Preparation method for cellulose ester films

A technology of cellulose ester and cellulose triacetate, which is applied in the field of adding adhesive tape to the shaft core to eliminate the indentation and gap marks of the shaft core. It can solve the problems of unusable, uneven, and gap marks, and improve the finished product rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

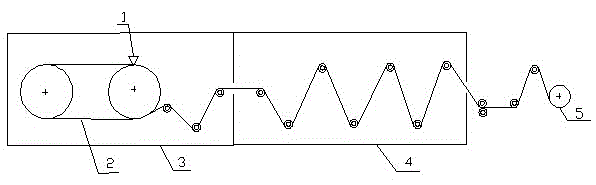

[0018] The preparation method of cellulose ester film is:

[0019] 1. Preparation of cellulose triacetate cotton glue solution

[0020] The process of preparing the cellulose triacetate cotton glue solution includes four steps: feeding, mixing and dissolving, filtering the cotton glue solution and standing at constant temperature for defoaming.

[0021] (1) Feeding

[0022] Pour the mixed solvent into the mixer, turn on the stirring and jacket water of the mixer, control the steady speed, slowly add the cellulose triacetate into the mixer, and add the plasticizer and auxiliary additives after the feeding is completed.

[0023] (2) Mix and dissolve

[0024] Adjust the stirring speed, jacket water temperature and other dissolution processes to dissolve the cellulose triacetate for 8 hours to prepare a uniform cellulose triacetate cotton glue solution.

[0025] (3) Filtration of cotton glue solution

[0026] In order to remove the mechanical impurities and insoluble matter in...

Embodiment 1

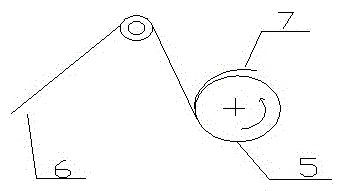

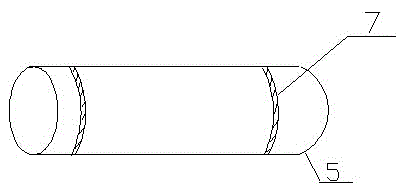

[0045] The preparation process of cellulose ester film 6: the preparation of cellulose triacetate cotton gum solution, casting, drying, slicing edge, embossing edge, winding on the core 5, before the start of winding, the corresponding fibers on the core 5 The wrapping tape 7 at the embossed position at both ends of the plain ester film 6 has a length of 1.0 m, a width of 0.5 cm, and a thickness of 0.05 mm. Afterwards, the cellulose ester film 6 is embossed and placed on the adhesive tapes 7 at both ends, and starts to be rolled until it is rolled into a full shaft. The indentation and hole printing were detected, and the results are shown in Table 1.

Embodiment 2

[0047] With reference to the preparation method of Example 1, the difference is that before the winding starts, the adhesive tape 7 is spirally wound at the width corresponding to the cellulose ester film 6 in the horizontal direction of the winding shaft core 5, and then the cellulose ester film 6 is rolled on the tape 7. On the shaft core 5, start to roll until it is rolled into a full shaft. The width of the adhesive tape 7 is 1cm, and the thickness is 0.15mm. The indentation and hole printing were detected, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com