Worm gear removal device

A technology of residual teeth and worms, which is applied in the field of worm processing equipment manufacturing, can solve problems such as low processing efficiency, high labor intensity of personnel, and inability to grind residual teeth, so as to improve processing efficiency, reduce labor intensity of personnel, and reduce product scrap rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

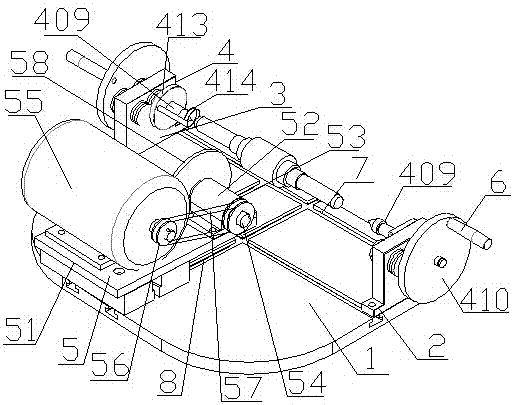

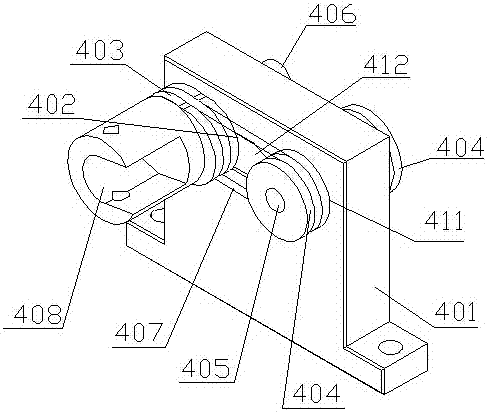

[0009] Embodiment 1: with reference to attached figure 1 and figure 2 . A worm gear removal device, comprising a base 1, the upper end surface of the base 1 is provided with a moving seat 2 and a fixed seat 3 oppositely, and a group of top components 4 are respectively arranged on the moving seat 2 and the fixed seat 3, and the moving seat 2 and the base 1 between the fixed seat 3 is provided with a track 7, the track 7 is convenient for the movable seat 2 to move and adjust the relative distance between the movable seat 2 and the fixed seat 3, so that the worm can be clamped on the two tops of the two sets of top components 4 Between 409, the upper end surface of the base 1 is provided with a grinding wheel assembly 5 and the grinding wheel assembly 5 is located on the side of the moving seat 2 and the fixed seat 3, the base 1 is provided with a track-8 and the track-8 is perpendicular to the track 7, and the track -8 facilitates the movement of the grinding wheel assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com