Autoclaved aerated concrete brick waste treatment device

A concrete brick and waste treatment technology, which is applied in grain treatment, transportation and packaging, solid waste removal, etc., can solve the problems of poor treatment effect, lack of segmental crushing and grinding mechanism, high energy consumption, etc., and achieve convenient and uniform grinding Thin, convenient and continuous circulation, and the effect of accelerating the crushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

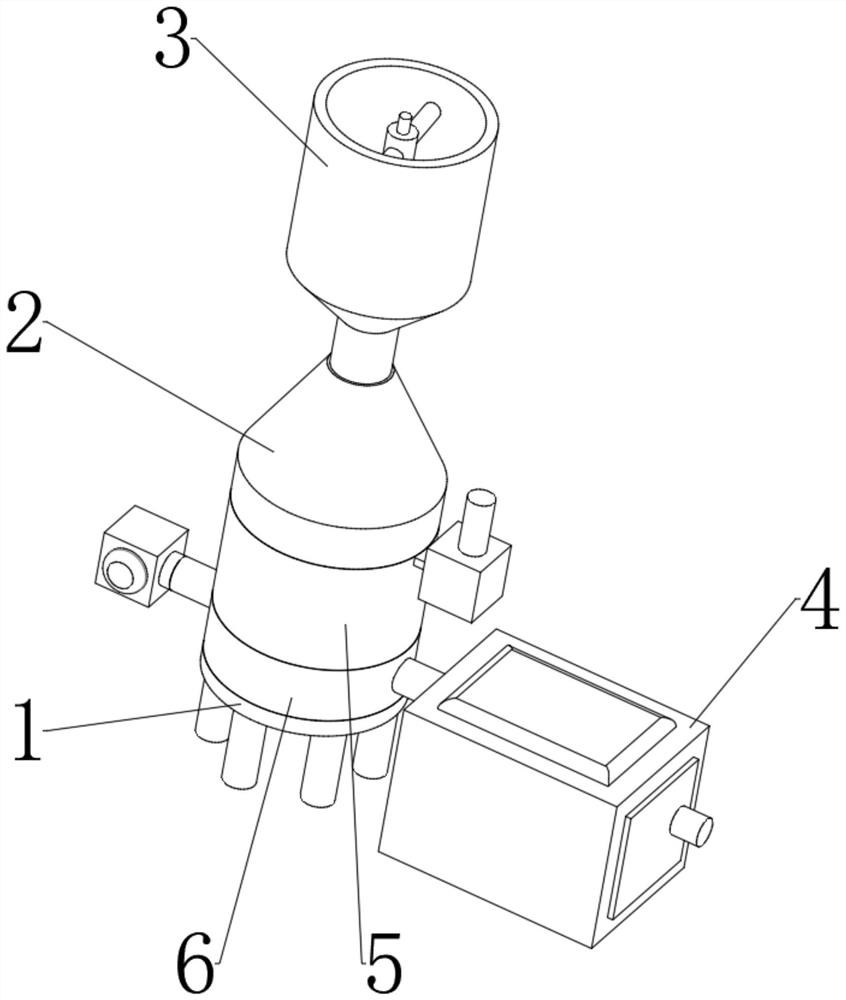

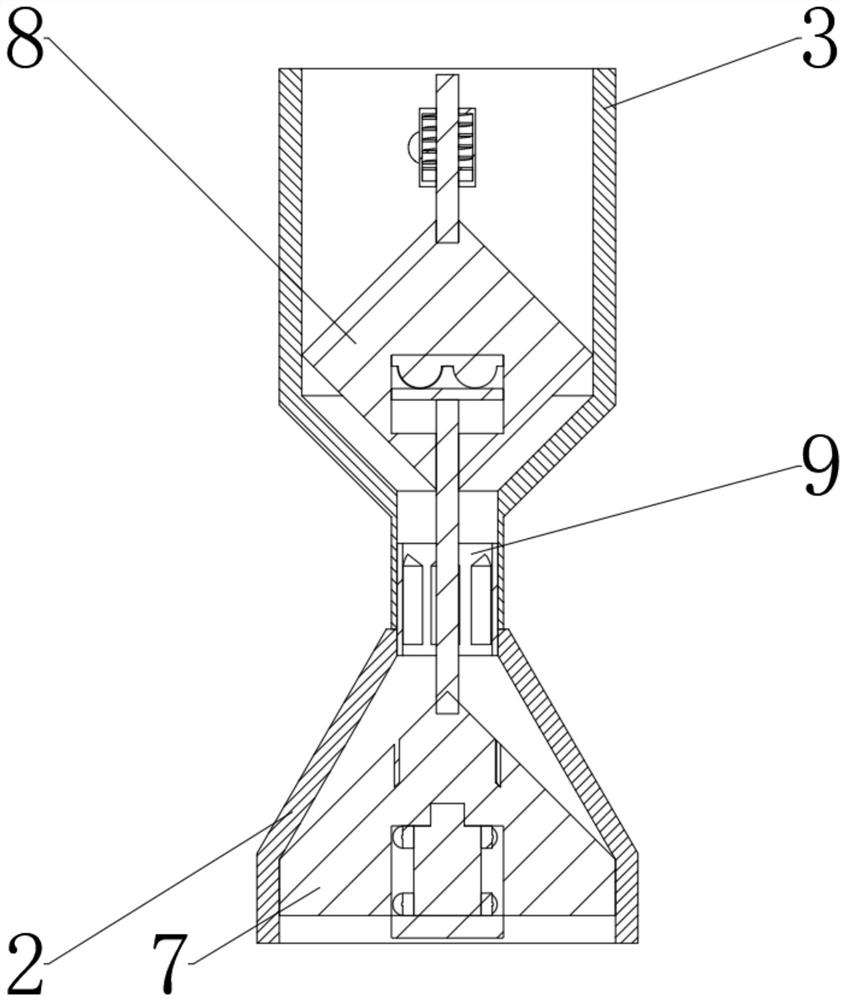

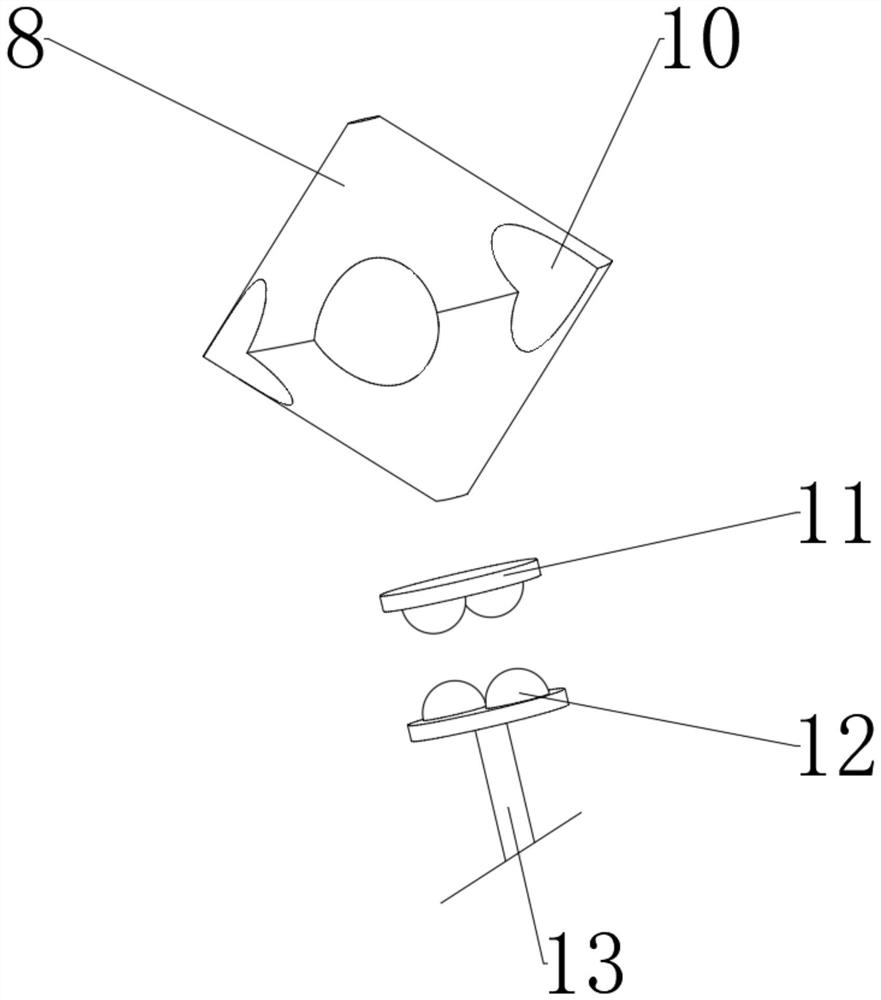

[0030] like Figure 1-Figure 9 As shown in the figure, the autoclaved aerated concrete brick waste processing device provided in this embodiment includes a frame 1 and a material guide assembly fixedly connected to the top of the material guide assembly. The assembly, by setting up a material guide assembly, a deep grinding assembly and a crushing assembly, can integrate the collected waste materials. The crushing function is that it can drive the synchronous movement of the unloading components, so as to facilitate the continuous flow of materials and avoid the blockage of the internal material channel by fragments. At the same time, the water body is used for was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com