Fixed block special for bending machine

A fixed block and twist bending machine technology, which is applied in the direction of positioning device, feeding device, storage device, etc., can solve the indentation or scratch in the twisted bending area of the pipe, the easy movement of the side of the twisted fixing block, and the size of the twisted product Non-compliance and other problems, to achieve the effect of good product quality, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

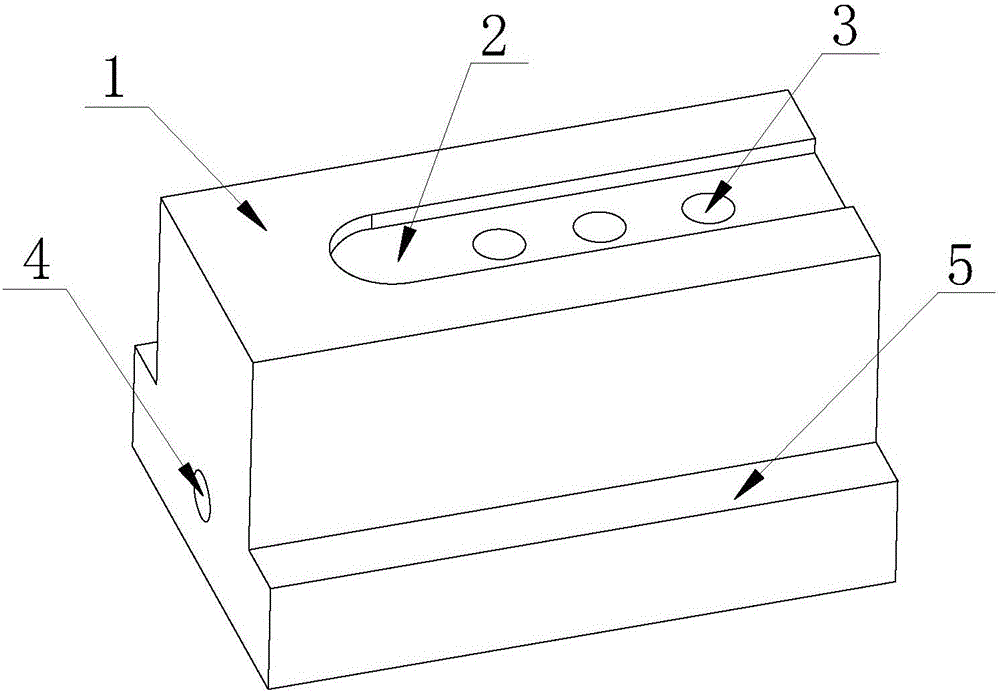

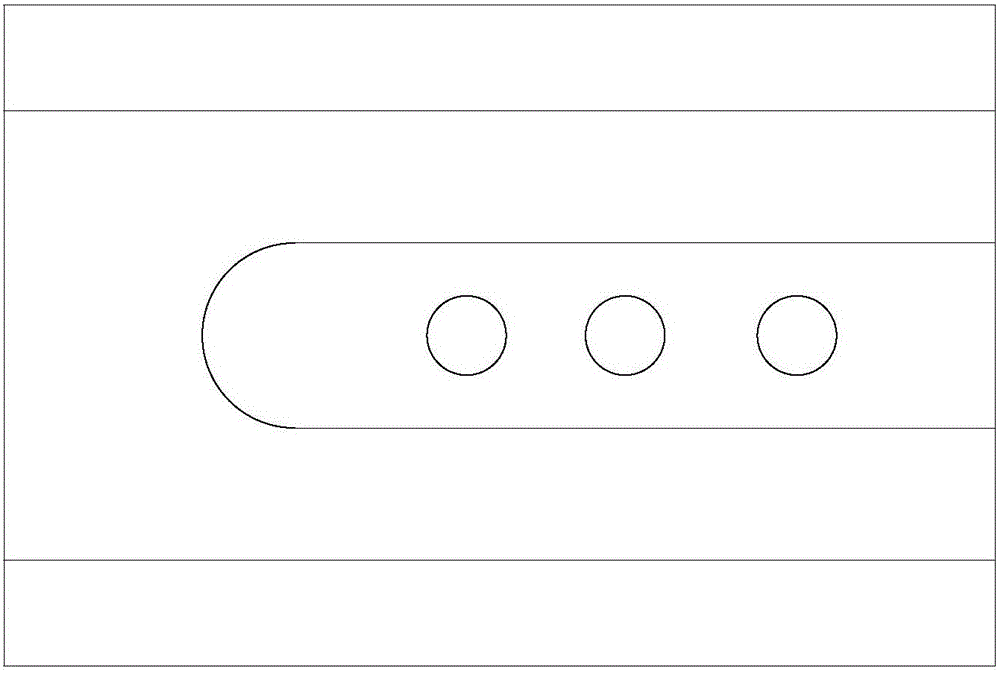

[0021] Such as figure 1 As shown, a special fixing block for twist bending machine is characterized in that it includes a T-shaped block structure 1 arranged symmetrically as a whole. There is a semi-submerged groove 2 with a depth of 2mm, the length of the semi-submerged groove 2 is 60mm, the right side of the groove extends to the right end of the T-shaped block structure 1, and the left side of the groove has a semicircular surface with a diameter of 14mm. There are three vertical threaded holes 3 on the center line of the bottom of the semi-submerged groove 2, and there is a horizontal threaded hole 4 on the left end surface of the T-shaped block structure 1.

[0022] The overall size of the T-shaped block structure 1 is 75×50×40 mm in length×width×height.

[0023] The three vertical threaded holes 3 have an aperture diameter of 6 mm and a depth of 11 mm. The distance between the vertical threaded holes 3 is 12 mm and 13 mm from left to right, and the distance between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com