Parallel-type soybean pulping system

A parallel-type, refining technology, which is applied in cocoa, grain processing, food science, etc., can solve the problems that the refining machine is prone to jamming and refining quality, the discharge speed cannot be controlled, and the equipment occupies a large area. Avoid the effects of poor refining quality, compact structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

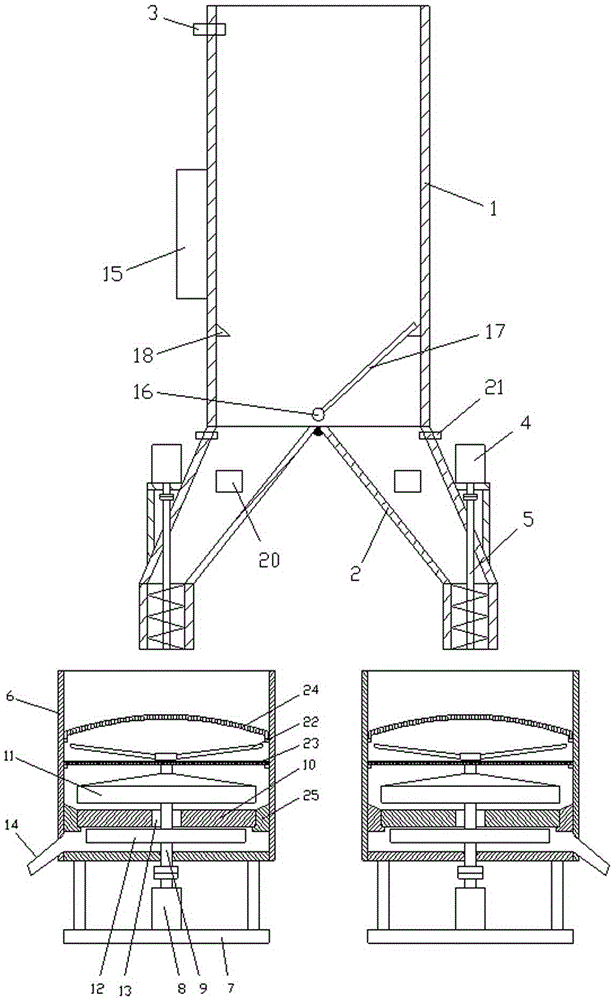

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] As shown in the figure, the parallel soybean refining system in this embodiment includes a transfer bin and a refining device;

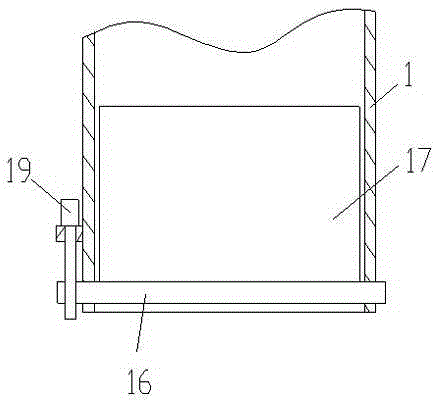

[0022] The transfer silo includes a silo body 1, two discharge pipes 2 symmetrically connected to the lower end of the silo body and a material level sensor 3 arranged on the silo body;

[0023] The discharge pipe is also provided with a uniform discharge mechanism, and the uniform feed mechanism includes a discharge motor 4 fixed outside the discharge pipe and a screw feed shaft arranged in the discharge pipe and connected with the rotor of the discharge motor 5;

[0024] The refining device is arranged in parallel under each discharge pipe, and the refining device includes a cylindrical casing 6, a support 7 supporting the casing, and a refining motor 8 arranged on the support. , and the rotating shaft 9 that is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com