Patents

Literature

44results about How to "Eliminate indentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

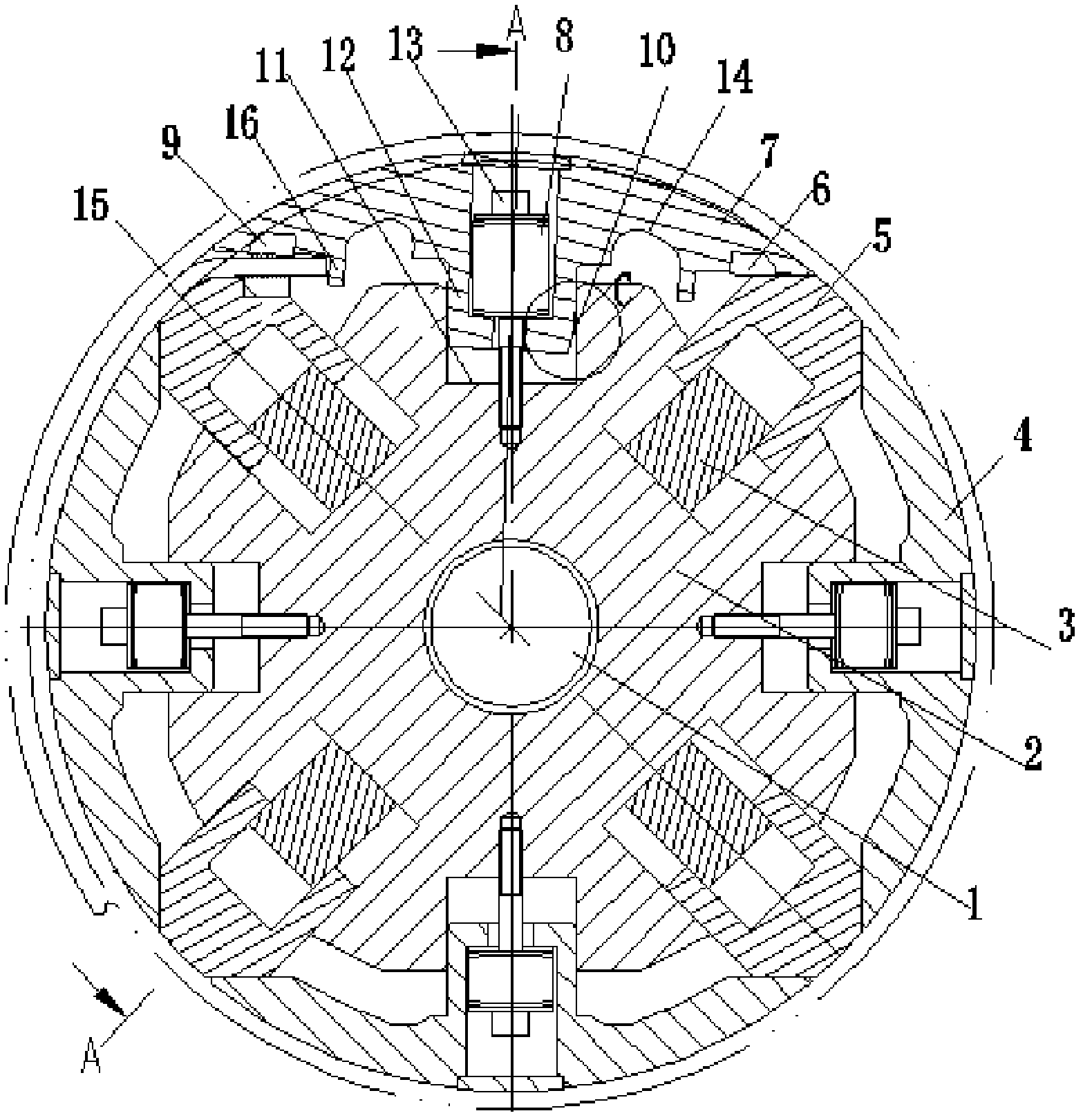

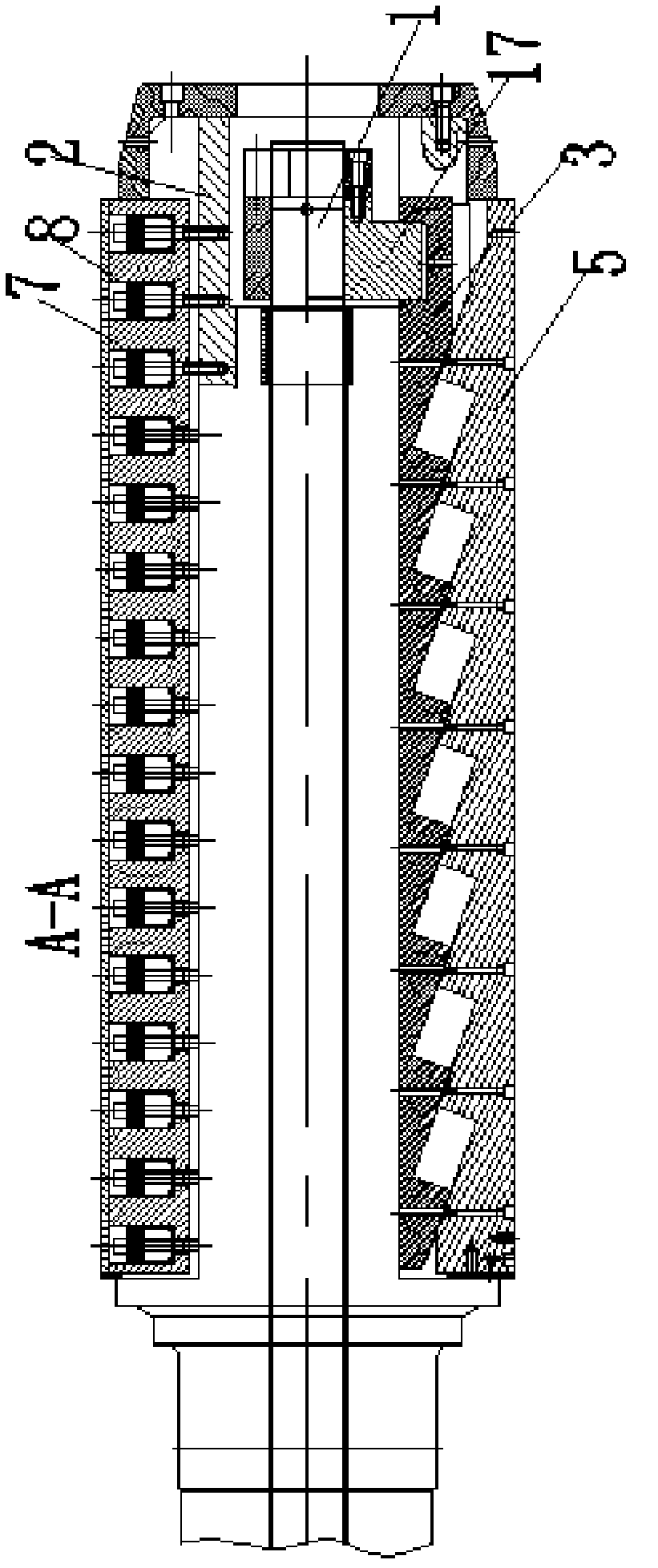

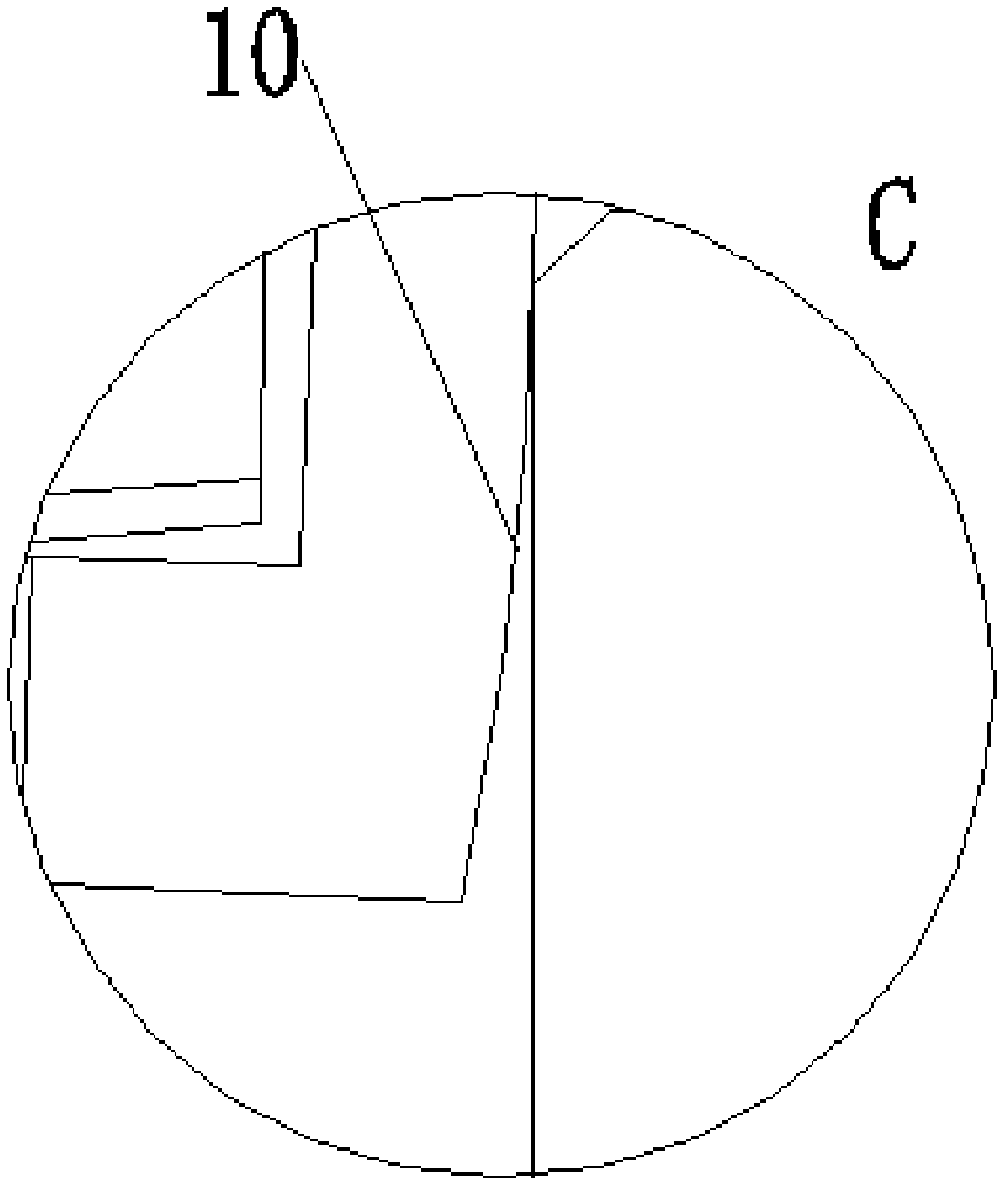

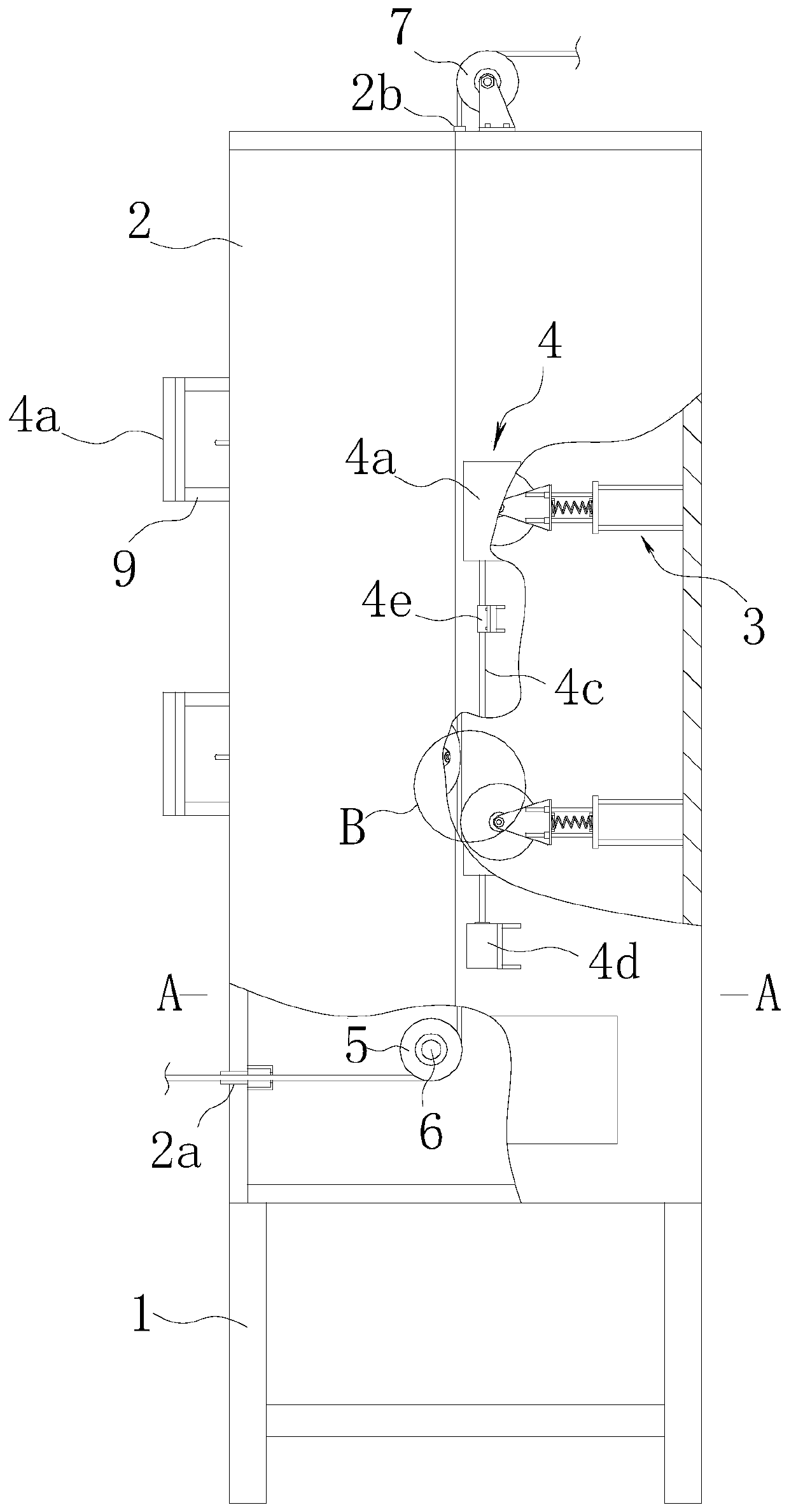

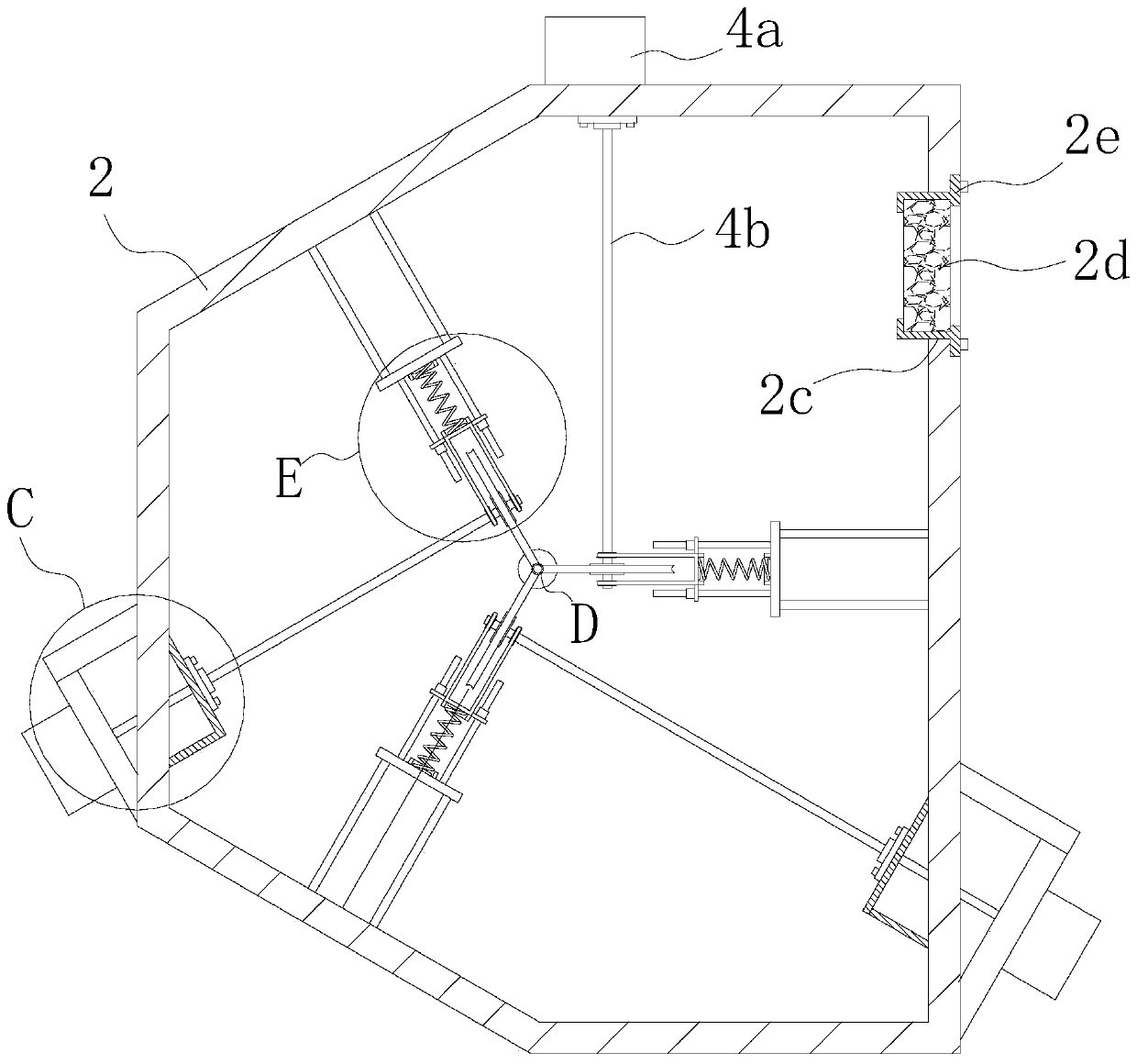

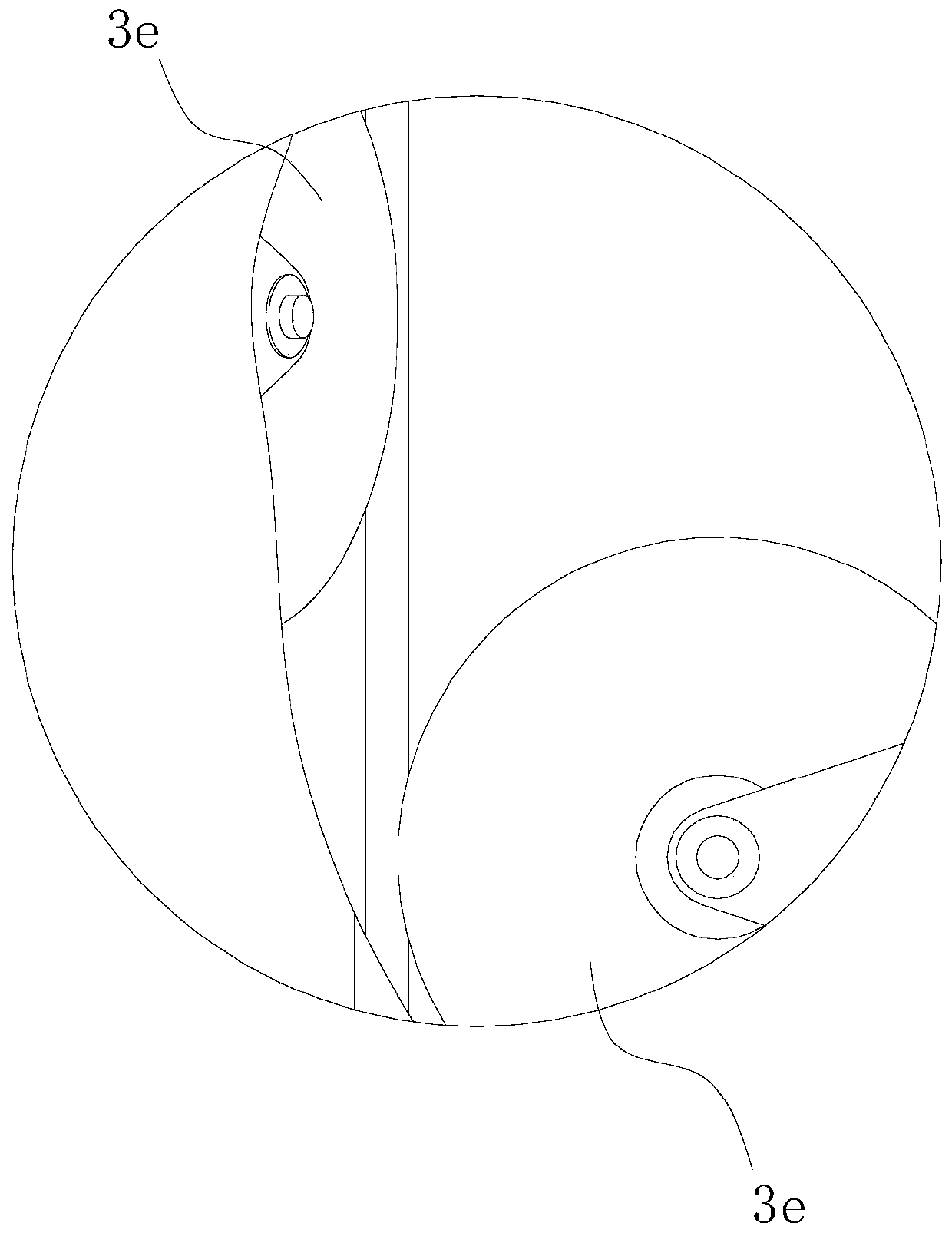

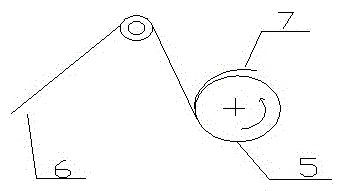

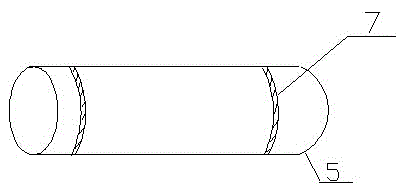

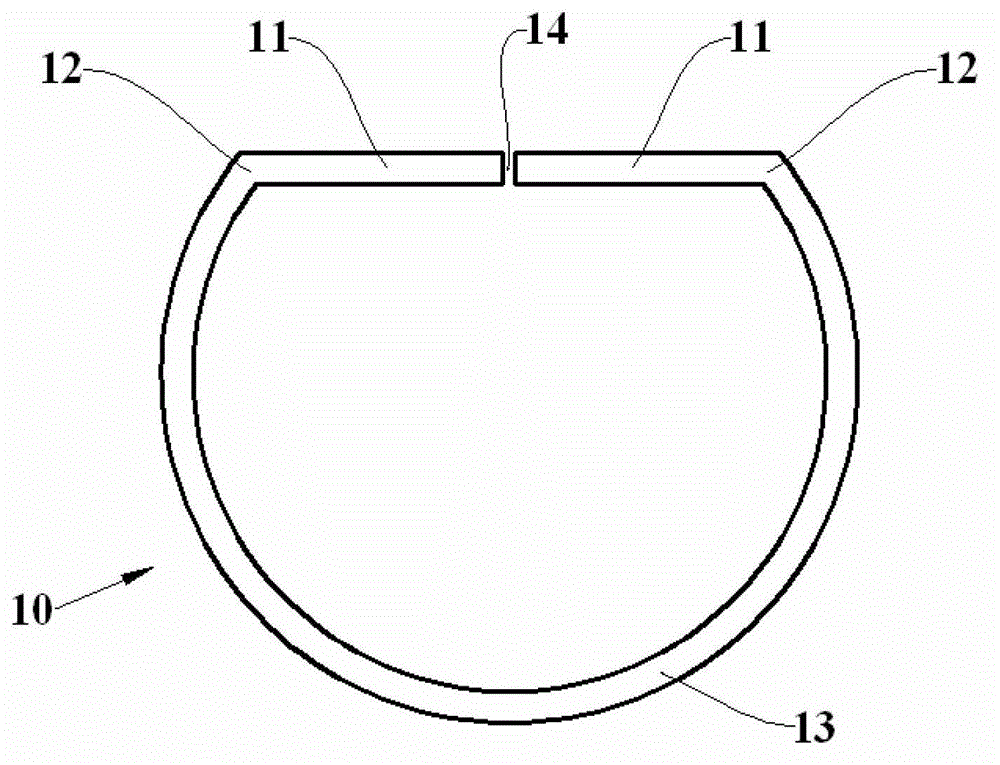

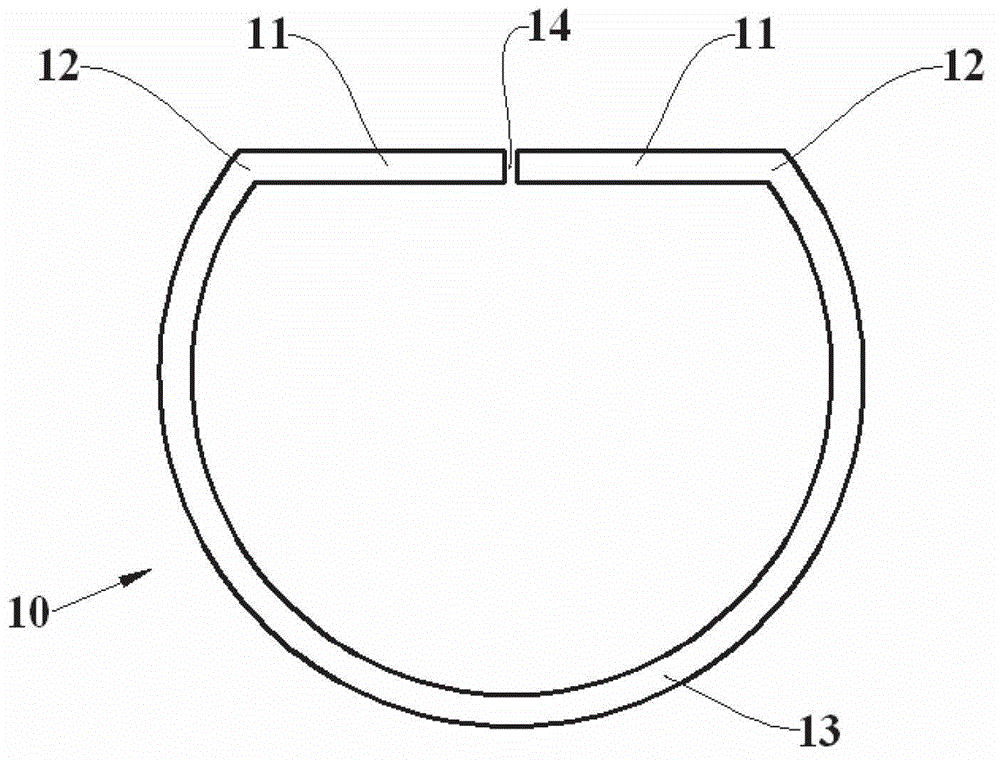

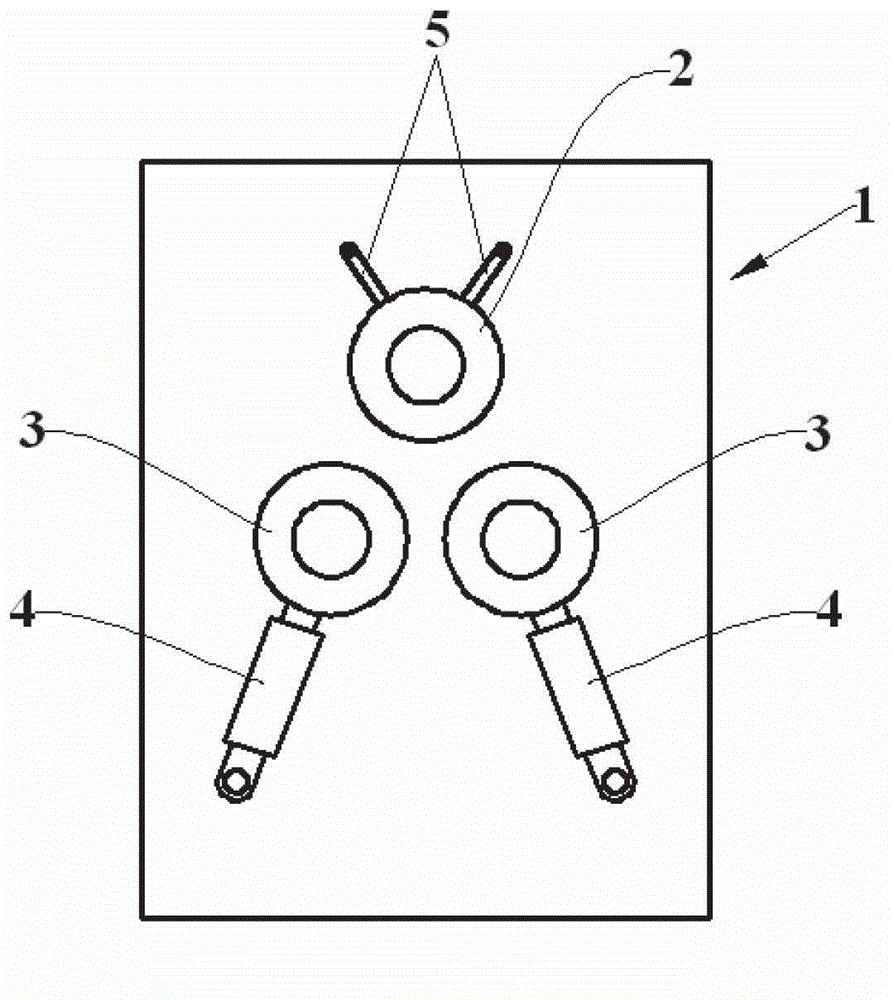

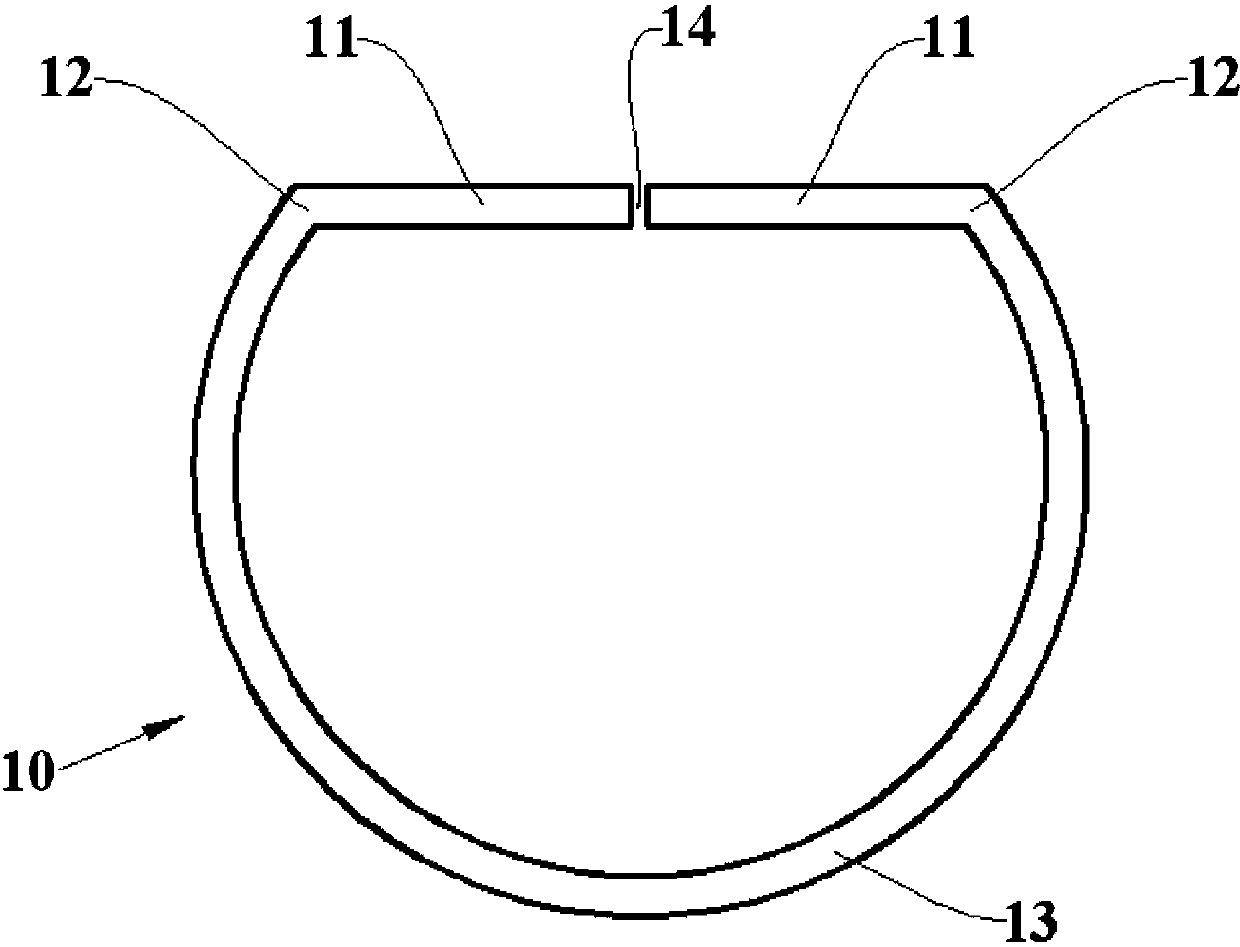

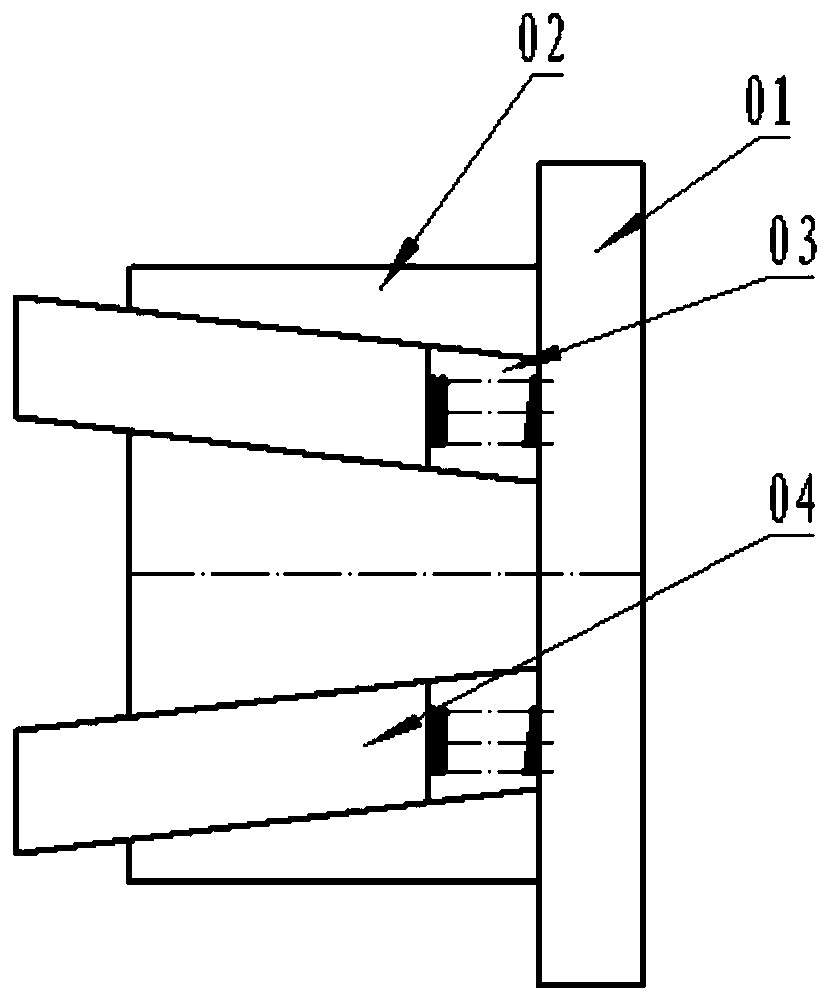

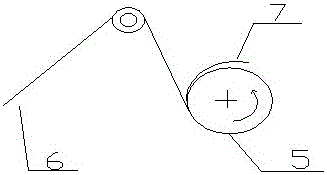

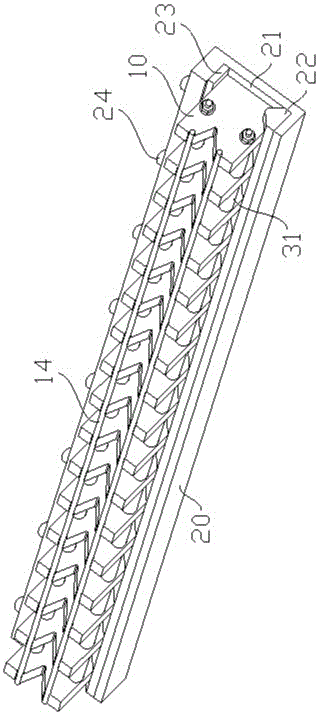

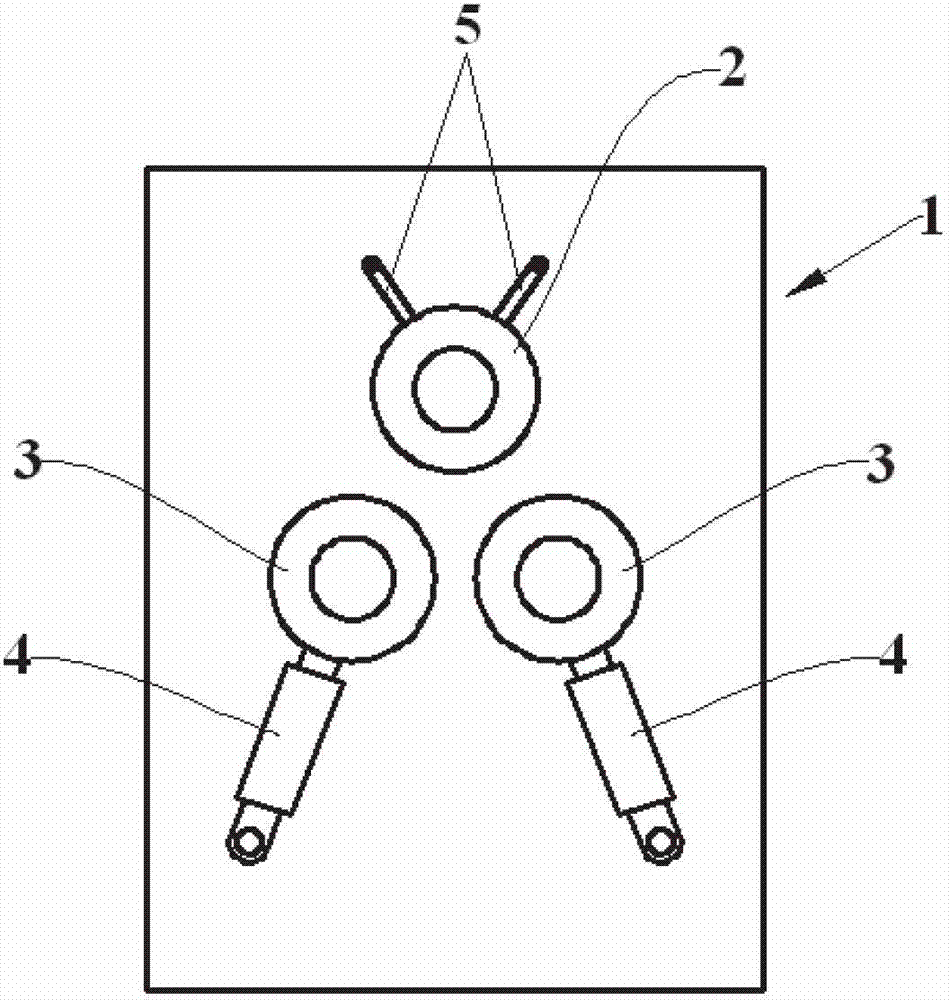

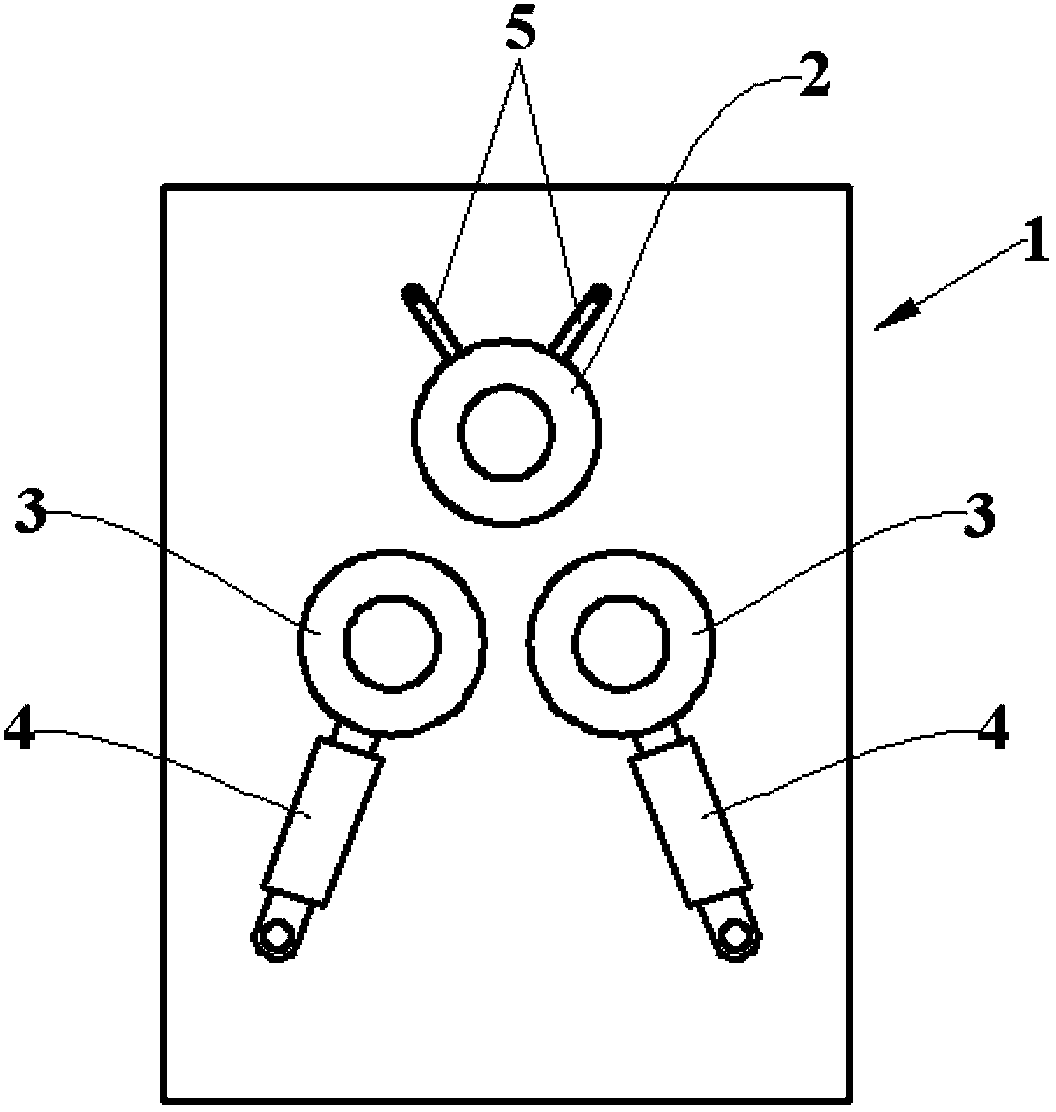

Coiling roller for coiling strip steel

The invention discloses a coiling roller for coiling strip steel, which comprises a pulling rod, a coiling shaft, a closed strip and a fan-shaped plate, wherein the pulling rod is arranged in a through hole at the center of the coiling shaft; the fan-shaped plate and the closed strip are arranged on the surface outside the coiling shaft; the fan-shaped plate comprises a jaw fan-shaped plate and a plurality of common fan-shaped plates; the jaw fan-shaped plate can perform circumferential relative rotation and radial stretching relative to the coiling shaft; the common fan-shaped plates can perform radial stretching relative to the coiling shaft; and stretching control components, which are used for controlling the radial stretching of the fan-shaped plates and are capable of forming proper circles together with the fan-shaped plates, are arranged between the adjacent fan-shaped plates on the coiling shaft. The coiling roller for coiling the strip steel, provided by the invention, has the advantages that the problem of horizontal indentation caused by the sudden change in the diameter of the steel coil on the surface of inter-layer circles of strip steel during the strip steel coiling process is perfectly solved, the quality of the strip steel is increased and the waste is reduced.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

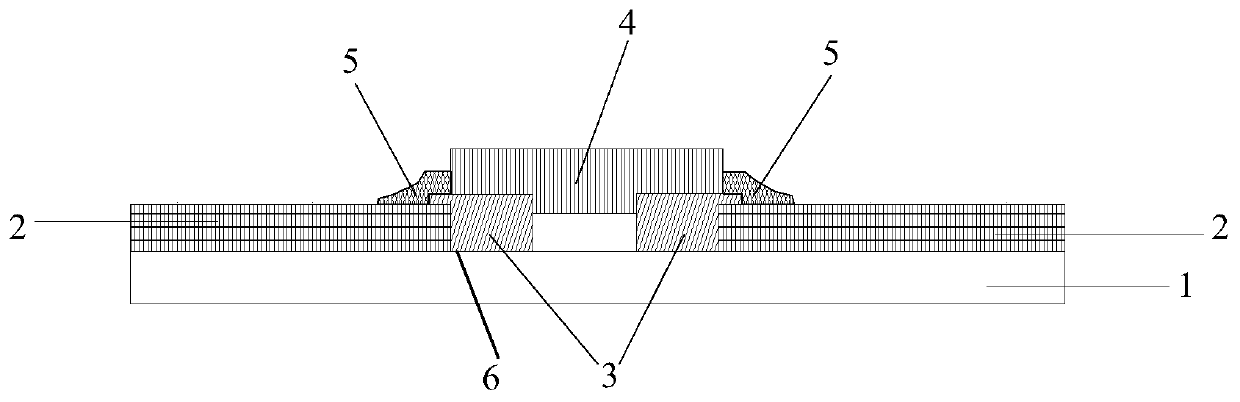

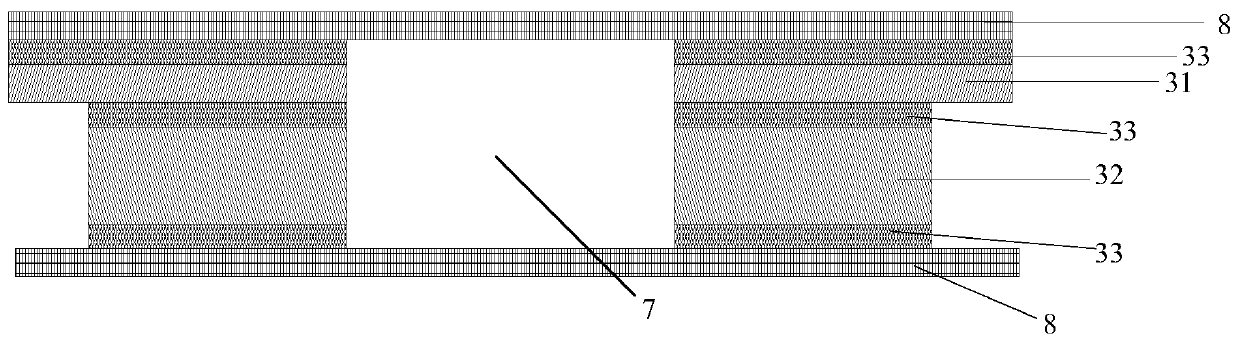

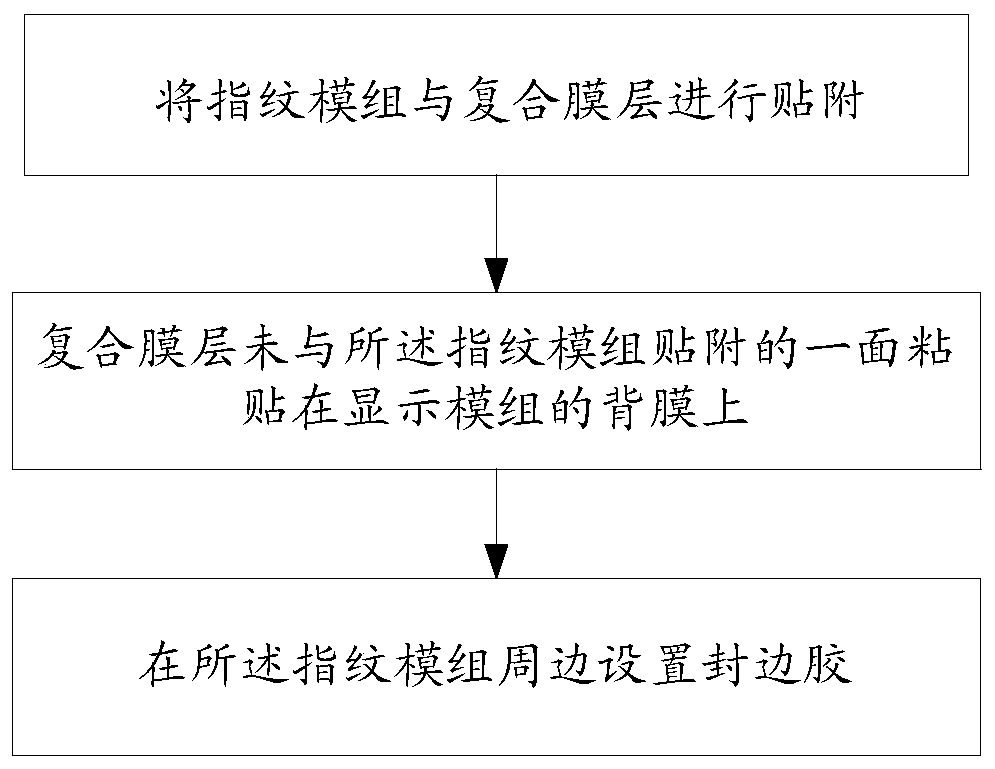

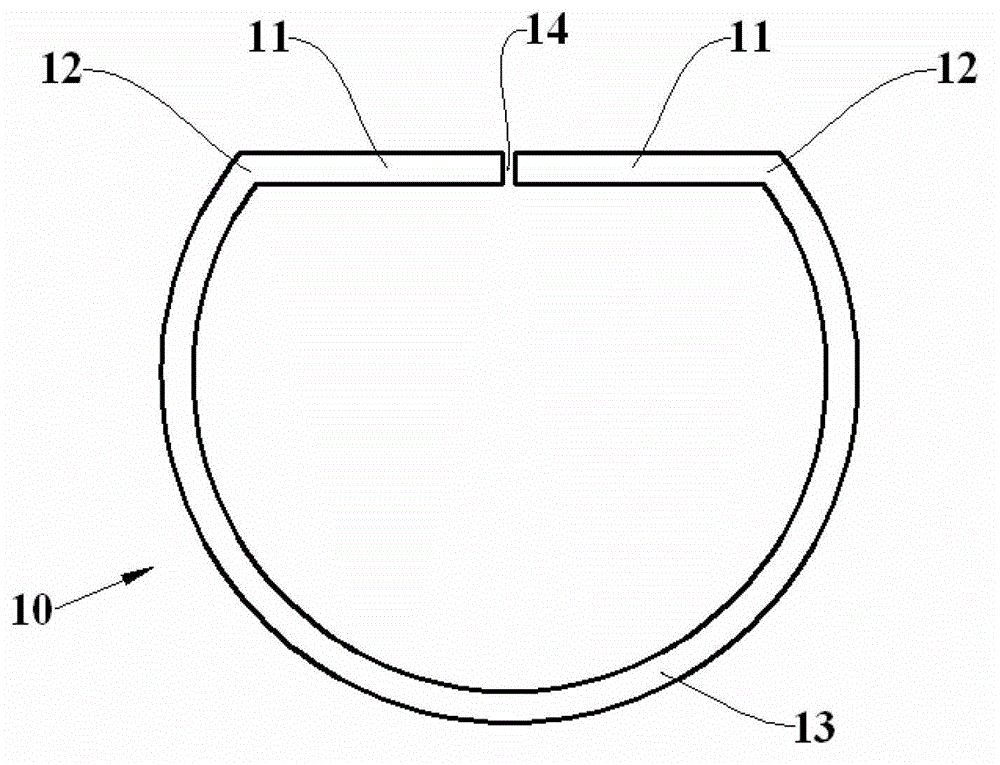

Display panel, display device and attaching method of fingerprint module

ActiveCN110197160AEliminate indentationReduce fit stressDigital data processing detailsLaminationFingerprintImpact stress

The invention discloses a display panel, a display device and an attaching method of a fingerprint module. The display panel comprises a display module; a heat dissipation film layer is arranged on aback film of the display module, a first opening is formed in the heat dissipation film layer, a composite film layer is arranged in the first opening, and the fingerprint module is attached to the composite film layer; the composite film layer comprises a supporting layer and a buffer layer which are bonded with each other, and the supporting layer is close to the fingerprint module. According tothe technical scheme provided by the embodiment of the invention, the composite film layer is arranged as the connecting layer between the fingerprint module and the display module, the composite film layer absorbs impact stress through the buffer layer and fixes and supports the fingerprint module through the supporting layer, and indentations caused by fitting pressure can be eliminated; according to the further provided attaching method, the attaching stress borne by the display module can be effectively reduced, the influence on the display module is avoided, the problem of mold printingduring laminating of the fingerprint module is effectively solved, and the yield of products is increased.

Owner:BOE TECH GRP CO LTD +1

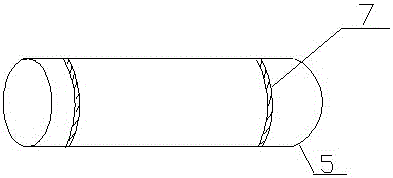

High-bonding strength copper-aluminum composite conductive material and preparation method thereof

ActiveCN106601324AReduce energy consumptionReduce heat lossConductive materialMetal/alloy conductorsConductive materialsCopper

The present invention provides a high-bonding strength copper-aluminum composite conductive material and a preparation method thereof. The high-bonding strength copper-aluminum composite conductive material comprises a clad copper layer and an aluminum core base body; an interatomic bonded metallurgical bonding layer is formed between the clad copper layer and the aluminum core base body; the thickness of the bonding layer ranges from 5 to 35 microns, and the bonding strength of the bonding layer is more than 40 MPa; a copper-aluminum intermetallic compound is dispersedly distributed in the bonding layer; the components of a diffusion layer adjacent to a copper base body are uniform, and the thickness of the diffusion layer is small; and a diffusion layer adjacent to an aluminum base body is of a reticular structure formed by a mixture of two or more components, and the thickness of the diffusion layer is large. According to the high-bonding strength copper-aluminum composite conductive material and the preparation method thereof of the invention, the bonding of copper and aluminum achieves a metallurgical bonding state, the corresponding bonding strength of the bonding of copper and aluminum is more than 40MPa; the thickness of the side copper layer of the copper-aluminum composite conductive material is about 1.6 to 2 times of the thickness of the plane copper layer of the copper-aluminum composite conductive material; the thickness of the side clad copper layer is large enough to meet the requirements of large current impact and heat dissipation; and the elongation rate of the copper-aluminum composite material is greater than 30%. The processing of torsion, spiraling and side bending of the high-bonding strength copper-aluminum composite conductive material in the application of the high-bonding strength copper-aluminum composite conductive material to new fields can be achieved.

Owner:YANTAI FISEND BIMETAL

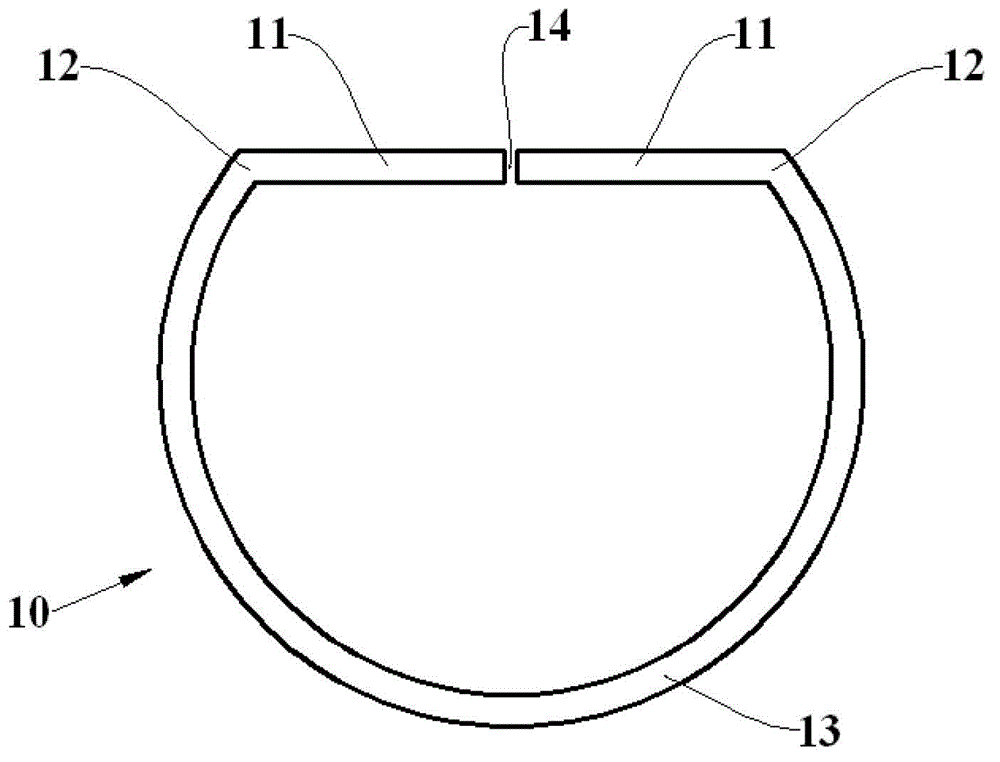

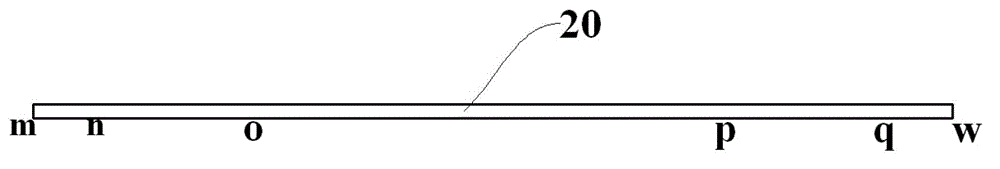

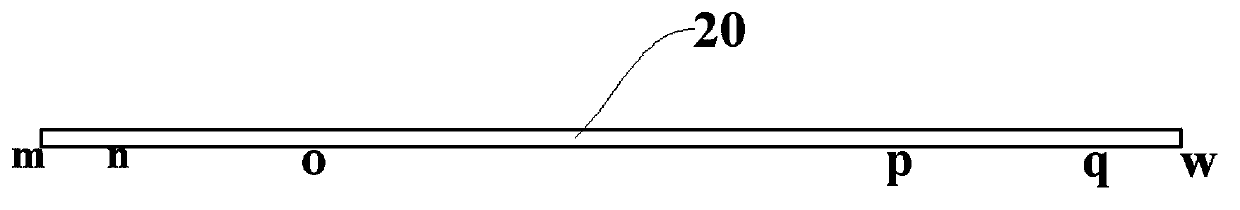

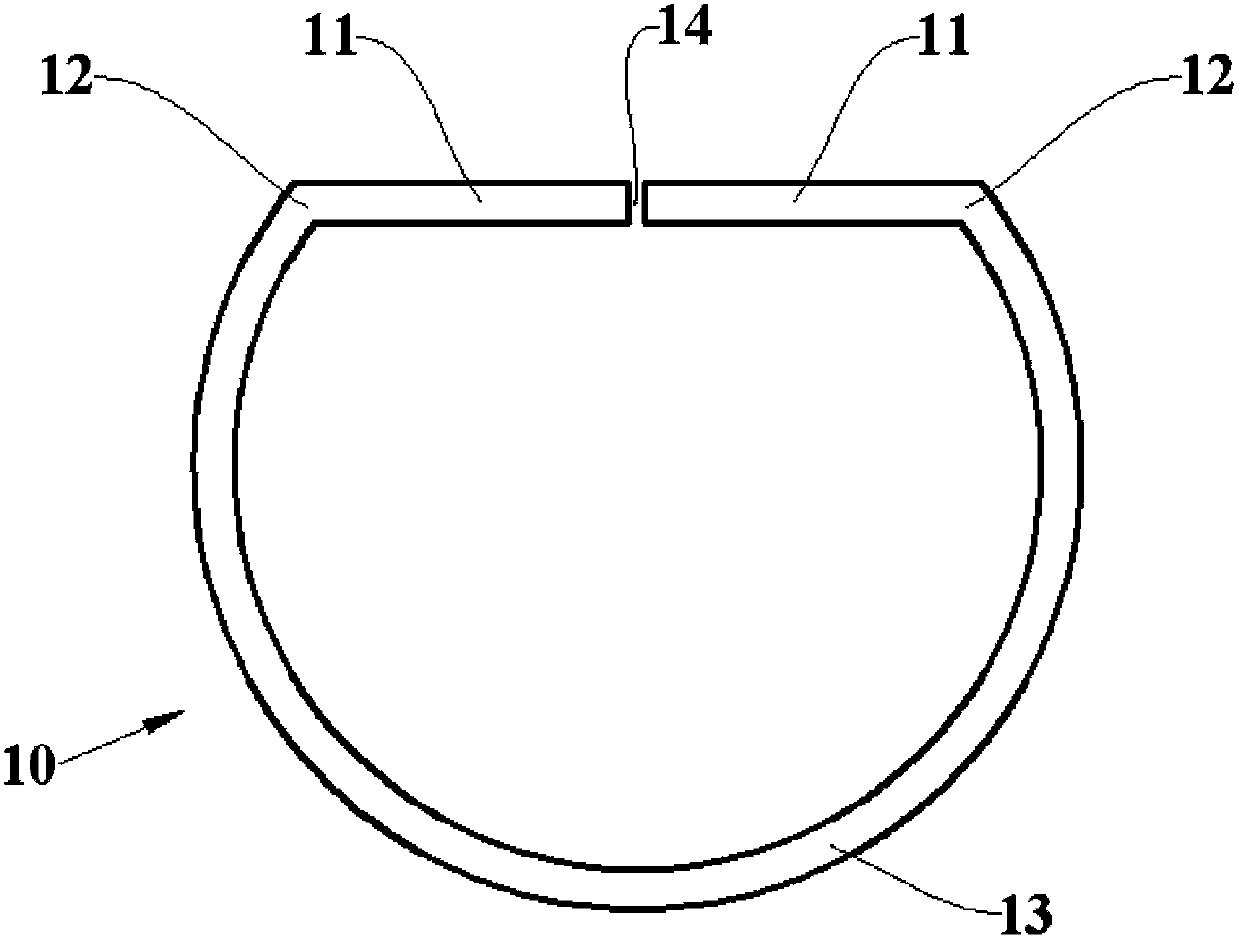

Bending blank manufacturing method for stainless steel flash welding thin-wall ring profiles

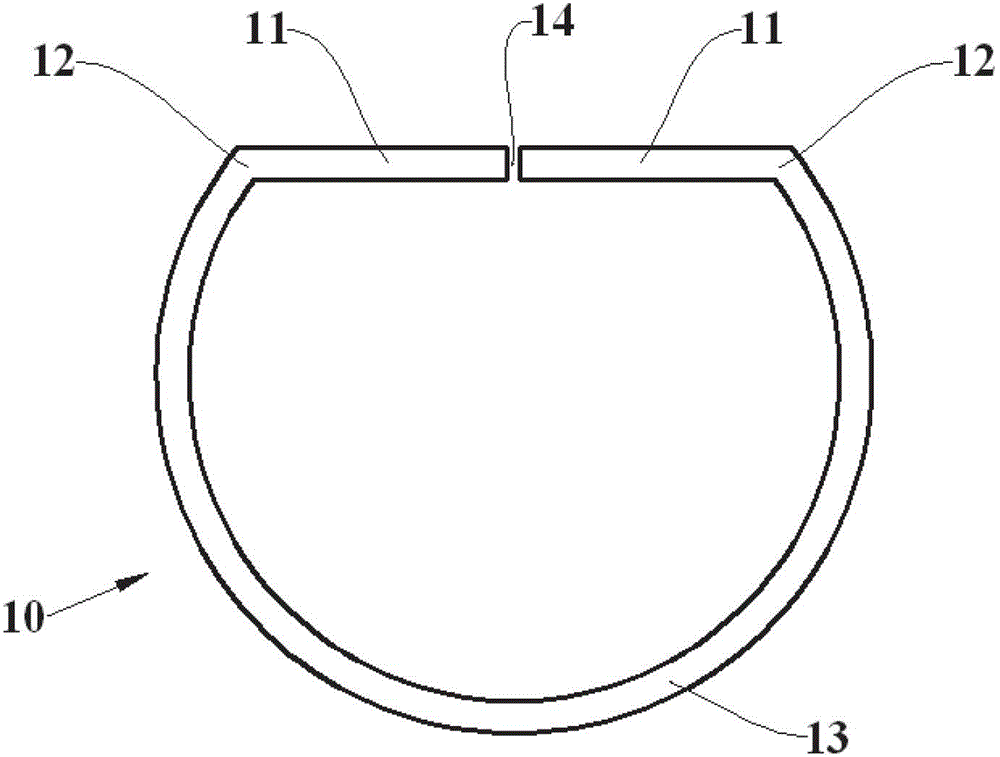

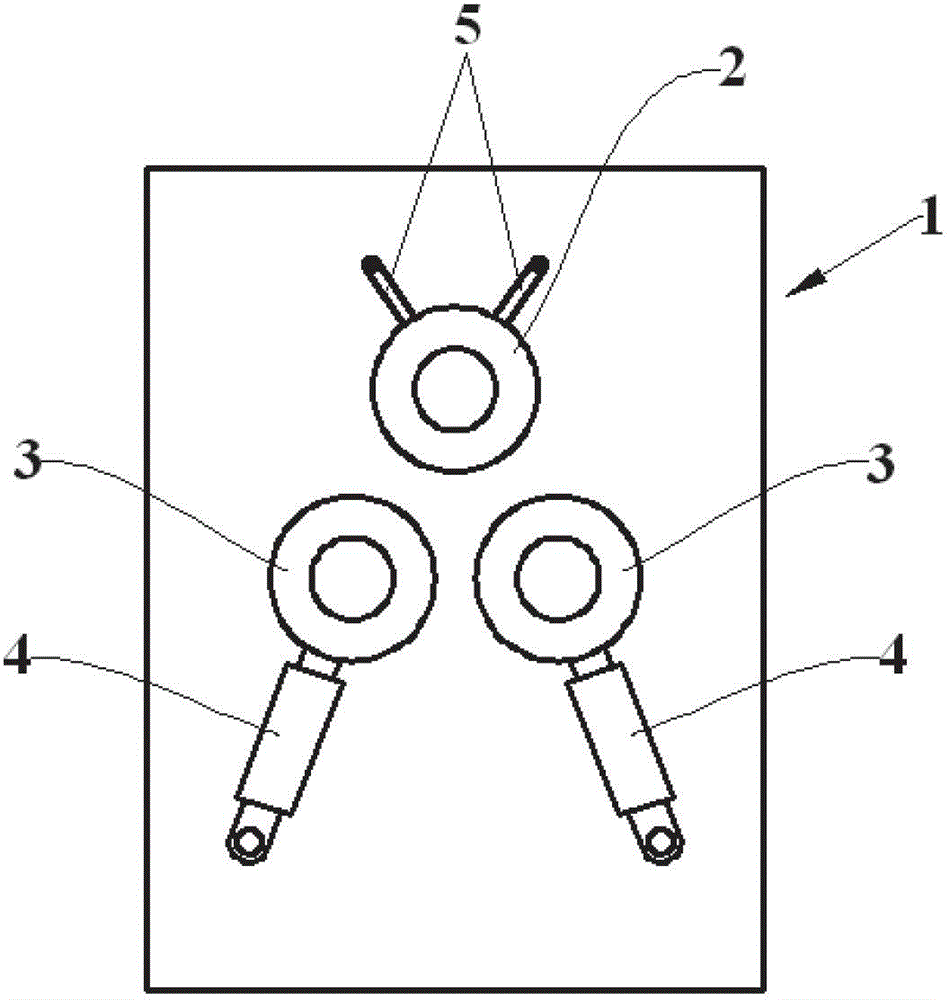

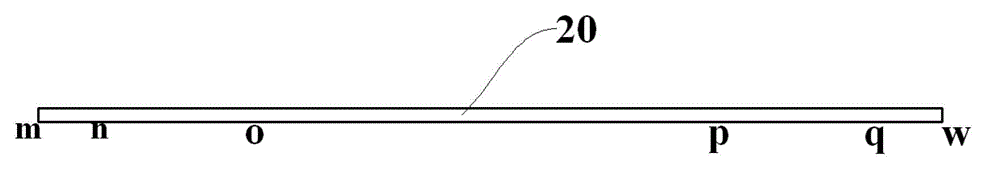

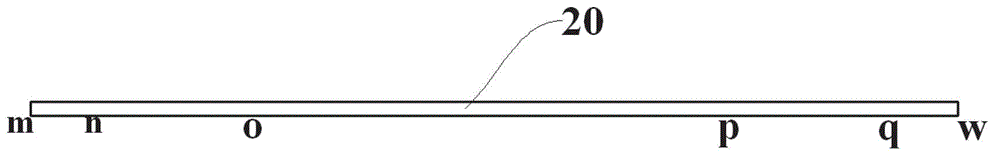

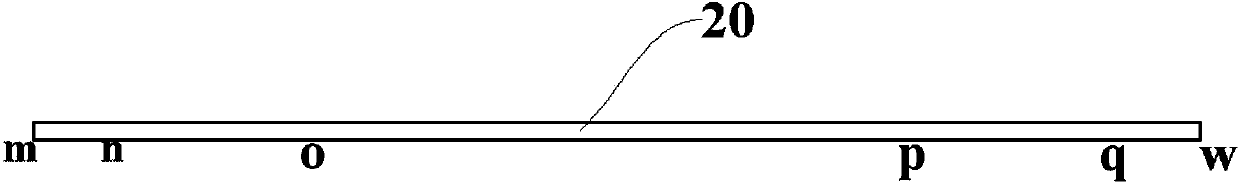

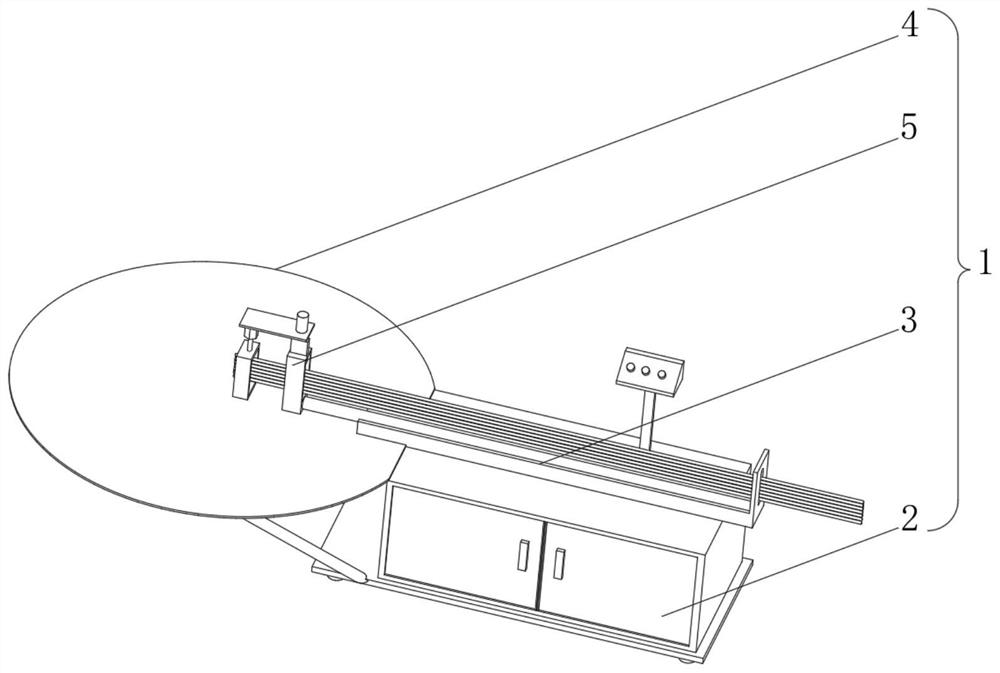

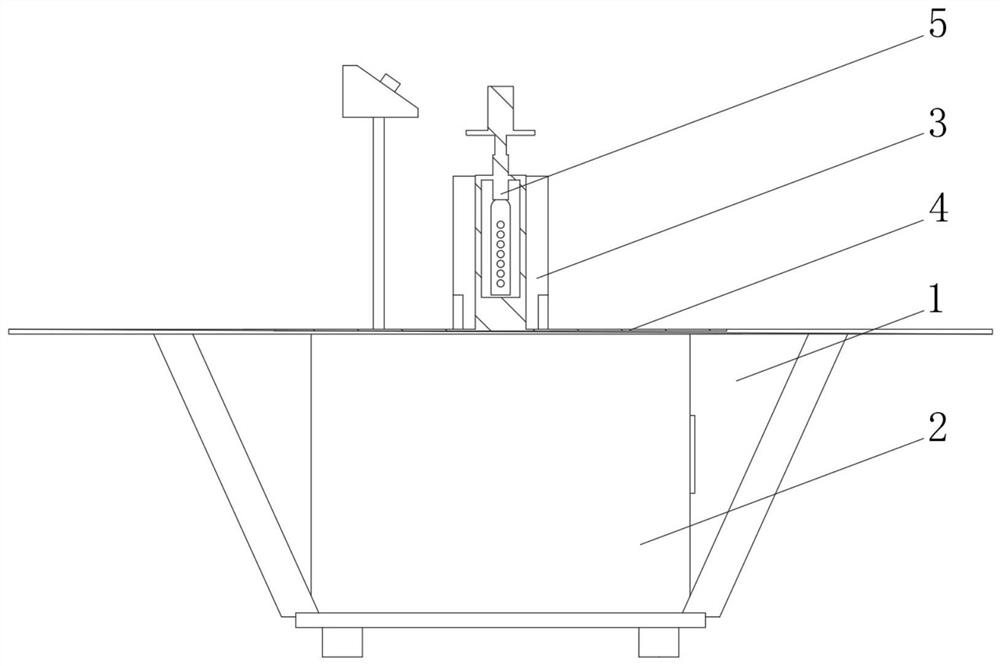

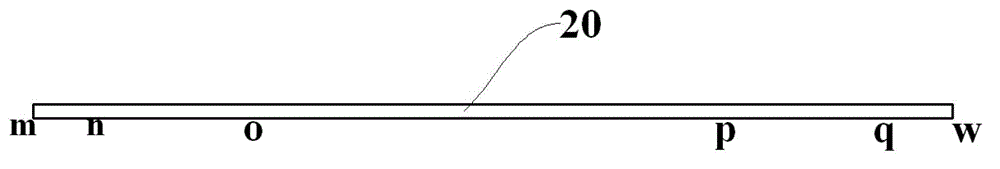

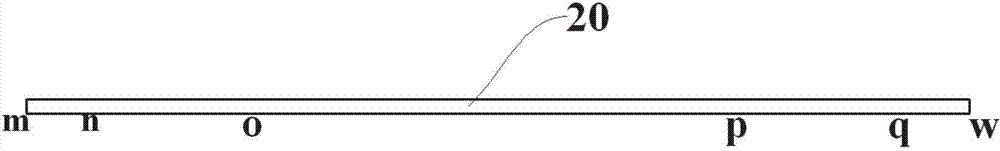

The invention discloses a bending blank manufacturing method for stainless steel flash welding thin-wall ring profiles. The method comprises the steps that a stainless steel profile fed according to specifications is divided into five segments of mn, no, op, pq and qw, heated to a temperature of 720 DEG C+ / -20 DEG C and fed in a bending machine for positioning. The op segment is bent, rotation linear speeds of an upper roller and two lower rollers are 2400 mm / min, the upward moving speeds of the two lower rollers are 10.0 mm / min, the bending is repeated for 3 times, and the op arc segment at this moment achieves a preset curvature radius; and the no segment and the pq segment are bent, the rotation linear speeds of the upper roller and the two lower rollers are 1200 mm / min, the downward moving speeds of the two lower rollers are 12.7 mm / min, the bending is repeated for 3 times, and the no and pq arc segments at this moment achieve preset curvature radii. The profile is bent and deformed into a D-shaped ring blank, two straight sides and an arc portion of the ring blank are connected through a transition arc segment, and phenomena of bent angles at connection positions of the two straight sides and the arc portion and indentations on the surface of the ring blank are eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

Bent blank manufacture method of section bar of aluminum alloy flash-welded thin-wall ring

The invention discloses a bent blank manufacture method of a section bar of an aluminum alloy flash-welded thin-wall ring. The bent blank manufacture method comprises the steps of dividing the aluminum alloy section bar blanked according to dimensions into an mn section, an no section, an op section, a pq section and a qw section, heating the five sections to 330 DEG C + / -20 DEG C, and then feeding the five sections into a bending machine to perform positioning; firstly, bending the op section, and performing repeated bend for 2 times, wherein the rotation linear speed of an upper roller and two lower rollers of the bending machine is 2400mm / min, the upward moving speed of the two lower rollers is 15mm / min, and at this time, the op arc section reaches the predetermined curvature radius; and then bending the no section and the pq section, and performing repeated bend for 2 times, wherein the rotation linear speed of the upper roller and the two lower rollers is 1200mm / min, the upward moving speed of the two lower rollers is 19mm / min, and at this time, the no arc section and the pq arc section reach the predetermined curvature radiuses. The section bar is bent into a D-shaped ring blank. Two straight sides of the ring blank are connected with an arc section through a transition arc section, and the break angle due to connection of the two straight sides and the arc section and creasing on the surface of the ring blank are eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

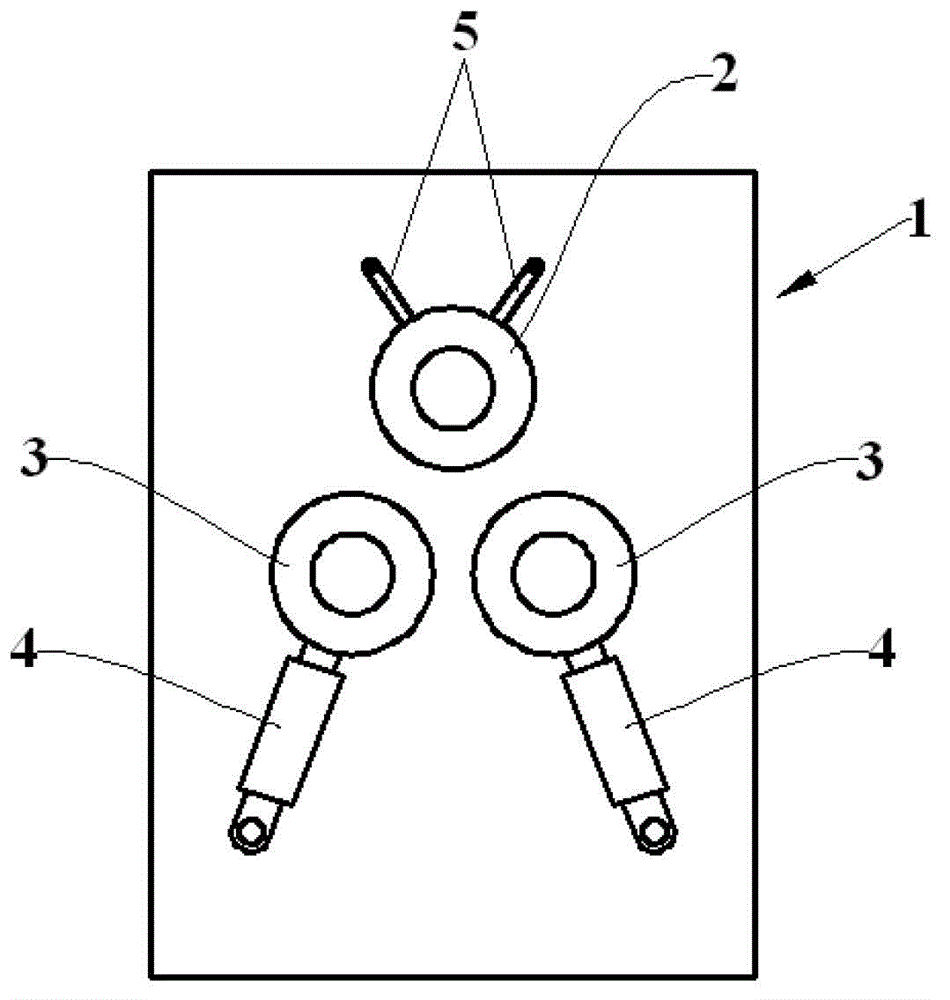

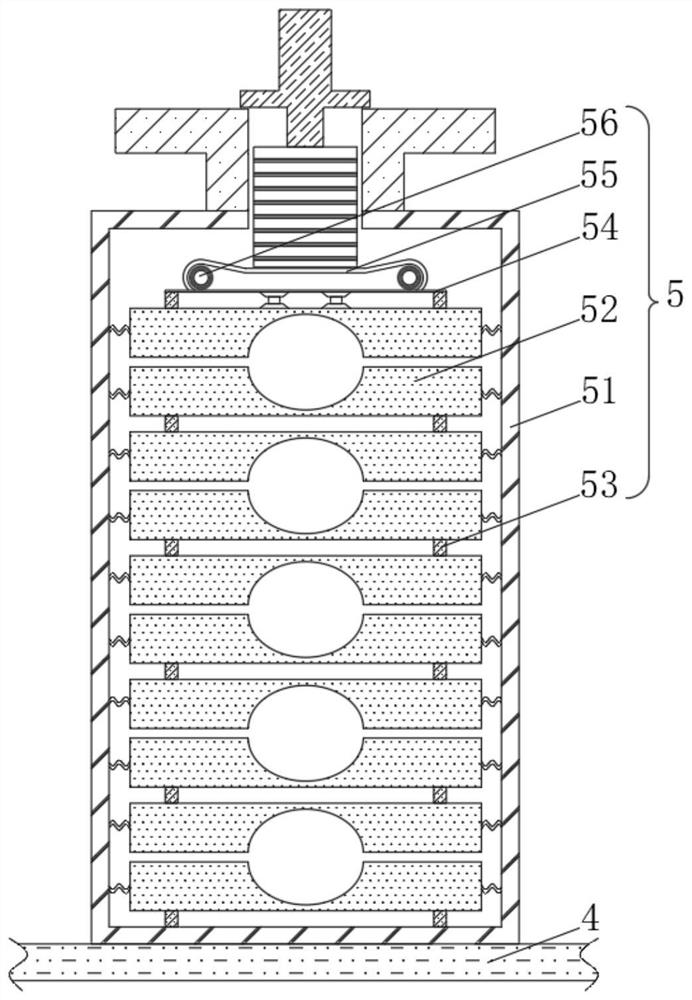

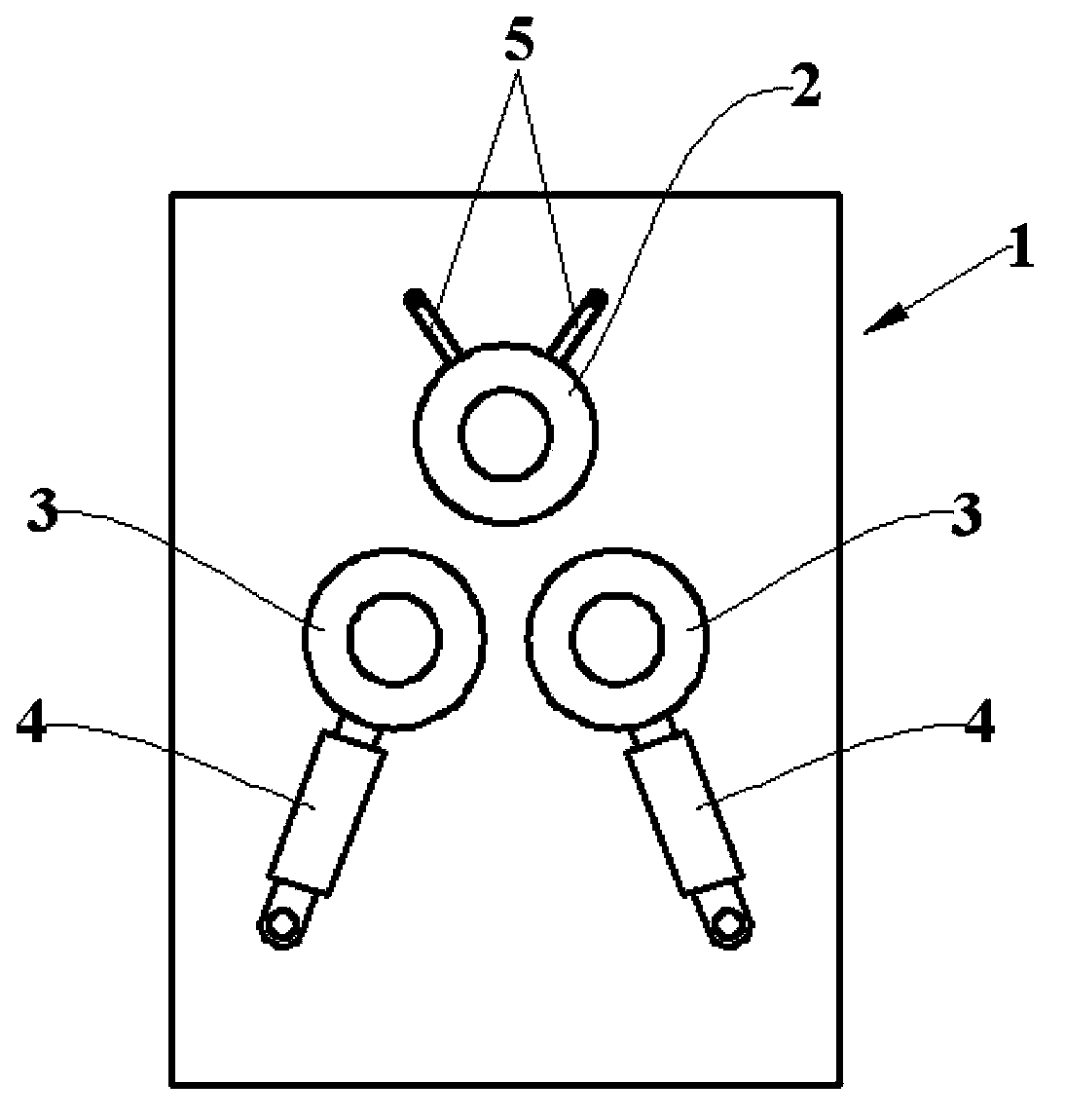

Polishing device special for up-drawing of oxygen-free copper rod

InactiveCN109746801AReduce the number of replacementsAchieve fine grindingGrinding machine componentsGrinding machinesGrinding wheelOxygen-free copper

The invention discloses a polishing device special for up-drawing of an oxygen-free copper rod, and belongs to the technical field of auxiliary polishing for varnished wire production. According to the technical key points, the polishing device comprises a bracket, a copper powder recovery box is arranged on the bracket in the vertical direction, a plurality of sets polishing units are arranged inthe copper powder recovery box at intervals in the height direction, and the to-be-polished copper rod passes through all the polishing units in the vertical direction; each polishing unit is composed of three or more grinding wheel polishing mechanisms which are evenly distributed at intervals in the circumferential direction of the to-be-polished copper rod and arranged in a staggered mode in the axial direction of the to-be-polished copper rod, and the grinding wheel polishing mechanisms comprise grinding wheels; the grinding wheels are arranged in the vertical direction, and the polishingend faces of the grinding wheels are each in an arc shape; and the total length of arc lines formed by contact between all the grinding wheels located on the same polishing unit and the to-be-polished copper rod is larger than the perimeter of the to-be-polished copper rod. The polishing device special for up-drawing of the oxygen-free copper rod is reasonable in structure, good in polishing effect and convenient to use, and is used for polishing of the oxygen-free copper rod.

Owner:广东金雁电工科技股份有限公司

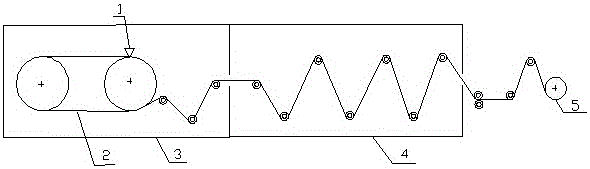

Preparation method for cellulose ester films

A preparation method for cellulose ester films comprises the steps of preparation and tape casting of cellulose triacetate collodion, drying, edge slicing, edge embossing, and winding on a central spindle. After improvement, when a cellulose ester film starts to be wound, adhesive tape is added to the embossed parts of the two ends, and the length of the adhesive tape is one to four times the perimeter of the central spindle. By means of the preparation method, the indentation and concave-convex phenomena on the part, close to the inner side of the central spindle, of the cellulose ester film are eliminated, and the yield is improved.

Owner:乐凯光电材料有限公司

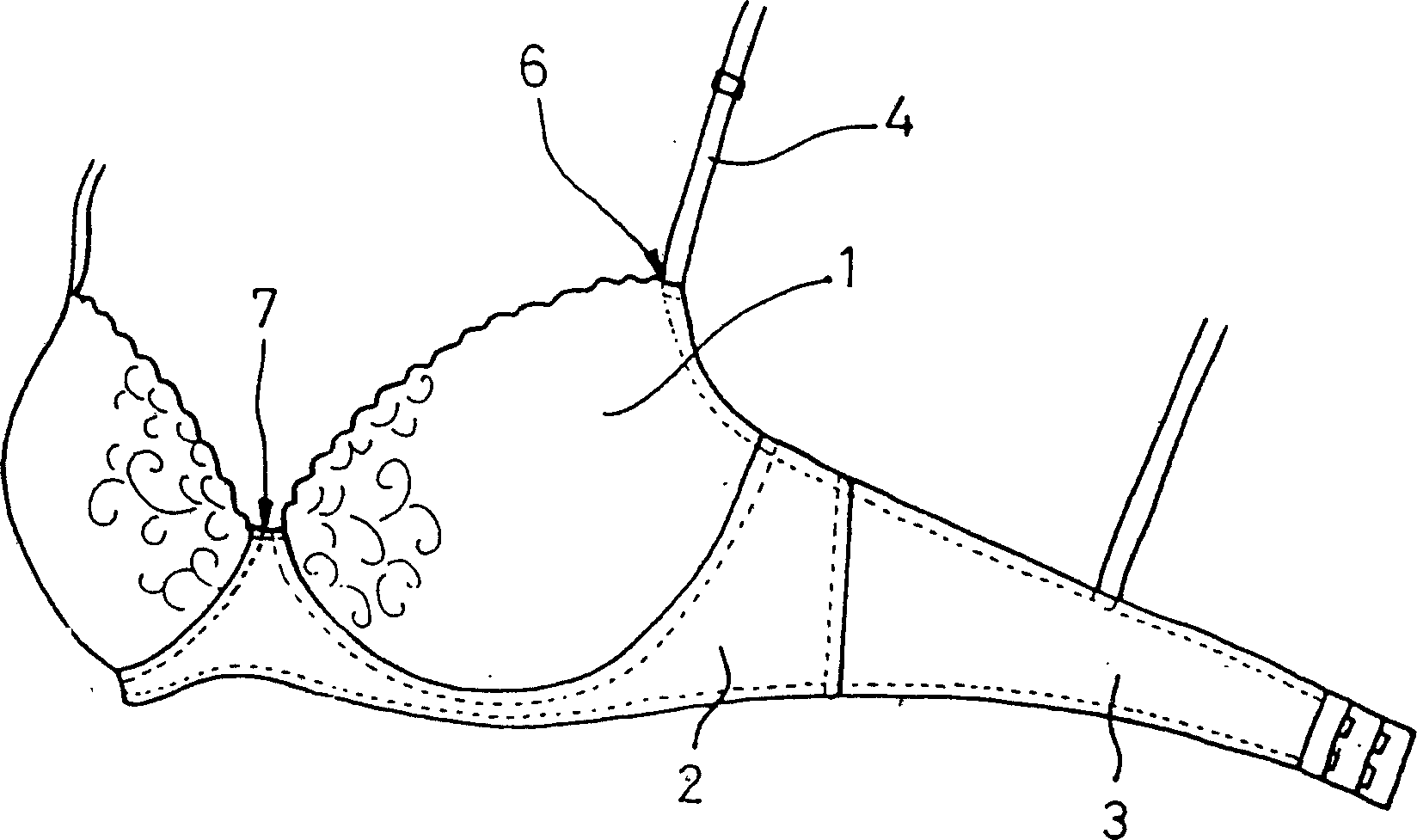

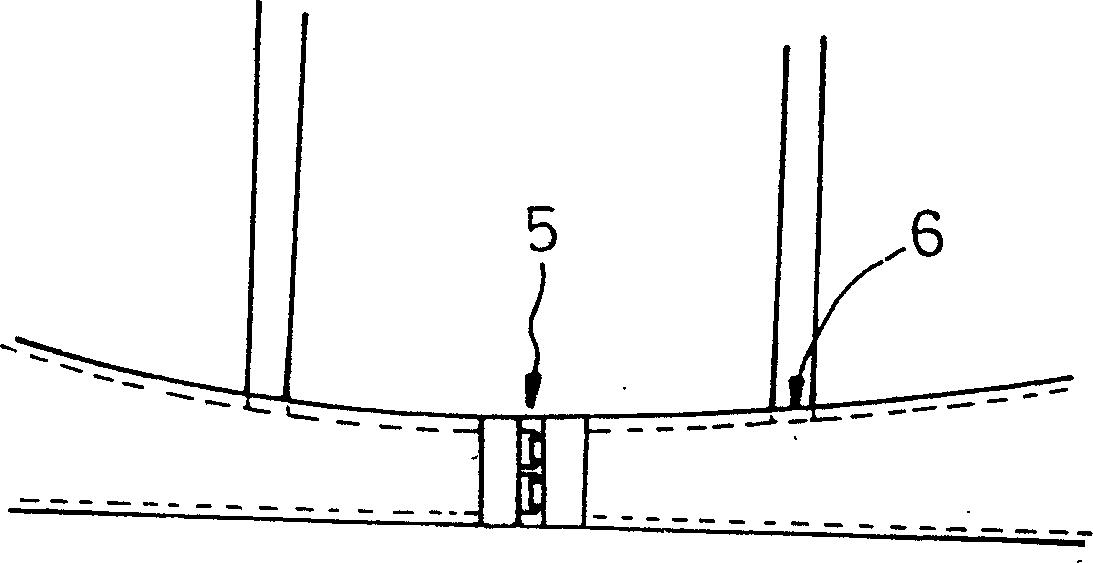

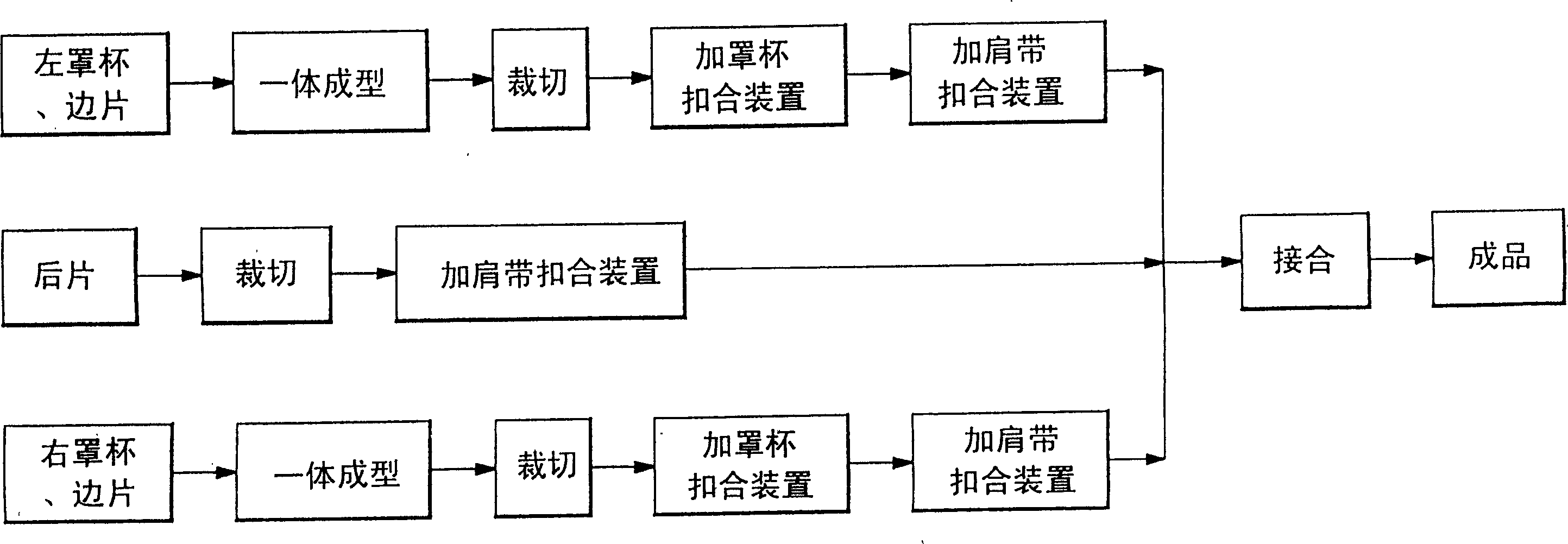

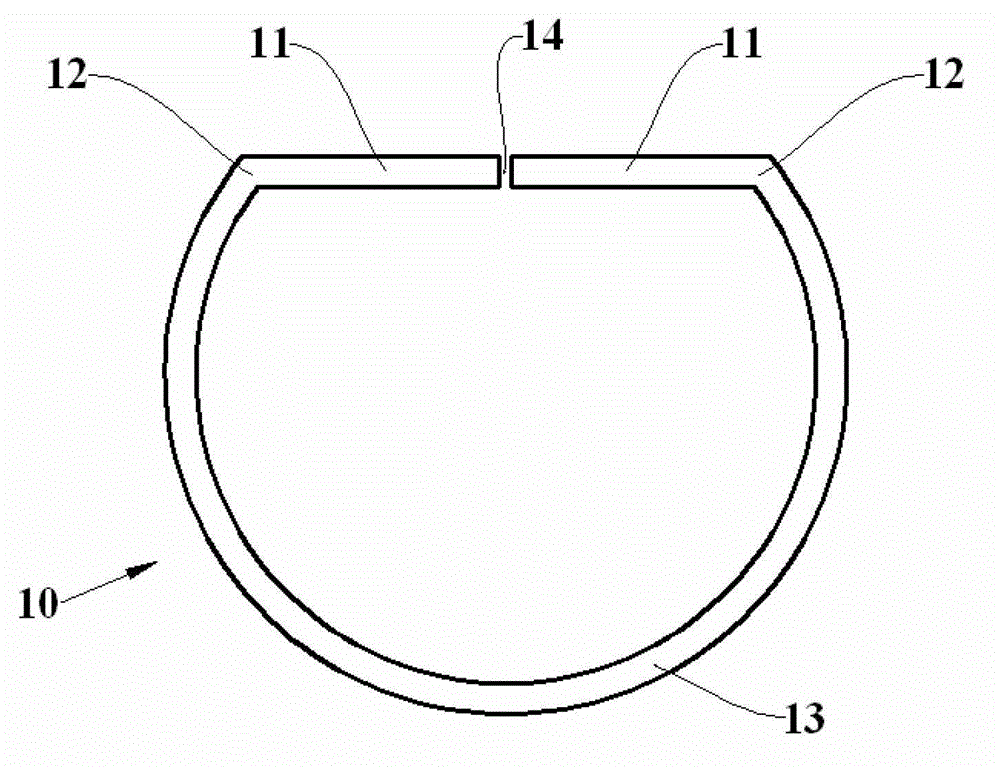

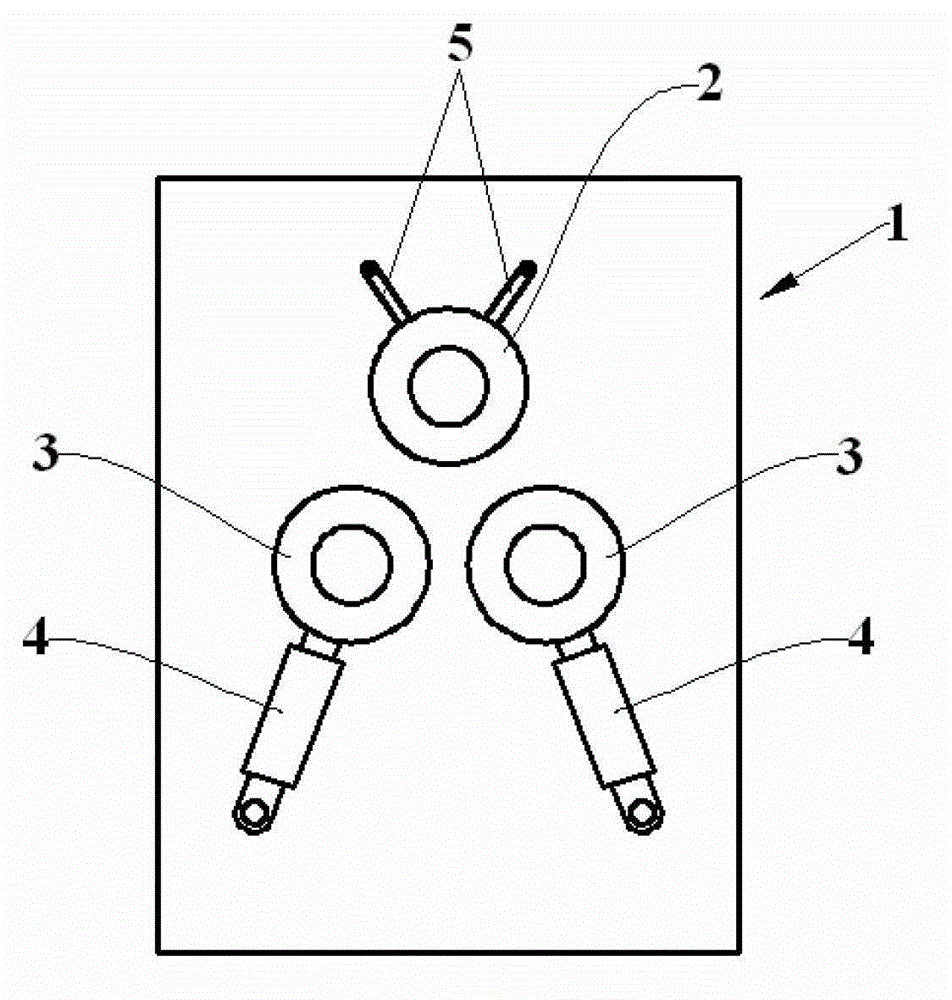

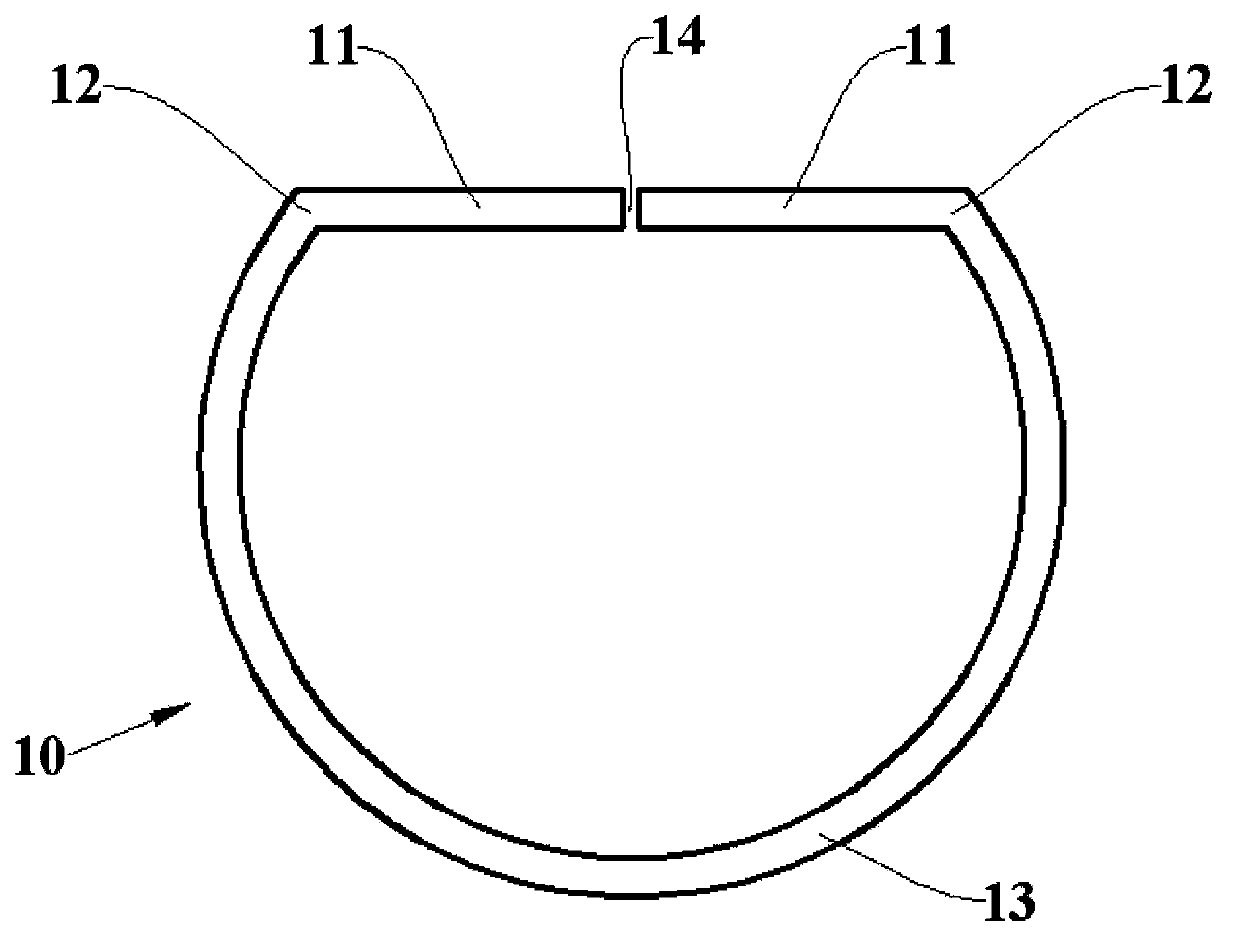

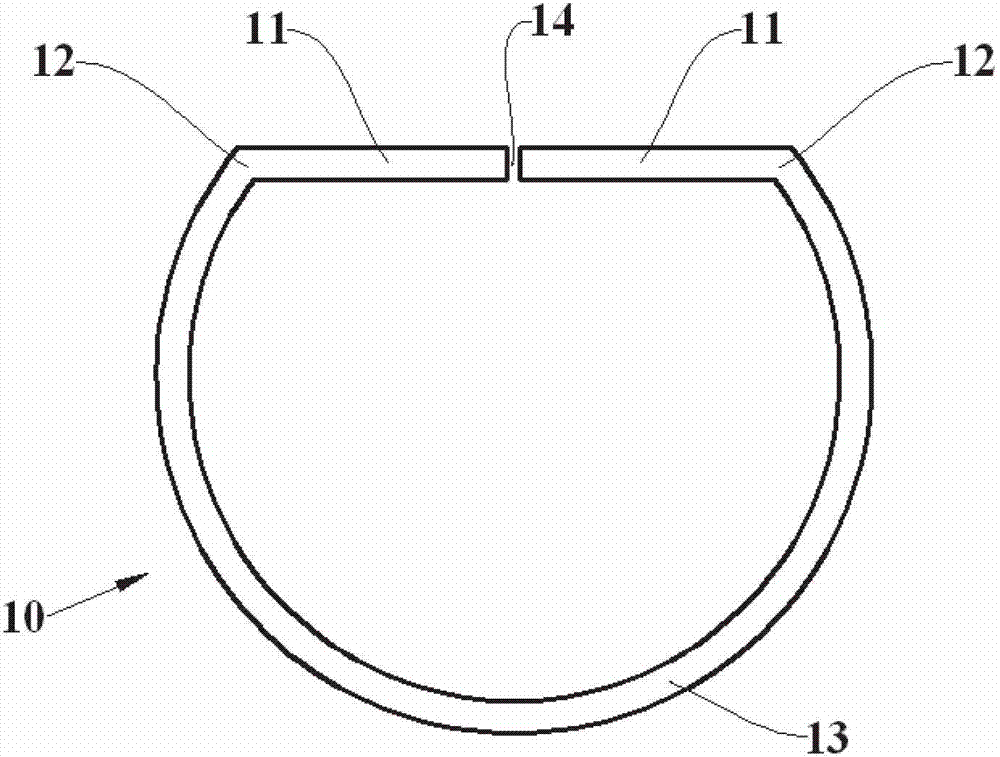

Brassiere

Owner:毛慧娜

Method for section bar bending blank manufacturing of ball bearing steel flash welding thin-wall annular member

The invention discloses a method for section bar bending blank manufacturing of a ball bearing steel flash welding thin-wall annular member. The method includes: dividing the ball bearing steel section bar discharged according to specification into an mn section, an no section, an op section, a pq section and a qw section, heating the five sections to the temperature of 730+ / -20DEG C and then filling the five sections into a bending machine for positioning; firstly bending the op section, wherein the rotating linear speed of an upper roller and two lower rollers of the bending machine is 240mm / min, and the upward moving speed of the two lower rollers is 6.0mm / min; performing bending for three times, and additionally enabling the op arc section to reach the preset radius of curvature; then bending the no section and the pq section, wherein the rotating linear speed of the upper roller and the two lower rollers is 1200mm / min, and the upward moving speed of the two lower rollers is 12.7mm / min; and repeating bending for 5 times, and at this time, enabling the no arc section and the pq arc section to reach the preset radius of curvature. The section bar is bent and deformed into a D-shaped annular blank, two straight edges of the annular blank and the arc part are connected through a transition arc section, and bent angles formed by connection between the two straight edges and arc parts and creasing generated on the surface of the annular blank are avoided.

Owner:GUIZHOU ANDA AVIATION FORGING

Section bending blank manufacturing method of iron-based high temperature alloy flash welding thin wall ring piece

The invention discloses a section bending blank manufacturing method of an iron-based high temperature alloy flash welding thin wall ring piece. The method includes the following steps: dividing an iron-based alloy section which is fed in specification into five sections including an mn section, an no section, an op section, a pq section and a qw section, heating the sections to the temperature of 670+-20 DEG C, installing the sections into a bending machine to be located, first bending the op section, enabling the wire rotating speed of an upper roller and two lower rollers of the bending machine to be 2400mm / min and the upward moving speed of the two lower rollers to be 6.0mm / min, repeatedly bending the section for 5 times at the moment when the op circular section reaches preset curvature radius, then bending the no section and the pq section, utilizing the wire rotating speed of the upper roller and the two lower rollers to be 1200mm / min and the upward moving speed of the two lower rollers to be 7.6mm / min, repeatedly bending the sections for 5 times at the moment when the no circular section and the pq circular section to reach the preset curvature radius. The section is bent and transformed into a 'D'-shaped ring blank. Two straight sides of the ring blank are connected with the transition circular section through the circular portion, and corner bending produced by connection of the two straight sides and the circular portion and impresses produced on the surface of the ring blank are removed.

Owner:GUIZHOU ANDA AVIATION FORGING

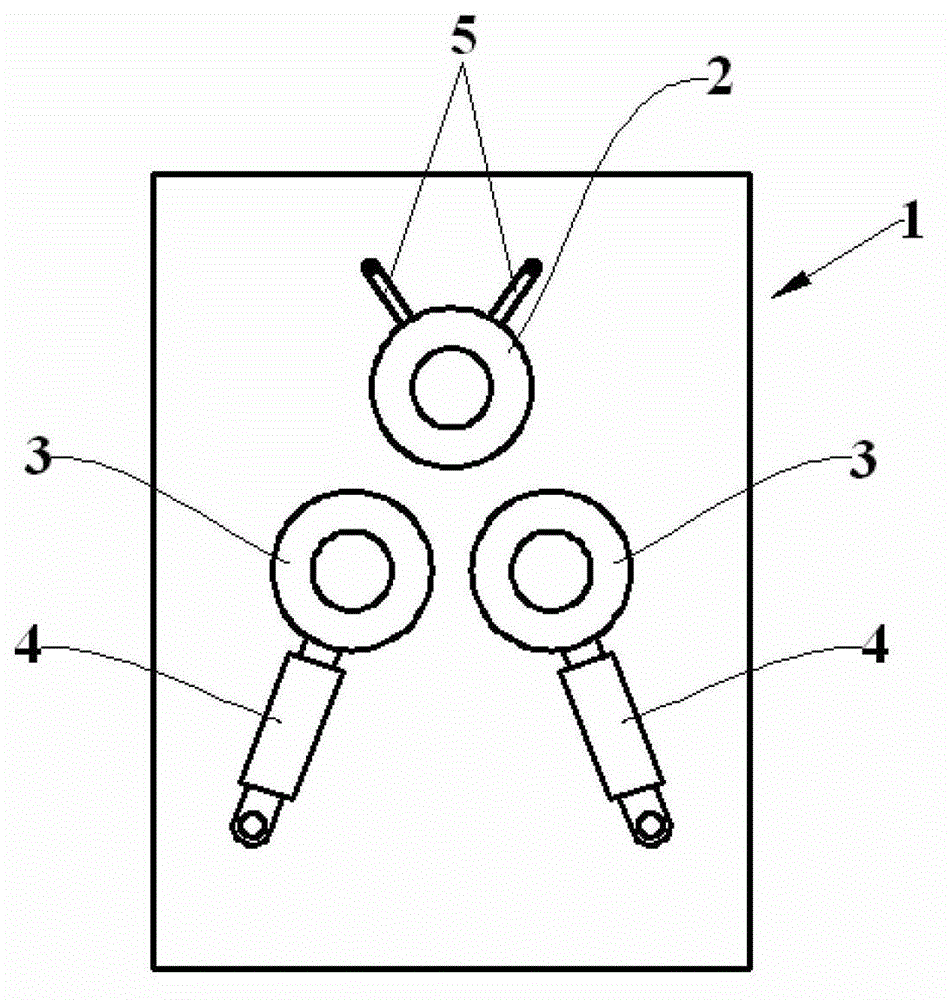

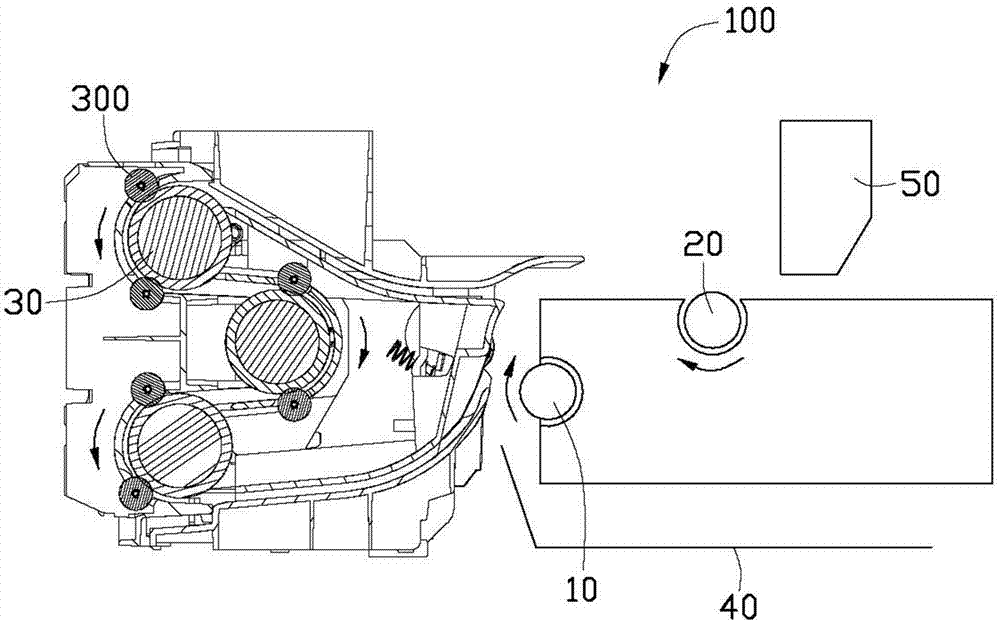

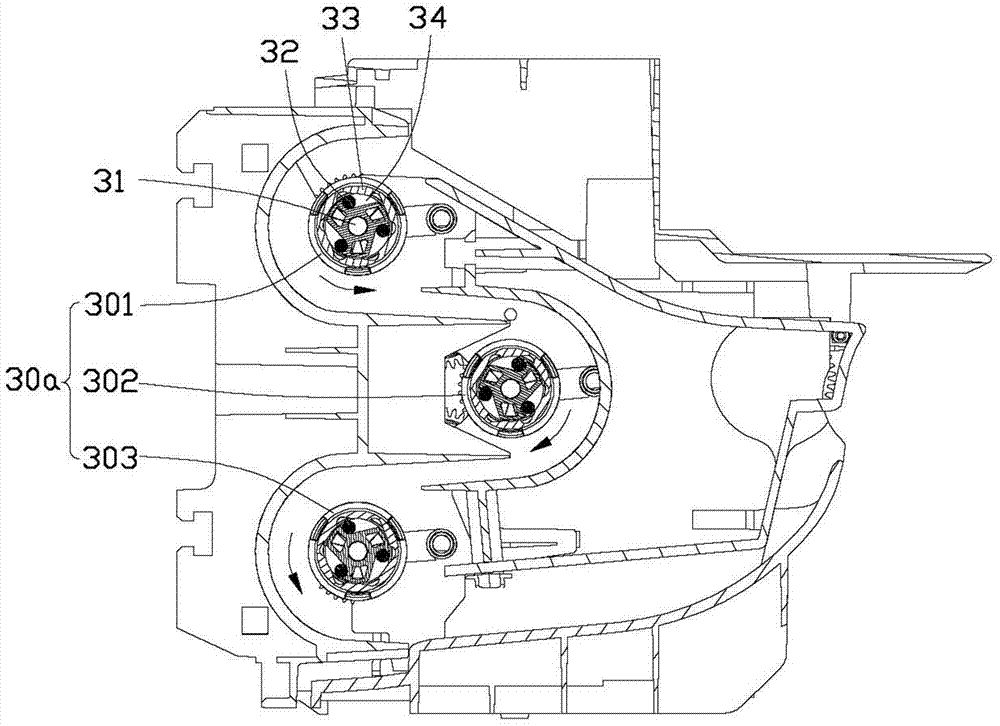

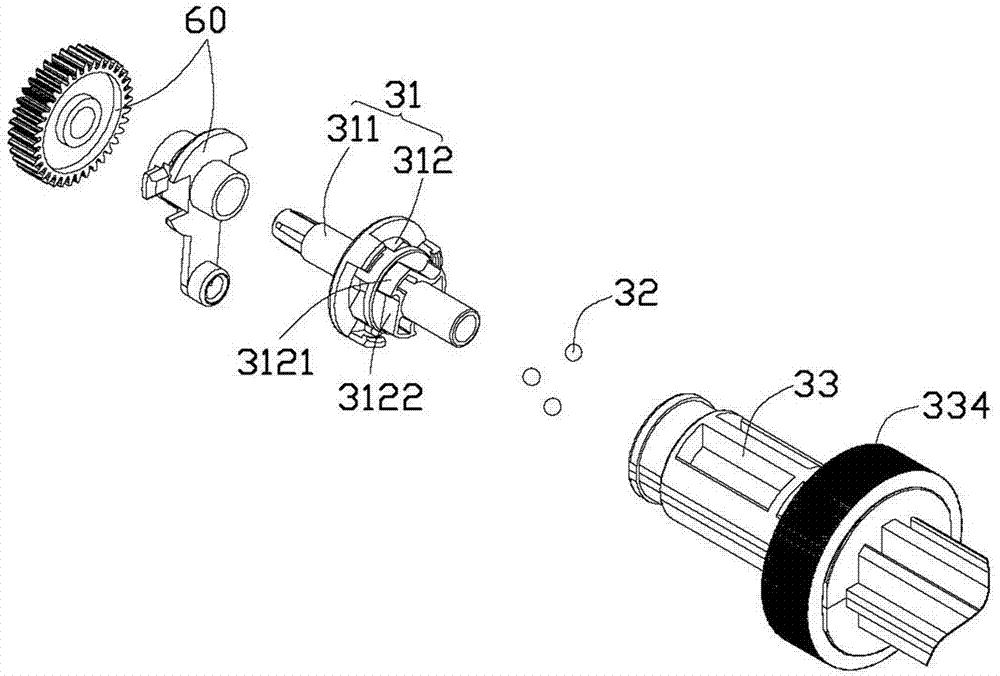

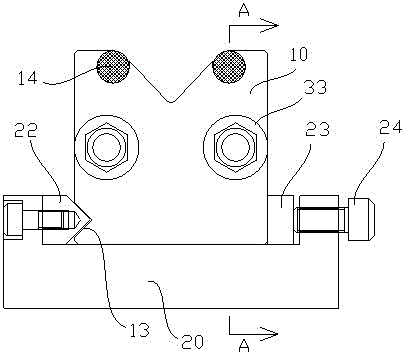

Printer and paper turning mechanism for same

InactiveCN102896915AEliminate indentationQuality improvementOther printing apparatusPulp and paper industryFriction force

Disclosed is a paper turning mechanism for a printer. At least one roller positioned at a paper outlet end of the paper turning mechanism comprises a driving component, a plurality of driving balls and a paper delivery roll. A containing cavity is reserved at one end of the paper delivery roll, and a plurality of containing grooves are arranged on the side wall of the containing cavity. The driving component comprises a plurality of blades, recesses are formed among adjacent blades, the driving component is contained in the containing cavity, multiple containing spaces are respectively formed between the recesses and the side wall of the containing cavity, and the driving balls are contained in the containing spaces and capable of moving therein. When the driving component is driven to rotate in the containing cavity along a preset direction, the driving balls are driven to move by the blades. When being driven to move into the containing grooves, the driving balls are limited by the containing grooves and incapable of moving, so as to transmit driving force of the blades to the paper delivery roll and drive the paper delivery roll to rotate along with the driving component. When the driving component stops rotating, the paper delivery roll is capable of continuously rotating relative to the driving component along the preset direction under action of friction force between the tail end of a paper sheet and the paper delivery roll.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Sectional material bending blank making method for cobalt-based high-temperature alloy flash welding thin-wall ring part

The invention discloses a sectional material bending blank making method for a cobalt-based high-temperature alloy flash welding thin-wall ring part. The sectional material bending blank making method comprises the steps of enabling a cobalt-based high-temperature alloy sectional material blanked according to specifications to be divided into an mn section, an no section, an op section, a pq section and a qw section, and enabling the five sections to be fed into a bending machine to be positioned after heating the five sections to 810 DEG C+ / -20 DEG C; first bending the op section, enabling rotating linear speeds of an upper roll and two lower rolls of the bending machine to be 240mm / min, enabling the speeds of the two lower rolls moving upwards to be 6.0mm / min, repeatedly bending for 5 times, and enabling the op arc-shaped section to reach a preset curvature radius; then bending the no section and the pq section, enabling the rotating linear speeds of the upper roll and the two lower rolls to be 1,200mm / min, enabling the speeds of the two lower rolls moving upwards to be 7.6mm / min, repeatedly bending for 5 times, and enabling the no section and the pq arc-shaped section to reach the preset curvature radius. The sectional material undergoes bending deformation to become a D-shaped ring blank, two straight edges of the ring blank are connected with an arc-shaped part through transition arc-shaped sections, folded corners generated at joints of the two straight edges and the arc-shaped part are eliminated, and indentation of the surface of the ring blank is eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

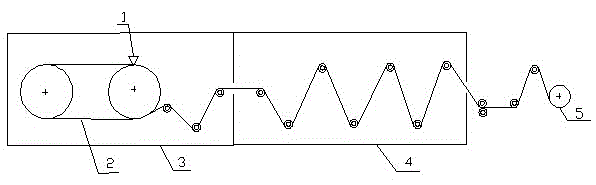

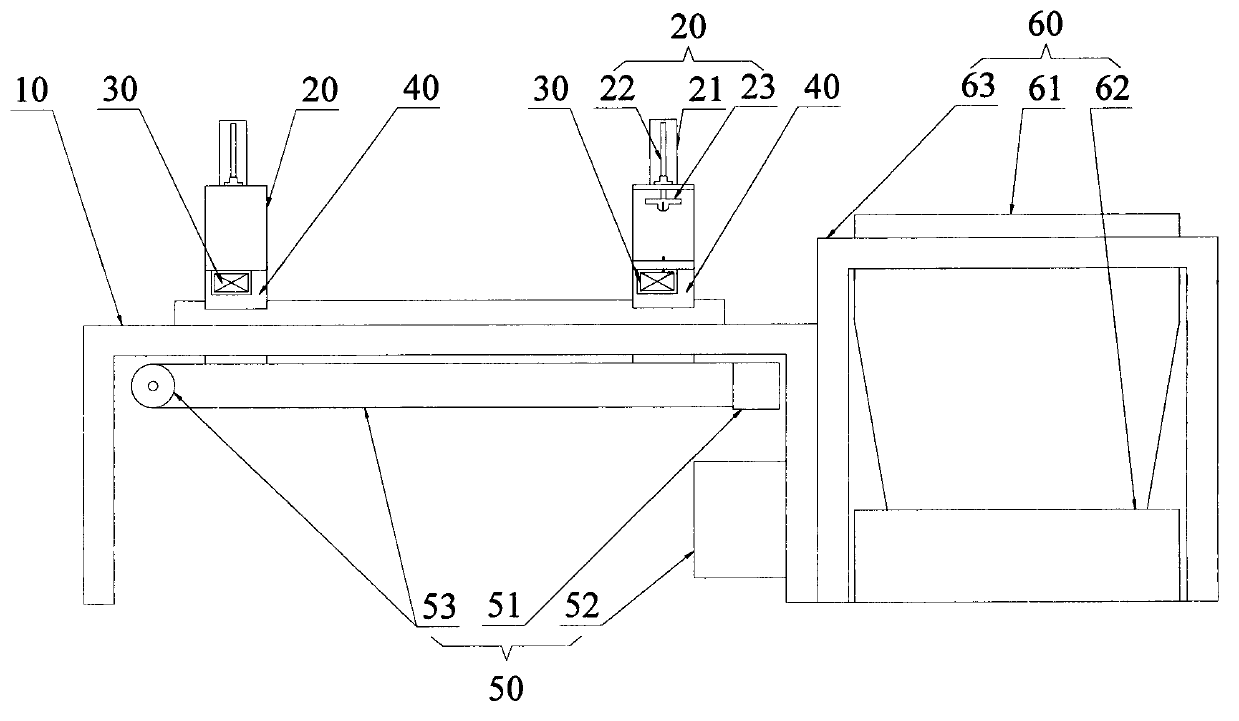

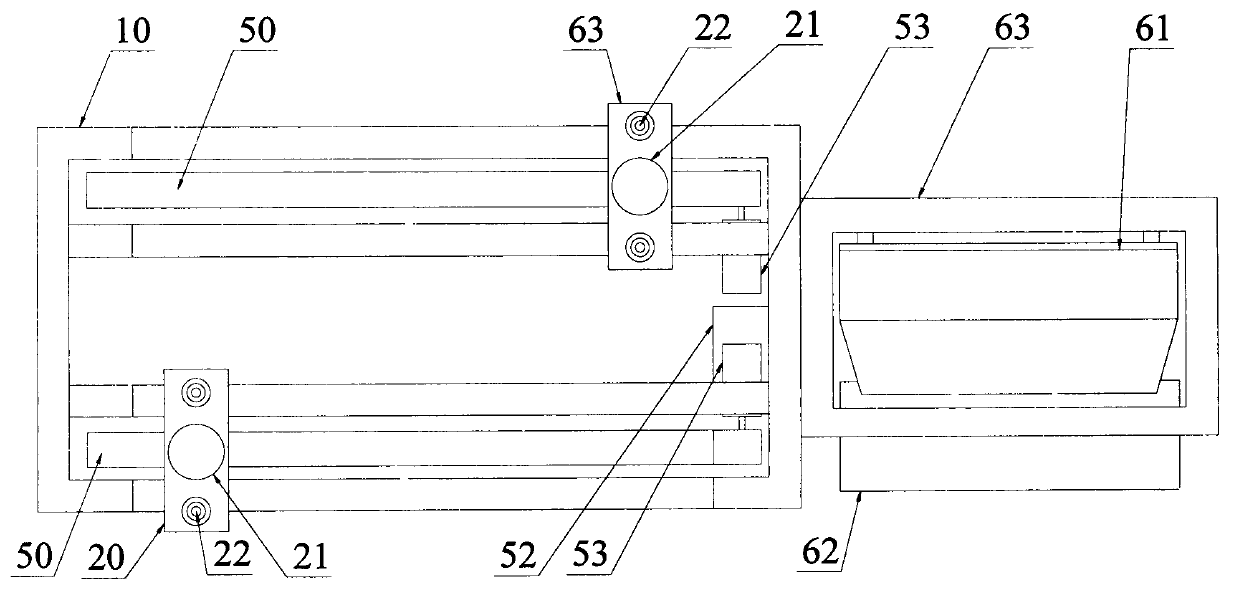

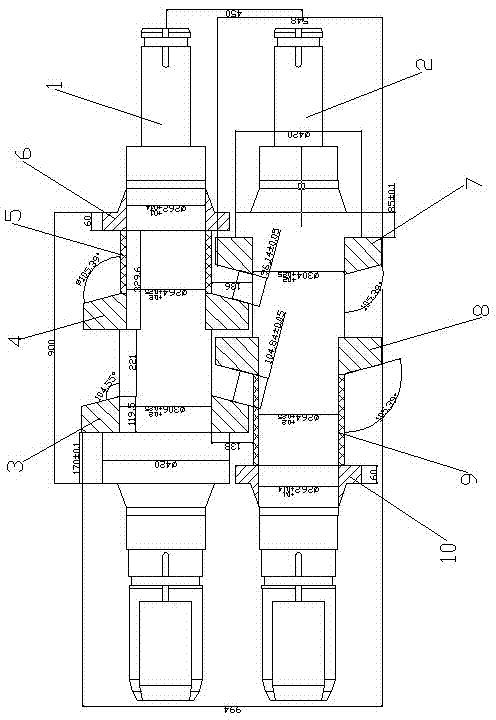

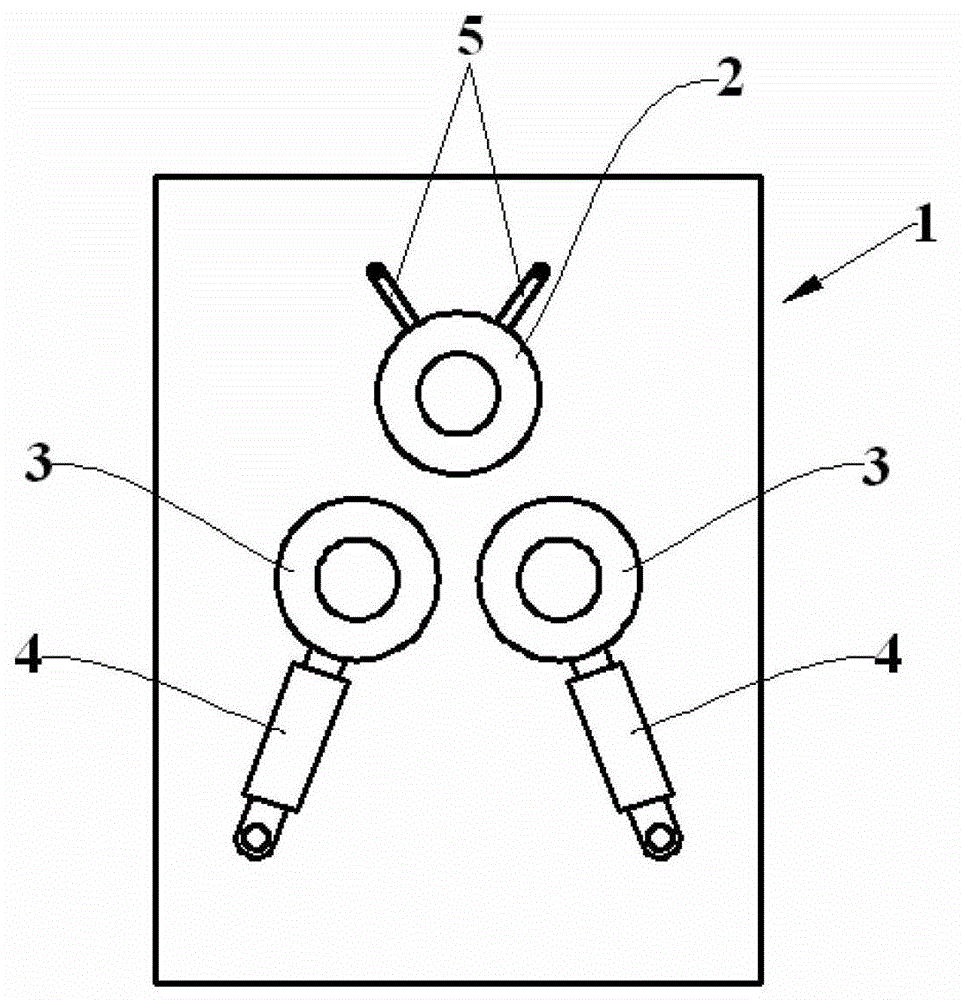

Synchronous on-line automatic pipe cutting device

The invention discloses a synchronous on-line automatic pipe cutting device which comprises a rack, a pressure maintaining device arranged on the rack and used for maintaining air pressure in a heat shrink pipe after positive-pressure expansion, a cutting device arranged below the press maintaining device, connected with the press maintaining device and used for cutting the heat shrink pipe, a transverse in / out device arranged between the pressure maintaining device and the rack and used for transversely moving the pressure maintaining device, a draft gear arranged in the rack, located right under the pressure maintaining device, used for longitudinally dragging the pressure maintaining device and keeping synchronous with the heat shrink pipe, and a material collecting device arranged on one side and connected with the rack. By adoption of the pressure maintaining device and the cutting device which are arranged in an integrated mode, the synchronous on-line automatic pipe cutting device can automatically maintain the air pressure in the heat shrink pipe after the positive-pressure expansion, automatically cut the heat shrink pipe with the given depth, and remove impression caused by clamp for maintaining the air pressure, therefore being capable of improving working efficiency, and saving labor cost and raw material cost.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

Method for section bar bending blank manufacturing of nickel-based superalloy flash welding thin-wall annular member

The invention discloses a method for section bar bending blank manufacturing of a nickel-based superalloy flash welding thin-wall annular member. The method includes: dividing the nickel-based superaloy section bar discharged according to specification into an mn section, an no section, an op section, a pq section and a qw section, heating the five sections to the temperature of 650+ / -20DEG C and then filling the five sections into a bending machine for positioning; firstly bending the op section, wherein the rotating linear speed of an upper roller and two lower rollers of the bending machine is 240mm / min, and the upward moving speed of the two lower rollers is 6.0mm / min; performing bending for five times, and additionally enabling the op arc section to reach the preset radius of curvature; then bending the no section and the pq section, wherein the rotating linear speed of the upper roller and the two lower rollers is 1200mm / min, and the upward moving speed of the two lower rollers is 7.6mm / min; and repeating bending for 5 times, and additionally, enabling the no arc section and the pq arc section to reach the preset radius of curvature. The section bar is bent and deformed into a D-shaped annular blank, two straight edges of the annular blank and the arc part are connected through a transition arc section, and bent angles formed by connection between the two straight edges and arc parts and creasing generated on the surface of the annular blank are avoided.

Owner:GUIZHOU ANDA AVIATION FORGING

Intelligent tube bending equipment

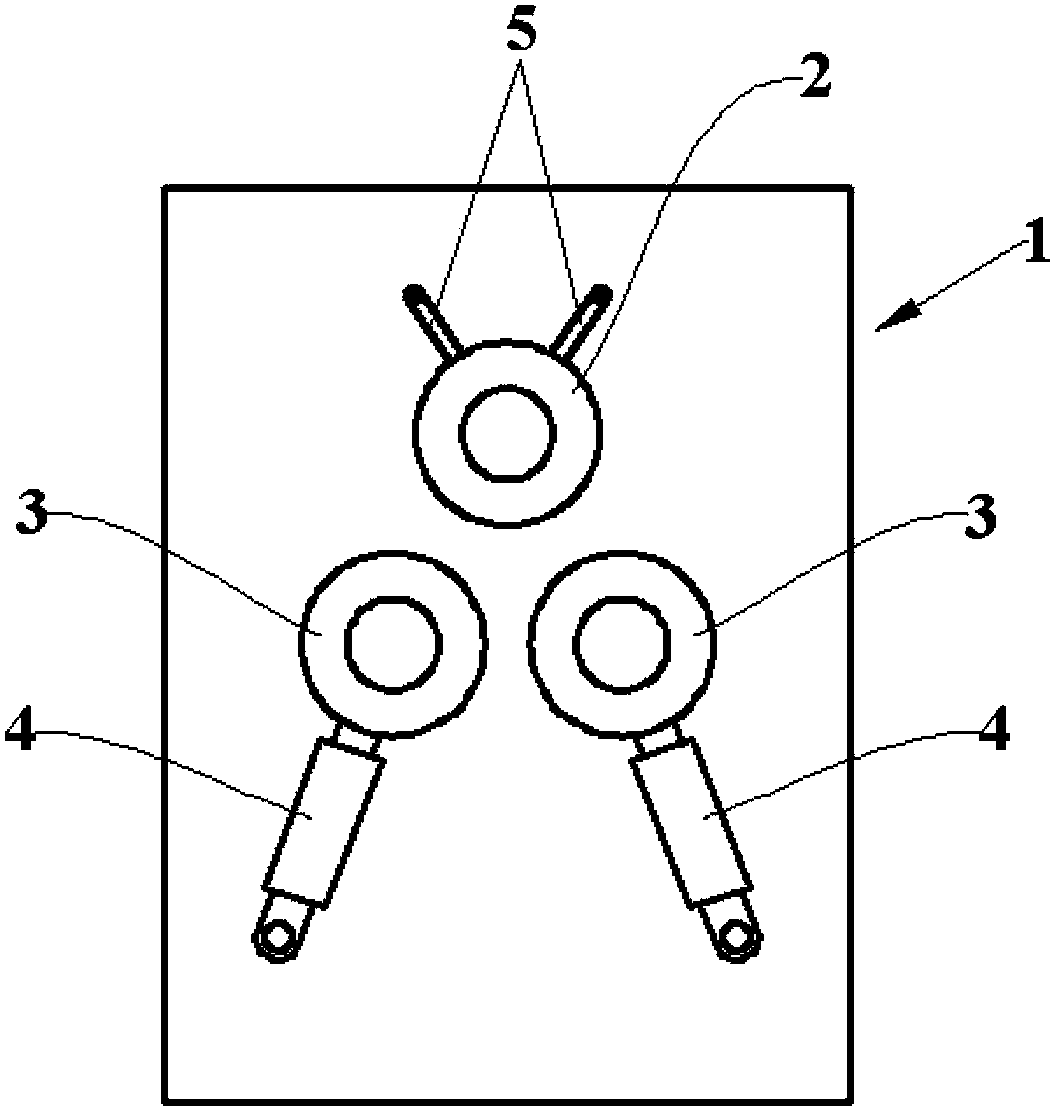

PendingCN113118264AGuaranteed stabilityHas a buffering effectMetal-working feeding devicesShaping safety devicesPipe fittingEngineering

The invention discloses intelligent tube bending equipment. The intelligent tube bending equipment comprises an intelligent tube bending equipment body consisting of an electric control mechanism, a feeding mechanism, a tube bending mechanism and a clamping mechanism, wherein the electric control mechanism is electrically connected to the feeding mechanism; the feeding mechanism is in sliding connection to the tube bending mechanism through a pipeline part; the tube bending mechanism is fixedly connected with the clamping mechanism; the clamping mechanism comprises a clamping frame; and the inner wall of the clamping frame is in sliding connection to a clamp; the top of the clamp is in sliding connection to a bearing block. The invention relates to the technical field of intelligent manufacturing equipment. The intelligent tube bending equipment solves problems that indentations are provided on the surface of the pipeline part as a tube bender directly clamps the pipeline part through a clamp in a pipeline processing process, pipe fitting scrap is caused by sliding during local tube bending if diameters of pipeline parts have difference, and generate noises are generated, the surrounding environment is severely affected and the service life of the clamp is reduced as mutual friction between the clamp and the pipeline part exists when the pipeline fitting feeds back and forth.

Owner:王学峰

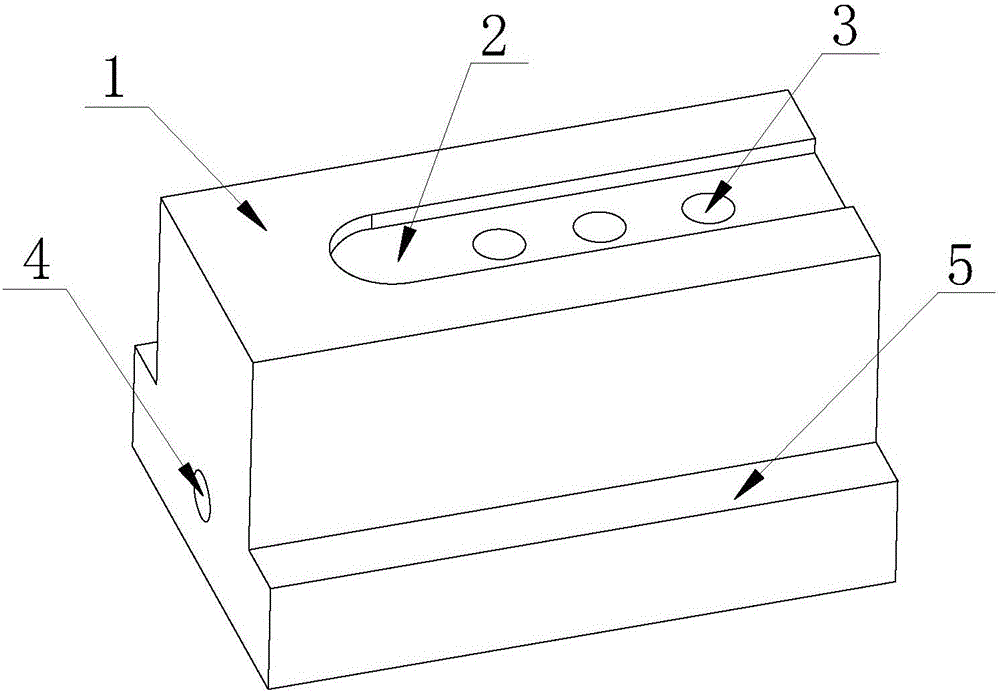

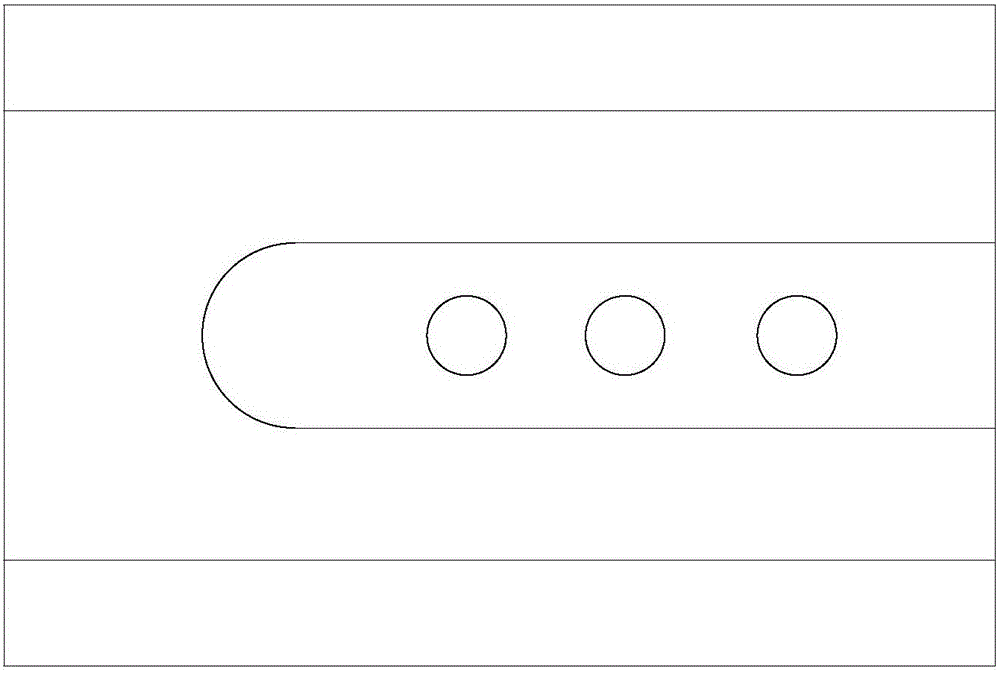

Fixed block special for bending machine

InactiveCN105834323ASolve the problem of easy movementEasy to deviateMetal-working feeding devicesHeat exchange apparatusPulp and paper industryEvaporator

The invention discloses a special fixing block for a twisting machine, which is characterized in that it comprises a T-shaped block structure arranged symmetrically as a whole, rectangular steps are symmetrically arranged on both sides of the T-shaped block structure, and a semi-submerged groove is opened on the top. The right side of the semi-sinking groove extends to the right end of the T-shaped block structure, and the left side of the groove has a semicircular surface with a diameter of 14 mm. There are three vertical threaded through holes on the center line of the bottom of the groove. There is a horizontal threaded hole on the left end face of the T-shaped block structure. The invention has the advantages of low cost, easy processing and forming, and long service life, and can ensure that when the twisting machine manufactures products, the positioning is accurate, the overall stability is good, the product quality is good, and the production efficiency is high, and it is suitable for mass production of the twisting and bending process of the fin evaporator production use.

Owner:HEFEI TAITONG REFRIGERATION TECH CO LTD

Method for forming torsion roller

ActiveCN104289521ATo achieve the purpose of turning aroundSmall aspect ratioRollsMetal rolling arrangementsEngineeringStructural engineering

The invention discloses a method for forming a torsion roller. The method includes the steps that (1) scrapped high-speed wire rollers are machined to be in a step shape; (2) torsion sleeves, distance sleeves and labyrinth rings are machined; (3) the upper roller torsion sleeves, the distance sleeve and the labyrinth ring are sequentially installed, and the lower roller torsion sleeves, the distance sleeve and the labyrinth ring are sequentially installed. By the adoption of the method, the waste rollers can be recycled by bushing, the cost of the torsion roller is lowered, the abrasion resistance of the torsion roller is improved, and the service life of the torsion roller is prolonged; after the device is used, the production cost of bars is saved, the defect that torsion roller consumption is large due to the poor abrasion resistance of the torsion roller is overcome, and considerable benefits can be created for enterprises.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A four-sided slider and pre-deformed battery shell mold

ActiveCN108115888BSimple structureEliminate indentationDomestic articlesStructural engineeringMechanical engineering

The invention relates to a four-sided slide block and a pre-deformed accumulator shell mold, which solves the defects of the existing molds such as product concave due to shrinkage and cooling deformation, side walls without reinforcement or handling structure, and the like. The mold can easily and quickly open the mold and pull the core while forming the ribs and slots on the battery case through the 4 oblique sliders arranged around the cavity, and the pre-designed protrusions compensate for the shrinkage after cooling. Product Size. The structure of the mold is relatively simple. After mass production verification, the concave phenomenon on both sides of the plastic shell is completely eliminated. There is no need for stereotyped tooling, the product size remains stable, the production efficiency is greatly improved, and customer satisfaction is high.

Owner:湖北三江航天江河橡塑有限公司

A kind of preparation method of cellulose ester film

A preparation method for cellulose ester films comprises the steps of preparation and tape casting of cellulose triacetate collodion, drying, edge slicing, edge embossing, and winding on a central spindle. After improvement, when a cellulose ester film starts to be wound, adhesive tape is added to the embossed parts of the two ends, and the length of the adhesive tape is one to four times the perimeter of the central spindle. By means of the preparation method, the indentation and concave-convex phenomena on the part, close to the inner side of the central spindle, of the cellulose ester film are eliminated, and the yield is improved.

Owner:乐凯光电材料有限公司

Bending blank manufacturing method for alpha-phase titanium alloy flash welding thin-wall ring profiles

The invention discloses a bending blank manufacturing method for alpha-phase titanium alloy flash welding thin-wall ring profiles. The method comprises the steps that an alpha-phase titanium alloy profile fed according to specifications is divided into five segments of mn, no, op, pq and qw, heated to a temperature of 720 DEG C+ / -20 DEG C and fed in a bending machine for positioning. The op segment is bent, rotation linear speeds of an upper roller and two lower rollers are 2400 mm / min, the upward moving speeds of the two lower rollers are 7.5 mm / min, the bending is repeated for 4 times, and the op arc segment at this moment achieves a preset curvature radius; and the no segment and the pq segment are bent, the rotation linear speeds of the upper roller and the two lower rollers are 1200 mm / min, the downward moving speeds of the two lower rollers are 9.5 mm / min, the bending is repeated for 4 times, and the no and pq arc segments at this moment achieve preset curvature radii. The profile is bent and deformed into a D-shaped ring blank, two straight sides and an arc portion of the ring blank are connected through a transition arc segment, and phenomena of bent angles at connection positions of the two straight sides and the arc portion and indentations on the surface of the ring blank are eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

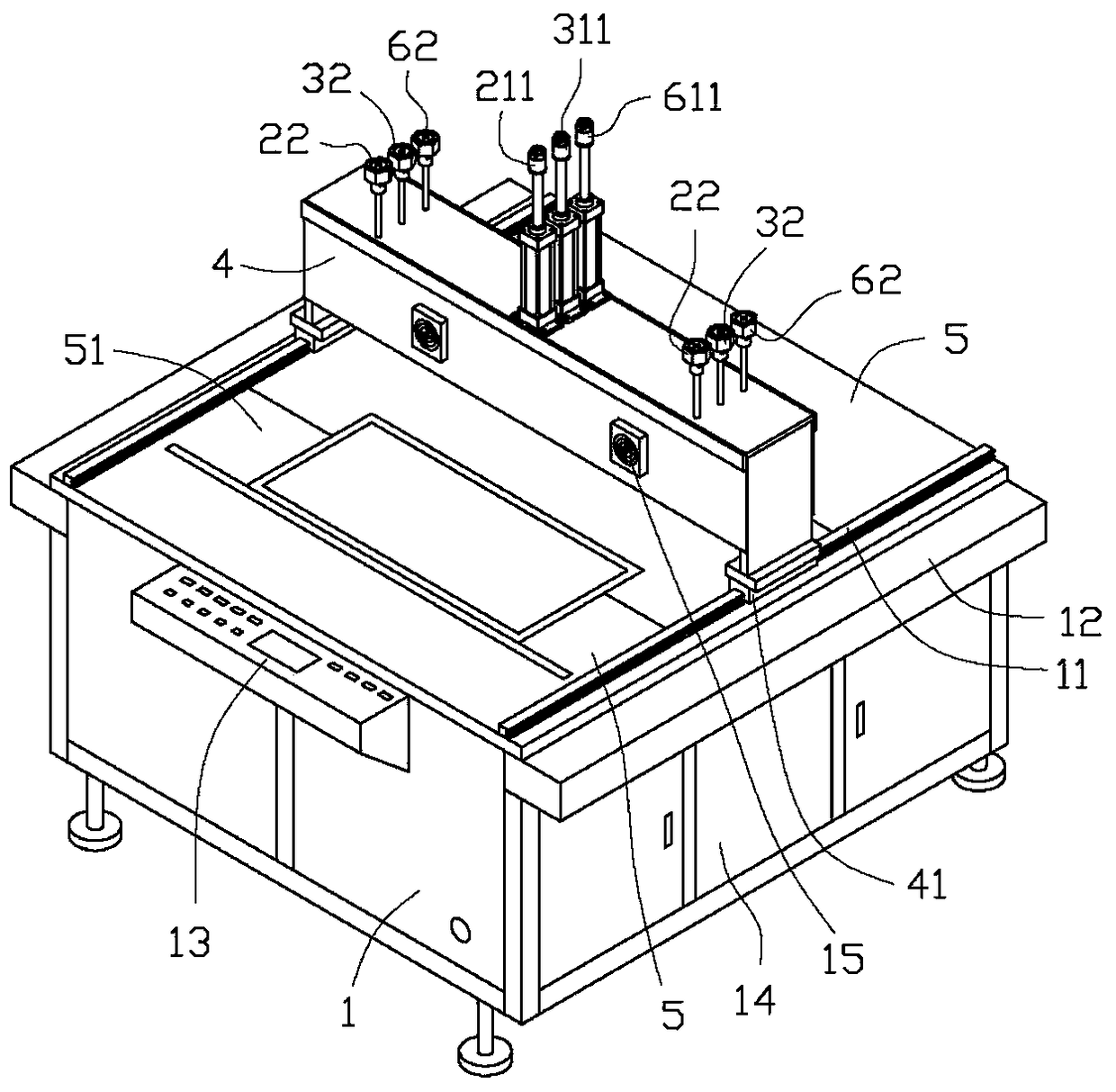

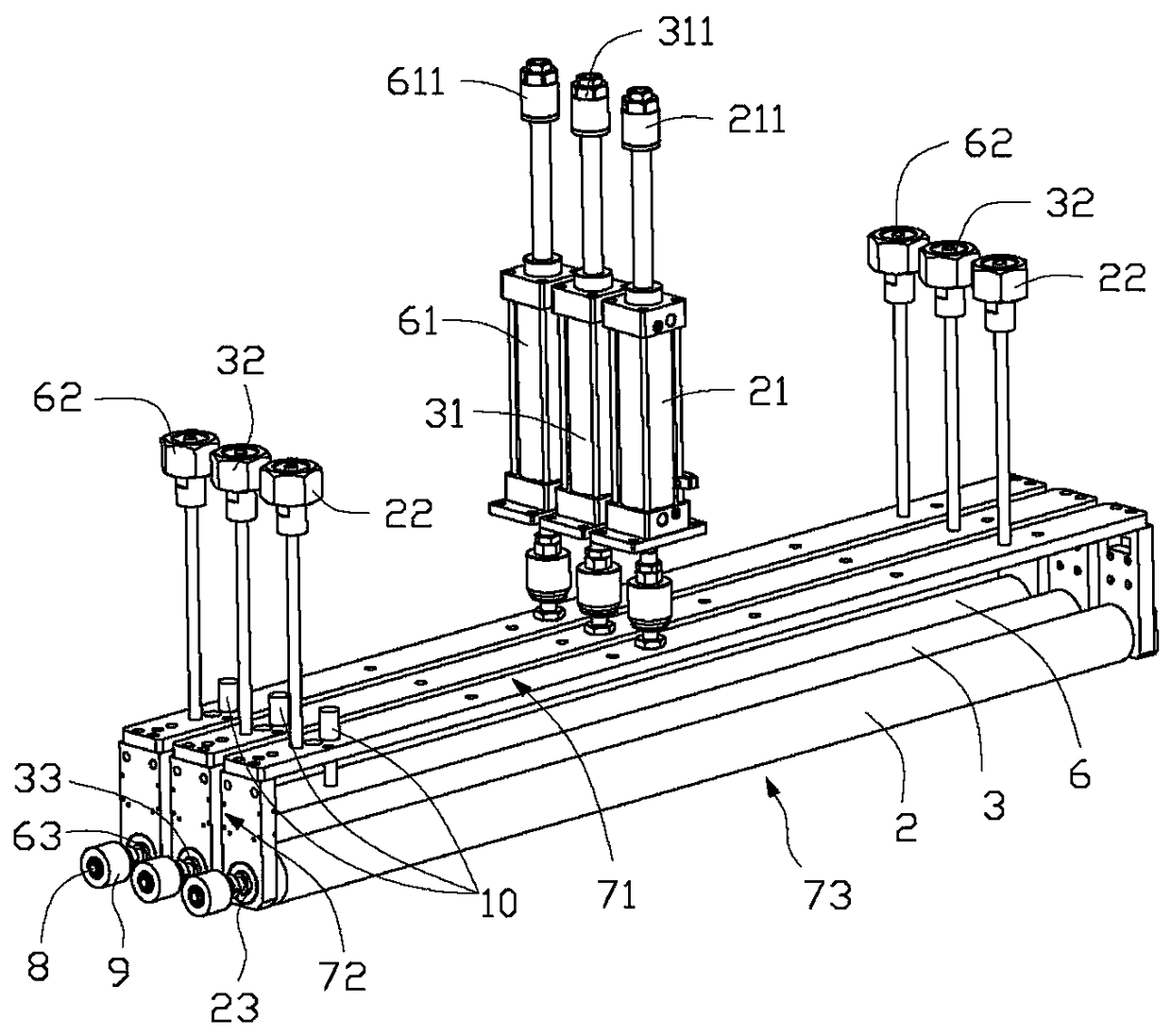

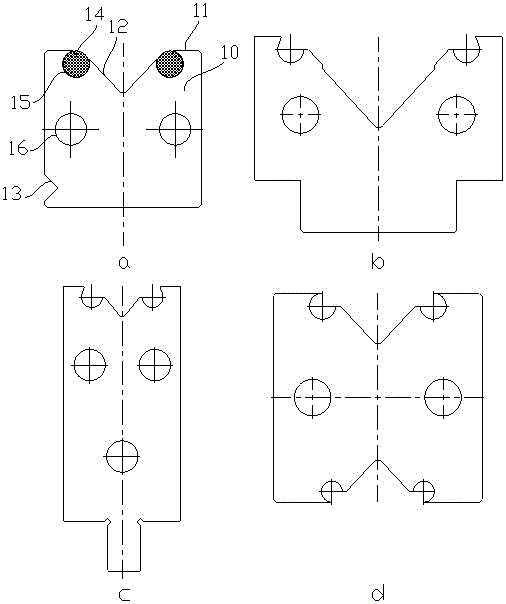

A kind of optical glue bonding equipment

ActiveCN106079812BAvoid it happening againAdjust fit adhesionLaminationLamination apparatusPortal frameAir bubble

Provided is optical adhesive laminating equipment. The optical adhesive laminating equipment comprises a rack, a laminating mechanism arranged on the rack, an operation platform and a controller; the laminating mechanism comprises a bubble removing roller, a first cylinder connected with the bubble removing roller, a primary high-temperature roller and a second cylinder connected with the primary high-temperature roller and a portal frame which is arranged on the rack and can shift in a reciprocating mode along the rack, and the bubble removing roller, the first cylinder, the primary high-temperature roller and a second cylinder are arranged on the portal frame respectively; the operation platform comprises a bottom die, vacuum adsorption holes formed in the bottom die and a vacuum adsorption device connected with the vacuum adsorption holes, and the controller is in signal connection with the laminating mechanism and the operation platform. Compared with existing laminating equipment, according to the hot-pressing laminating equipment, air in a material is removed through the bubble removing roller before laminating is conducted, and bubbles are avoided; the high-temperature rollers synchronously press downwards, laminating adhesion is adjusted, and corrugations, indentations, crushed damage, water corrugations and the like generated after laminating are eliminated.

Owner:SHENZHEN CHENG XI ELECTROMECHANICAL EQUIP +1

Bending machine lower mold, laminated combination non-indentation bending lower mold device

Owner:ANHUI LIANMENG MOLD IND

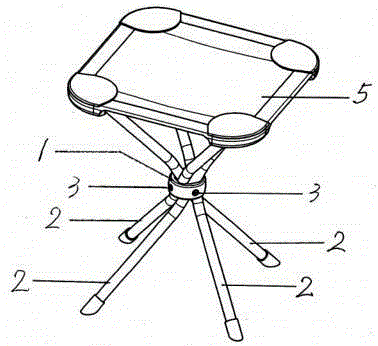

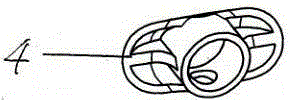

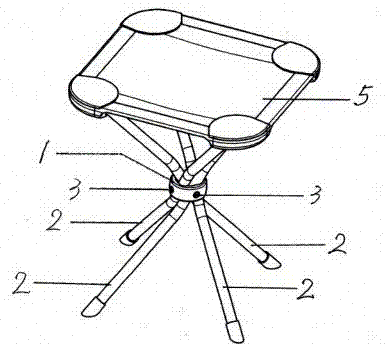

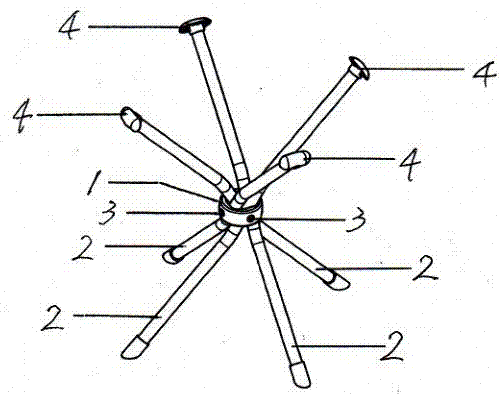

Portable folding stool

ActiveCN105167435AEfficient manufacturingImprove installation efficiencyDismountable chairsFoldable chairsEngineeringRivet

The invention discloses a portable folding stool, which comprises a waist ring, four leg rods, four step bolts, four trapezoid pipe sleeves and a cloth stool surface, wherein four arc-shaped recesses are formed in the inner side of the waist ring; holes are respectively formed in the four recesses; the arc-shaped recesses of the waist ring correspond to wavy curves, which are formed by unfolding and folding of the leg rods, of the leg rods; holes are formed in the outer sides of the wavy curves in the middle parts of the leg rods, and riveting nuts are riveted in the round holes; the four leg rods are arranged into a nylon ring of the waist ring in a penetrating manner; the four holes of the waist ring and the riveting nuts of the four leg rods are connected in a rotatable manner through the four step bolts so as to form a wheel cover shape, and the middle is integrally connected with a pipe sleeve; a round hole is formed in the side surface of each trapezoid pipe sleeve; the four trapezoid pipe sleeves sleeve the tops of the four leg rods; sleeving bags at the four corners of the cloth stool surface sleeve the four trapezoid pipe sleeves at the tops of the four leg rods, and the bottom surfaces of the sleeving bags at the four corners of the cloth stool surface are riveted with the round holes in the side surfaces of the four trapezoid pipe sleeves and the round holes in the upper ends of the four leg rods through four core-pulled rivets.

Owner:乐陵市回弹仪厂

A single-side pouring method for wind power blade web

The invention discloses a unilateral pouring method for the web of a wind power blade, which comprises mold preparation, laying of the lower layer of release cloth, laying of the lower layer of the sheet, laying of the PVC sheet, laying of the upper layer of the sheet, laying of the lightning protection wire, preheating of the mold, Laying of the upper layer of release cloth, laying of auxiliary materials, vacuum infusion, solidification of the web, and finally the production of the web, wherein, in the process of laying the auxiliary materials, it is segmented from the blade root to the blade tip at the side of the outer edge of the mold Lay the spiral pipe, lay the flow channel from the blade root to the blade tip on the other side of the outer edge of the mold, and lay the diversion net under the flow channel. At the same time, the spiral pipe is sealed and connected to the buffer tank, and the buffer tank is sealed to connect the vacuum pump. The spiral tube is placed on one side of the mold, and the spiral tube is connected to the buffer tank through the vacuum tube, and the buffer tank is connected to the vacuum pump. The spiral tube replaces the vacuum device on the original mold, reducing the consumption of the more expensive steel wire spiral tube. The road is laid in sections, which saves the amount of auxiliary materials and reduces the production cost of the web.

Owner:SINOMATECH JIUQUAN WIND POWER BLADE CO LTD

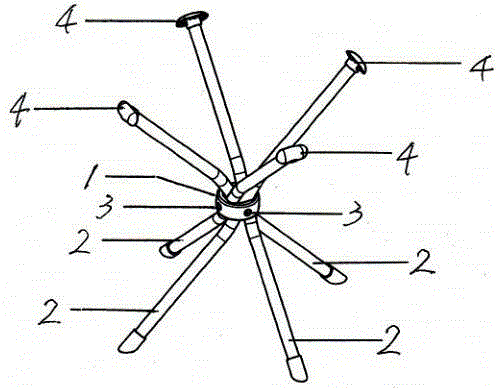

Portable folding stool

ActiveCN105167435BEfficient manufacturingImprove installation efficiencyDismountable chairsFoldable chairsEngineeringRivet

A portable folding stool, including a waist ring, four-legged rods, four step bolts, four trapezoidal sleeves and a cloth stool surface, four arc-shaped depressions inside the waist ring, and holes in each of the four depressions, the arc shape of the waist ring The depression corresponds to the wavy bending of the foot bar when it is stretched and folded. The outer side of the wavy bend in the middle of the foot bar has a hole, and a rivet nut is riveted in the round hole, and the four-legged bar is inserted into the nylon circle of the waist ring. The four-step bolts connect the four holes of the waist ring with the rivet nuts of the four-legged rod to form a wheel cover shape, and a sleeve is connected in the middle. There is a round hole on the side of the trapezoidal sleeve, and the four trapezoidal sleeves are sleeved on the four-legged rod. The four-corner bag on the cloth stool surface is sleeved on the four-trapezoidal sleeve on the top of the four-legged rod, and the bottom surface of the four-corner bag on the cloth stool surface is connected to the side round hole of the four-trapezoidal sleeve and the four-legged rod with four blind rivets. The round holes at the upper end of the machine are riveted together.

Owner:乐陵市回弹仪厂

Section bar bending and blank manufacturing method for structural steel flash welding thin-wall ring

The invention discloses a section bar bending and blank manufacturing method for structural steel flash welding thin-wall ring. The method comprises the steps of dividing a structural steel section bar blanked according to specification into an mn section, an no section, an op section, a pq section and a qw section and heating the structural steel section bar to 780 DEG C + / - 20 DEG C and then feeding the structural steel section bar into a bending machine to be positioned; first bending the op section, and repeating the bending for three times to enable the op circular arc section to have preset curvature radius, wherein the rotary linear speed of an upper roller and two lower rollers of the bending machine is 2400mm / min, and the upward moving speed of the two lower rollers is 10.0mm / min; and then bending the no section and the pq section, and repeating the bending for three times to enable the no section and the pq section to have preset curvature radius, wherein the rotary linear speed of the upper roller and the two lower rollers of the bending machine is 1200mm / min, and the upward moving speed of the two lower rollers is 12.7mm / min. The section bar is bent and deforms into a D-shaped ring blank, two straight sides of the ring blank are connected with the circular arc portion through a transition circular arc section, and a phenomenon that the connection of the two straight sides and the circular arc portion causes break angles and creasing on the surface of the ring blank is eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

Sectional material bending blank making method for cobalt-based high-temperature alloy flash welding thin-wall ring part

Owner:GUIZHOU ANDA AVIATION FORGING

Blanking-making method achieved by bending section bar of alpha-beta two-phase titanium alloy thin-wall ring piece

The invention discloses a blanking-making method achieved by bending a section bar of an alpha-beta two-phase titanium alloy thin-wall ring piece. The method includes steps that the alpha-beta two-phase titanium alloy section bar blanked according to specifications is divided into five sections of mn, no, op, pq and qw, then heated to 704 DEG C + / - 20 DEG C and filled into a bending machine for positioning. The op section is firstly bent, rotation linear speeds of an upper roller and two lower rollers of the bending machine are 2400 mm / min, the upward moving speeds of the two lower rollers are 7.5mm / min, the op section is repeatedly bent for four times, and at this time, the op circular arc section reaches a preset curvature radius; and then the no section and the pq section are bent, the rotation linear speeds of the upper roller and the two lower rollers are 1200 mm / min, the upward moving speeds of the two lower rollers are 9.5mm / min, the no section and the pq section are repeatedly bent for four times, and at this time, the no circular arc section and the pq circular arc section reach preset curvature radii. The section bar is bent and deformed to be a D-shaped ring blank, two straight edges and a circular arc portion of the ring blank are connected together through transition circular arc sections, so that the phenomena that folded corners are produced at the position of the connection of the two straight edges and the circular arc portion, and pressing marks are produced on the surface of the ring blank are eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

A method for forming twisted rolls

ActiveCN104289521BLow costTo achieve the purpose of turning aroundRollsMetal rolling arrangementsWear resistanceMechanical engineering

The invention discloses a forming method of a torsion roll, which comprises (1) processing the discarded high-line roll into a stepped shape; (2) processing a torsion sleeve, a spacer sleeve, and a labyrinth ring; (3) sequentially following the upper roll torsion sleeve , Isolation sleeve, labyrinth ring, lower roller torsion sleeve, isolation sleeve, labyrinth ring. The invention realizes the purpose of reusing waste rolls through inserts, reducing the cost of the twisted rolls, improving the wear resistance of the twisted rolls, and prolonging the service life of the twisted rolls. After using the device, the bar production cost is saved, and the defect of high roll consumption caused by the poor wear resistance of the torsion roll is solved, creating considerable benefits for the enterprise.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

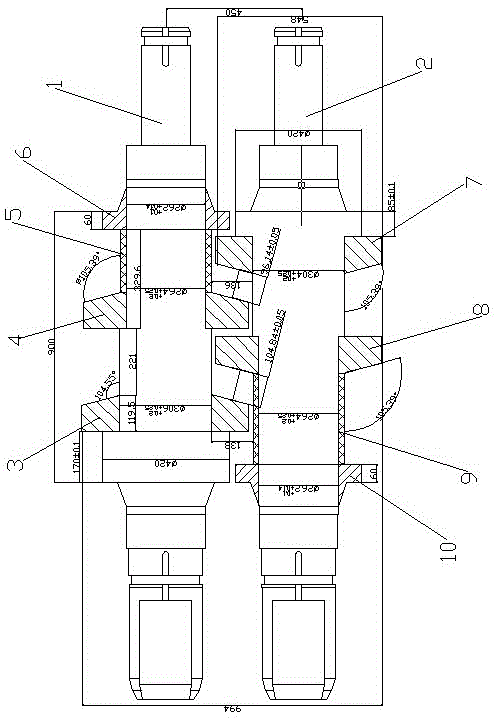

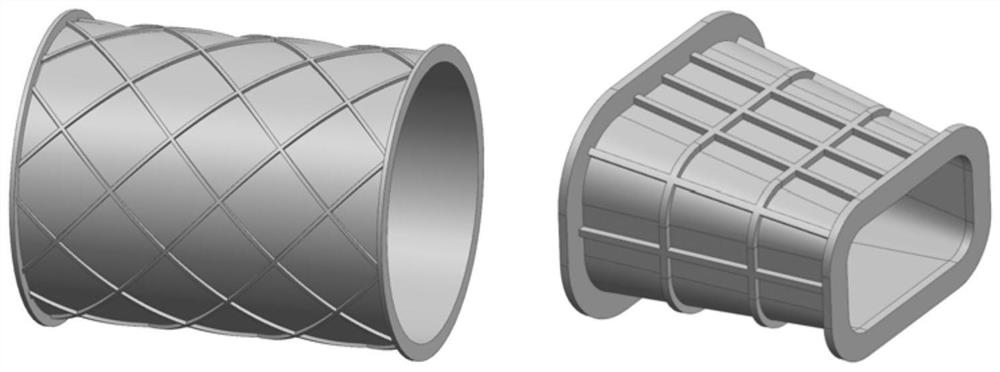

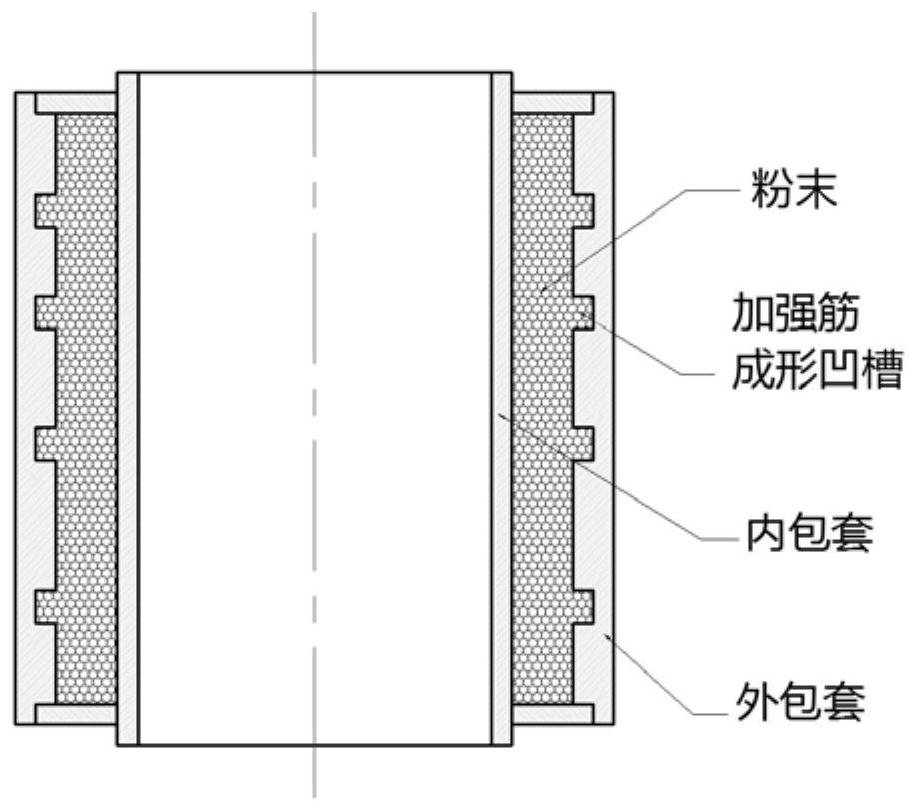

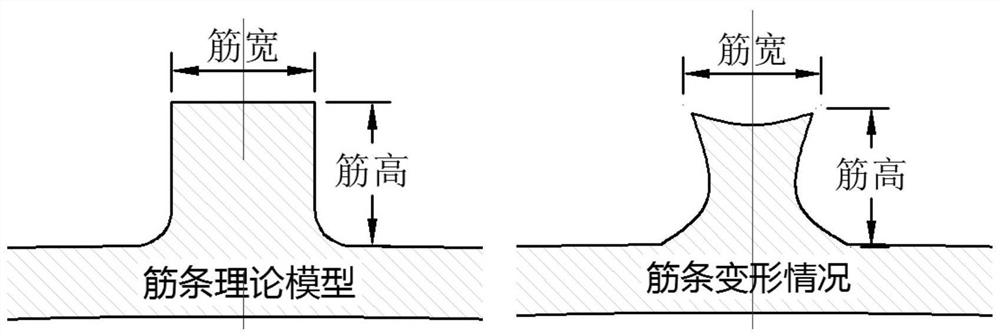

An Outer Cover and Method for Eliminating Dimension Deviation of Rib Structure in Powder Metallurgy Components

The invention discloses an outer sheath and method capable of removing size deviation of a rib structure in a powder metallurgical component. The outer sheath is of a groove structure containing ribs,the groove depth and the groove width are both larger than the theoretical height and the theoretical rib width of the ribs, the bottom plane and the side walls of the groove are in transition through an arc splicing structure, and the side walls of the groove incline outwards from the bottom. Through design of the reasonable outer sheath, a die groove is formed, and the problem that after the ribs are formed, secondary machining is needed is solved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com