Powder flattening device for dry pressing large-size laser transparent ceramic green bodies

A laser-transparent, large-scale technology, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of evenly paving ceramic powder and uneven densification of green bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

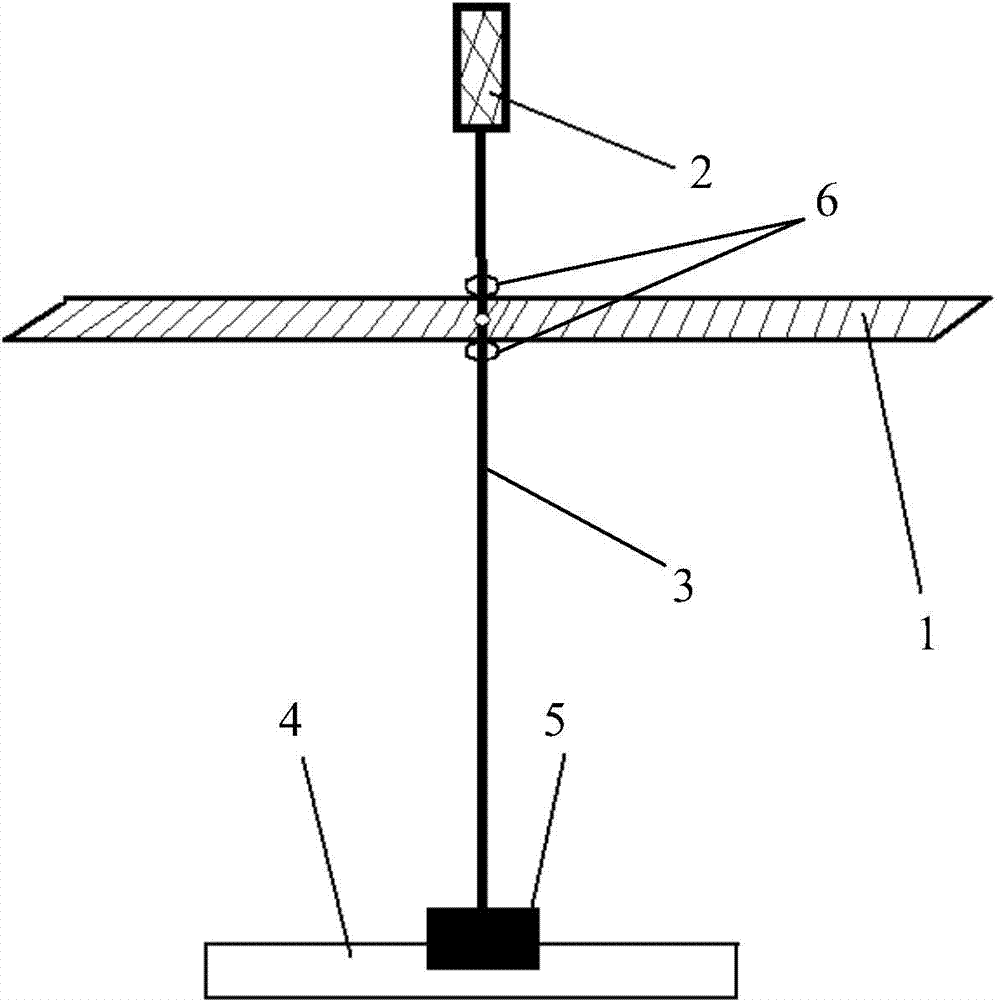

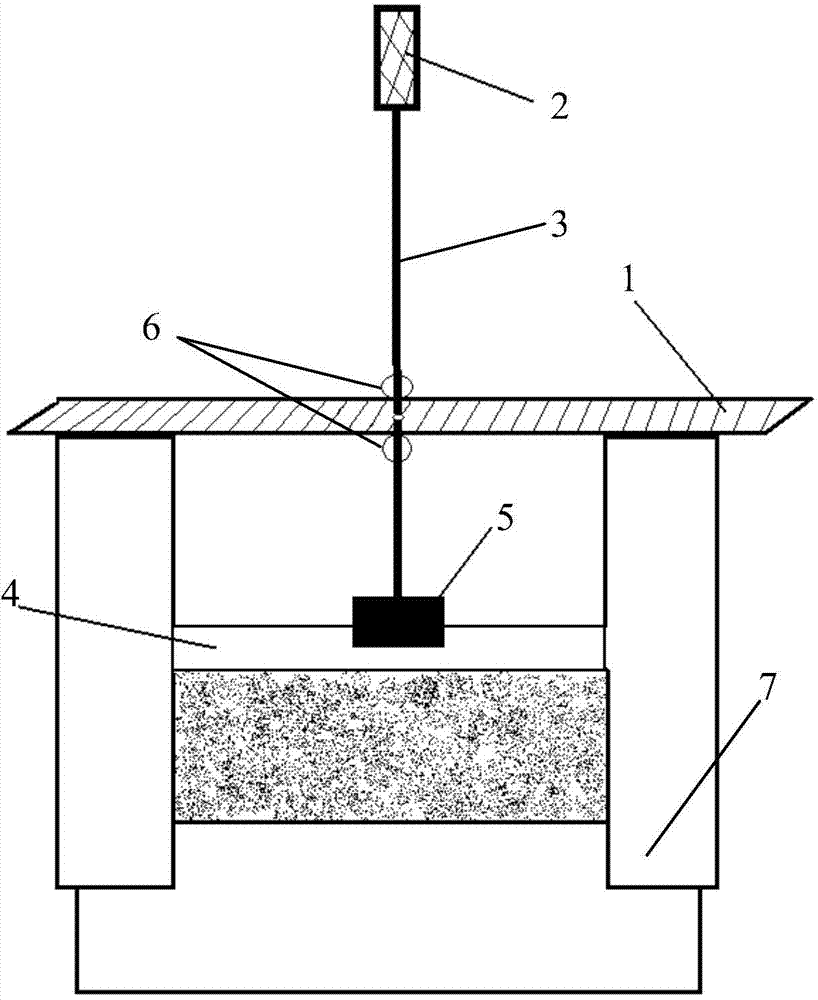

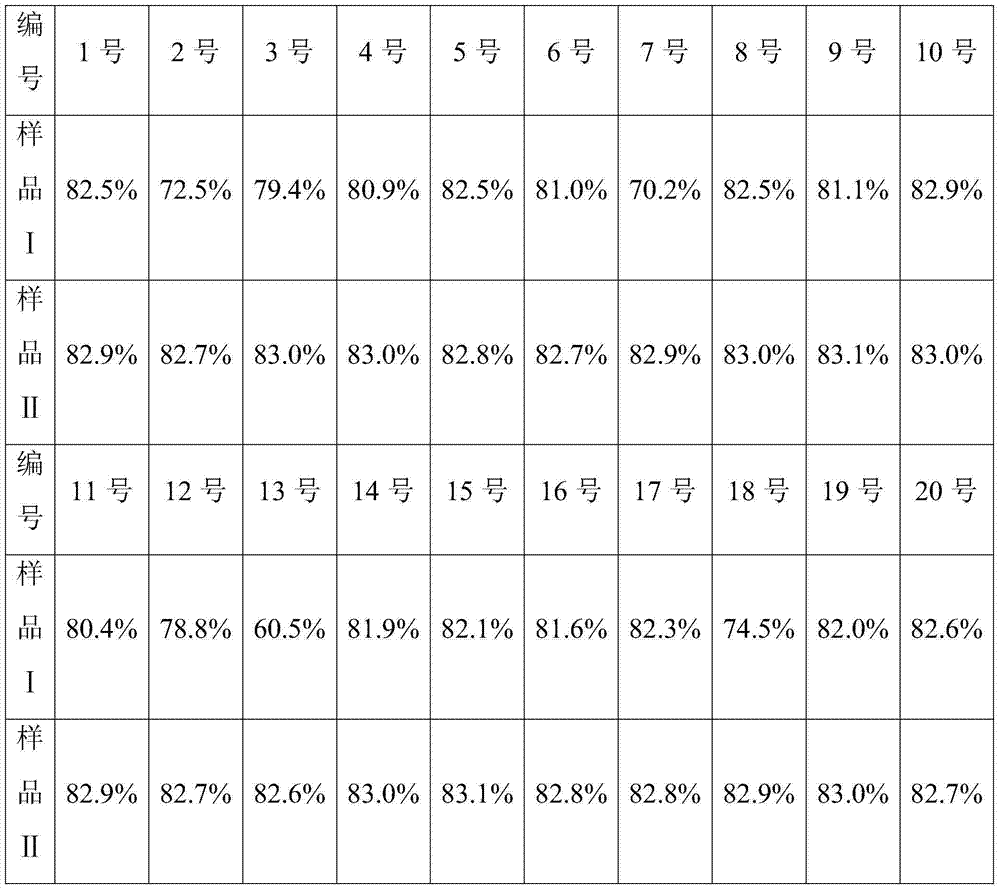

[0033] Such as figure 2 As shown, it is a schematic diagram of the specific use of the combined mold 7 of the present invention. First, about 130g of laser transparent ceramic powder is poured into a mold with a diameter of 100mm; the PVC transparent A4 film with a thickness of 0.3mm is cut into a size of 99.5mm× 20mm rectangular flattening plate 4, then insert the flattening plate 4 into the clamping groove 5 at a symmetrical position in the middle and clamp it; place the device of the present invention on the mold, rotate the handle 2, and adjust the height of the handle bar 3 properly until it is in the mold The laser transparent ceramic powder is completely evenly spread; after that, the mold can be closed and pressed into tablets to obtain a large-sized and high-quality laser transparent ceramic green body with uniform internal density, and then go through sintering, annealing, polishing and other processes. Obtain high-quality large-scale laser-transparent ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com