Sectional type feed grinding device for animal husbandry and using method

A segmented, feed technology, applied in feed, application, cocoa and other directions, can solve the problems of poor pulverization effect, low degree of automation, high waste rate, and prevent the feed grinding particles from being too large, with simple structure and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

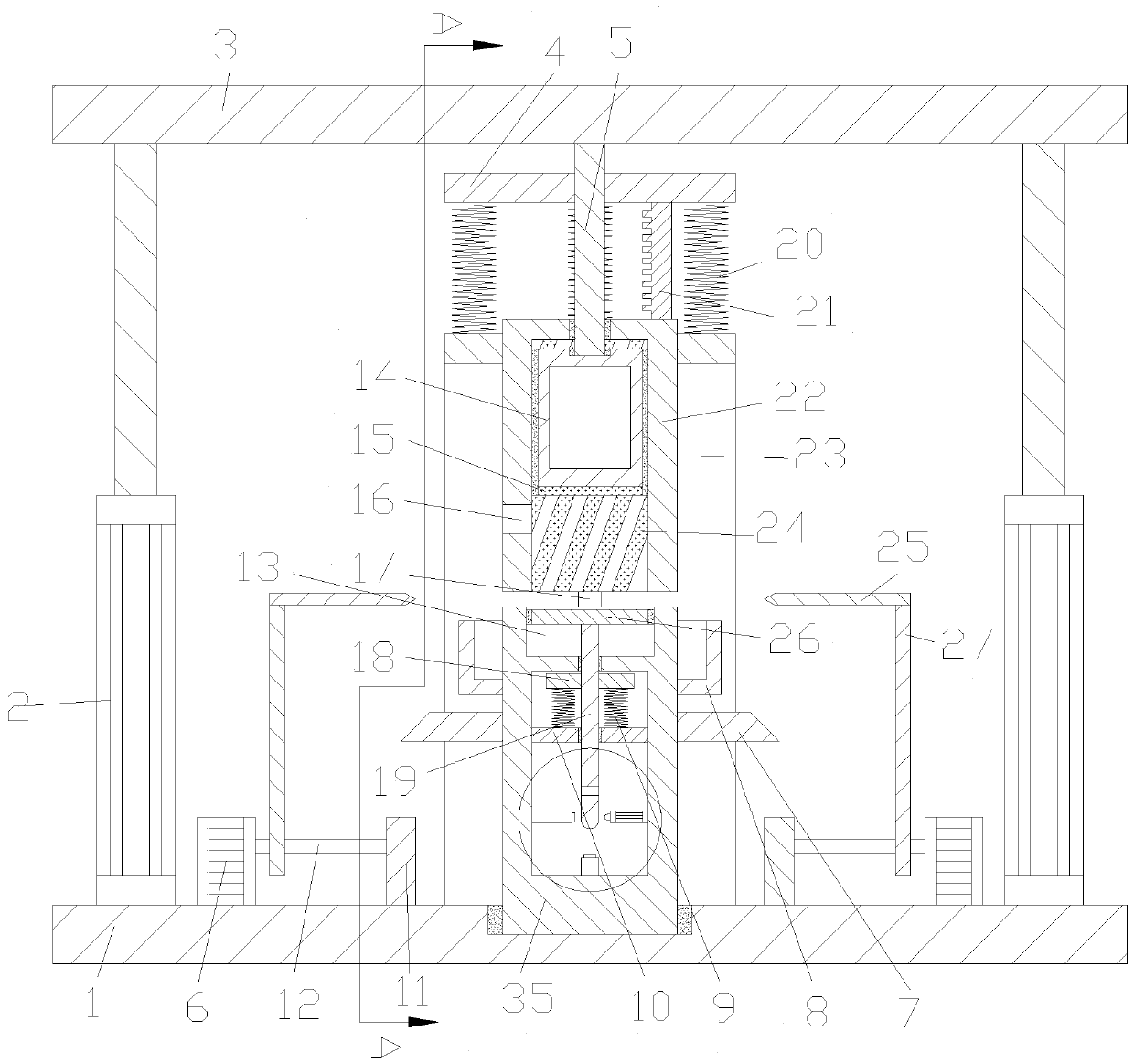

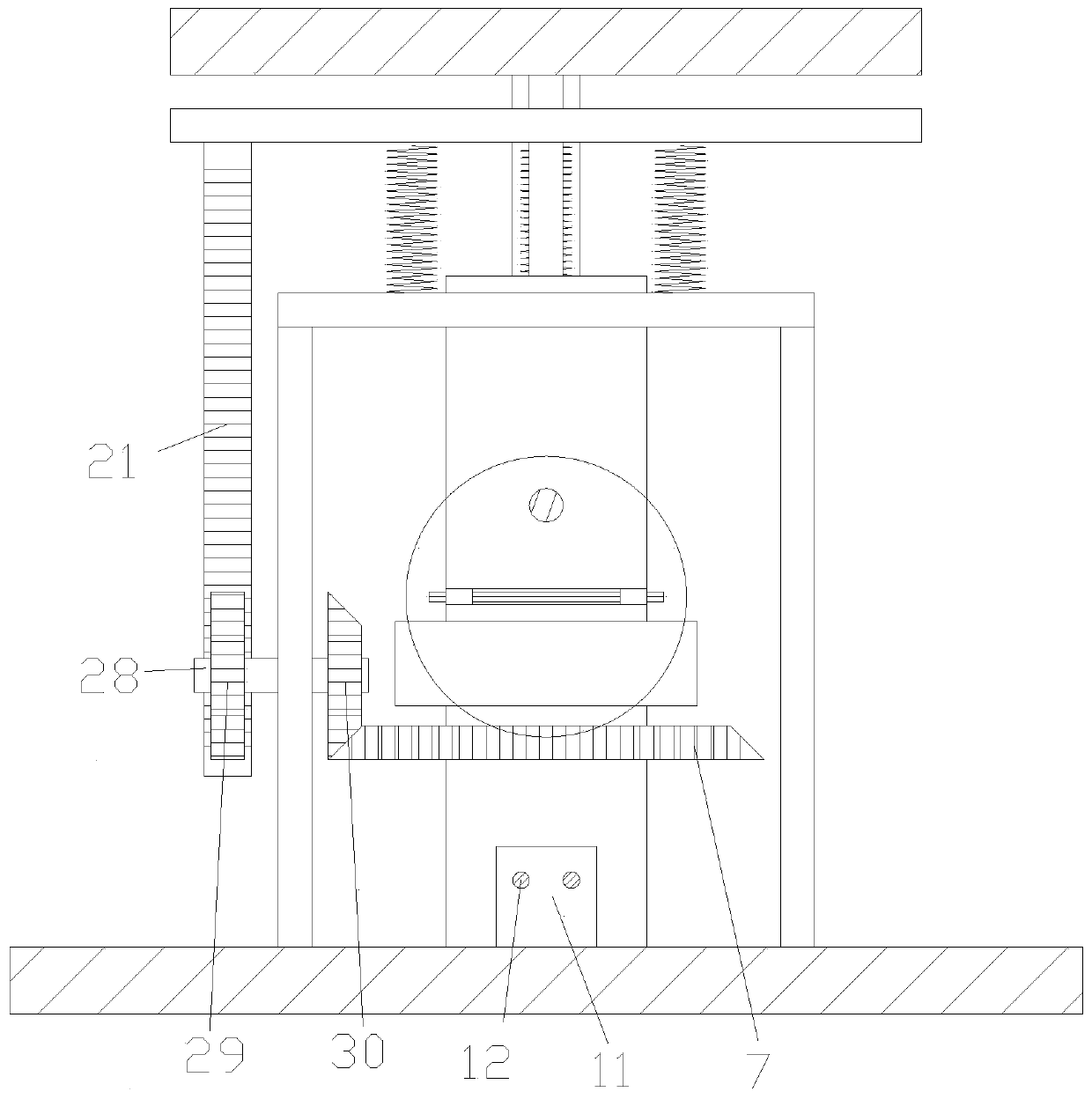

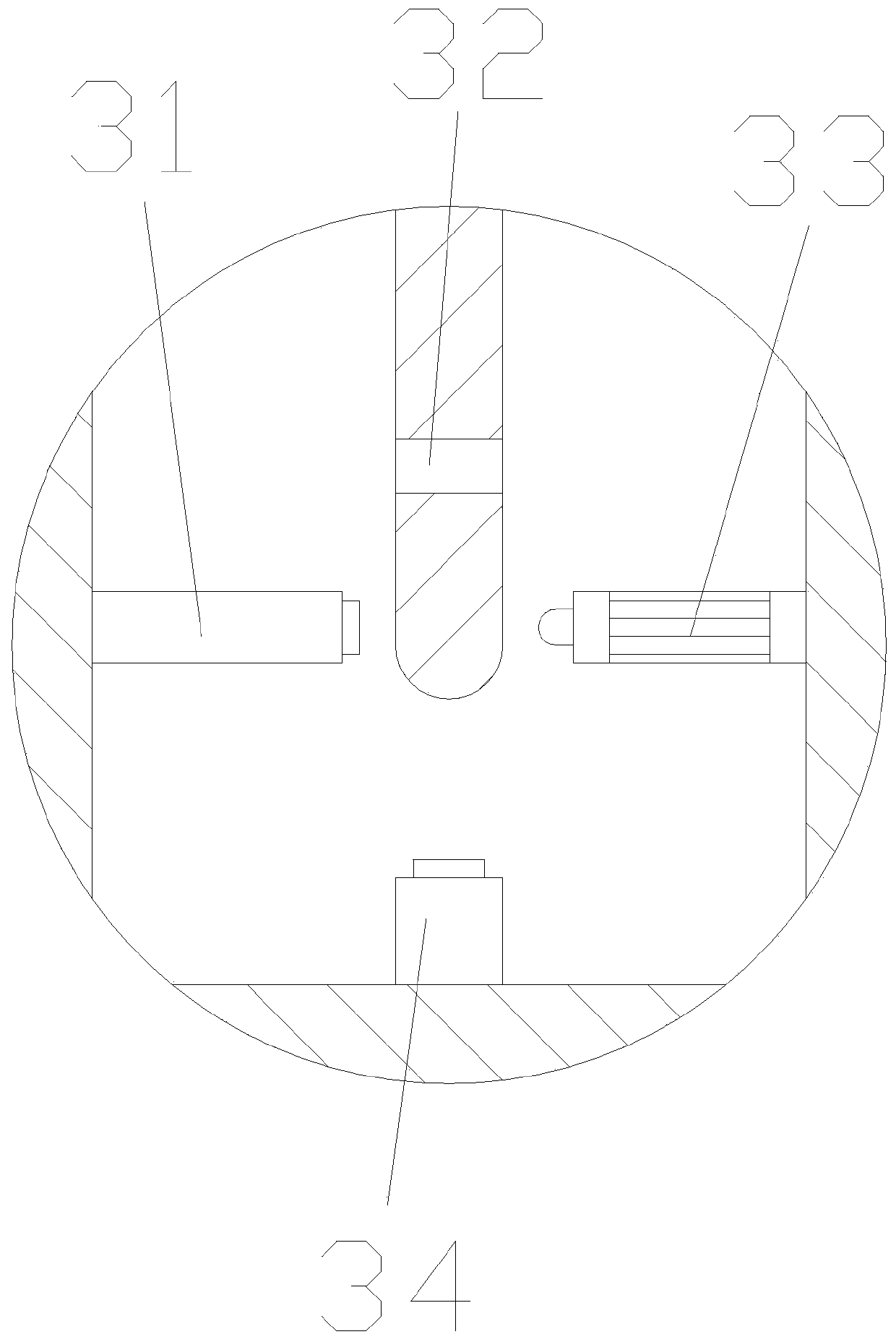

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Refer to attached figure 1 , 2, 3, 4: In this embodiment, the segmented feed grinding device for animal husbandry includes a base 1, the center of the top of the base 1 is movably connected with a lower cylinder 35, and the top of the lower cylinder 35 is provided with a The groove 13, the inner wall of the groove 13 is slidably connected with a grinding plate-26, the partition plate 10 is fixedly installed between the inner walls of the middle part of the lower cylinder 35, and the bottom of the grinding plate-26 is provided with a bottom After passing through the bottom center of the inner wall of the groove 13 and the center of the partition 10 in turn, the sliding rod 19 at the lower half of the lower cylinder body 35 is reached. The sliding rod 19 is fixedly installed on the outer side between the inner wall of the top of the lower cylinder 35 and the partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com