Bending machine lower mold, laminated combination non-indentation bending lower mold device

A laminated, mold technology, applied in the field of bending processing of sheet metal parts, can solve the indentation and scratches on the surface of the workpiece, production cycle, manufacturing cost, standardization requirements are getting higher and higher, affecting the appearance quality of the workpiece and precision problems, to eliminate indentation and scratches, improve appearance quality and precision, and facilitate mold management and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

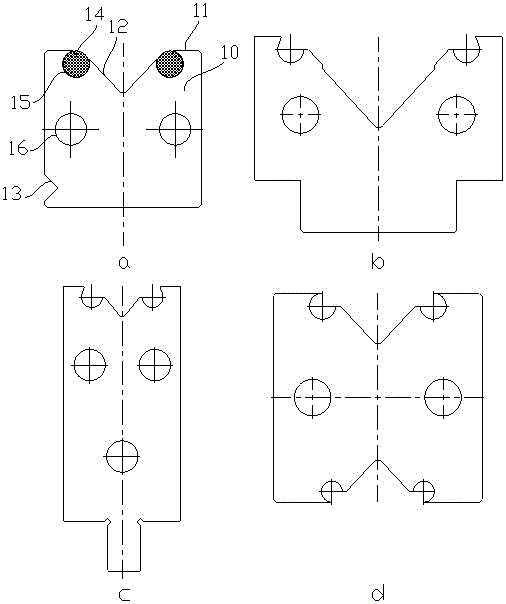

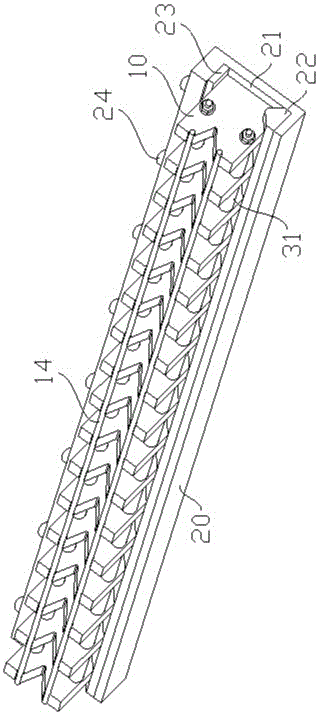

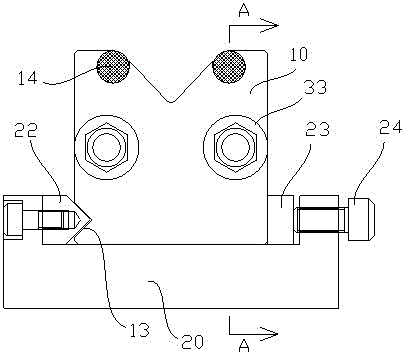

[0033] See first figure 1 a. The lower mold of the bending machine specifically includes a lower mold body 10. The lower mold body 10 has a processing plane 11 that fits the workpiece to be bent, and the processing plane 11 has a tool for bending the workpiece to be bent into a set shape. The groove 12, the joint between the two ends of the groove 12 and the adjacent processing plane 11 is provided with an arc-shaped through hole 15 penetrating the lower mold body 10, and the arc-shaped through hole 15 is penetrated For the core rod 14 whose axis rotates, the opening of the arc-shaped through hole 15 is enclosed by the surface of the core rod 14 to form a smooth transition between the processing plane 11 and the groove 12.

[0034] When the lower die body 10 is used to bend the metal sheet, the workpiece only contacts the mandrel 14 on the lower die body 10 during the entire bending process, and the mandrel 14 will follow the moving direction of the plate (same as bending The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com