A four-sided slider and pre-deformed battery shell mold

A battery and pre-deformation technology, which is applied in the field of auto parts, can solve the problems of simple structure, easy shrinkage and deformation, etc., and achieve the effect of improving production efficiency, simple mold structure, and eliminating the phenomenon of indentation on both sides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, further description will be given below in conjunction with specific examples.

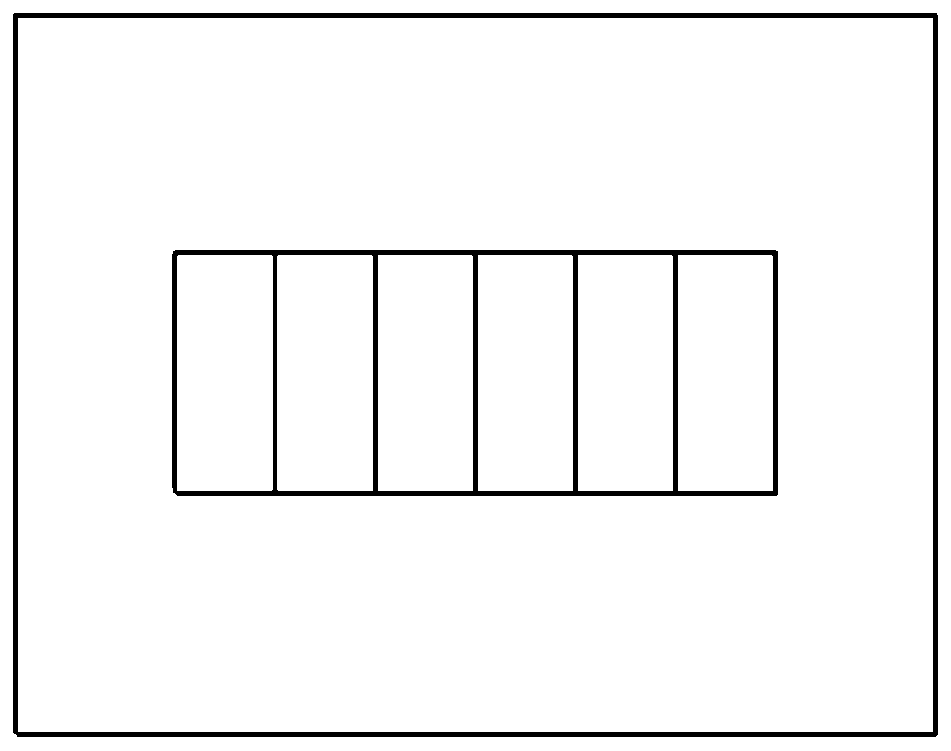

[0017] figure 1 It is a common structure of injection molds for battery casings at present. A cavity is provided on a whole template, and a rectangular battery casing is injection-molded by cooperating with the core of another template. After considering demoulding and cost factors, generally no special structure will be designed on the side wall of the cavity (at this time, the side wall of the cavity is flat and perpendicular to the plane of the template). The side wall of the storage battery casing formed by the mold will shrink and deform inwardly after cooling, and is inconvenient to carry.

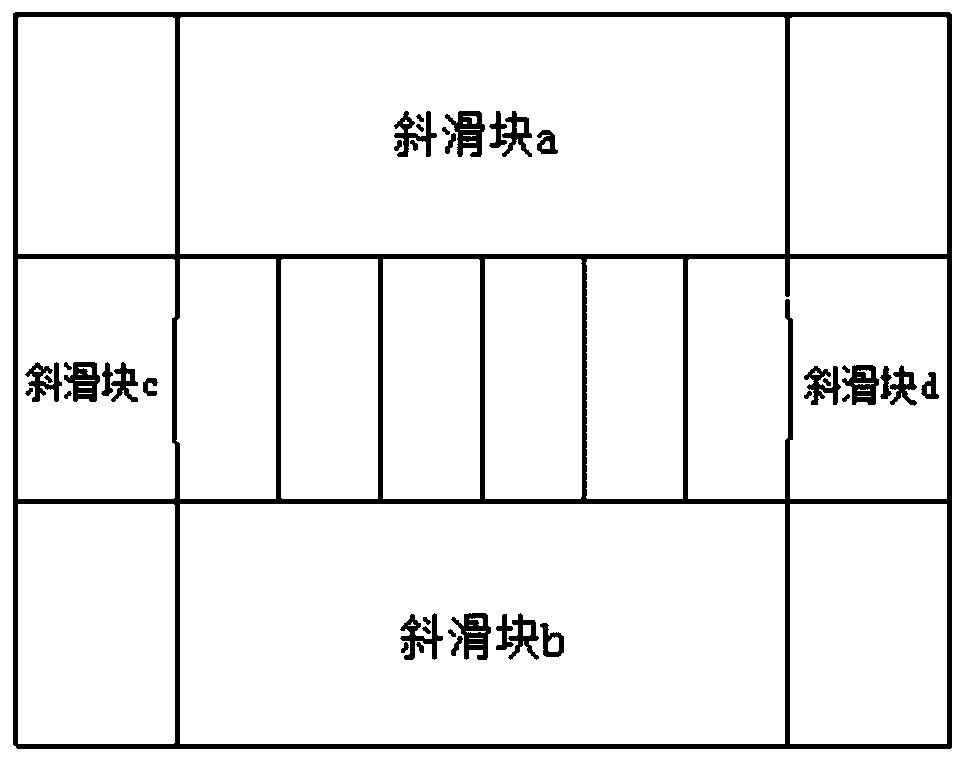

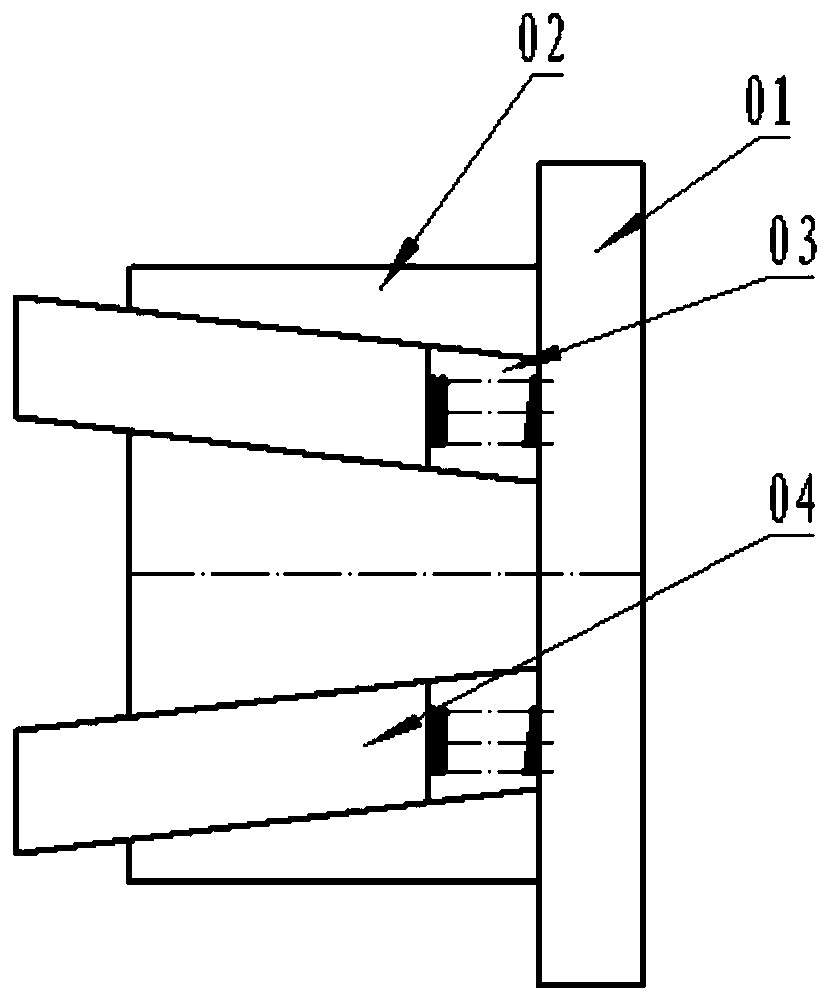

[0018] In order to solve the above problems, the applicant has designed a set of new battery shell molds, such as Figure 2-5 shown. The mold includes a match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com