Automatic worm gear removal device and method for removing residual teeth

A technology for worms and residual teeth, which is applied in the field of automatic worm gear removal devices, can solve the problems of low processing efficiency, inability to grind residual teeth, and high labor intensity, so as to improve processing efficiency, reduce product scrap rate, and reduce labor costs. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

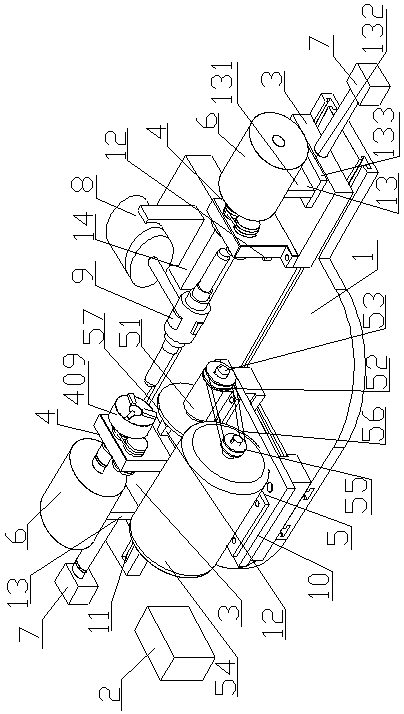

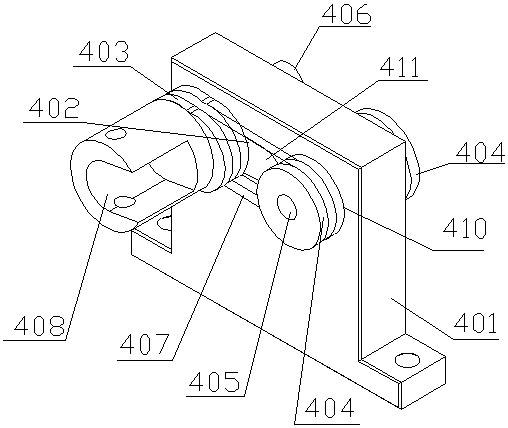

[0010] Embodiment 1: with reference to attached figure 1 and figure 2 . An automatic worm gear removal device, comprising a base 1 and a controller 2, two moving seats 3 are provided opposite to each other on the upper end of the base 1, and a group of variable trajectory rotating clamp assemblies 4 are respectively arranged on the two moving seats 3, The base 1 between the two moving seats 3 is provided with a track 11, the track 11 is convenient for the relative movement of the two moving seats 3, so that the worm can be clamped between the two pneumatic chucks 409 of the two groups of variable trajectory rotating clamp assemblies 4, so Two sets of shock absorbing stoppers 12 are arranged on the track, and the shock absorbing stoppers 12 ensure that the two sets of variable trajectory rotary clamp assemblies 4 driven by the two cylinders 7 can clamp the worm at a predetermined position. The track rotating clamp assembly 4 is driven to rotate synchronously by two stepping ...

Embodiment 2

[0011]Embodiment 2: On the basis of Embodiment 1, a method for removing residual teeth of an automatic worm screw removal device, firstly place the worm on the manipulator 9 and adjust the worm so that the outer contour of the residual teeth to be polished in the worm and the cam 403 The outer contours are aligned; then the grinding wheel 57 grinds the remaining teeth on one side of the worm. Under the control of the controller 2, firstly, when the manipulator 9 clamps the middle part of the worm, the two cylinders 7 push the two moving seats 3 so that the two ends of the worm are located at the two ends. Among the two pneumatic chucks 409, the second two pneumatic chucks 409 clamp the two ends of the worm while the manipulator 9 releases the worm, and then two stepping motors 6 synchronously drive the two pneumatic chucks 409 and are clamped between the two pneumatic chucks 409. While the worm rotates, the slider of the servo slide 10 drives the grinding wheel assembly 5 to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com