Ceramic blank automatic polishing machine

A ceramic embryo, automatic technology, applied in ceramic molding machines, grinding racks, grinding machine parts, etc., can solve the problems of manual grinding process, low production efficiency, uneven product quality, etc., to achieve automation Grinding embryos, improving the grinding effect and narrowing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. Numerous details are described below in order to provide a thorough understanding of the present invention, but for those skilled in the art, the present invention may be practiced without these details.

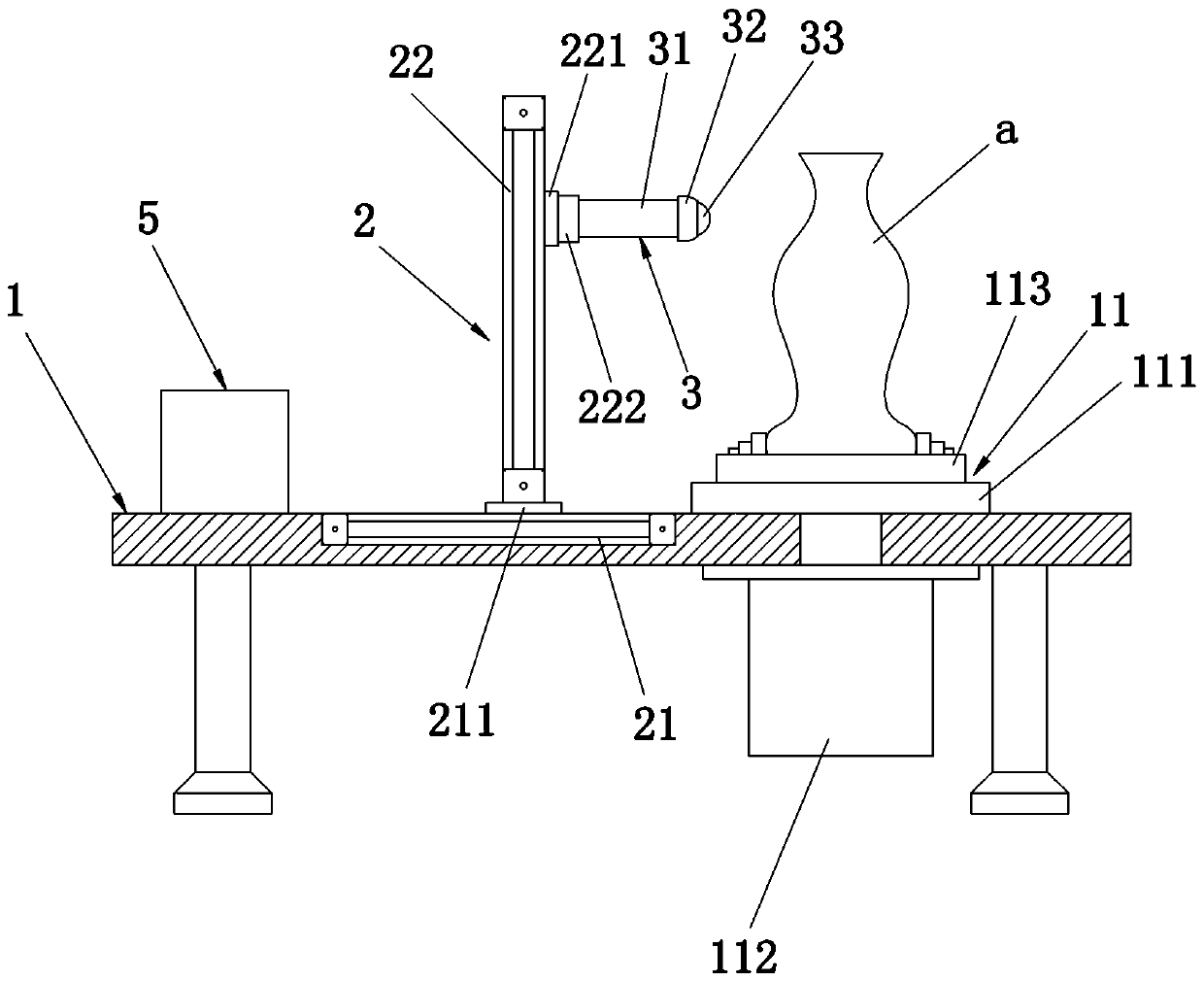

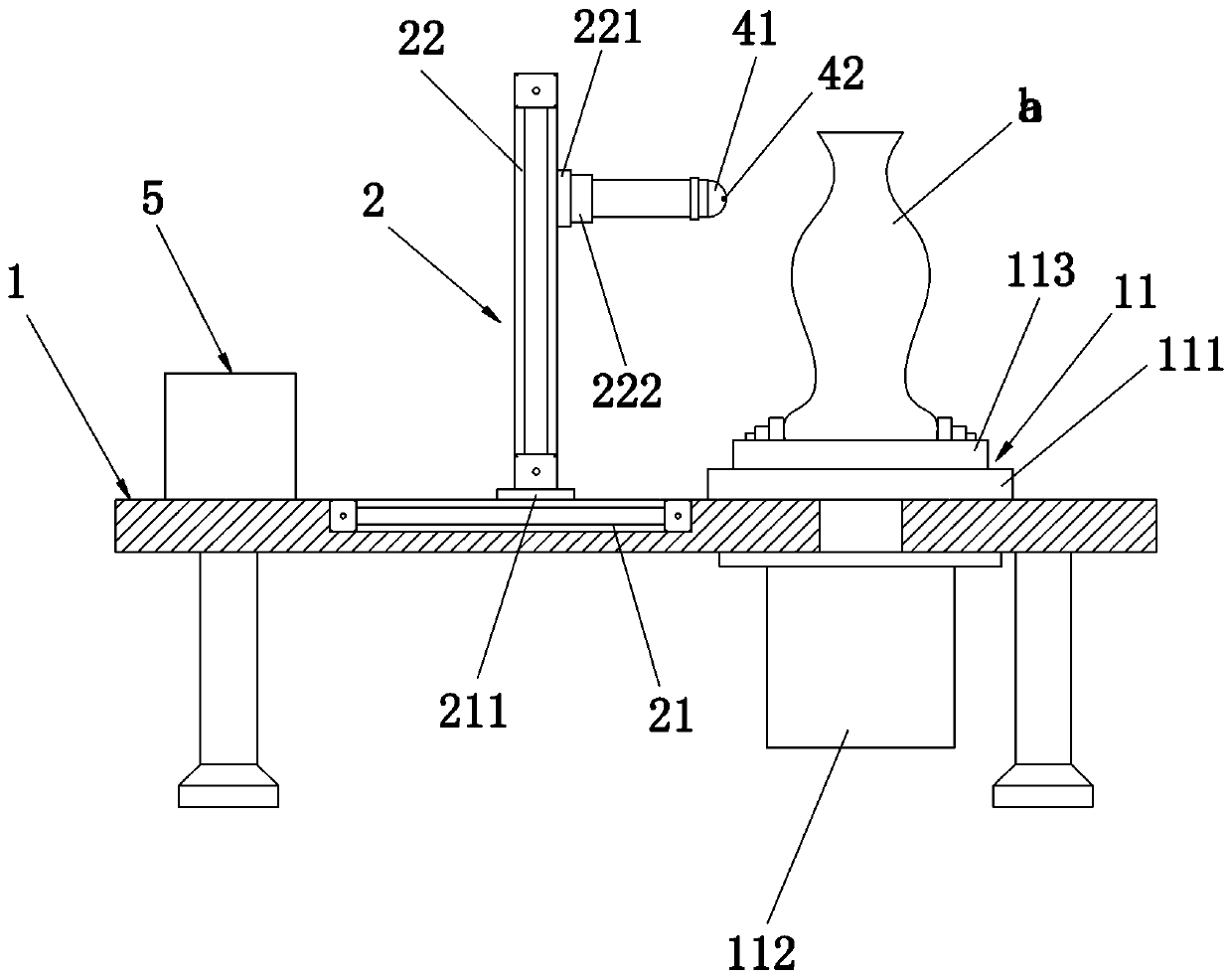

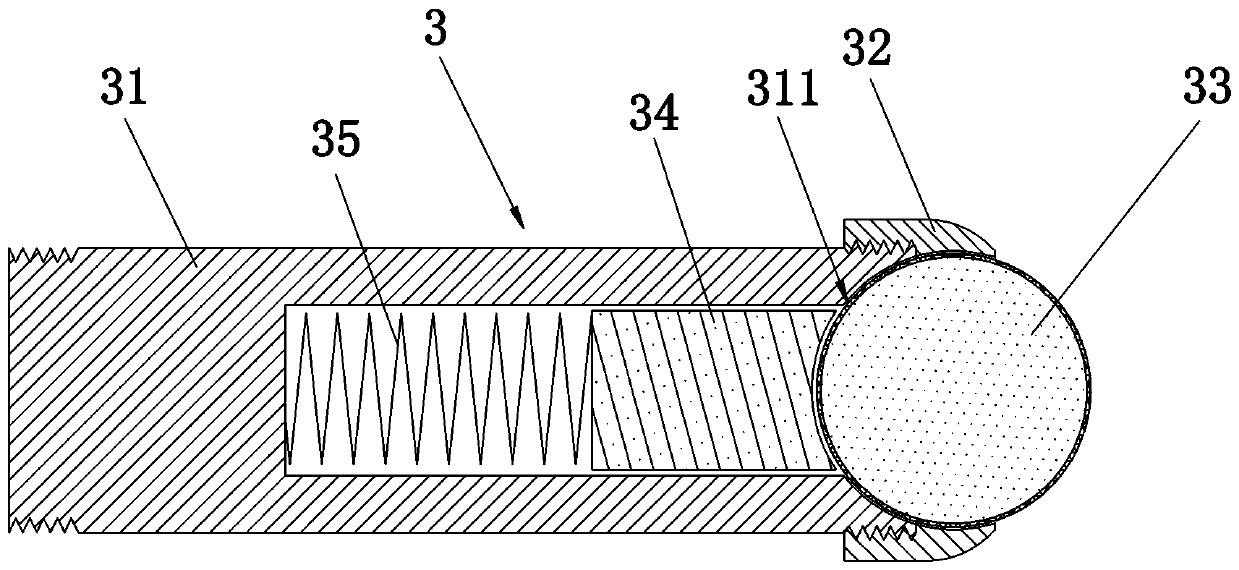

[0022] refer to figure 1 , a ceramic automatic grinding machine, including a worktable 1, a sandbag grinding head 3 and a driving device 2, the worktable 1 is rotatably provided with a fixed seat 11 for placing a ceramic embryo, and the sandbag grinding head 3 is arranged on the worktable 1 It moves up and down along the outer surface of the ceramic body under the action of the driving device 2 to realize the grinding of the ceramic body. Thus, the present invention can realize automatic grinding of the ceramic embryo, which is beneficial to improve the grinding effect and grinding efficiency of the ceramic embryo, and solves the problems that the tradit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com