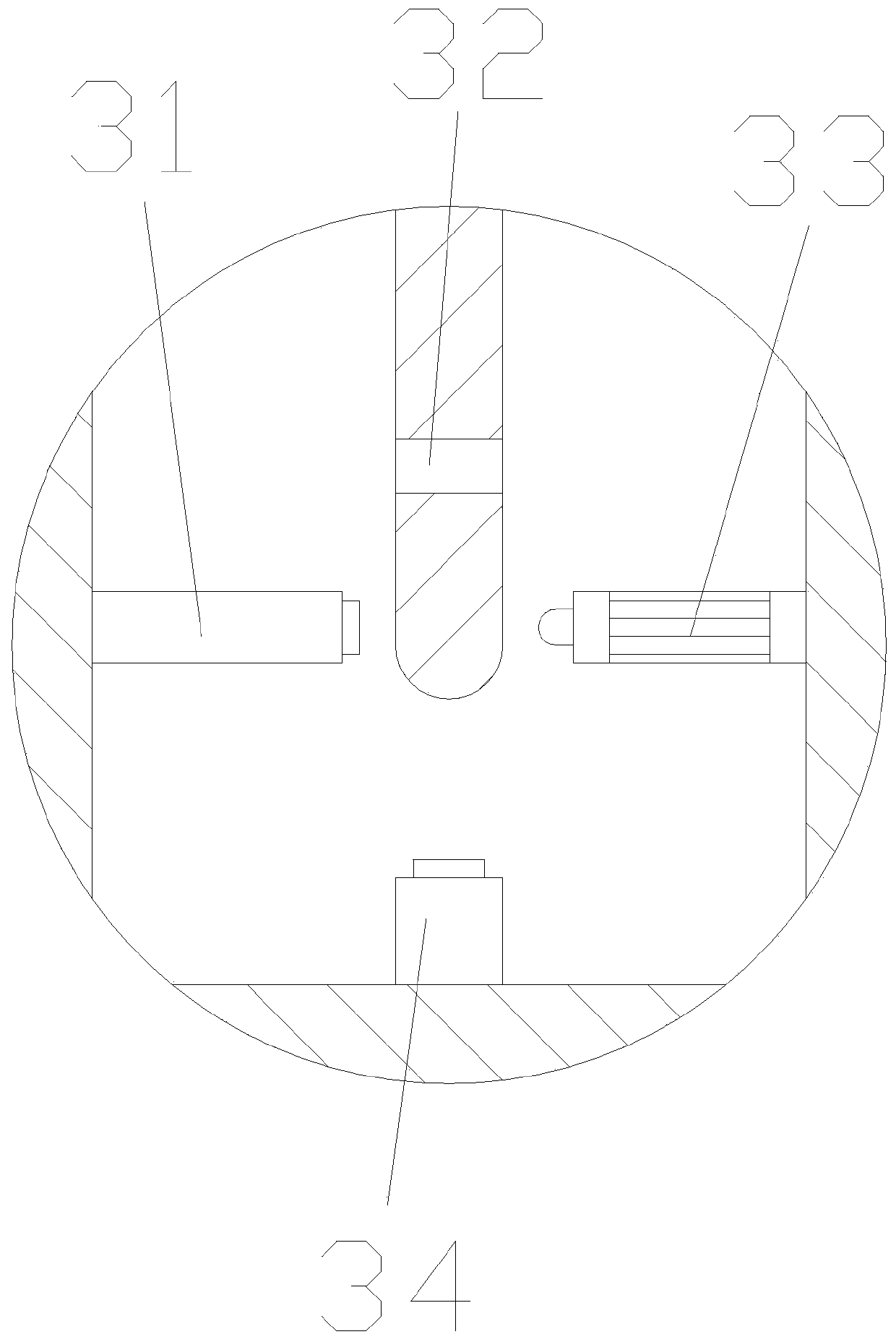

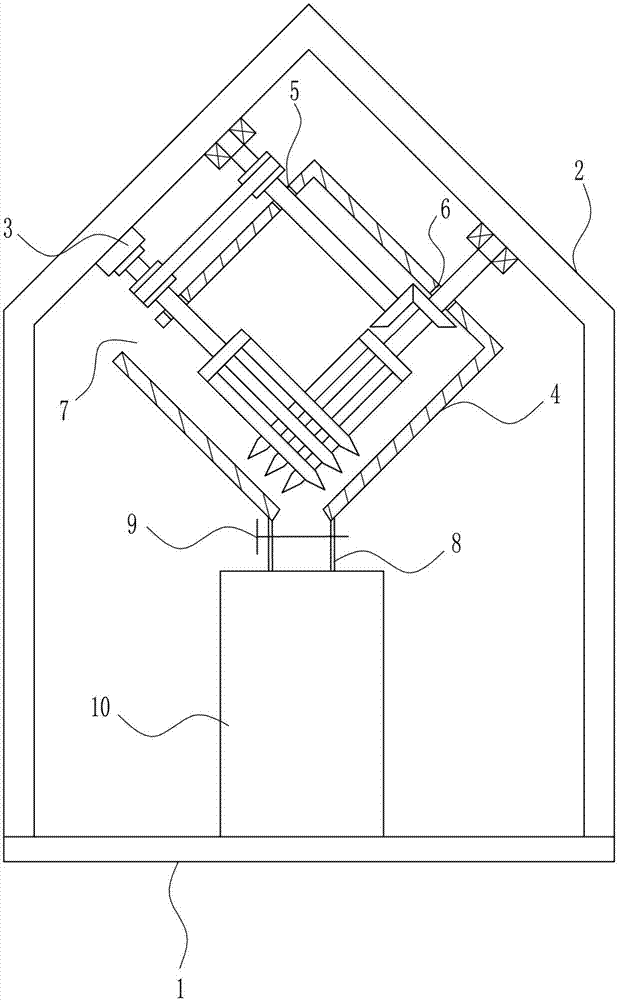

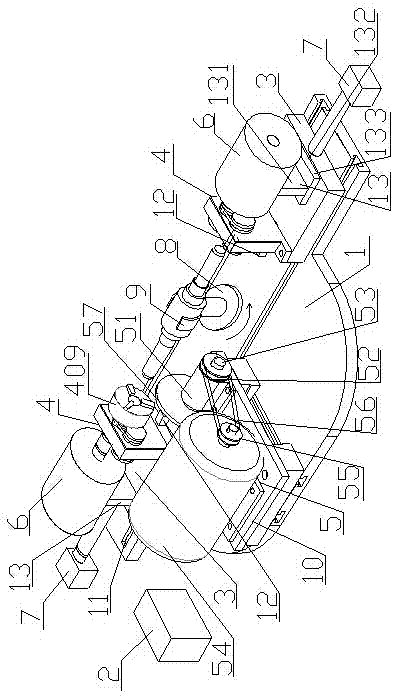

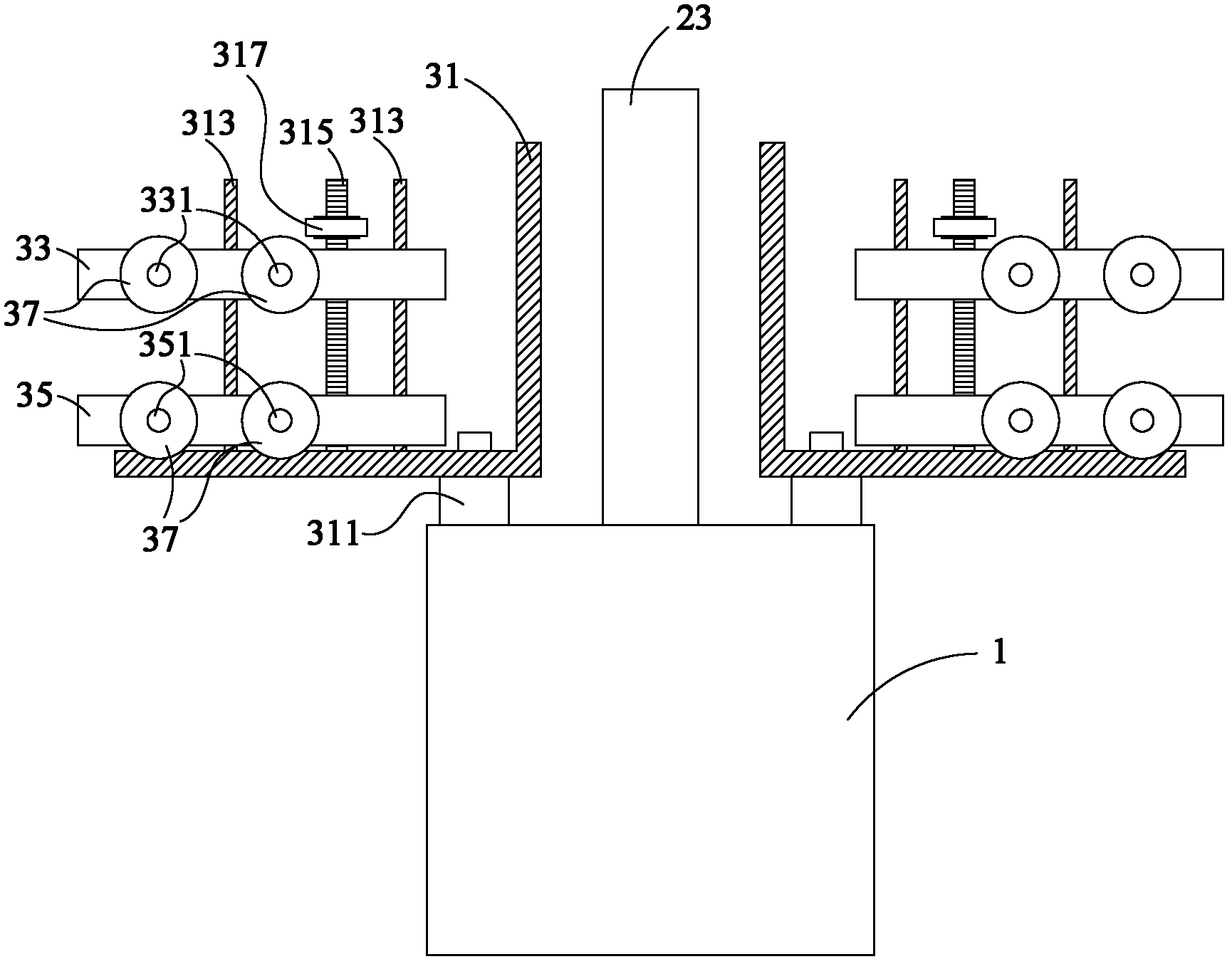

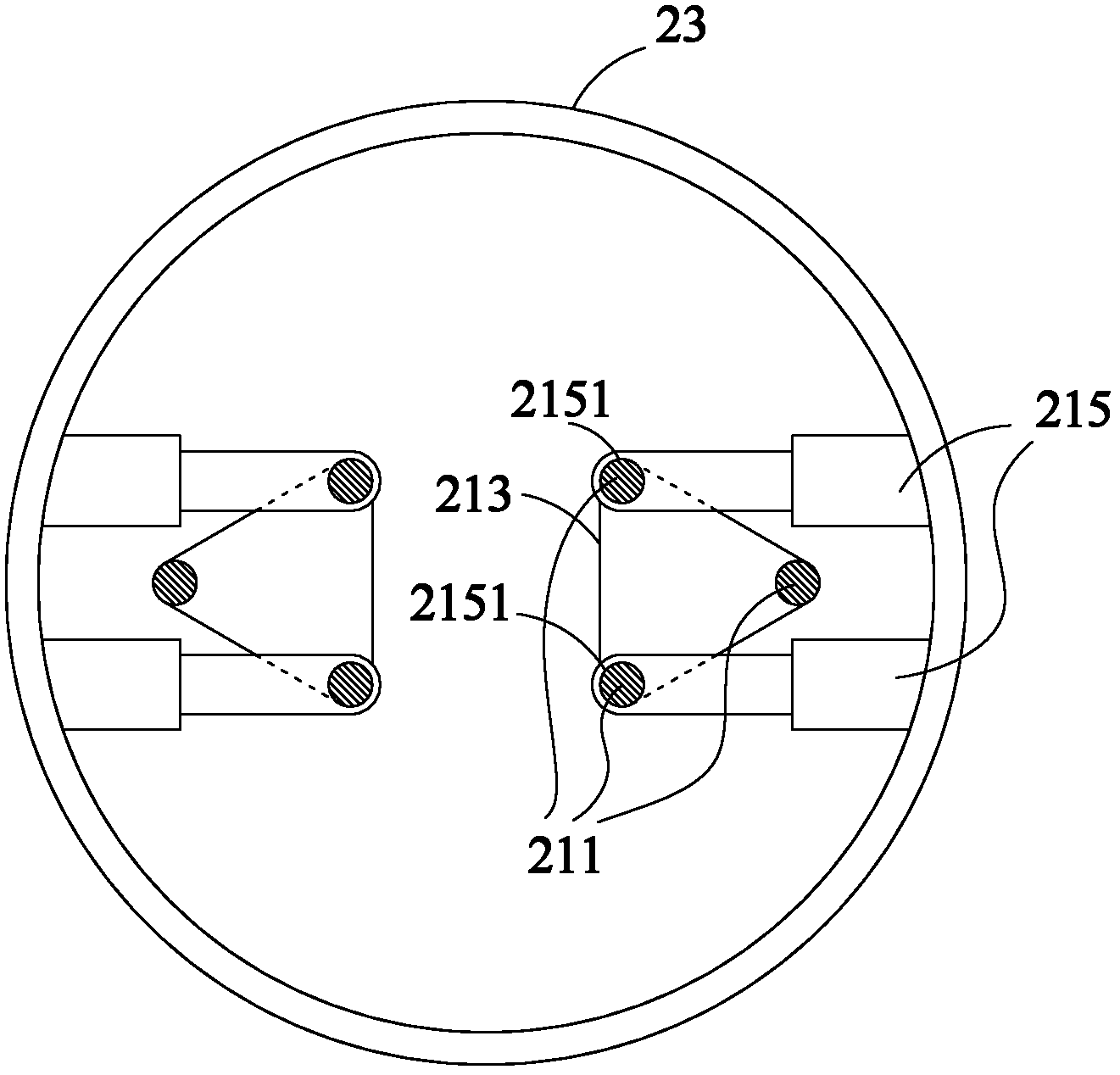

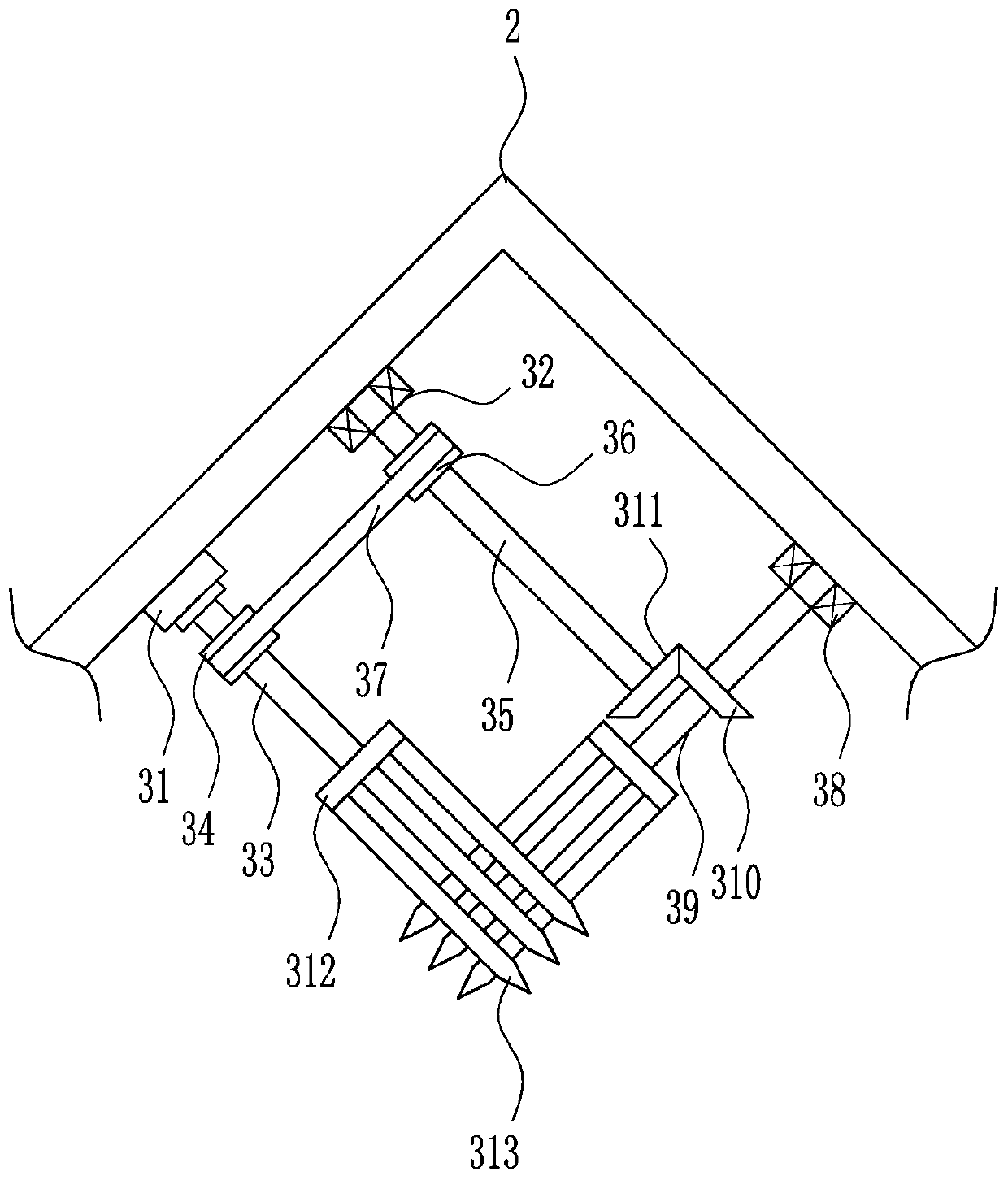

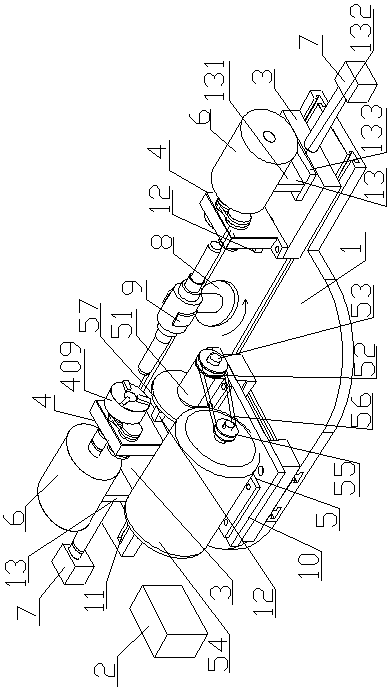

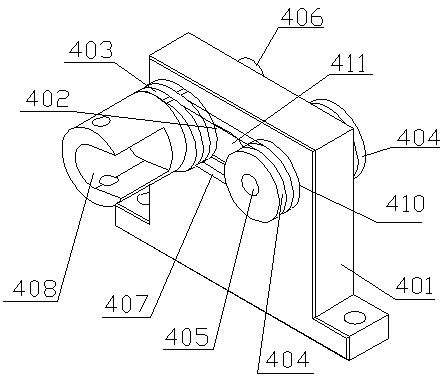

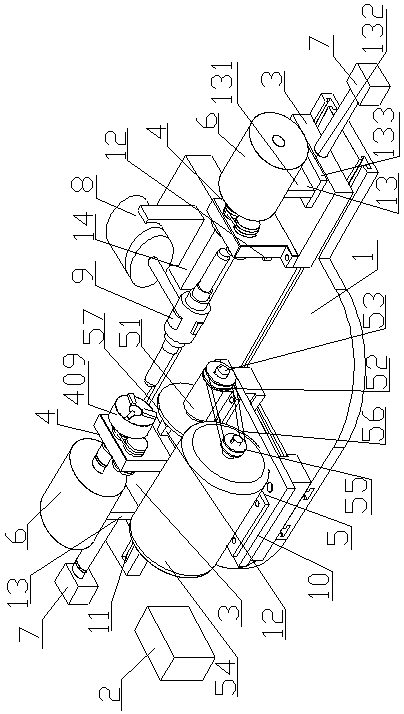

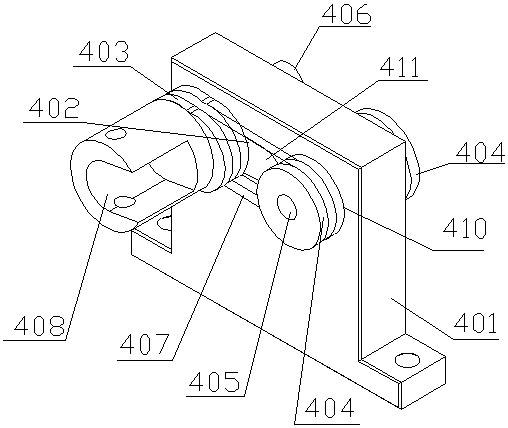

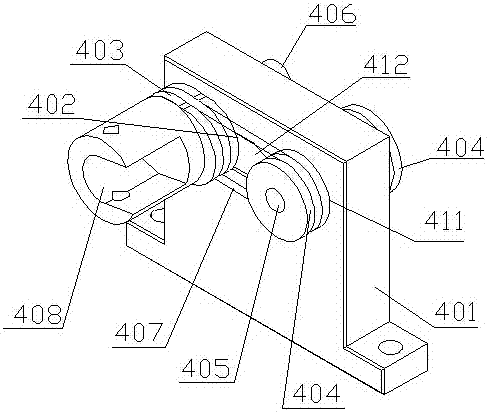

Automatic worm residual tooth removing device and residual tooth removing method thereof

The invention relates to an automatic worm residual tooth removing device capable of smoothening residual teeth on the two sides of a worm at a time and a residual tooth removing method thereof. The automatic worm residual tooth removing device is characterized in that two movable seats are oppositely arranged on the upper end surface of a base; a variable track rotating clamp assembly is arranged on each of the two movable seats; the two variable track rotating clamp assemblies are synchronously driven to rotate by two stepping motors respectively; two cylinders are arranged on the upper end surface of the base, and are respectively positioned on the two sides of the two movable seats; piston ends of the two cylinders are fixedly connected with the outer side surfaces of the two movable seats respectively; a rotary table mounting seat is arranged on one side of the base; a rotary table is horizontally mounted on the rotary table mounting seat; a mechanical hand is horizontally arranged on the table surface of the rotary table; a clamping part of the mechanical hand is positioned right between the two movable seats; a servo sliding table is arranged on the upper end surface of the base; and a grinding wheel assembly is arranged on a sliding block of the servo sliding table. The automatic worm residual tooth removing device has the advantages that residual sharp edge parts on the worm can be quickly and uniformly smoothened, so that the processing efficiency is improved, and the rejection rate of a product is decreased.

Owner:ZHEJIANG ESSOR PRECISION MACHINERY

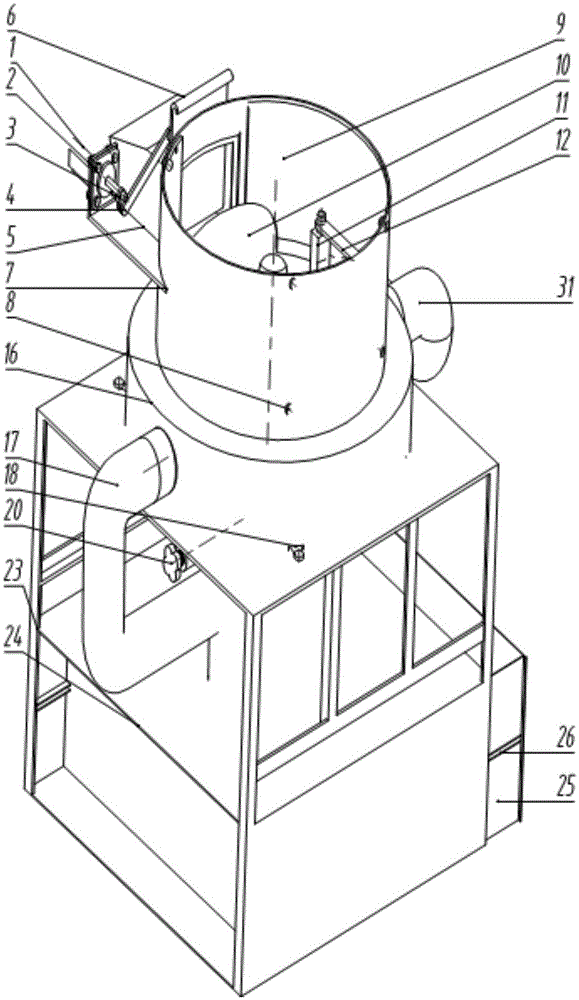

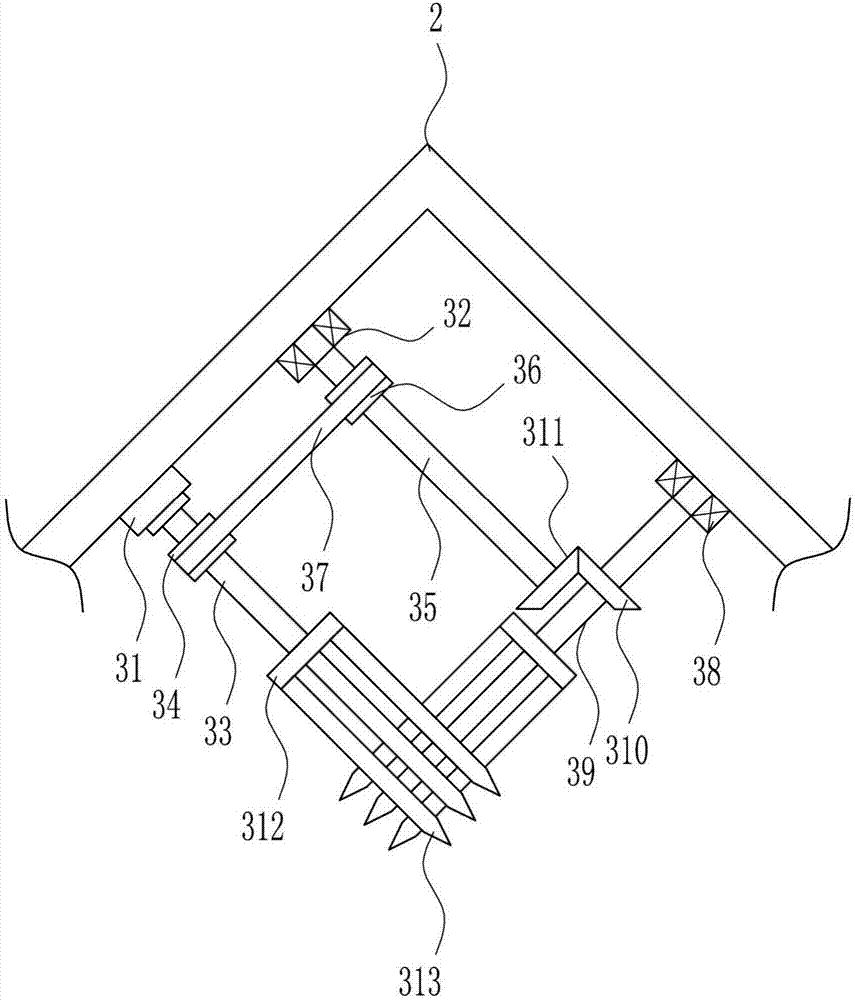

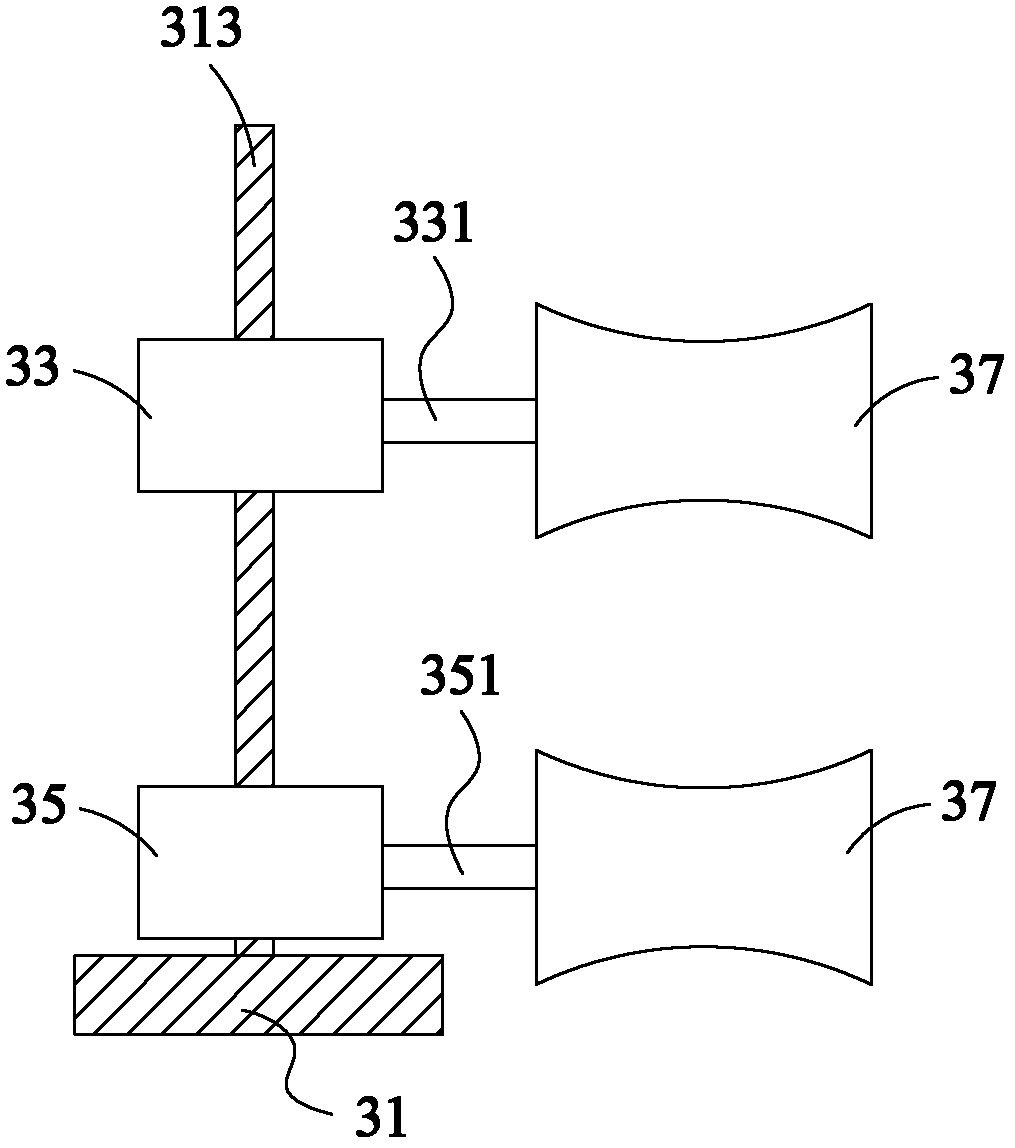

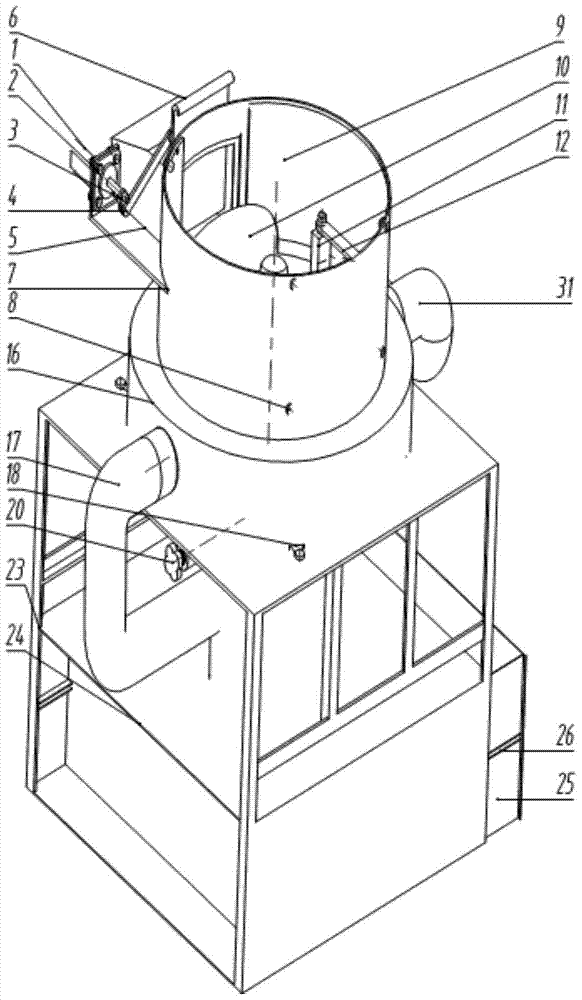

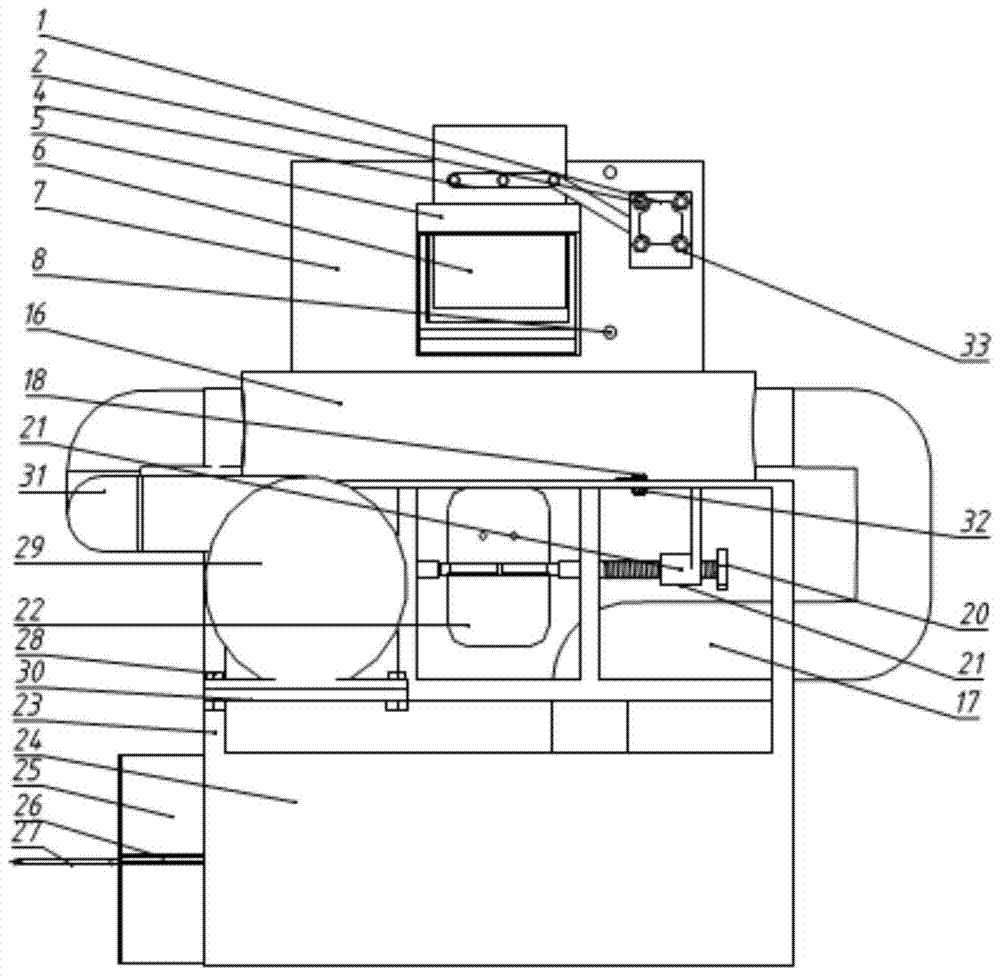

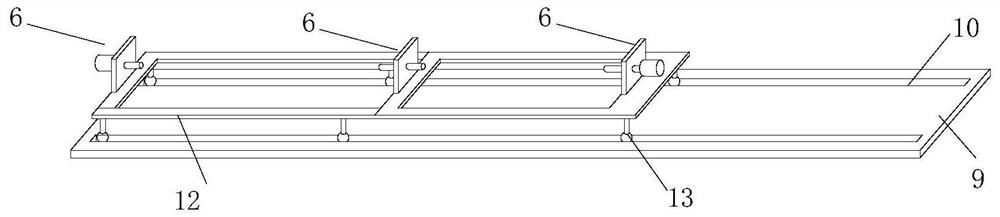

Sectional type feed grinding device for animal husbandry and using method

ActiveCN110270405ASimple structureSimple and efficient operationFeeding-stuffCocoaMechanical engineeringLower half

The invention provides a sectional type feed grinding device for animal husbandry. The feed grinding device comprises a base, wherein a lower cylinder body 35 is movably connected to the center of the top of the base, a groove communicating with the outside is formed in the top of the lower cylinder body 35, a grinding plate I is slidably connected between the inner walls of the groove, a partition plate is fixedly arranged between the inner walls of the middle of the lower cylinder body 35, and the bottom of the grinding plate I is provided with a sliding rod with the bottom sequentially penetrating through the center of the bottom of the inner wall of the groove and the center of the partition plate to reach the lower half part of the inner part of the lower cylinder body 35. The sectional type feed grinding device for the animal husbandry has the beneficial effects that the structure is simple, the operation is simple and convenient, and large-grained feed can be subjected to grinding treatment; the feeding amount each time is very uniform, and the problem that feed grinding particles are too large due to the fact that the feeding amount is too much during manual operation is solved; and ground feed is automatically collected, so that four requirements of fine grinding, uniform grinding, quantitative grinding and automatic grinding of the feed are realized, and the device is simple, efficient, convenient and rapid.

Owner:董建芬

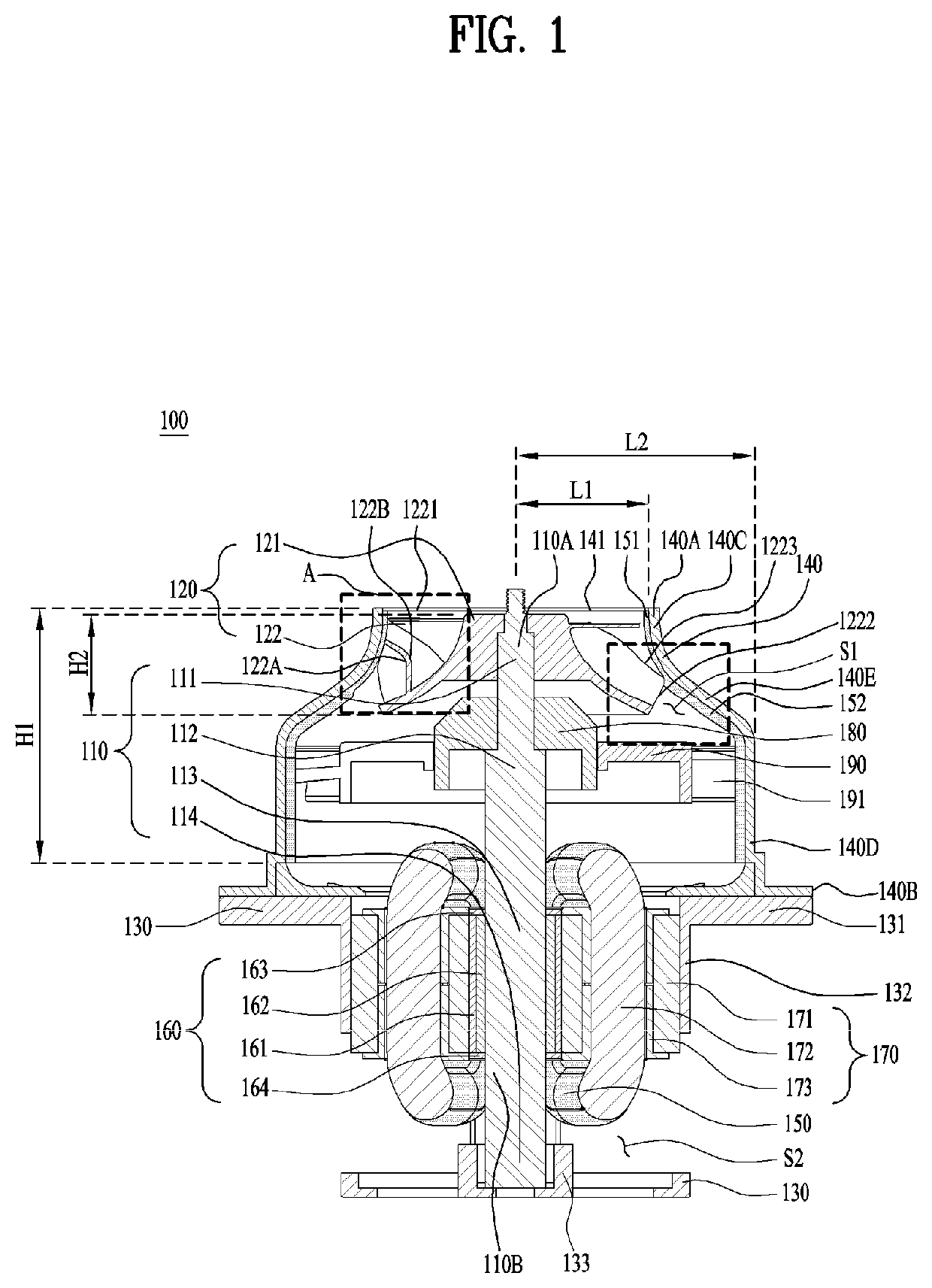

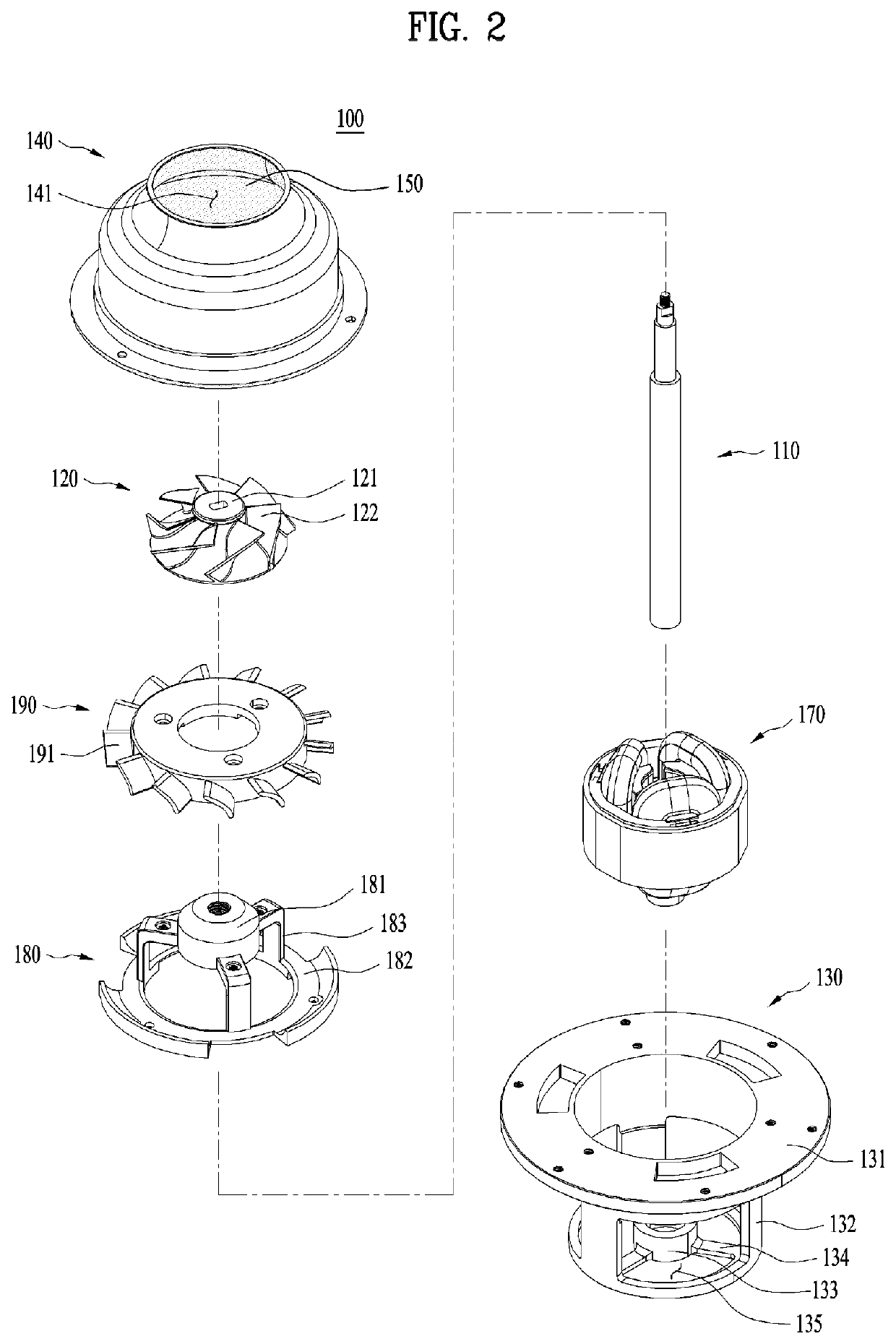

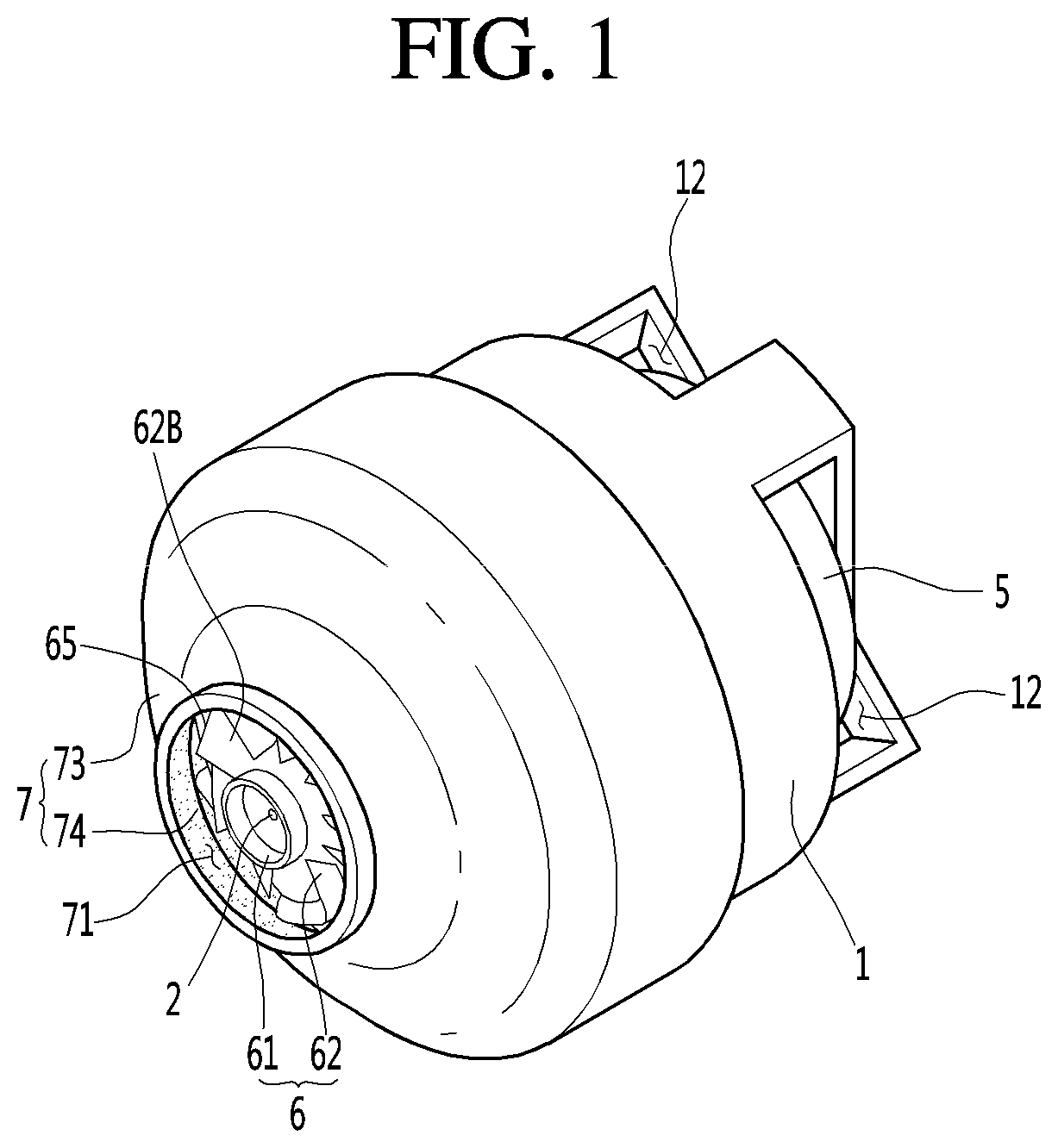

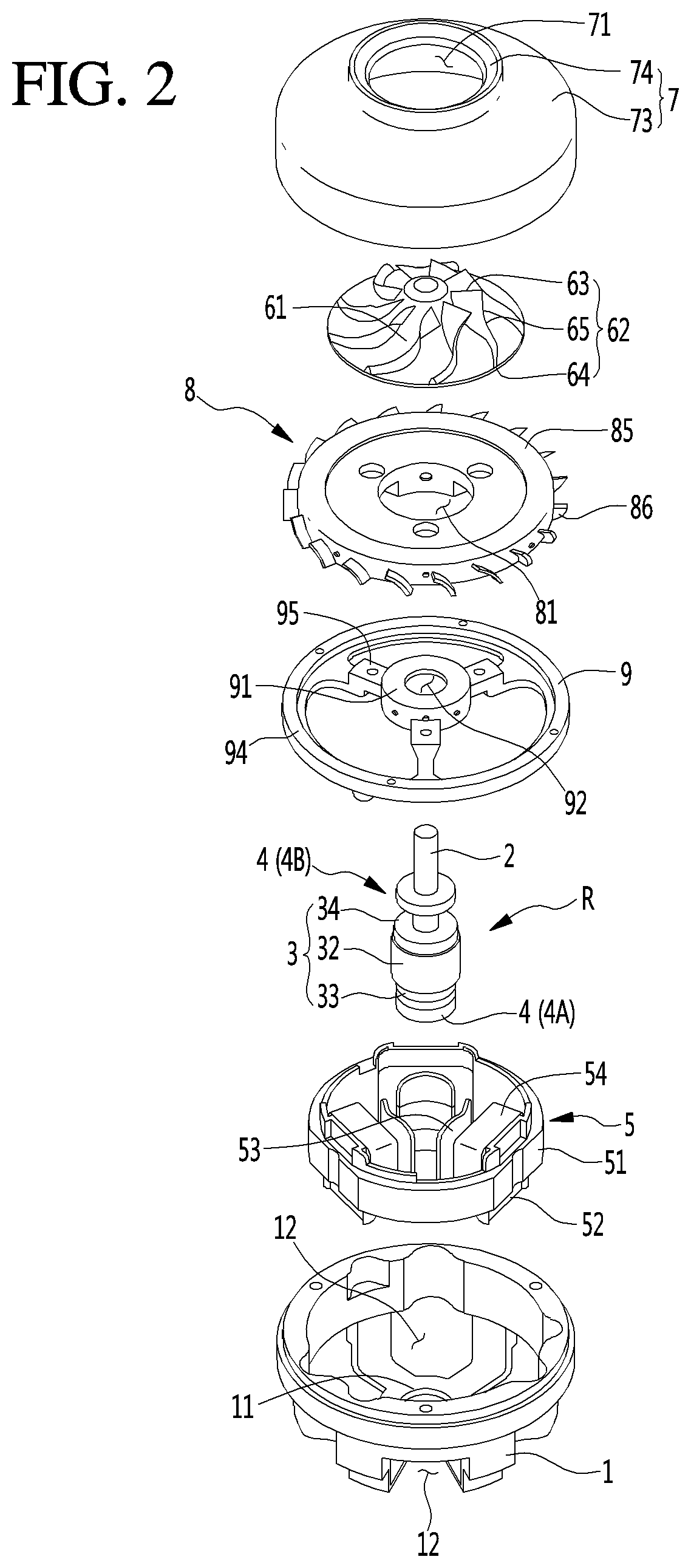

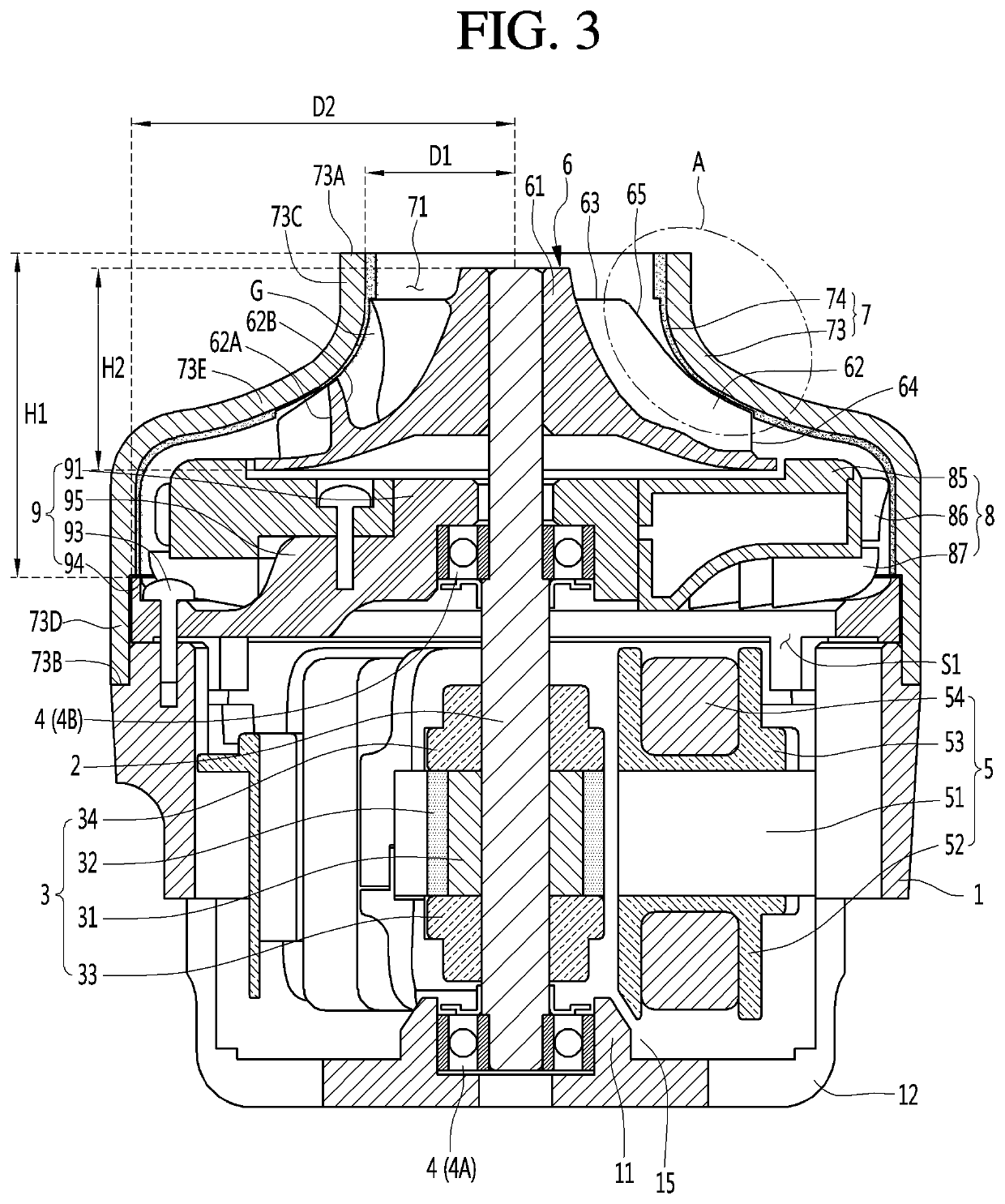

Motor assembly and method for manufacturing the same

An embodiment of the present disclosure discloses a motor assembly including a rotation shaft, an impeller including a hub fastened to the rotation shaft, and a plurality of blades protruding outward from an outer surface of the hub, an inlet body for surrounding an outer circumference of the impeller, and a coating layer coated on an inner surface of the inlet body, wherein at least a portion of the coating layer is ground in a form of powder by friction with the plurality of blades during rotation of the impeller.

Owner:LG ELECTRONICS INC

Medicinal material pulverizer for medical use

The invention relates to a pulverizer, in particular to a medicinal material pulverizer for a medical use. The medicinal material pulverizer for the medical use comprises a bottom plate, a fixing frame, a crushing device, a crushing box, a discharging pipe, a valve and the like. The fixing frame is connected with the top of the bottom plate, the crushing device is arranged at the top of the interior of the fixing frame, the crushing box is connected with the rear portion of the interior f the fixing frame, and a first through hole is formed in the left side of the top of the crushing box; a second through hole is formed in the right side of the top of the crushing box, a feeding port is formed in the left side of the top of the crushing box, and the discharging pipe is connected with the bottom of the crushing box; and the valve is connected with the discharging pipe, and a pulverizing device is placed in the middle of the top of the bottom plate. According to the pulverizer, the effect that medicinal materials can be grinded evenly is achieved, using is simple and convenient, and the reliability is high.

Owner:安徽道源堂中药饮片有限公司

Automatic worm residual tooth removing device and residual tooth removing method thereof

The invention relates to an automatic worm residual tooth removing device with the capability of grinding residual teeth on the two sides of a worm to smooth at a time and a residual tooth removing method thereof. Two movable seats are arranged on the upper end surface of a base opposite to each other; two groups of variable-trajectory rotation clamping components are arranged on the two movable seats respectively and are synchronously driven by two stepping motors to rotate; two cylinders are arranged on the upper end surface of the base and on the outer sides of the two movable seats respectively; piston ends of the two cylinders are fixedly connected with the outer side surfaces of the two movable seats respectively; a rotary table is arranged on the upper end surface of the base and just at the middle part between the two movable seats; a manipulator is vertically arranged on the rotary table; a servo sliding table is arranged on the upper end surface of the base; and a grinding wheel component is arranged on a sliding block of the servo sliding table. The automatic worm residual tooth removing device has the advantages that a sharp blade part on each residual tooth of the worm can be rapidly and uniformly ground to smooth, so that the processing efficiency is improved, and the reject rate of a product is lowered.

Owner:ZHEJIANG ESSOR PRECISION MACHINERY

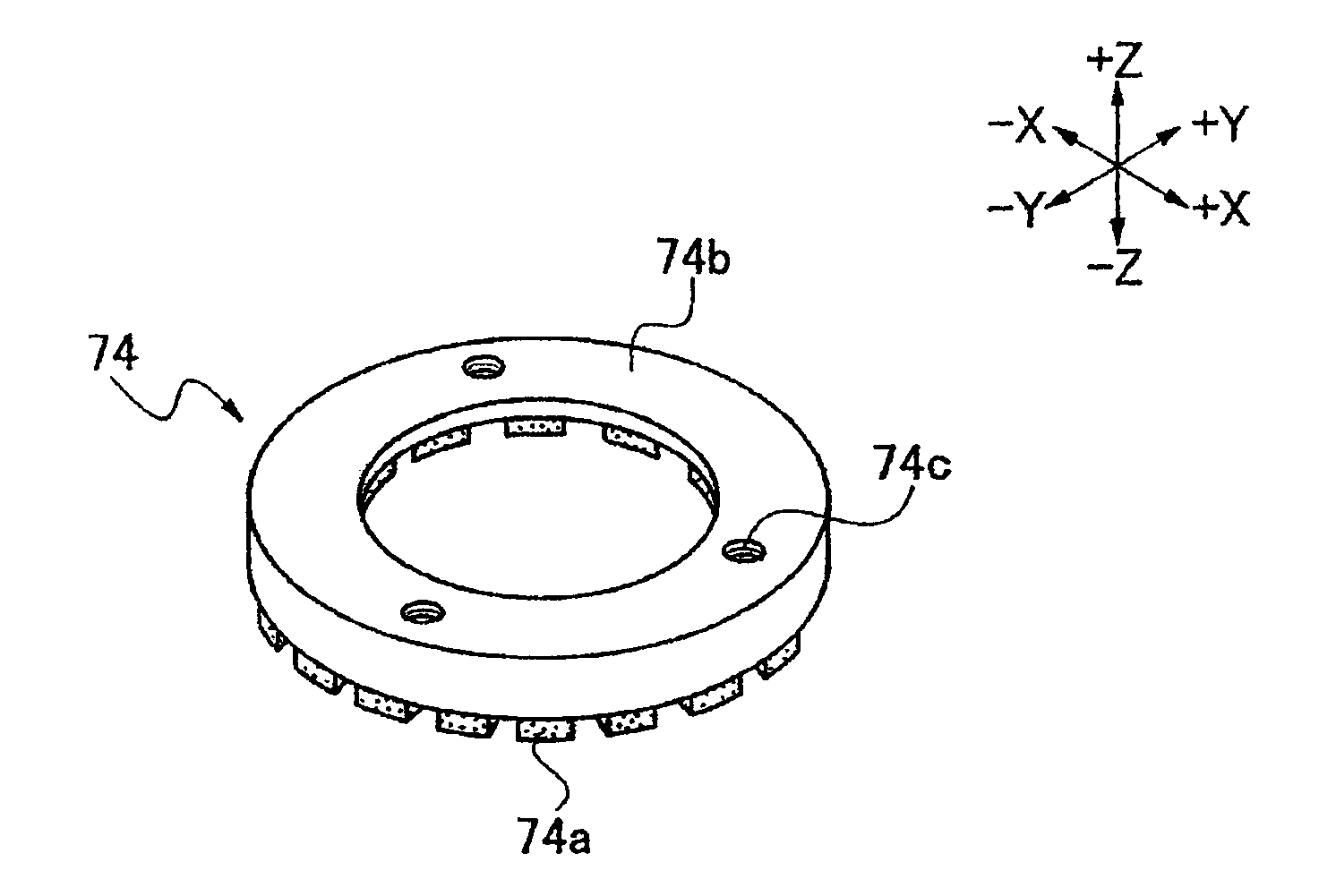

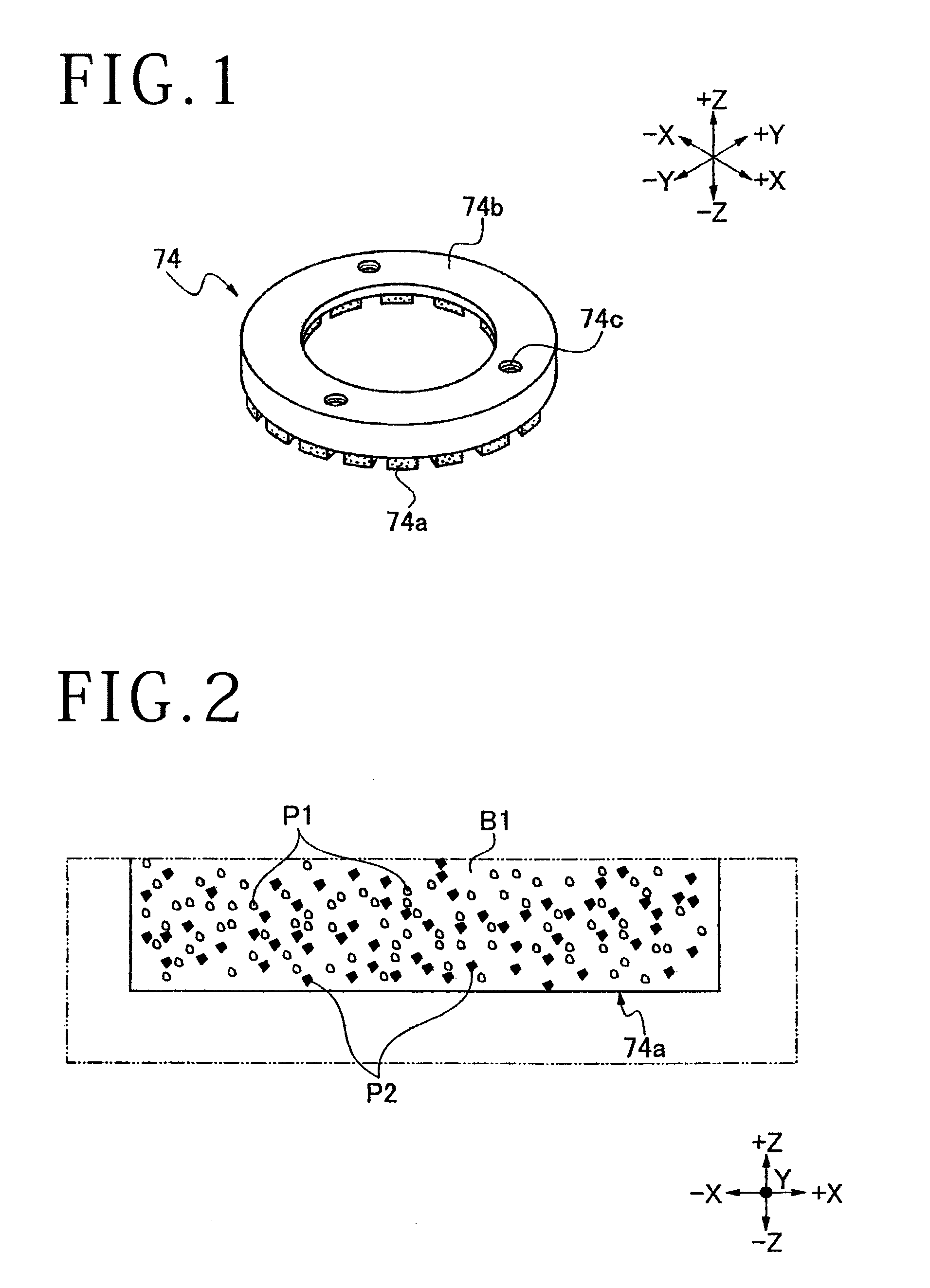

Fan motor and manufacturing method of the same

A fan motor according to an embodiment of the present invention may include: an impeller a hub connected to a rotary shaft and at least one blade formed on the outer surface of the hub; a shroud surrounding the outer circumference of the impeller; and a coating layer coated on the inner circumferential surface of the shroud. The coating layer may include: a polymer having strength lower than the strength of the blade; and a plurality of beads mixed with the polymer and having strength higher than the strength of the polymer.

Owner:LG ELECTRONICS INC

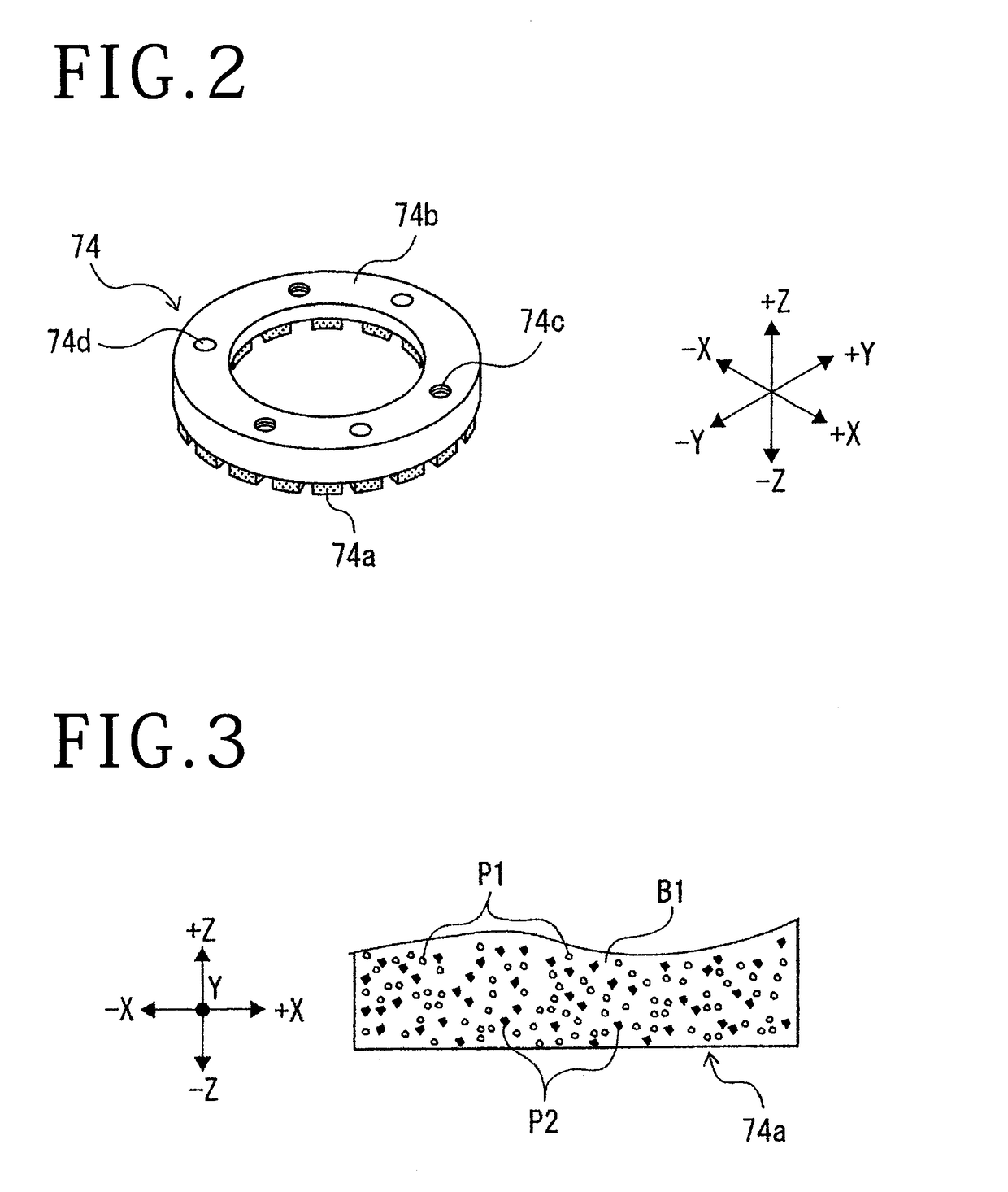

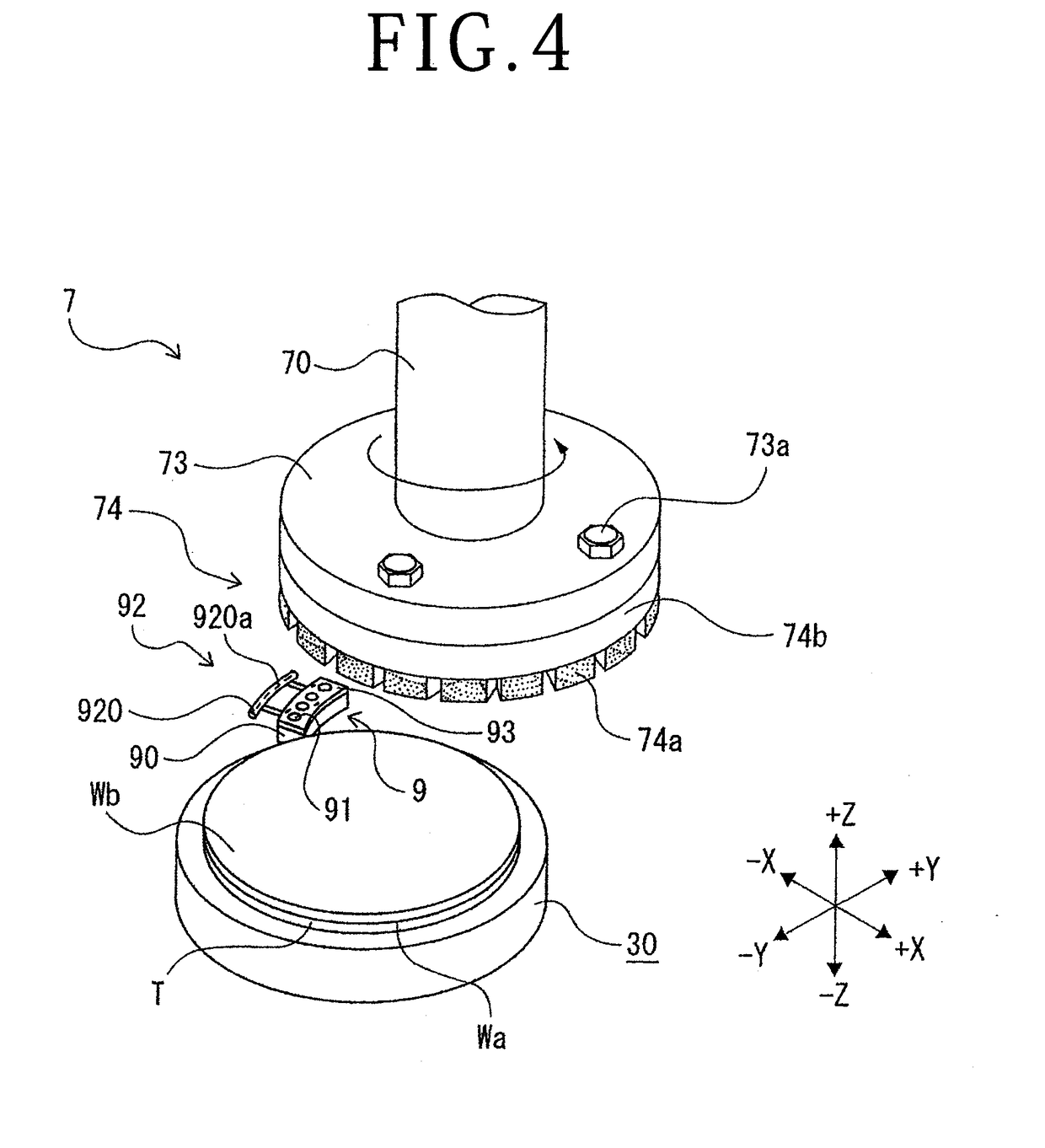

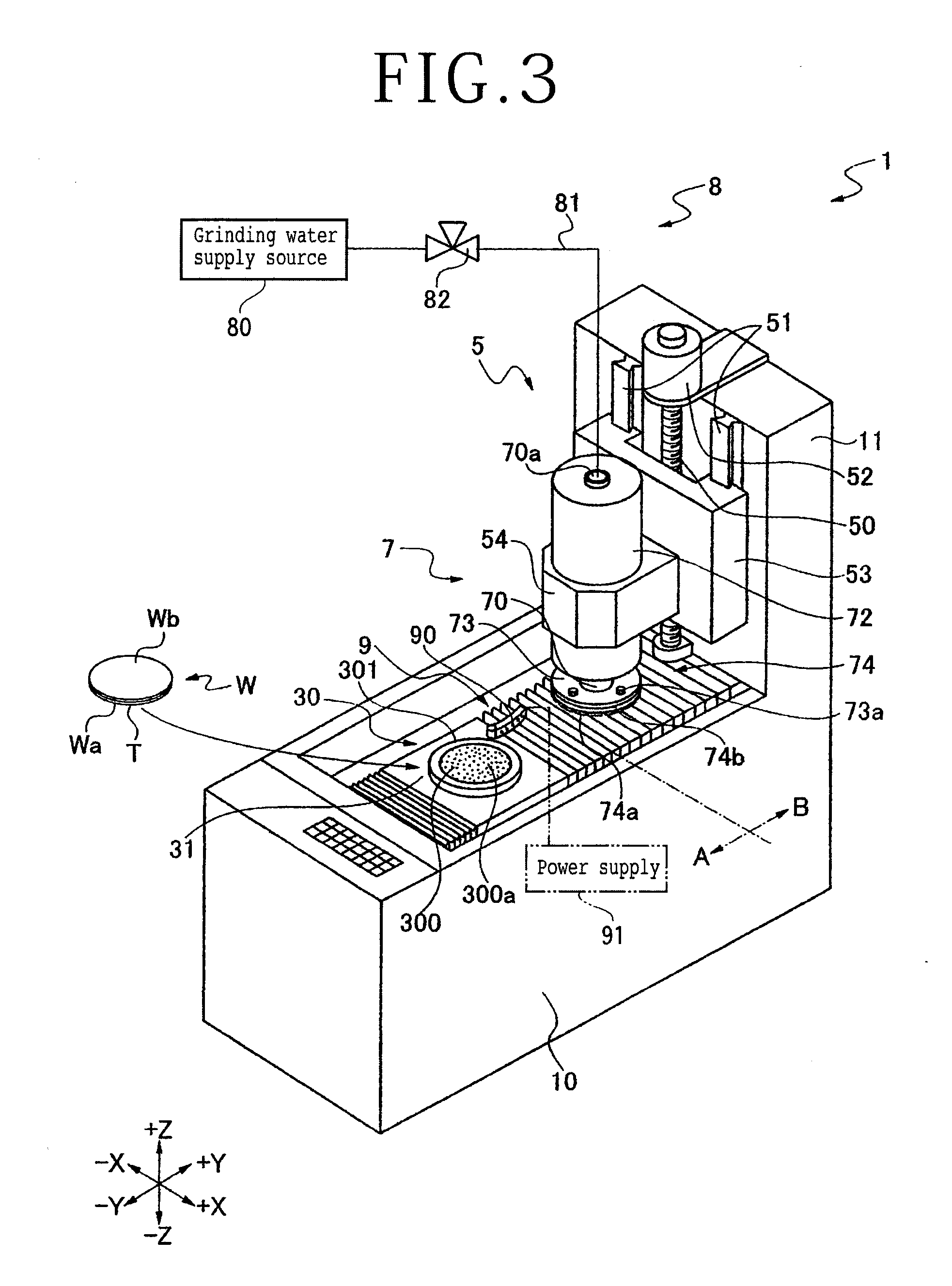

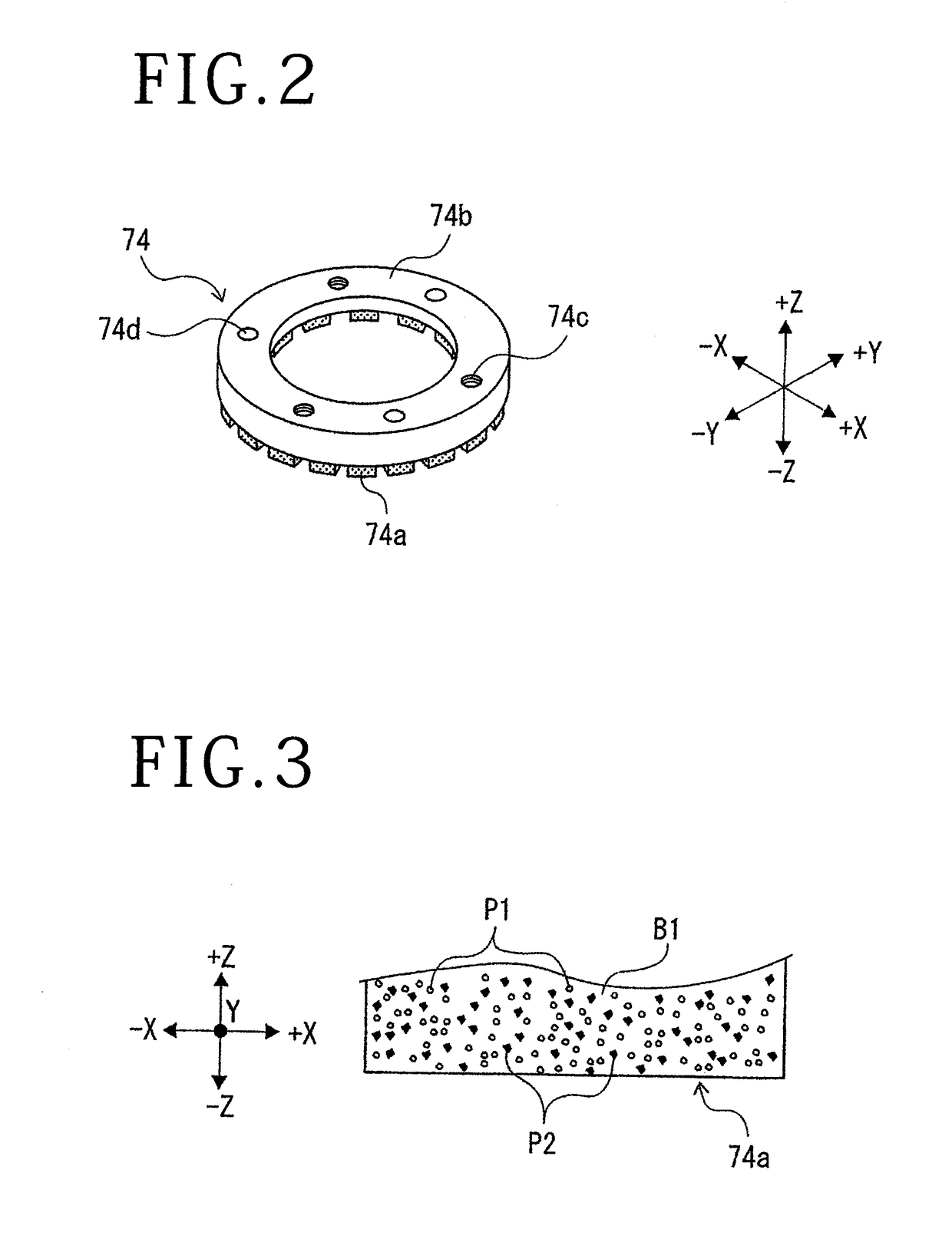

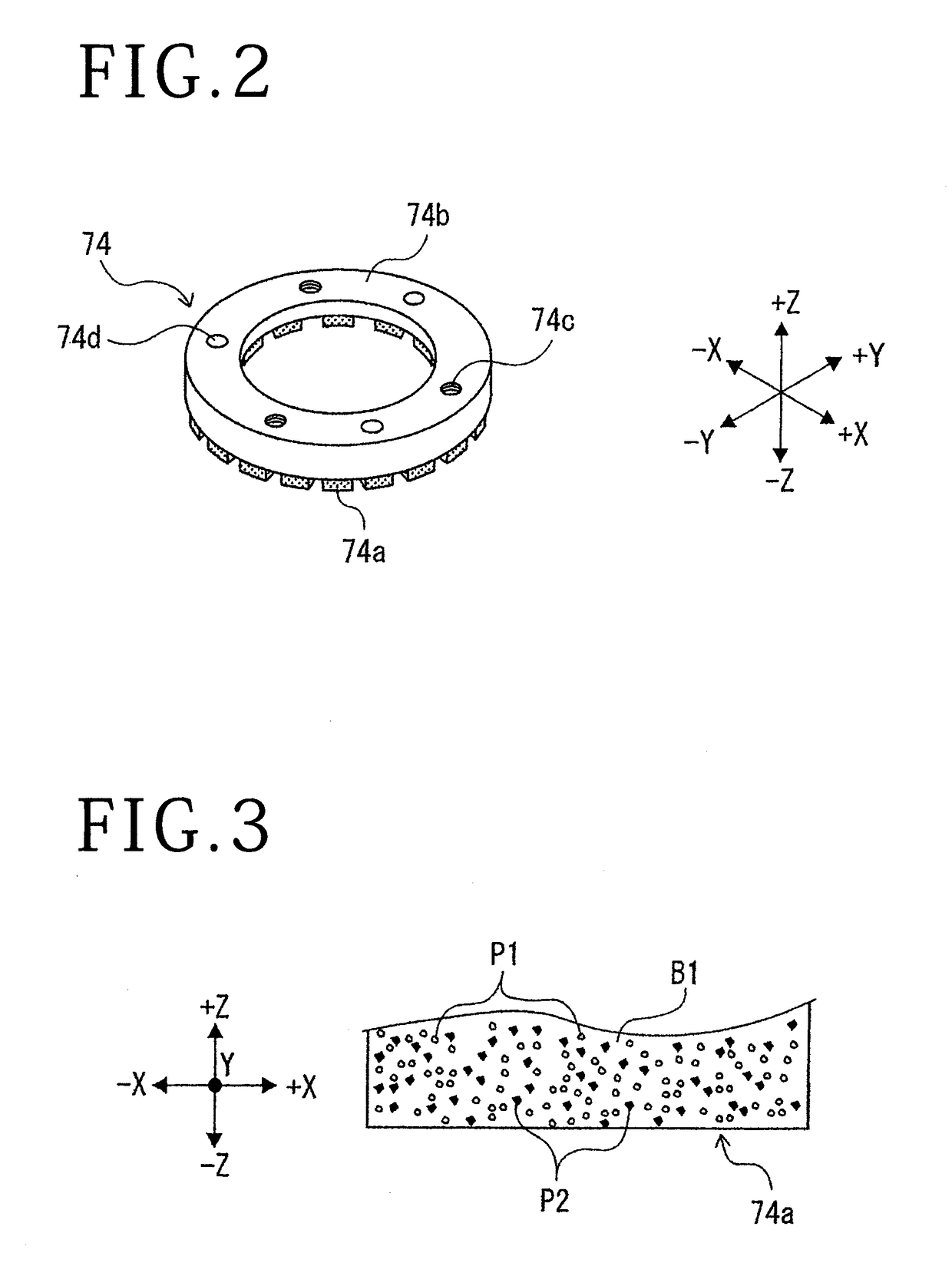

Grinding wheel, grinding apparatus, and method of grinding wafer

ActiveUS20160256981A1Strong oxidize powerSmoothly be groundSemiconductor/solid-state device manufacturingBonded abrasive wheelsTitanium oxideGrinding wheel

Disclosed herein is a grinding wheel including an annular wheel base and a plurality of grinding stones fixed to an outer circumferential portion of the lower end of the annular wheel base. Each of the grinding stones is made of a mixture of abrasive grains and photocatalytic particles which are held together by a binder. The abrasive grains are diamond abrasive grains, and the photocatalytic particles are titanium oxide (TiO2) particles.

Owner:DISCO CORP

Method of grinding wafer

ActiveUS10076825B2Smoothly grinding a waferEvenly groundSemiconductor/solid-state device manufacturingBonded abrasive wheelsGrinding wheelTitanium oxide

Disclosed herein is a grinding wheel including an annular wheel base and a plurality of grinding stones fixed to an outer circumferential portion of the lower end of the annular wheel base. Each of the grinding stones is made of a mixture of abrasive grains and photocatalytic particles which are held together by a binder. The abrasive grains are diamond abrasive grains, and the photocatalytic particles are titanium oxide (TiO2) particles.

Owner:DISCO CORP

Grinding apparatus

ActiveUS20190061109A1Inhibit wearGrind evenlySemiconductor/solid-state device manufacturingGrinding feed controlEngineeringGrinding wheel

A grinding apparatus includes a table that holds a workpiece, and a grinding unit including a grinding wheel mounted to a spindle. The grinding wheel has a grindstone formed by binding abrasive grains with a bonding agent. In addition, the grinding apparatus further includes: a supply unit that supplies grinding water to at least the grindstone when grinding the workpiece; and a light applying unit that is disposed adjacent to the table and that applies light to a grinding surface of the grindstone grinding the workpiece held by the table. The light applying unit includes a light emission section that emits light, and a diffusion preventive wall that surrounds the light emission section and prevents diffusion of the light.

Owner:DISCO CORP

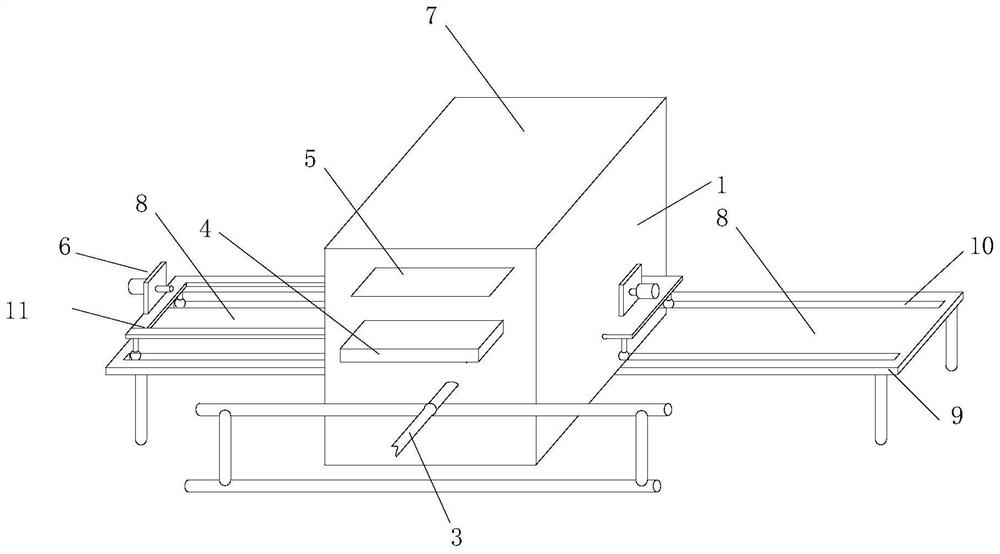

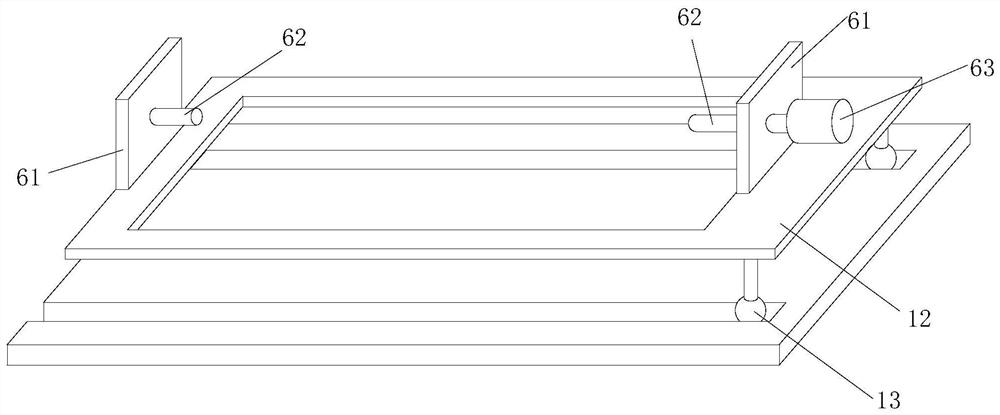

Transverse wire grinding machine of arc-shaped door handle of refrigerator

InactiveCN102528616AAvoid transverse grindingEvenly groundBelt grinding machinesMechanical equipmentDrive motor

The invention discloses a transverse wire grinding machine of an arc-shaped door handle of a refrigerator. The transverse wire grinding machine comprises a chassis, a wire grinding device positioned at the middle and transmission devices positioned on two sides, wherein the wire grinding device is arranged at the upper end of the chassis and equipped with a driving motor. The transverse wire grinding machine disclosed by the invention has the advantages of preventing working staff from performing manual wire grinding machining on the surface of the handle, ensuring uniform wire grinding of the handle with the assistance of mechanical equipment and realizing simplicity and convenience in operation and significant effects.

Owner:滁州安迈达特种铝业有限公司

A grinding machine for medical medicinal materials

The invention relates to a pulverizer, in particular to a medicinal material pulverizer for a medical use. The medicinal material pulverizer for the medical use comprises a bottom plate, a fixing frame, a crushing device, a crushing box, a discharging pipe, a valve and the like. The fixing frame is connected with the top of the bottom plate, the crushing device is arranged at the top of the interior of the fixing frame, the crushing box is connected with the rear portion of the interior f the fixing frame, and a first through hole is formed in the left side of the top of the crushing box; a second through hole is formed in the right side of the top of the crushing box, a feeding port is formed in the left side of the top of the crushing box, and the discharging pipe is connected with the bottom of the crushing box; and the valve is connected with the discharging pipe, and a pulverizing device is placed in the middle of the top of the bottom plate. According to the pulverizer, the effect that medicinal materials can be grinded evenly is achieved, using is simple and convenient, and the reliability is high.

Owner:安徽道源堂中药饮片有限公司

An automatic and repeated crushing device for animal feed and its use method

ActiveCN110420728BEvenly groundPrevent the problem of oversized grinding particlesFeeding-stuffGrain treatmentsCrop livestockEngineering

An automatic repeated crushing device for livestock feed, comprising a box body 1, the front and rear ends of the box body 1 communicate with the outside world, and the top of the box body 1 is sealed and connected with a box body 2 whose left and right ends communicate with the outside world. The upper half of the front and rear ends of the body are sealed and connected with baffles, and the opposite ends of the baffles are respectively provided with chute, and the inside of the chute is slidably connected with a sliding plate. The beneficial effect of the present invention is that the structure of the present invention is simple, It is easy to operate and can grind large-grained feed, and the amount of feeding is very uniform each time, which prevents the problem of excessive grinding of feed particles caused by too much single-feeding during manual operation, and has a great impact on grinding. The final feed is automatically collected, which realizes the four requirements of fine grinding, uniform grinding, quantitative grinding and automatic grinding of feed, which is simple, efficient, convenient and fast.

Owner:陈惠英

Automatic worm gear removal device and method for removing residual teeth

The invention relates to an automatic worm residual tooth removing device with the capability of grinding residual teeth on the two sides of a worm to smooth at a time and a residual tooth removing method thereof. Two movable seats are arranged on the upper end surface of a base opposite to each other; two groups of variable-trajectory rotation clamping components are arranged on the two movable seats respectively and are synchronously driven by two stepping motors to rotate; two cylinders are arranged on the upper end surface of the base and on the outer sides of the two movable seats respectively; piston ends of the two cylinders are fixedly connected with the outer side surfaces of the two movable seats respectively; a rotary table is arranged on the upper end surface of the base and just at the middle part between the two movable seats; a manipulator is vertically arranged on the rotary table; a servo sliding table is arranged on the upper end surface of the base; and a grinding wheel component is arranged on a sliding block of the servo sliding table. The automatic worm residual tooth removing device has the advantages that a sharp blade part on each residual tooth of the worm can be rapidly and uniformly ground to smooth, so that the processing efficiency is improved, and the reject rate of a product is lowered.

Owner:ZHEJIANG ESSOR PRECISION MACHINERY

Full-automatic feed grinding device for livestock raising and using method

The invention provides a full-automatic feed grinding device for livestock raising. The grinding device comprises a case body, wherein a material fixing case is arranged at the upper half part in thecase body, and a feeding pipe which communicates with the outside is fixedly arranged at the left half part of the inner wall of the top of the material fixing case; and the inner wall of the bottom of the fixed material case is a slope from high to low from the left to the right. The full-automatic feed grinding device has the beneficial effects that the structure is simple, and the operation iseasy and convenient to achieve; large-particle feed can be subjected to grinding treatment, and the amount of feeding at each time is very uniform; the problem that the feed grinding particles are toolarge due to the fact that the single feeding amount is too much during manual operation is solved, so that the four requirements of fine grinding, uniform grinding, quantitative grinding and automatic grinding on the feed are realized; and the method is simple, efficient, convenient and rapid.

Owner:黎星满

Autoclaved aerated concrete brick waste treatment device

ActiveCN114749464AFacilitate continuous circulationEvenly groundSolid waste managementSolid waste disposalBrickWaste treatment

The invention discloses an autoclaved aerated concrete brick waste treatment device, and belongs to the technical field of environmental protection material recovery treatment, the autoclaved aerated concrete brick waste treatment device comprises a rack and a material guide assembly fixedly connected to the top of the rack, the top of the material guide assembly is provided with a deep grinding assembly, and the top of the deep grinding assembly is provided with a crushing assembly; the crushing assembly comprises a lower conical cover and an upper conical cover fixedly connected to the top of the lower conical cover. By arranging the material guiding assembly, the deep grinding assembly and the crushing assembly, collected waste can be subjected to integrated treatment, the crushing assembly crushes fragments generated by cutting, subsequent deep grinding is facilitated, the crushing assembly can drive a discharging component to move synchronously when executing the crushing function, and the crushing efficiency is improved. And meanwhile, washing and grinding are conducted through water in the deep grinding assembly, and dust diffusion can be avoided.

Owner:安徽玉龙新型建材有限公司

An intelligent lotus seed whitening device

ActiveCN105054259BEvenly groundRealize quantitative exportFood treatmentSurface mountingPulp and paper industry

The invention relates to an intelligent lotus seed whitening device, which includes a whitening system, a lotus skin collecting device and a lotus seed exporting device, wherein a weight sensor is installed on the lower surface of the grinding wheel in the whitening system; the lotus skin collecting device is installed on the whitening At the lower end of the system, the lotus seed exporting device is installed on the side wall of the whitening system; the weight sensor is connected with the lotus seed exporting device, and when the reduction of lotus seeds in the sandpaper tube reaches the set value, the lotus seed exporting device is closed. On the basis of the original whitening device, a flip blade with a matte material that rotates at a different speed from the device's grinding wheel is added to achieve uniform whitening in all directions. A weight sensor is added at the bottom of the grinding wheel, which can realize the quantitative export of lotus seeds after the whitening process, which is convenient for quantitative packaging. A color sensor is added in the whitening device. During the whitening process, when the lotus seeds change from brown to white, the color sensor senses and accurately controls the degree of whitening during the whitening process.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Automatic worm gear removal device and method for removing residual teeth

The invention relates to an automatic worm residual tooth removing device capable of smoothening residual teeth on the two sides of a worm at a time and a residual tooth removing method thereof. The automatic worm residual tooth removing device is characterized in that two movable seats are oppositely arranged on the upper end surface of a base; a variable track rotating clamp assembly is arranged on each of the two movable seats; the two variable track rotating clamp assemblies are synchronously driven to rotate by two stepping motors respectively; two cylinders are arranged on the upper end surface of the base, and are respectively positioned on the two sides of the two movable seats; piston ends of the two cylinders are fixedly connected with the outer side surfaces of the two movable seats respectively; a rotary table mounting seat is arranged on one side of the base; a rotary table is horizontally mounted on the rotary table mounting seat; a mechanical hand is horizontally arranged on the table surface of the rotary table; a clamping part of the mechanical hand is positioned right between the two movable seats; a servo sliding table is arranged on the upper end surface of the base; and a grinding wheel assembly is arranged on a sliding block of the servo sliding table. The automatic worm residual tooth removing device has the advantages that residual sharp edge parts on the worm can be quickly and uniformly smoothened, so that the processing efficiency is improved, and the rejection rate of a product is decreased.

Owner:ZHEJIANG ESSOR PRECISION MACHINERY

Grinding apparatus

ActiveUS20190067018A1Avoid excessive wearEfficiently make hydrophilicRevolution surface grinding machinesAbrasion apparatusEngineeringGrinding wheel

A grinding apparatus includes a table that holds a workpiece, and a grinding unit including a grinding wheel mounted to a spindle. The grinding wheel has a grindstone formed by binding abrasive grains with a bonding agent. In addition, the grinding apparatus further includes: a grinding water supply unit that supplies grinding water to at least the grindstone; a light applying unit that is disposed adjacent to the table and that applies light to a grinding surface of the grindstone grinding the workpiece held by the table; and a light applying unit moving section by which the light applying unit can be positioned at a first position on a rotational trajectory of the grinding wheel in the case where the grinding wheel has a first diameter and a second position on a rotational trajectory of the grinding wheel in the case where the grinding wheel has a second diameter.

Owner:DISCO CORP

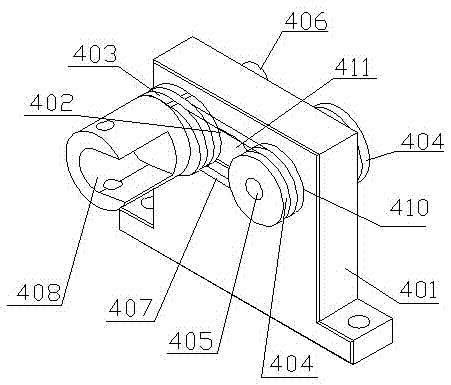

Worm gear removal device

The invention relates to a residual tooth removing device for a worm. The residual tooth removing device can rapidly and uniformly grind a sharp blade part on a residual tooth of the worm to smooth. A grinding wheel component is arranged on the upper end surface of a base and on one sides of a movable seat and a fixed seat and is composed of a supporting plate, two bearings, two cams, two grooved wheels, a grooved wheel shaft, a cam shaft, two elastic tightening belts, an apex seat, apexes, a rotary wheel, a driving plate and a hoop; a grooved wheel shaft hole and a cam shaft hole are formed in the supporting plate side by side; the grooved wheel shaft is installed in the grooved wheel shaft hole through one bearing; the grooved wheels are installed at the two ends of the grooved wheel shaft respectively; the cam shaft is installed in the cam shaft hole through the other bearing; the cams are installed at the two ends of the cam shaft respectively; the two cams and the two grooved wheels are close together through the two elastic tightening belts respectively; the rotary wheel is installed at the end of the outer side of the cam shaft; the apex seat is installed at the end of the inner side of the cam shaft; and the apexes are arranged in the apex seat. The residual tooth removing device has the advantages of improving the processing efficiency, lowering the reject rate of a product and simultaneously weakening the labor intensity of personnel.

Owner:ZHEJIANG ESSOR PRECISION MACHINERY

Spraying part rough grinding and spraying all-in-one machine

InactiveCN112338810AEvenly groundImprove work efficiencyAbrasive machine appurtenancesSpray boothsMachiningDust pollution

The invention relates to the technical field of spraying, in particular to a spraying part rough grinding and spraying all-in-one machine. In the spraying industry, spraying parts are basically pre-machined in a manual rough grinding manner, efficiency is low, and the hurt to the bodies of staff is large. In order to solve the above problems, the following technical scheme is adopted, wherein thethe spraying part rough grinding and spraying all-in-one machine comprises a rough grinding station and spraying stations and further comprises a bottom frame, three stations are arranged on the bottom frame, the rough grinding station is arranged in the middle, the spraying stations are arranged on two sides, a conveying device is arranged among the three stations, and the conveying device can carry spraying parts to move back and forth among the three stations; and the conveying device comprises sliding grooves formed in the bottom frame and a tackle capable of sliding in the sliding groovesin the forward direction and the reverse direction, the spraying parts are placed on the tackle, and two spraying part containing positions are arranged on the tackle side by side in the conveying direction. According to the scheme, flying dust pollution during manual rough grinding is avoided, mechanical machining is adopted, and the working efficiency is high.

Owner:德清德奥热喷涂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com