Polishing device special for up-drawing of oxygen-free copper rod

An oxygen-free copper rod and copper rod technology, used in grinding/polishing safety devices, grinding machines, parts of grinding machine tools, etc. problems, to achieve the effect of smooth copper rod surface, reducing the number of replacements, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

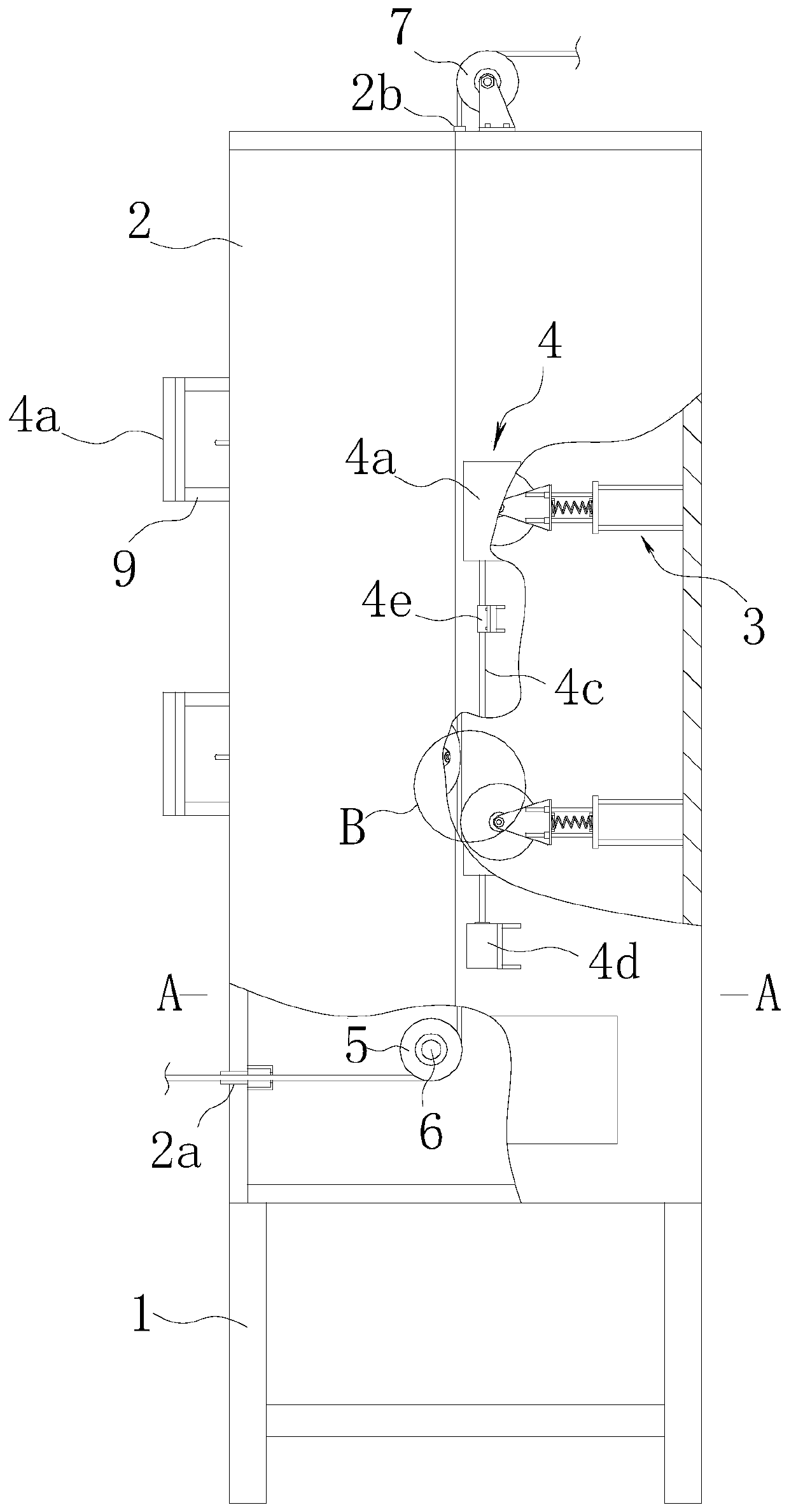

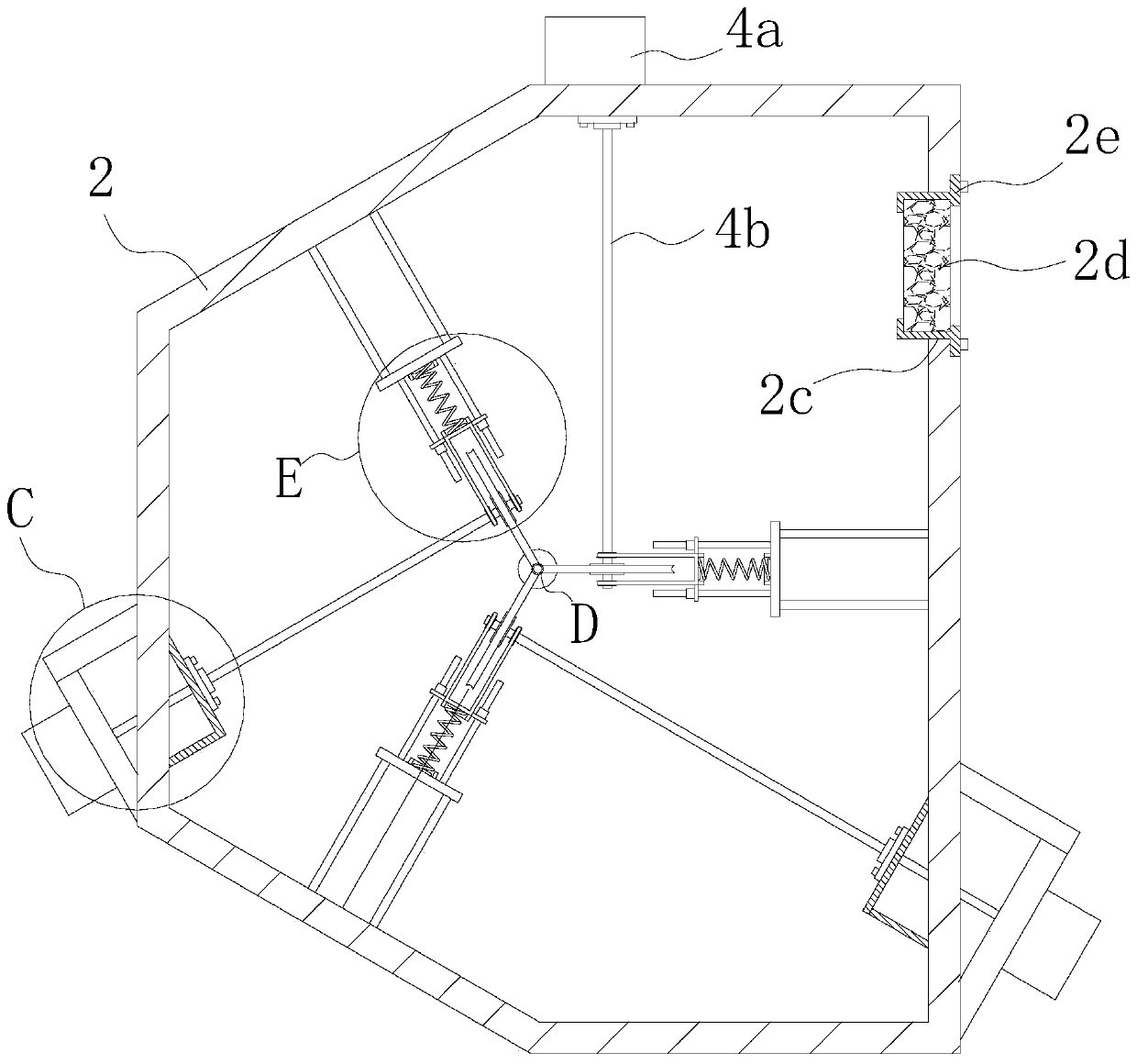

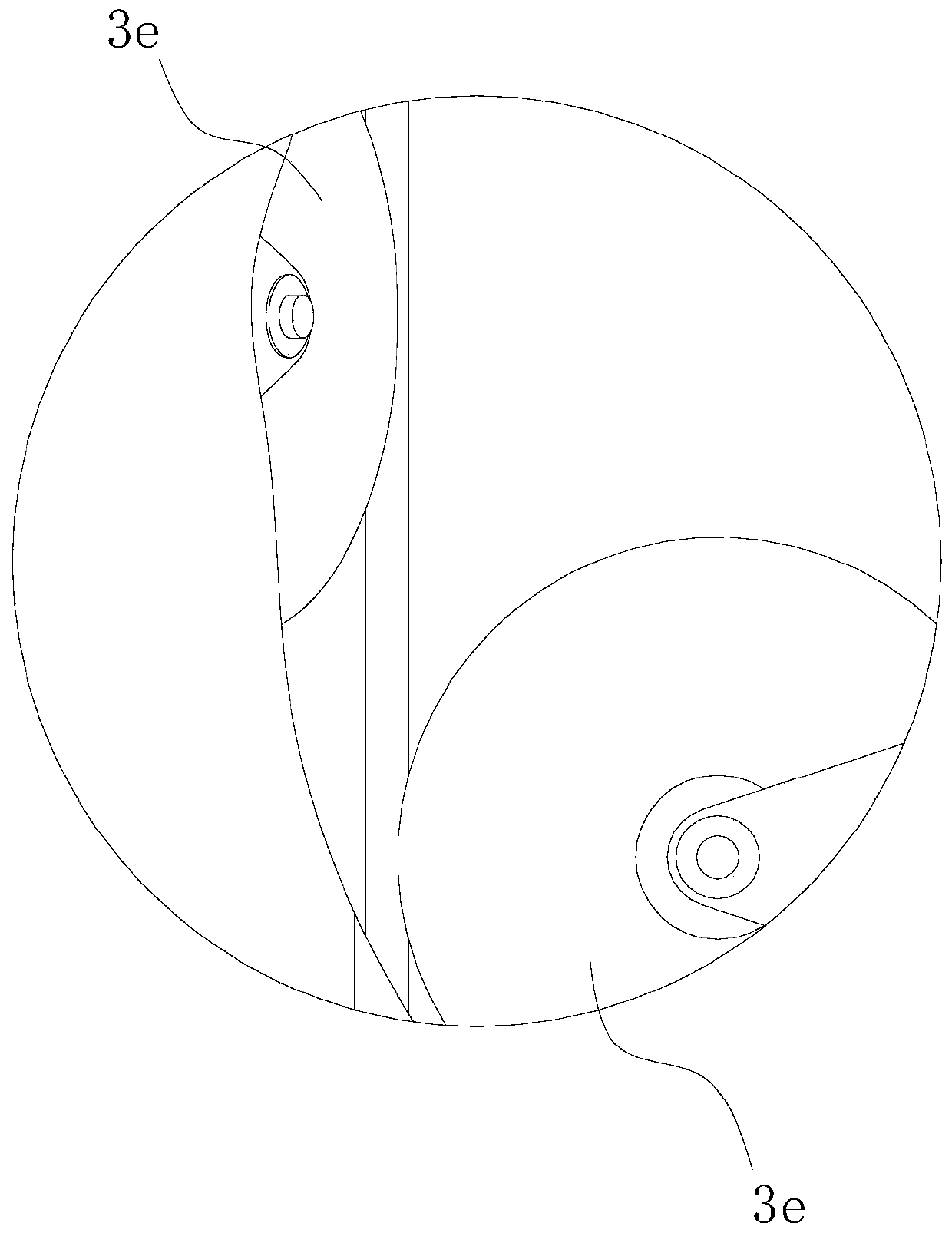

[0023] refer to Figure 1 to Figure 6 As shown, a special polishing device for upwardly drawing oxygen-free copper rods of the present invention includes a bracket 1, a copper powder recovery box 2 is arranged on the bracket 1 along the vertical direction, and a copper powder recovery box 2 is arranged on the lower side wall of the copper powder recovery box. Inspection port, the inspection port is used for maintenance personnel to inspect internal components and remove internal copper powder. Copper powder recovery box 2 is provided with feed hole 2a, discharge hole 2b and exhaust port 2c, and filter cotton 2d is provided at exhaust port 2c; Preferably, described feed hole 2a is positioned at copper powder recovery box 2 On the lower side wall, the discharge hole 2b is located at the top of the copper powder recovery box 2; the copper powder recovery box 2 is provided with a first guide rubber wheel 5 matched with the feed hole 2a and the discharge hole 2b, so that The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com