Mounting structure of ceramic flat plate membrane and membrane filtration unit

An installation structure, flat membrane technology, applied in membrane technology, semi-permeable membrane separation, permeation/dialysis water/sewage treatment, etc., can solve the problems of cumbersome installation process, easy movement of ceramic flat membrane, etc., to simplify the installation process, The effect of reducing assembly difficulty and overall weight, reducing movement damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

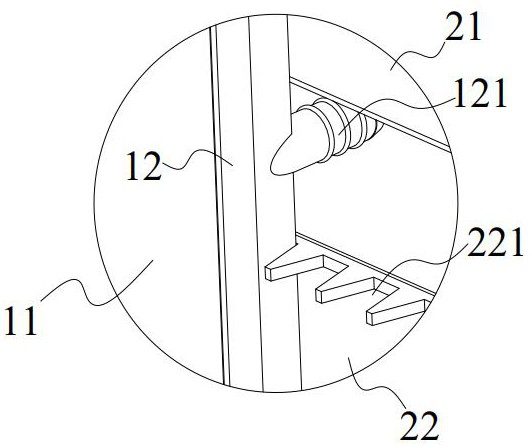

[0069] In the membrane filtration equipment in the prior art, a plurality of ceramic flat membranes are vertically arranged in parallel and spaced apart. Alveoli are installed up and down on the opposite sides of the supporting frame, and the two ends of the ceramic plate are rested on the supporting frame and fixed in the alveoli. A sealing frame and a sealing plate are installed around the supporting frame to form a circulation channel inside the membrane filtration device. The membrane filtration equipment has the following defects:

[0070] 1. Before the ceramic flat membrane is installed, it is necessary to weld the tooth grooves on the supporting frame in advance, and the process is cumbersome;

[0071] 2. After the ceramic flat membrane is installed, its height direction and the direction perpendicular to the surface of the ceramic flat membrane will not move due to the limitation of the bearing frame and the tooth groove, but its length direction is not fixed, and it ...

Embodiment 2

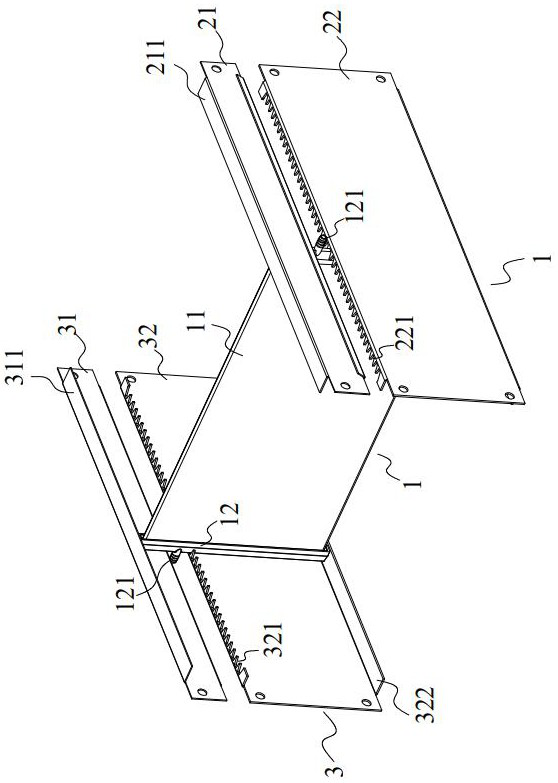

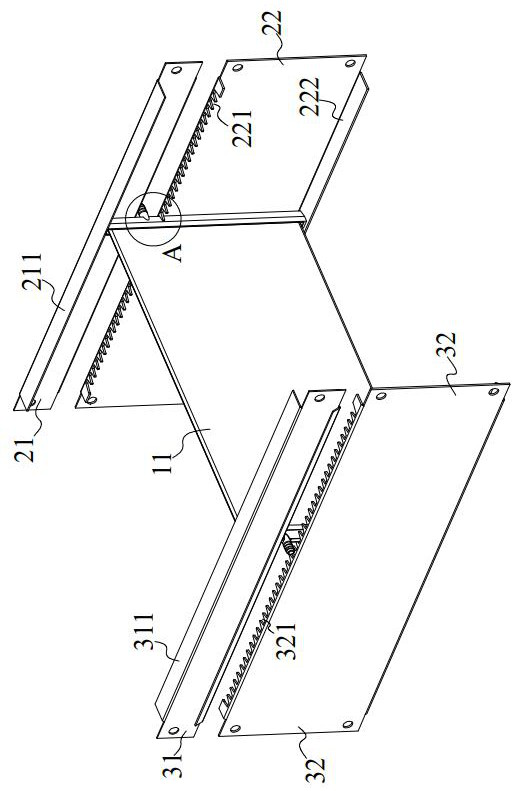

[0084] A membrane filtration unit, such as attached Figure 4 and 5 shown. The membrane filtration unit includes a ceramic flat plate membrane 1 , a front side plate 2 , a rear side plate 3 , a left side plate assembly 4 , a right side plate assembly 5 and a water collection pipe 6 . Wherein, the front side plate 2 and the rear side plate 3 are arranged in parallel. The left side plate assembly 4 and the right side plate assembly 5 are arranged in parallel. The front side panel 2 , the right side panel assembly 5 , the rear side panel 3 and the left side panel assembly 4 are sequentially connected to form a rectangular cylindrical structure with both ends penetrating. The ceramic flat membrane 1 is arranged in the rectangular cylindrical structure in a direction roughly parallel to the left side plate assembly 4 , and its two ends in the longitudinal direction are clamped and fixed by the front side plate 2 and the rear side plate 3 .

[0085] Specifically, the ceramic fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com