Constant-force grinding system integrating detection with grinding

A detection system and grinding technology, which can be applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of increased grinding force, burns on grinding surfaces, and high labor intensity of workers. , to achieve the effect of improving production efficiency, improving processing quality and expanding grinding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

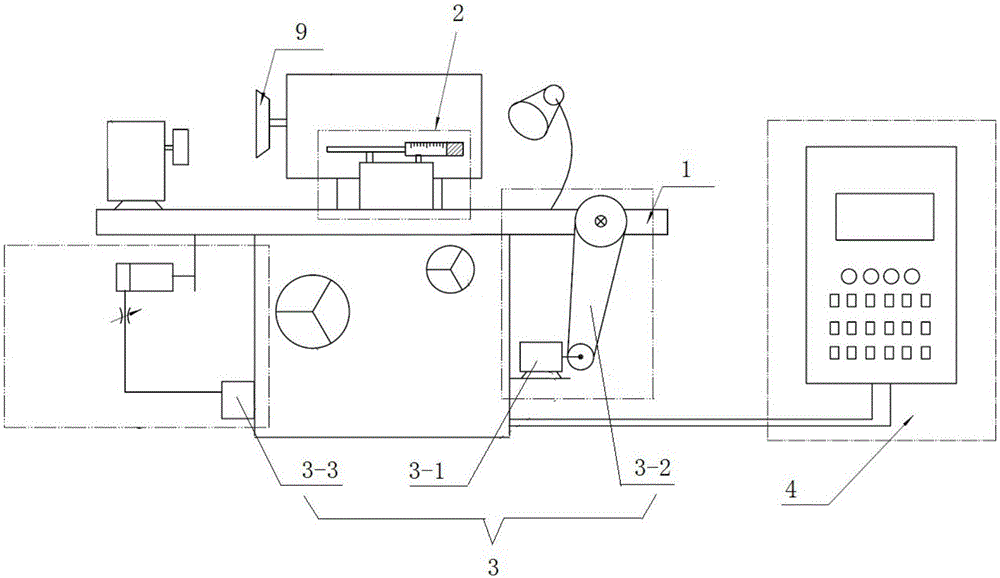

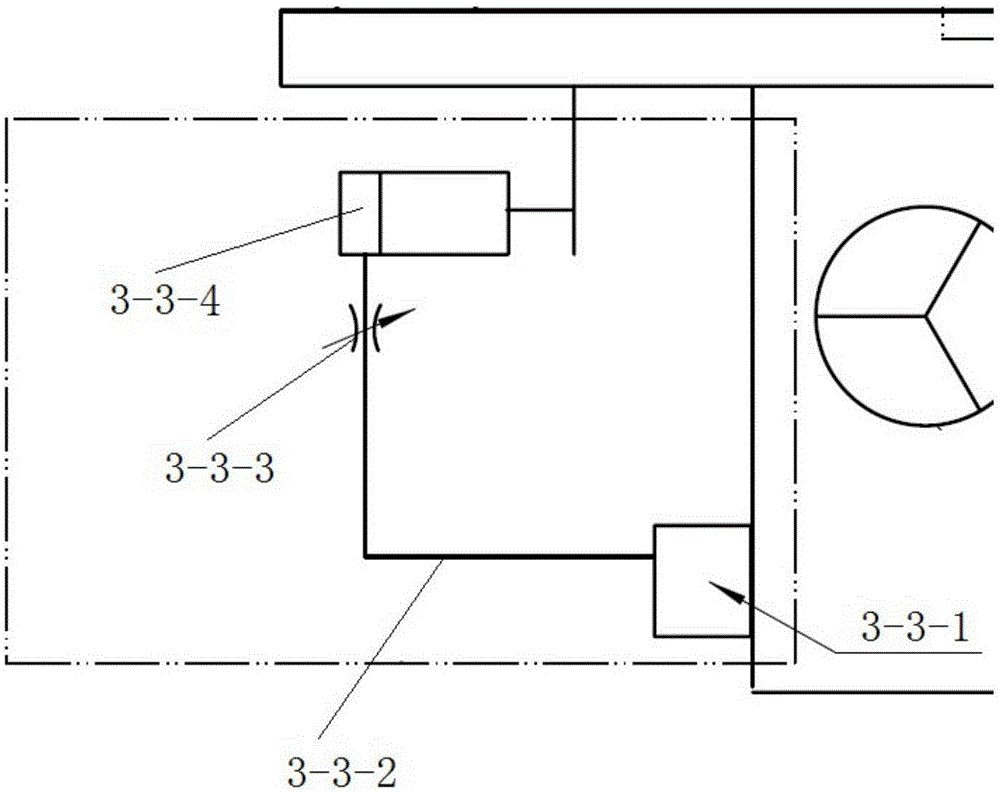

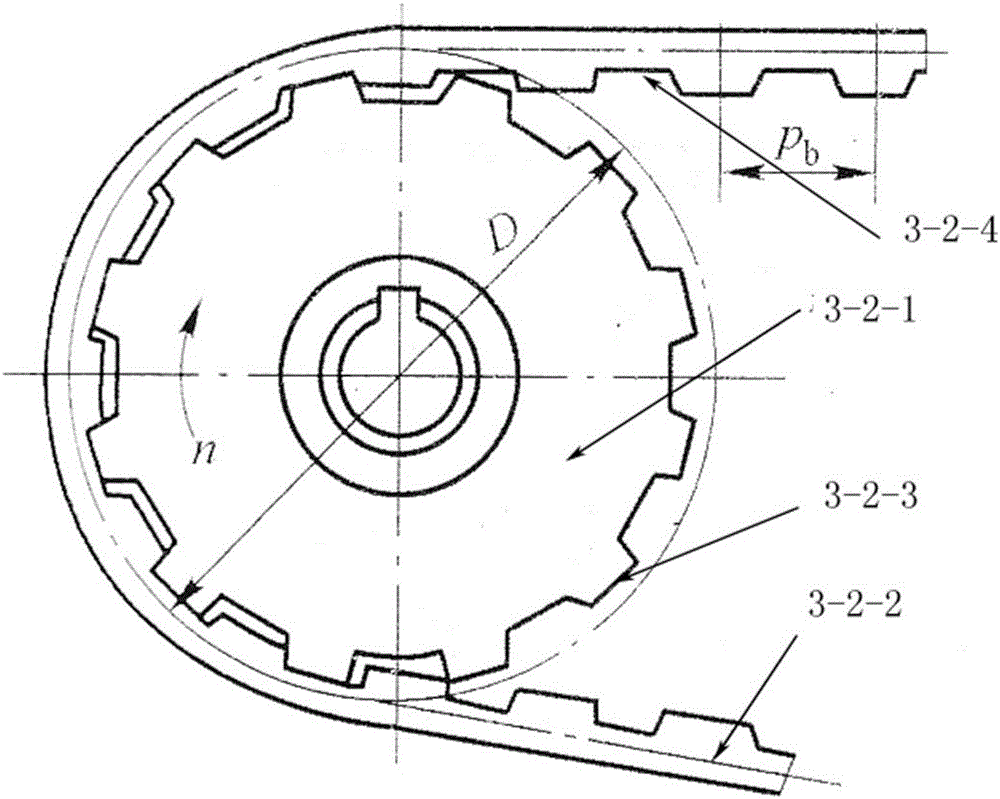

[0032] Such as figure 1 , figure 2 As shown, a constant force grinding system integrating detection and grinding functions includes: a workbench 1, an online inspection system installed on the workbench 1, a constant force grinding system 3, and a controller 4. The controller 4 controls the constant force grinding system 3 to work according to the information fed back from the online detection system 2. The constant force grinding system 3 is composed of a servo motor 3-1, a synchronous transmission mechanism 3-2, and a worktable retracting device 3. -3 composition, the servo motor 3-1 is a constant torque servo motor, the constant torque servo motor is converted into a constant feed force of the worktable 1 through a synchronous transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com